The global grinding equipment market is experiencing steady expansion, driven by increasing demand for precision machining across the automotive, aerospace, and metal fabrication industries. According to a 2023 report by Mordor Intelligence, the global industrial grinding machines market was valued at approximately USD 4.2 billion and is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This growth is fueled by the rising adoption of advanced material processing technologies and the shift toward automation in manufacturing. Belt grinders, in particular, have gained traction among hobbyists and professionals alike due to their versatility in sharpening, shaping, and surface finishing—functions that traditional bench grinders struggle to match efficiently. As manufacturers innovate to bridge the gap between these two tools, the market has seen a surge in hybrid and high-performance bench-to-belt grinder conversions. Based on current industry trends, technological advancements, and customer feedback, we’ve analyzed the top 10 manufacturers leading the charge in developing durable, adaptable, and high-value bench grinder to belt grinder solutions.

Top 10 Bench Grinder To Belt Grinder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Bench Belt Grinder Manufacturers and Factory, Suppliers

Domain Est. 2021

Website: allwin-tools.com

Key Highlights: Bench Belt Grinder – Factory, Suppliers, Manufacturers from China · CE certified 370W powered 200mm electric bench grinder with flexible working light · CSA ……

#2 Belt Grinders

Domain Est. 1999

Website: burrking.com

Key Highlights: Burr King manufactures American-made industrial belt grinders, deburring and polishing machines, vibratory bowls, disc grinders, and more….

#3 6000 Belt Grinder

Website: ellissaw.com

Key Highlights: The Ellis Belt Grinder is a quality machine shop grinder. Use for grinding, beveling, deburring, descaling, finishing and tool grinding and sharpening….

#4 Palmgren 4″ Bench Belt Grinder

Domain Est. 1996

#5 Multitool Complete Belt Grinder with 1 hp Motor

Domain Est. 1996

Website: advmachinery.com

Key Highlights: Free delivery over $100 30-day returnsThis is a powerful bench grinder that removes metal 5 times faster than stone wheels. You can switch between belts in an instant for polishing…

#6 Combination 8″ Bench Grinder & 4″ Belt Grinder

Domain Est. 2001

Website: baileigh.com

Key Highlights: Baileigh backs this combination 8″ bench grinder & 4″ belt grinder with a 1-year warranty and lifetime technical support from our knowledgeable team. Questions?…

#7 Beaumont Metal Works

Domain Est. 2001

Website: beaumontmetalworks.com

Key Highlights: We design, engineer, and manufacture all of our adjustable 2×72 belt grinders, 2×48 belt grinders, disc grinders, sanding machines, attachments and parts in ……

#8 2SK7 Combination Bench Grinder and Sander

Domain Est. 2007

Website: kalamazooind.com

Key Highlights: The Kalamazoo 2SK7 combination belt sander & grinder is a powerful all-in-one tool that gives your shop both grinder and sander capability in a ……

#9 Grinders Designed to Work

Domain Est. 2016

Website: ameribrade.com

Key Highlights: American Made Belt Grinders, Bench Grinders, Parts, Contact Wheels, and Abrasives….

#10 Multitool Grinders

Domain Est. 2019

Website: multitoolgrinders.com

Key Highlights: The original Multitool grinder attachments are serious metalworking tools for professionals and hobbyists….

Expert Sourcing Insights for Bench Grinder To Belt Grinder

H2: Market Trends Shaping the Transition from Bench Grinders to Belt Grinders (2026 Outlook)

The landscape for grinding tools is undergoing a significant shift, with a clear trend emerging: the growing dominance of belt grinders over traditional bench grinders in many professional and enthusiast applications. By 2026, this transition will be accelerated by several converging market forces, technological advancements, and evolving user demands. Here’s an analysis of the key trends driving this transformation:

1. Rising Demand for Precision and Versatility (H2):

* Trend: Users across industries (metal fabrication, woodworking, knife making, automotive) increasingly require tools capable of handling diverse tasks with high precision – from aggressive stock removal to fine finishing and intricate contouring.

* Impact on Transition: Bench grinders, primarily designed for basic grinding, sharpening, and shaping on a fixed wheel, lack the inherent versatility of belt grinders. Belt grinders offer interchangeable belts (varying grits, materials – aluminum oxide, zirconia, ceramic) and often include contact wheels or platen systems, enabling precise contouring, bevel creation, and consistent edge finishing. By 2026, the demand for this multifunctionality will make belt grinders the preferred primary tool for shops prioritizing efficiency and quality.

2. Growth of Maker Culture and Small-Scale Manufacturing (H2):

* Trend: The global maker movement, DIY communities, and the rise of micro-manufacturing (especially in knife making, custom tools, and metal art) are booming. These users value tools that offer professional results without industrial-scale costs.

* Impact on Transition: Bench grinders are ubiquitous but often seen as limited. Belt grinders, particularly high-quality benchtop models, have become the de facto standard in these communities due to their ability to achieve mirror finishes, create consistent bevels, and perform complex tasks essential for custom work. This grassroots adoption is driving innovation and lowering costs, making belt grinders more accessible. By 2026, this segment will be a major driver of belt grinder sales, solidifying their position beyond just industrial use.

3. Advancements in Belt Grinder Technology and Accessibility (H2):

* Trend: Continuous innovation is making belt grinders more powerful, user-friendly, durable, and affordable.

* Impact on Transition: Key developments include:

* Higher Power & Efficiency: Motors are becoming more powerful (1HP+ common even in benchtop models) and efficient, enabling faster stock removal and handling tougher materials.

* Improved Dust Collection: Integrated and highly effective dust extraction systems are becoming standard, addressing a major historical drawback and improving workshop safety and cleanliness – a significant advantage over often dusty bench grinders.

* Enhanced Design & Features: Features like easily adjustable tensioners, quick-change belt systems, variable speed control, precision angle guides, and robust cast-iron or steel frames are now common, improving usability and results.

* Modularity: Many systems allow adding accessories (discs, wheels, sanding drums) to a single motor base, increasing value.

* Cost Reduction: Economies of scale and competition are driving down prices for capable models. By 2026, the performance gap between a good bench grinder and a mid-tier belt grinder will be vast, while the price gap continues to narrow, making the belt grinder a more compelling investment.

4. Focus on Safety and Ergonomics (H2):

* Trend: Workplace safety regulations and user awareness are increasing. Tools that minimize risks like kickback, wheel shatter, and repetitive strain are favored.

* Impact on Transition: Bench grinders pose inherent risks: exposed high-RPM grinding wheels can shatter, and the fixed geometry can lead to workpiece kickback. Belt grinders generally have a lower profile, enclosed drive mechanisms, and the flexible belt conforms better to the workpiece, reducing kickback potential. The ability to use jigs and fixtures for consistent, hands-free operation further enhances safety and reduces operator fatigue during repetitive tasks. This safety and ergonomic advantage will be a key selling point by 2026.

5. Shift in Material Processing Needs (H2):

* Trend: Increased use of harder steels (e.g., in knives, tools), exotic alloys, and non-ferrous metals requires more efficient material removal and heat management.

* Impact on Transition: Bench grinders can struggle with hard steels, generating excessive heat that can ruin temper (“burn” the metal). Belt grinding, especially with modern ceramic or zirconia belts, offers superior heat dissipation due to the larger contact area and the continuous movement of the abrasive surface. This allows for faster, cooler grinding, preserving material integrity. This capability is crucial for modern applications and will make belt grinders essential for working with advanced materials by 2026.

Conclusion (H2):

By 2026, the market trend is decisively moving towards the belt grinder as the primary grinding tool for a wide range of users, from professional fabricators to serious hobbyists. While bench grinders will retain a niche for quick, simple tasks like tool sharpening or rough shaping, their role as the central grinding station is diminishing. The superior versatility, precision, safety, technological advancements, and suitability for modern materials offered by belt grinders make them the future-focused investment. The market will be characterized by continued innovation in belt grinder design, further blurring the lines between benchtop and industrial models, and cementing the belt grinder’s place as the dominant force in precision grinding applications.

Common Pitfalls Sourcing a Bench Grinder to Belt Grinder Conversion (Quality, IP)

Converting a bench grinder into a belt grinder is a popular DIY project, but sourcing parts and plans comes with several potential pitfalls related to quality and intellectual property (IP). Being aware of these can save time, money, and legal complications.

Poor Quality Components Leading to Safety Hazards

Many DIY conversion kits and individual parts (especially from online marketplaces) lack quality control. Using substandard bearings, idler pulleys, or motors can lead to excessive vibration, premature failure, or even dangerous disintegration during operation. Cheap materials may not withstand heat and stress, increasing the risk of injury.

Inaccurate or Incomplete Design Plans

Free or low-cost plans found online may contain errors in dimensions, mounting specifications, or material requirements. These inaccuracies can result in misalignment, belt tracking issues, or non-functional builds. Poor documentation often lacks critical safety warnings or assembly guidance, compromising both performance and user safety.

Misrepresentation of Motor Specifications

Sellers sometimes exaggerate motor power (RPM, torque) or duty cycle capabilities. A motor not rated for continuous use may overheat during extended grinding sessions, posing a fire hazard or reducing the tool’s lifespan. Always verify motor specs with independent sources or manufacturer data.

Lack of Intellectual Property Respect in Shared Designs

Many effective grinder designs are the result of significant R&D by independent makers or small businesses. Sharing or selling these designs without permission violates copyright and design patents. Sourcing plans from unauthorized sources supports IP theft and discourages innovation in the maker community.

Using Proprietary Designs Without Licensing

Some high-performance conversion kits or plans are protected by trademarks or patents. Copying these designs—even for personal use—can infringe on IP rights. Commercial resellers who replicate branded grinders face legal action, reputational damage, and potential takedown notices.

Overlooking Safety Certification and Compliance

Homemade or imported conversion parts often lack safety certifications (e.g., CE, UL). This not only increases liability but may void insurance coverage in a workshop setting. Proper grounding, guarding, and emergency stop compliance are frequently missing in DIY setups.

Conclusion

To avoid these pitfalls, source components from reputable suppliers, verify technical specifications independently, and use only legally shared or licensed design plans. Respecting IP and prioritizing quality ensures a safer, more reliable, and ethically sound build.

Logistics & Compliance Guide: Bench Grinder to Belt Grinder Conversion

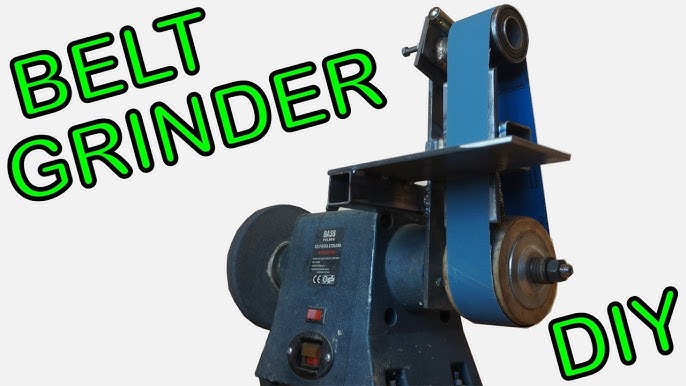

Overview of Conversion Process

Converting a bench grinder to a belt grinder involves modifying the existing motor and housing to support a continuous abrasive belt system. This transformation enhances versatility for tasks like shaping, deburring, and sharpening. Proper planning ensures safety, regulatory compliance, and efficient operation.

Safety Considerations

Adhering to safety standards is critical during and after conversion. Ensure all moving parts are guarded per OSHA 29 CFR 1910.215. Use protective components such as belt tracking guards, emergency stop mechanisms, and secure work rests. Always disconnect power before making adjustments. Operators must wear appropriate PPE, including safety glasses, hearing protection, and gloves.

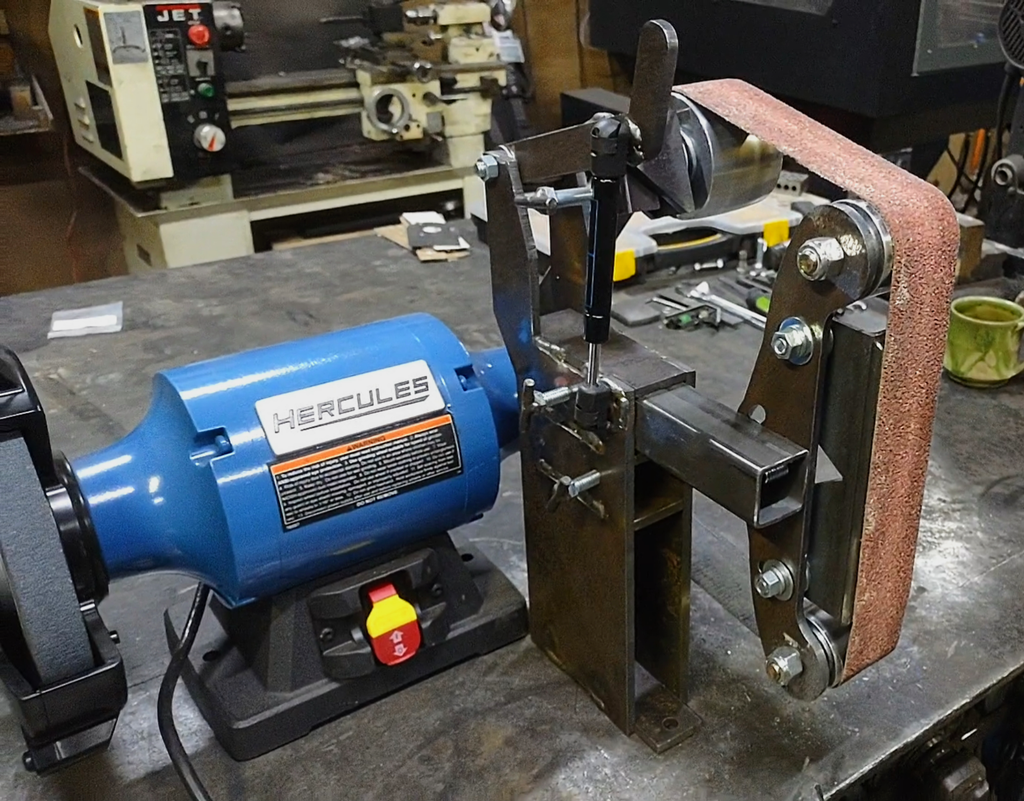

Equipment Requirements and Modifications

Key components for conversion include a drive wheel, idler wheel, belt tracking mechanism, platen or contact wheel, and a compatible abrasive belt (typically 1”x30” or 2”x72”). Confirm motor RPM and shaft compatibility—most bench grinder motors (3,450 RPM) work well with pulley adjustments. Use high-quality bearings and secure mounting hardware to prevent vibration and misalignment.

Electrical Compliance and Power Supply

Verify that the modified grinder remains within the original motor’s electrical specifications. Modifications must not void existing UL or CSA certifications. Use grounded power cords and consider installing a dedicated circuit with a GFCI breaker, especially in damp environments. Label all electrical enclosures clearly.

Noise and Vibration Control

Belt grinders can generate higher noise levels than bench grinders. Monitor sound output and employ noise-dampening materials where possible. Secure the unit to a stable workbench using anti-vibration pads to reduce operator fatigue and improve precision. Ensure compliance with local noise ordinances in commercial settings.

Dust Collection and Air Quality

Grinding operations produce fine particulates that pose respiratory hazards. Integrate a dust extraction system compliant with OSHA PEL (Permissible Exposure Limits) for metal dust. Use HEPA-filtered vacuums or downdraft tables where applicable. Provide adequate ventilation in the workspace to maintain air quality.

Regulatory Compliance Check

Ensure the modified equipment meets relevant standards, including:

– OSHA 29 CFR 1910.215 (Grinding Wheel Safety)

– ANSI B7.1 (Safety Requirements for the Use, Care, and Protection of Abrasive Wheels)

– Local fire codes (for spark and heat management)

Maintain documentation of modifications and safety inspections.

Operational Training and Documentation

Provide formal training for all users on startup, belt changes, tracking adjustments, and shutdown procedures. Keep a log of maintenance, belt replacements, and safety checks. Clearly label controls and include warning decals on pinch points and rotating components.

Disposal and Environmental Responsibility

Dispose of used abrasive belts and collected dust in accordance with local environmental regulations. Metal-laden dust may be classified as hazardous waste—consult EPA or regional guidelines. Recycle components where possible, such as steel housings or motors.

Final Inspection and Certification

Before regular use, conduct a full operational test under supervision. Confirm belt tracking stability, absence of excessive heat, and proper guarding. In commercial environments, consider third-party inspection to validate compliance with workplace safety standards.

Conclusion: Transitioning from Sourcing a Bench Grinder to Building a Belt Grinder

While sourcing a bench grinder may initially seem like a cost-effective and practical solution for grinding, sanding, and sharpening tasks, converting or building a belt grinder offers significant long-term advantages in versatility, performance, and customization. Bench grinders are limited in function—primarily suited for coarse material removal and tool sharpening—but lack the adaptability needed for detailed metalworking, knife making, or precision sanding.

By repurposing a bench grinder motor or investing in a suitable power source to build a DIY belt grinder, users gain the ability to use various abrasive belts, control grinding speed, adjust contact wheel configurations, and tailor the setup to specific applications. This transition enhances efficiency, improves control over the workpiece, and expands the range of achievable finishes—from coarse stock removal to fine polishing.

In conclusion, while sourcing a bench grinder addresses basic grinding needs, evolving toward a belt grinder setup represents a strategic upgrade that maximizes utility, precision, and creative potential. For hobbyists, craftsmen, and small-scale manufacturers, the shift not only optimizes workflow but also provides a solid foundation for future tool development and workshop scalability.