The global starter motor market is experiencing steady growth, driven by rising vehicle production, increasing demand for fuel-efficient engines, and advancements in electric and hybrid vehicle technologies. According to Mordor Intelligence, the starter motor market was valued at USD 7.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This expansion is further supported by Grand View Research, which highlights sustained demand from both OEMs and the aftermarket, particularly in emerging economies across Asia-Pacific and Latin America. As a leading provider of automotive braking and powertrain solutions, Bendix—part of Knorr-Bremse—has extended its engineering expertise into starter motor systems, collaborating with or supplying key manufacturers in the space. Below are the top six starter motor manufacturers associated with Bendix technology or distribution, selected based on market presence, innovation, global reach, and alignment with industry growth trends.

Top 6 Bendix For Starter Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1997

Website: knorr-bremse.com

Key Highlights: Knorr-Bremse is the world’s leading manufacturer of braking systems and a leading supplier of safety-critical sub-systems for rail and commercial….

#2 Starters and Alternators

Domain Est. 2004

Website: boschautoparts.com

Key Highlights: Bosch Professional Preferred Remanufactured Starter Motors are built for extreme heat, cold and high demand. Every engine starter component is 100% factory ……

#3 Start page

Domain Est. 1995

Website: bendix.com

Key Highlights: Bendix Commercial Vehicle Systems, a member of Knorr-Bremse, develops and supplies leading-edge active safety technologies, energy management solutions….

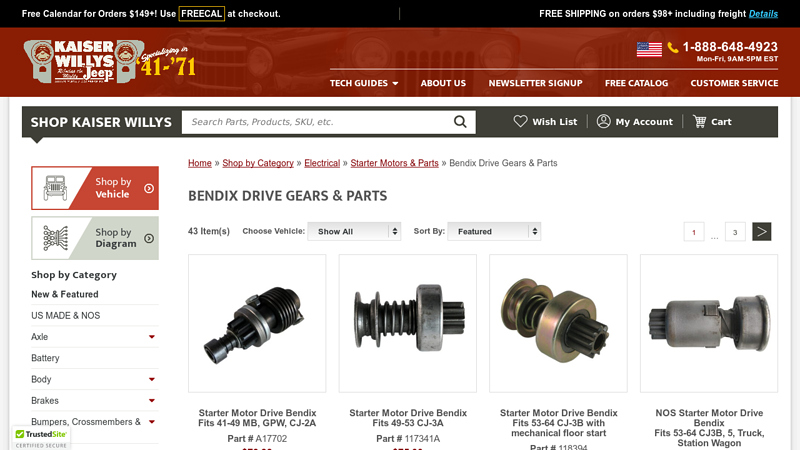

#4 Bendix Drive Gears & Parts

Domain Est. 2000

Website: kaiserwillys.com

Key Highlights: Free delivery over $98Starter Motor Drive Bendix Fits 53-64 CJ-3B with mechanical floor start. Part # 118394. $75.00. MSRP: $75.00. Add to Cart….

#5 Starter Motor Bendix

Domain Est. 2015

Website: firepowerparts.com

Key Highlights: Starter Motor Bendix |26-1141 … All electrical items are final sale and cannot be returned. Direct O.E.M. replacement; 1 year limited warranty against ……

#6 Manufacturing in Australia since 1955

Website: bendix.com.au

Key Highlights: Our range includes brake pads, rotors, brake shoes, and auto care products for a wide range of vehicle types. Explore our products to find your fit….

Expert Sourcing Insights for Bendix For Starter Motor

H2: 2026 Market Trends for Bendix in Starter Motors

The Bendix drive mechanism, a critical component in starter motor systems, continues to play a pivotal role in internal combustion engine (ICE) vehicles, despite the growing shift toward electrification. As we approach 2026, several market trends are shaping the demand, innovation, and application of Bendix components in starter motors across global automotive and industrial sectors.

-

Declining ICE Vehicle Production, but Sustained Aftermarket Demand

While original equipment manufacturer (OEM) demand for starter motors with Bendix drives is expected to decline due to the rising adoption of electric vehicles (EVs), the aftermarket segment remains robust. With millions of ICE vehicles still on the road globally—especially in emerging markets—replacement demand for reliable starter components like the Bendix drive is projected to remain strong through 2026. Bendix, as a trusted brand under Knorr-Bremse, benefits from brand loyalty and established distribution networks in the replacement parts market. -

Focus on Durability and Cost-Effectiveness

As vehicle lifespans extend in developing economies, there is growing emphasis on cost-effective, durable starter components. Bendix’s reputation for high-quality engagement mechanisms aligns with this trend. Manufacturers and consumers alike prioritize reliability and longevity, driving continued investment in improved materials and manufacturing processes for Bendix drives to resist wear, shock loading, and environmental stress. -

Hybrid Vehicles as a Growth Niche

Hybrid electric vehicles (HEVs) and mild hybrids still rely on internal combustion engines and, therefore, require starter motors with Bendix mechanisms. As the transition to full electrification progresses gradually, HEVs are expected to account for a significant portion of new vehicle sales through 2026, particularly in regions with evolving charging infrastructure. This creates a niche growth opportunity for Bendix-compatible starter systems designed for frequent start-stop cycles. -

Technological Enhancements in Starter Systems

Advancements in starter motor design, including integrated smart starters and enhanced solenoid systems, are influencing Bendix drive integration. Innovations aim to reduce engagement noise, improve gear synchronization, and increase torque transfer efficiency. Bendix’s R&D efforts are likely focused on optimizing the mechanical engagement process to meet stricter noise, vibration, and harshness (NVH) standards in modern vehicles. -

Regional Market Divergence

Market dynamics vary significantly by region. In North America and Europe, declining ICE production may reduce OEM volume, but the mature vehicle fleet supports strong aftermarket sales. In contrast, regions like Southeast Asia, Africa, and parts of Latin America are expected to sustain demand for ICE vehicles and starter motor components through 2026 due to lower EV adoption rates and economic factors. Bendix is strategically positioned to serve these high-growth aftermarket regions through localized distribution and partnerships. -

Supply Chain and Manufacturing Optimization

With increasing pressure on cost and delivery timelines, Bendix suppliers are likely to invest in automation, lean manufacturing, and localized production to remain competitive. Digital supply chain tools and predictive analytics will enhance inventory management and response times in the aftermarket, ensuring availability of Bendix components where and when needed. -

Sustainability and Material Innovation

Environmental regulations are prompting a reevaluation of materials used in automotive components. Trends toward recyclable and lightweight materials may influence future Bendix gear designs. While the core mechanical function remains unchanged, material science advancements could lead to quieter, lighter, and more sustainable Bendix drives.

In summary, while the long-term outlook for starter motors faces headwinds from electrification, the Bendix drive is expected to remain relevant through 2026 due to sustained aftermarket demand, hybrid vehicle applications, and ongoing improvements in performance and durability. Bendix’s brand strength, combined with strategic adaptation to regional and technological shifts, will be key to maintaining market position in this evolving landscape.

Common Pitfalls When Sourcing Bendix for Starter Motor (Quality, IP)

Sourcing a Bendix drive (also known as a starter drive or starter gear) for a starter motor involves several potential pitfalls, especially concerning quality and intellectual property (IP). Being aware of these can help avoid operational failures, legal issues, and cost overruns.

Poor Quality Components

One of the most frequent issues when sourcing Bendix drives is receiving substandard parts that fail prematurely. Low-quality Bendix units often use inferior materials and manufacturing processes, leading to problems such as:

- Premature wear or stripping of gear teeth, resulting in failure to engage the flywheel.

- Weak springs or damaged overrunning clutches, causing the Bendix to fail to retract or allowing engine back-drive.

- Improper tolerances, leading to misalignment, noise, and reduced starter efficiency.

These failures can cause engine starting issues, increased downtime, and higher long-term maintenance costs—especially in heavy-duty or commercial applications.

Counterfeit or Non-OEM Parts

The market is flooded with counterfeit or imitation Bendix drives falsely marketed as genuine OEM (Original Equipment Manufacturer) components. These parts may:

- Mimic branding and packaging of reputable manufacturers like Bosch, Denso, or Mitsubishi.

- Lack proper certification or traceability, making it difficult to verify authenticity.

- Perform inconsistently under load or in extreme temperatures.

Using counterfeit parts not only jeopardizes reliability but can also void warranties on the starter motor or engine.

Intellectual Property (IP) Infringement

Sourcing Bendix drives from unauthorized or unverified suppliers can lead to IP violations. Many original Bendix designs are protected by patents, trademarks, and technical copyrights. Risks include:

- Legal liability for distributing or using components that infringe on patented mechanisms (e.g., specific overrunning clutch designs).

- Supply chain disruptions if IP holders issue cease-and-desist orders or initiate legal action against suppliers or distributors.

- Damage to brand reputation, especially for OEMs or service providers who unknowingly integrate infringing parts.

Lack of Compliance with Industry Standards

Genuine Bendix drives adhere to strict international standards (e.g., ISO, SAE, DIN) for performance, durability, and safety. Off-brand alternatives may not meet these specifications, leading to:

- Incompatibility with original starter motors or engine systems.

- Failure during critical start cycles, particularly in high-torque or cold-start environments.

- Non-compliance in regulated markets, which can result in rejected shipments or fines.

Inadequate Supplier Verification

Many procurement teams source Bendix drives through third-party vendors or online marketplaces without verifying the supplier’s authorization or track record. This increases exposure to:

- Unreliable quality control processes.

- Inconsistent part numbering and specifications.

- Limited after-sales support or warranty coverage.

Conclusion

To mitigate these pitfalls, always source Bendix drives from authorized distributors or reputable suppliers with verifiable OEM partnerships. Conduct due diligence on quality certifications, request product testing data, and ensure compliance with IP and industry standards. Investing in genuine or certified aftermarket components ultimately ensures reliability, legal compliance, and long-term cost savings.

Logistics & Compliance Guide for Bendix for Starter Motor

This guide outlines the essential logistics and compliance considerations for handling, transporting, and managing Bendix components used in starter motors. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and product integrity.

Product Identification and Specifications

Ensure accurate identification of the Bendix (also known as starter drive or starter drive gear) by verifying the part number, compatible engine models, and technical specifications (e.g., gear type, pitch, overrunning clutch mechanism). Use only genuine Bendix components specified by Bendix Commercial Vehicle Systems or authorized distributors to maintain performance and warranty compliance.

Packaging and Handling Requirements

Bendix components must be stored and transported in original manufacturer packaging or equivalent protective materials to prevent damage to the gear teeth, shaft, or clutch mechanism. Handle with care to avoid impacts or exposure to moisture, dust, and extreme temperatures. Always use appropriate lifting and handling equipment when moving bulk shipments.

Storage Conditions

Store Bendix units in a dry, climate-controlled environment with temperatures between 10°C and 30°C (50°F to 86°F) and relative humidity below 60%. Keep products off the floor on pallets or shelves to prevent moisture absorption and contamination. Ensure proper stock rotation (FIFO—First In, First Out) to minimize shelf-life degradation.

Transportation and Shipping

Ship Bendix components via approved freight carriers compliant with DOT (Department of Transportation) and IATA (if air freight) regulations. Secure loads to prevent shifting during transit. Use temperature-controlled vehicles when shipping through extreme climates. Maintain documentation including shipping manifests, packing lists, and hazardous materials declarations (if applicable).

Import/Export Compliance

Ensure compliance with international trade regulations when shipping across borders. This includes accurate HS (Harmonized System) code classification (e.g., 8511.40 for motor vehicle electrical ignition or starting equipment), proper country of origin labeling, and adherence to export control laws such as EAR (Export Administration Regulations). Obtain necessary permits or licenses for restricted destinations.

Regulatory and Environmental Compliance

Bendix components may contain materials subject to environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Confirm compliance through provided documentation (e.g., Certificates of Compliance, SDS). Recycle or dispose of packaging and non-functional units in accordance with local environmental laws.

Documentation and Traceability

Maintain complete records for traceability, including purchase orders, batch/lot numbers, inspection reports, and certificates of conformance. Implement a system for tracking inventory and warranty claims. Ensure all documentation is retained for a minimum of seven years or as required by regional regulations.

Quality and Inspection Procedures

Conduct incoming inspections to verify part number accuracy, physical condition, and packaging integrity. Use calibrated tools to check critical dimensions if required. Report discrepancies immediately to the supplier. Follow ISO 9001 quality management practices where applicable.

Emergency and Safety Protocols

Train personnel on safe handling procedures. In case of damaged packaging or suspected contamination, quarantine the affected units and report to the quality assurance team. Maintain spill kits and PPE (Personal Protective Equipment) if handling lubricants or cleaners during inspection.

Conclusion for Sourcing Bendix for Starter Motor:

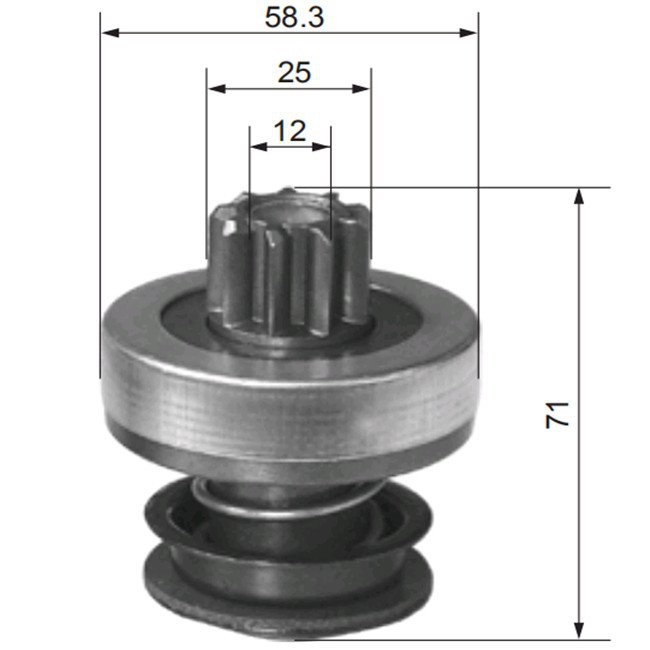

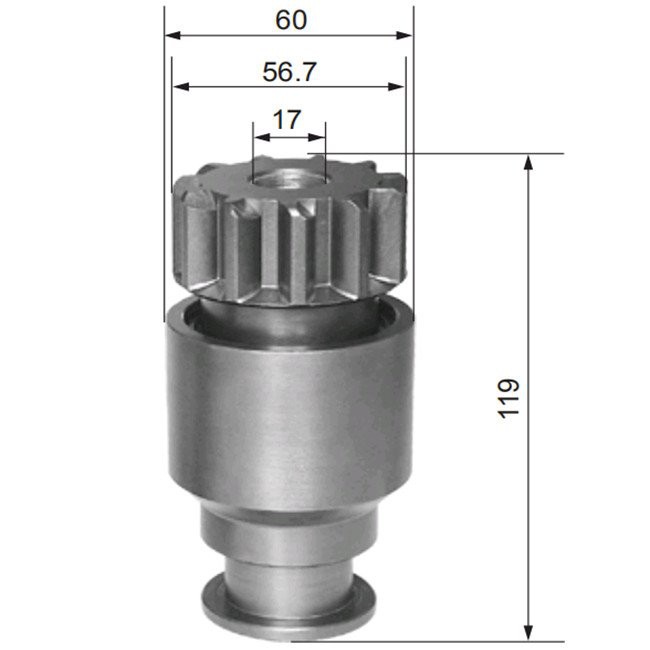

Sourcing a Bendix drive (also known as a starter drive or starter gear) for a starter motor requires careful consideration of compatibility, quality, and supplier reliability. The Bendix is a critical component responsible for engaging the starter motor’s pinion gear with the engine’s flywheel to initiate combustion, and disengaging once the engine starts. Therefore, selecting the correct model—based on specifications such as spline count, gear tooth configuration, length, and thread type—is essential for reliable performance and longevity.

After evaluating various sourcing options—including OEM (original equipment manufacturer) parts, aftermarket alternatives, and reconditioned units—it is evident that OEM Bendix drives offer the highest level of assurance in terms of fit, durability, and performance, albeit at a higher cost. High-quality aftermarket brands can provide a cost-effective alternative without significantly compromising reliability, provided they meet industry standards.

Additionally, sourcing from reputable suppliers with strong quality control, warranty support, and technical expertise ensures reduced risk of premature failure or compatibility issues. For critical applications—such as commercial vehicles, industrial machinery, or high-performance engines—investing in genuine or premium aftermarket Bendix units is recommended to maintain operational efficiency and minimize downtime.

In summary, successful sourcing of a Bendix for a starter motor hinges on accurate identification of specifications, choosing trusted suppliers, and balancing cost with long-term reliability. Proper selection and installation will ensure optimal starter motor function and extended service life.