The global bandsaw market is experiencing steady growth, driven by increasing demand for precision cutting tools across metal fabrication, automotive, and construction industries. According to Grand View Research, the global circular and bandsaw market size was valued at USD 1.87 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This expansion reflects rising industrial automation and the need for compact, efficient machinery—including benchtop bandsaw metal cutting machines—in both large-scale operations and small workshops. Mordor Intelligence further supports this trend, highlighting increased adoption of energy-efficient and high-precision equipment in metalworking applications, particularly across North America and Asia-Pacific. As the demand for portable, space-saving, and high-performance cutting solutions grows, manufacturers are innovating to deliver durable, accurate benchtop models. In this competitive landscape, nine key players have distinguished themselves through engineering excellence, advanced material handling capabilities, and strong market presence—making them leaders in the benchtop bandsaw segment for metal cutting.

Top 9 Benchtop Bandsaw Metal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Forrest Mfg. Co.: Bandsaw Manufacturers

Domain Est. 1998

Website: forrestmfg.com

Key Highlights: Forrest is a leading manufacturer of specialty and custom bandsaw with a 50 plus year history serving many industries….

#2 DoALL Saws

Domain Est. 2004

Website: doallsaws.com

Key Highlights: DoALL Sawing Products is the original manufacturer of metal-cutting industrial bandsaws and continues to be an industry leader after more than 97 years….

#3 Cosen Saws

Domain Est. 2011

Website: cosensaws.com

Key Highlights: Cosen Saws is a worldwide leader in industrial band saw manufacturing. Our band saws include various horizontal & vertical styles….

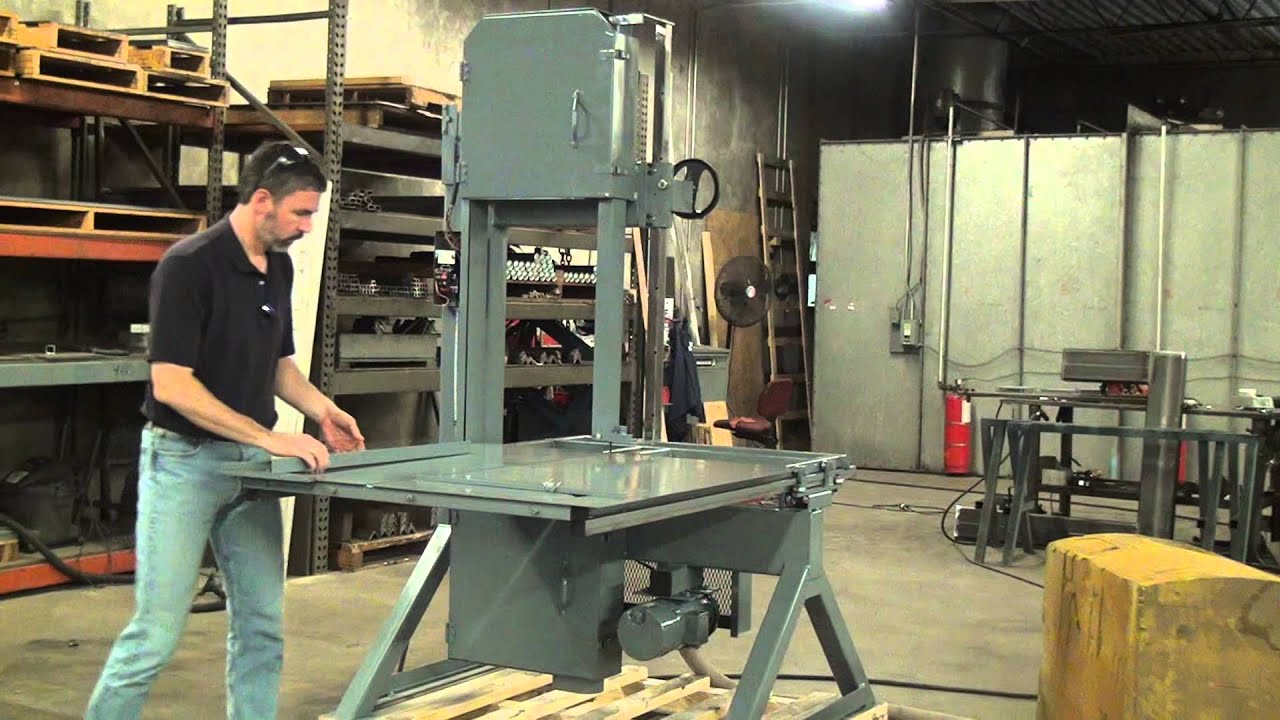

#4 Roll-In Saw

Domain Est. 1999

Website: rollinsaw.com

Key Highlights: Roll-In Saw has been a leading American manufacturer of metal cutting band saws and cutting accessories for over 75 years….

#5 Benchtop Band Saws

Domain Est. 1996

Website: hemsaw.com

Key Highlights: The Benchtop band saws are specifically manufactured for HE&M Saw, by our Italy based partner FEMI. These craftsman-built products are “machine-tool grade” band ……

#6 The M.K. Morse Company

Domain Est. 1997

Website: mkmorse.com

Key Highlights: Straight Pitch Bi-Metal Portable Band Saw Blade. Bi-Metal Portable Band Saw Blades. For machinable metals including stainless steel, pipe, tubing, and solids….

#7 Shop WEN Woodworking Bandsaws

Domain Est. 1999

#8 Eberle

Website: eberle-augsburg.de

Key Highlights: Our Eberle product range includes band saws, saw blades, bi-metal and carbide saw blades, strip steel, bi-metal saw blades, and carbon steel….

#9 Metal Cutting Bandsaw Machine Manufacturers

Domain Est. 1998

Website: everising.com

Key Highlights: As an innovative bandsaw machine manufacturer, we produce various metal cutting bandsaws with our smart manufacturing DIKW platform to integrate all the ……

Expert Sourcing Insights for Benchtop Bandsaw Metal

2026 Market Trends for Benchtop Bandsaw Metal

The benchtop bandsaw metal market is poised for dynamic evolution by 2026, shaped by technological innovation, shifting industrial demands, and sustainability imperatives. Key trends include:

Increased Automation and Smart Features

Manufacturers are integrating smart technologies such as digital readouts, programmable cutting cycles, and IoT connectivity into benchtop models. By 2026, expect widespread adoption of sensors for blade tension monitoring, automatic feed rate adjustment, and predictive maintenance alerts. These features enhance precision, reduce operator error, and improve workflow efficiency—especially in small to mid-sized fabrication shops embracing Industry 4.0 principles.

Demand for Compact, High-Performance Models

Space efficiency remains a critical factor for workshops and educational institutions. In response, manufacturers are focusing on designing more compact yet powerful benchtop bandsaws with improved cutting capacity (e.g., up to 6″ x 8″ capacity in footprint-friendly designs). Enhanced motor efficiency and improved gearbox systems allow smaller units to deliver performance previously seen only in floor-standing models.

Growth in Prosumer and Educational Markets

Beyond industrial use, the prosumer (professional hobbyist) and technical education sectors are driving demand. DIY metalworkers and makerspaces are increasingly investing in reliable, affordable benchtop bandsaws. By 2026, expect more user-friendly models with safety features tailored for training environments, such as blade guards, emergency stops, and simplified controls.

Sustainability and Energy Efficiency

Environmental regulations and cost-saving initiatives are pushing demand for energy-efficient motors and recyclable materials in construction. Variable-speed drives and brushless DC motors are becoming standard, reducing power consumption and heat generation. Additionally, longer blade life and reduced coolant usage are key selling points aligning with green manufacturing trends.

Regional Market Expansion

Emerging markets in Southeast Asia, Latin America, and parts of Africa are showing growing demand for affordable metalworking tools. Localized production and partnerships with regional distributors will be essential for global brands to capture market share. Meanwhile, North America and Europe remain strong due to continuous demand in metal fabrication, automotive repair, and aerospace prototyping.

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to diversify sourcing and increase regional production. By 2026, more benchtop bandsaw production is expected to occur closer to end markets to reduce lead times and mitigate geopolitical risks, potentially impacting pricing and availability dynamics.

In summary, the 2026 benchtop bandsaw metal market will be defined by smarter, more efficient, and compact machines catering to a broader user base—from hobbyists to high-precision industrial users—while responding to sustainability and supply chain resilience challenges.

Common Pitfalls When Sourcing Benchtop Bandsaw Metal (Quality, IP)

Sourcing a benchtop bandsaw for metal cutting requires careful evaluation to avoid performance issues, safety hazards, and costly downtime. Overlooking key quality and intellectual property (IP) aspects can lead to significant problems. Here are the most common pitfalls:

Poor Blade Quality and Material Compatibility

Many low-cost bandsaws come equipped with substandard blades made from inferior bi-metal or carbon steel, which dull quickly or break when cutting harder metals. Users often assume all blades can handle stainless steel or alloyed materials, but without proper blade selection (e.g., variable tooth pitch, appropriate HSS or bimetal composition), cutting efficiency drops drastically and risks damaging the workpiece or machine.

Inadequate Frame and Build Quality

A flimsy frame made from thin-gauge steel or poor welds leads to excessive vibration during operation. This reduces cutting accuracy, accelerates wear on components, and shortens the machine’s lifespan. High-quality bandsaws use cast iron or reinforced steel structures to dampen vibration and ensure straight, precise cuts.

Misleading Power and Speed Specifications

Some suppliers exaggerate motor power (e.g., claiming 1 HP when it’s peak or surge power, not continuous duty) or offer fixed-speed models unsuitable for various metals. Real-world cutting performance depends on consistent torque and adjustable speed settings matched to the material. Without variable speed control, users risk blade breakage or poor surface finishes.

Lack of Dust and Chip Management

Metal cutting generates fine swarf and chips that can clog the blade, overheat the motor, or pose safety risks. Low-quality models often omit chip brushes, coolant systems, or effective chip trays. This results in frequent maintenance, reduced blade life, and potential fire hazards from accumulated metal dust.

Ignoring Safety Features and Compliance

Benchtop bandsaws must meet regional safety standards (e.g., CE, UL). Poorly sourced machines may lack emergency stops, proper blade guards, or fail to provide safety interlocks. Using non-compliant equipment exposes users to liability and increases the risk of workplace accidents.

Counterfeit or IP-Infringing Equipment

Some suppliers offer machines that mimic well-known brands but violate intellectual property rights. These counterfeit units often use knock-off components, lack technical support, and offer no warranty. Purchasing such equipment supports illegal manufacturing practices and typically results in unreliable performance and difficulty sourcing replacement parts.

Absence of Technical Support and Spare Parts

Even with good initial quality, machines require maintenance. Sourcing from vendors without local support or spare parts availability leads to long downtimes when blades, tires, or motors fail. Reputable brands provide accessible service networks and maintain parts inventories.

Overlooking Calibration and Alignment

Poor factory calibration leads to blade drift, inaccurate cuts, and premature blade wear. Low-cost bandsaws may arrive out-of-square or with misaligned blade guides. Without proper setup tools and instructions, users struggle to achieve precision, defeating the purpose of investing in a metal-cutting bandsaw.

Avoiding these pitfalls requires due diligence: verify material specifications, check for safety certifications, source from reputable suppliers, and prioritize build quality over initial cost savings.

Logistics & Compliance Guide for Benchtop Bandsaw (Metal)

Overview

This guide outlines the logistics and compliance considerations for the safe handling, transportation, installation, operation, and regulatory adherence of a benchtop bandsaw used for cutting metal. Proper attention to these aspects ensures workplace safety, regulatory compliance, and equipment longevity.

Transportation and Handling

Ensure the benchtop bandsaw is securely packaged for transit. Use appropriate lifting techniques or equipment (e.g., pallet jack, forklift) when moving the unit, as these machines typically weigh between 100–300 lbs (45–136 kg). Avoid tilting excessively to prevent internal component damage. Verify that the blade is tensioned correctly or removed before shipment to prevent breakage or injury.

Delivery and Receiving

Inspect the package upon delivery for visible damage. Check the contents against the packing slip, ensuring all components (blade, wrenches, manual, stand if included) are present. Report any discrepancies or damage to the supplier or carrier immediately. Store the bandsaw in a dry, secure location until installation.

Installation Requirements

Place the bandsaw on a stable, level surface capable of supporting its weight and vibration. Ensure adequate clearance around the machine for operation and maintenance. Connect to a dedicated electrical circuit matching the voltage and amperage requirements specified in the manual (typically 110V or 220V, single-phase). Ground the unit properly to prevent electrical hazards.

Safety and Operational Compliance

Adhere to Occupational Safety and Health Administration (OSHA) standards and local regulations. Key requirements include:

– Machine Guarding: Ensure blade, wheels, and moving parts are fully enclosed per OSHA 29 CFR 1910.213.

– Emergency Stop: Verify the emergency stop function is operational.

– Personal Protective Equipment (PPE): Require operators to wear safety glasses, hearing protection, and avoid loose clothing or gloves.

– Training: Only trained personnel should operate the bandsaw. Maintain training records.

Blade and Material Compliance

Use only blades rated for metal cutting, with appropriate TPI (teeth per inch) for the material thickness. Confirm blade compatibility with the machine’s specifications. Do not cut materials beyond the machine’s rated capacity (e.g., hardened steel, non-ferrous alloys unless specified). Follow manufacturer guidelines for blade tension and tracking.

Environmental and Waste Management

Collect metal chips and coolant (if used) in designated containers. Dispose of swarf and used blades as industrial waste per EPA and local environmental regulations. If coolant is used, ensure proper containment and recycling/disposal to prevent soil or water contamination.

Maintenance and Inspection

Perform routine maintenance as per the manufacturer’s schedule. Inspect blade condition, tension, and alignment weekly. Check belts, motors, and electrical connections monthly. Document all inspections and repairs. Replace worn parts promptly to maintain safe operation.

Regulatory Documentation

Maintain access to the following:

– Original equipment manual and safety instructions

– OSHA compliance checklists

– Equipment maintenance logs

– Employee training records

– Material Safety Data Sheets (MSDS) for coolants or lubricants

International Considerations (if applicable)

For import/export, ensure compliance with:

– CE marking (EU) for machinery directive 2006/42/EC

– UKCA marking (United Kingdom)

– CSA certification (Canada)

– FCC compliance (USA) for any electronic components

Verify voltage compatibility and include appropriate power adapters or transformers if operating in regions with differing electrical standards.

Conclusion

Proper logistics planning and adherence to compliance standards are essential for the safe and legal use of a benchtop metal bandsaw. Regular training, documentation, and maintenance ensure long-term operational efficiency and regulatory alignment.

In conclusion, sourcing a benchtop bandsaw for cutting metal requires careful consideration of key factors such as cutting capacity, motor power, blade quality, build durability, and safety features. It is essential to match the machine’s specifications with your specific cutting needs—whether for light-duty maintenance tasks or more frequent industrial applications. Evaluating reputable brands, reading user reviews, and comparing warranties and after-sales support can further ensure a reliable and cost-effective purchase. Additionally, prioritizing models with variable speed controls and proper blade guidance systems enhances precision and efficiency when working with different types of metal. Ultimately, investing in a high-quality benchtop metal bandsaw improves productivity, accuracy, and workplace safety, making it a valuable addition to any workshop or fabrication environment.