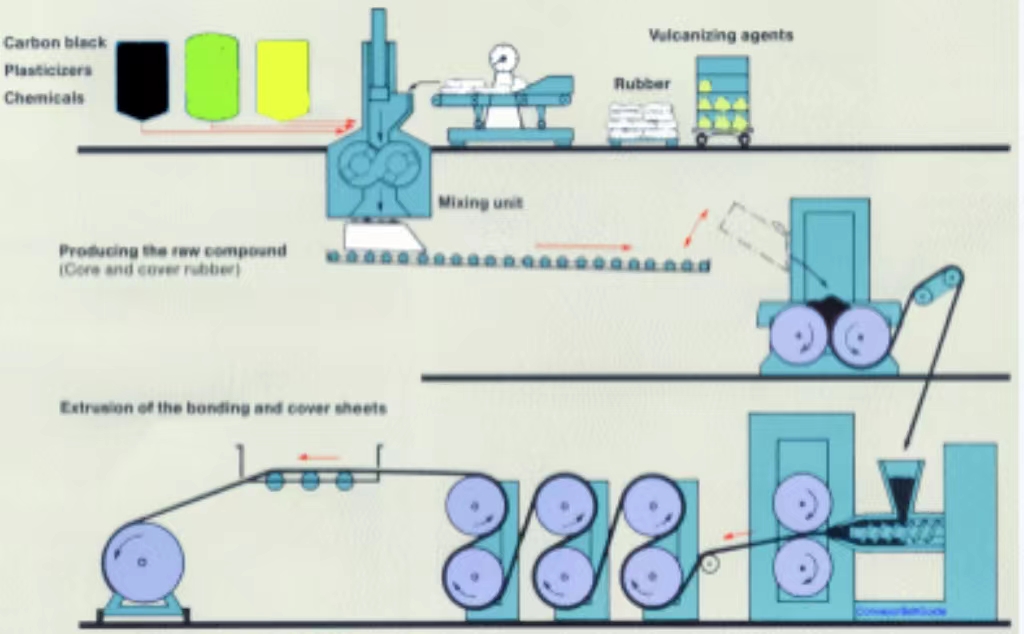

The global belt fastener market is experiencing steady expansion, driven by rising demand across industries such as mining, manufacturing, agriculture, and logistics. According to Grand View Research, the global conveyor belt market—of which belt fasteners are a critical component—was valued at USD 6.3 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is fueled by increasing automation, the need for efficient material handling systems, and infrastructure development in emerging economies. As reliability and durability become paramount in high-throughput environments, manufacturers of belt fasteners are innovating to meet rigorous performance standards. In this competitive landscape, seven leading companies have distinguished themselves through technological advancement, global reach, and comprehensive product portfolios—setting the benchmark for quality and efficiency in belt joining solutions.

Top 7 Belt Fastener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Textron

Domain Est. 1992

Website: textron.com

Key Highlights: Textron Aviation Defense LLC , a Textron Inc. (NYSE:TXT) company, today announced that the company has finalized its first contract to deliver the Beechcraft T- ……

#2 SUPER

Domain Est. 2021

Website: mltgroup-conveyor.com

Key Highlights: MLT is a French belt lacing manufacturer whose core business is the splicing of conveyor belts, the manufacture of technical belts and conveyor equipment….

#3 Mechanical Belt Fastening Systems

Domain Est. 1993

Website: flexco.com

Key Highlights: Flexco Mechanical Fasteners offer strength and durability with fast, easy installation for a quality, long-term splicing option….

#4 Flexco Belt Fasteners

Domain Est. 1999

Website: ammeraalbeltech.com

Key Highlights: Rydell Beltech carries a wide selection of Flexco belt fasteners and equipment to suit a wide variety of belt installations….

#5 Flexco Belt Fasteners

Domain Est. 2002

Website: mdsofmi.com

Key Highlights: Shop Flexco Mechanical Belt Fasteners offer strength and durability with fast, easy installation for a quality, long-term splicing option from MDS….

#6 Conveyor Belt Fasteners

Domain Est. 2007

Website: carrolltechnologiesgroup.com

Key Highlights: Carroll Technologies Provides a Range of Conveyor Belt Fasteners and Accessories Tailored to Your Application. Enquire Online Today….

#7 Conveyor belt splicing with fasteners

Domain Est. 2009

Website: dunlopservice.com

Key Highlights: Our expert teams deliver seamless, high-quality splicing for all types of conveyor belts, including plied rubber, solid woven PVC, and steel cord….

Expert Sourcing Insights for Belt Fastener

H2: Projected Market Trends for Belt Fasteners in 2026

The global belt fastener market is poised for significant transformation by 2026, driven by industrial automation, infrastructure expansion, and evolving material handling demands. Several key trends are expected to shape the industry landscape over the next few years.

1. Rising Demand from Mining and Aggregate Industries

The mining, quarrying, and aggregate sectors remain primary consumers of belt fasteners due to the heavy-duty nature of conveyor systems in these operations. As global infrastructure projects increase—particularly in Asia-Pacific and Africa—demand for durable, high-performance belt fasteners is expected to grow steadily. By 2026, the need for splice reliability and reduced downtime will drive demand for advanced mechanical fasteners and cold bonding solutions.

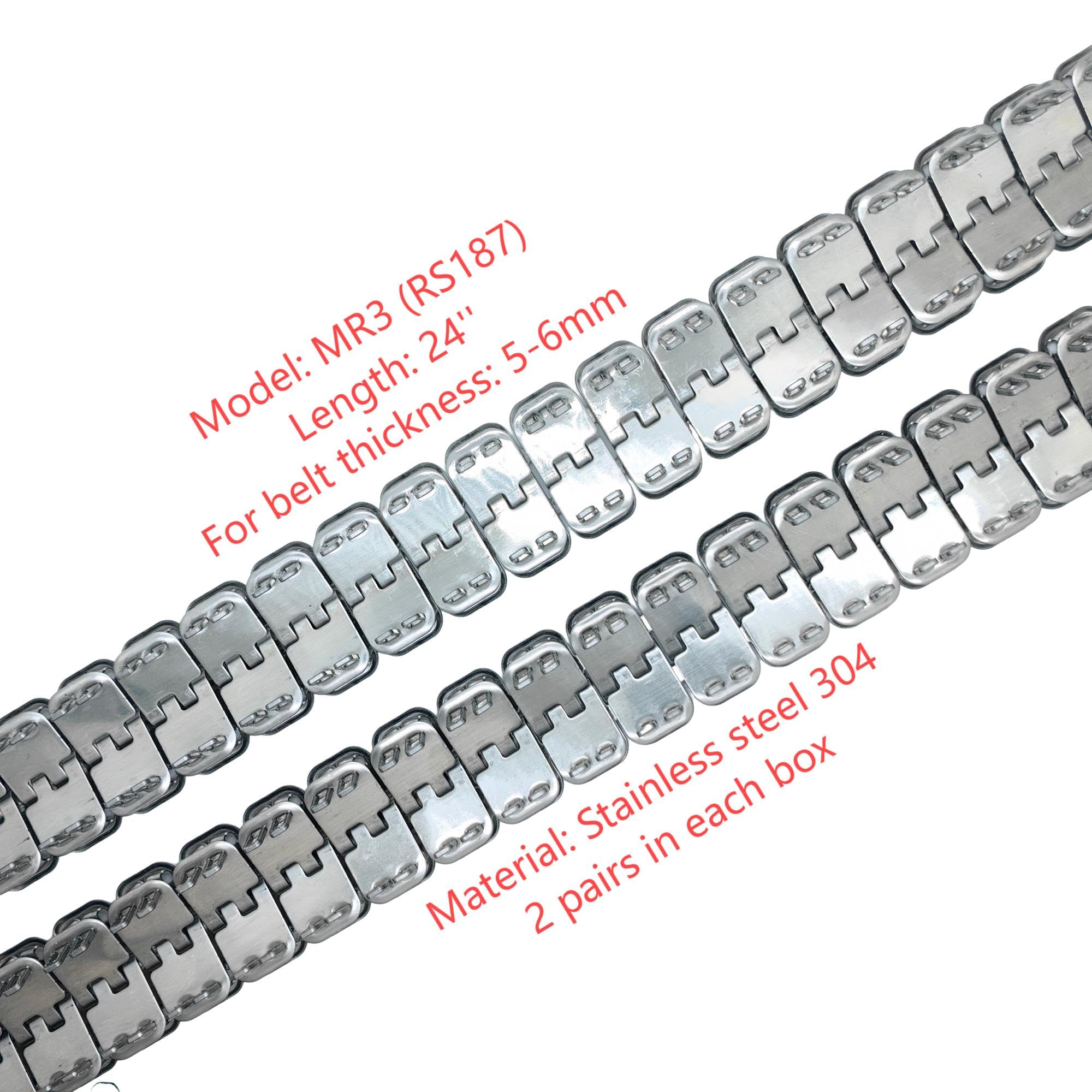

2. Shift Toward High-Strength and Corrosion-Resistant Materials

Manufacturers are increasingly adopting alloy steels, galvanized coatings, and polymer-based fasteners to enhance durability in harsh environments. This shift is driven by the need for longer service life and reduced maintenance costs. Innovations in surface treatment technologies, such as zinc-nickel plating and epoxy coatings, are expected to gain traction by 2026, particularly in corrosive or high-moisture applications.

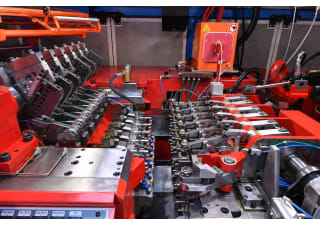

3. Growth in Automated Fastening Systems

With the rise of Industry 4.0, automated belt fastening equipment—such as powered hammers and alignment-guided insertion tools—is becoming more prevalent. These systems improve installation precision, worker safety, and operational efficiency. By 2026, integration with predictive maintenance platforms and IoT-enabled monitoring could further accelerate adoption in large-scale industrial settings.

4. Regional Market Expansion in Asia-Pacific and Latin America

China, India, and Southeast Asian nations are expected to lead market growth due to rapid industrialization and investments in mining and bulk material handling. Similarly, Latin American countries with expanding mining sectors—such as Chile and Peru—will contribute to increased demand. Localized manufacturing and distribution networks are likely to emerge, reducing lead times and logistics costs.

5. Sustainability and Circular Economy Considerations

Environmental regulations and corporate sustainability goals are influencing product design. Reusable fasteners, recyclable materials, and solutions that extend conveyor belt life are gaining attention. By 2026, environmentally certified products may become a competitive differentiator, especially in European and North American markets.

6. Competitive Landscape and Innovation

Leading players such as Flexco, Habasit, and Ammeraal Beltech are investing in R&D to develop faster, stronger, and easier-to-install fastening systems. Patented designs, modular configurations, and compatibility with a wide range of belt types will be key focus areas. Market consolidation through mergers and acquisitions may also occur as companies aim to expand their technological and geographic reach.

In conclusion, the belt fastener market in 2026 will be shaped by technological innovation, regional industrial growth, and sustainability imperatives. Companies that prioritize performance, automation, and environmental responsibility are likely to lead the next phase of market evolution.

Common Pitfalls When Sourcing Belt Fasteners (Quality and Intellectual Property)

Sourcing belt fasteners—especially for critical industrial applications like conveyor systems—can present several challenges related to quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate operational, legal, and financial risks.

Poor Quality Control and Inconsistent Materials

One of the most frequent issues is receiving belt fasteners that do not meet required strength, durability, or dimensional specifications. Suppliers, particularly low-cost manufacturers, may use substandard alloys or inconsistent heat treatment processes, leading to premature fastener failure. This can result in unplanned downtime, safety hazards, and increased maintenance costs. Always verify material certifications (e.g., mill test reports) and conduct regular quality audits or third-party inspections.

Lack of Compliance with Industry Standards

Many belt fasteners must comply with international or industry-specific standards (e.g., ISO, CEMA, or DIN). Sourcing from suppliers who do not adhere to these standards can result in incompatibility with existing systems or non-compliance during safety audits. Ensure suppliers provide documentation proving conformity and have relevant quality management certifications like ISO 9001.

Counterfeit or Reverse-Engineered Products

Some suppliers may offer fasteners that mimic patented designs from reputable brands without proper licensing. These counterfeit or reverse-engineered products may infringe on intellectual property rights, exposing the buyer to legal liability, especially in regions with strong IP enforcement. Using such products can also compromise system performance and void equipment warranties.

Inadequate Documentation and Traceability

Reliable sourcing requires clear traceability of materials and manufacturing processes. Suppliers that fail to provide detailed product documentation—such as material origin, manufacturing location, and test results—create risks in quality assurance and regulatory compliance. Lack of traceability also complicates root cause analysis in the event of a failure.

Hidden IP Infringement in “Generic” Fasteners

Even when sourcing “generic” or “compatible” fasteners, there is a risk of unintentional IP infringement if the design closely replicates a patented mechanism. Suppliers may claim their product is original while copying key patented features. Conduct due diligence by reviewing patent databases or consulting legal experts to ensure designs do not violate existing IP rights.

Overlooking Supplier Reliability and Long-Term Support

Choosing suppliers based solely on price can lead to issues with supply chain continuity, after-sales support, and technical assistance. Unreliable suppliers may discontinue product lines or fail to support warranty claims, leaving operations vulnerable. Evaluate suppliers not just on cost, but on track record, customer service, and willingness to provide long-term support.

Failure to Secure Proper Licensing Agreements

When using fasteners based on proprietary technology, ensure your supplier has the appropriate licensing agreements in place. Purchasing from unauthorized manufacturers—even unknowingly—can result in cease-and-desist orders, recalls, or litigation. Require suppliers to disclose any licensed technology and provide proof of authorization.

By proactively addressing these common pitfalls, organizations can ensure they source belt fasteners that are both high-quality and free from intellectual property complications.

Logistics & Compliance Guide for Belt Fastener

Overview

Belt fasteners are mechanical components used to join the ends of conveyor belts in industrial, mining, and manufacturing applications. Proper logistics and compliance management ensure safe, efficient delivery and adherence to regulatory standards across international and domestic supply chains.

Classification & Tariff Codes

Identify the correct Harmonized System (HS) code for belt fasteners to facilitate customs clearance and accurate duty assessment. Typical classifications include:

– HS Code 7318.19: Other screws, bolts, and nuts, of iron or steel (common for metal fasteners)

– HS Code 8431.39: Parts suitable for use with conveyor machinery

Verify with local customs authorities, as classification may vary based on material, design, and intended use.

Packaging & Handling Requirements

Proper packaging ensures product integrity during transit:

– Use moisture-resistant, corrugated cardboard or wooden crates for bulk shipments

– Include desiccants if shipping to humid or maritime environments

– Label packages with handling instructions: “Fragile,” “This Side Up,” and “Keep Dry”

– Secure fasteners in partitioned containers to prevent abrasion or deformation

Shipping & Transportation

Consider the following for domestic and international shipments:

– Mode of Transport: Belt fasteners are typically shipped via road, rail, or sea freight due to their weight and volume

– Weight & Dimensions: Optimize container or pallet loading; standard pallet size is 1200mm × 1000mm (EUR) or 48″ × 40″ (US)

– Hazardous Materials: Belt fasteners are generally non-hazardous but verify coating or plating materials (e.g., zinc, chrome) for REACH or RoHS compliance

– Temperature Control: Not typically required, but avoid extreme temperatures that may damage packaging

Import/Export Documentation

Ensure all required documentation is prepared and accurate:

– Commercial Invoice

– Packing List

– Bill of Lading/Air Waybill

– Certificate of Origin (for preferential tariff treatment under trade agreements)

– Material Test Reports (if required by customer or regulation)

– Export Declaration (if applicable)

Regulatory Compliance

Adhere to regional and international standards:

– REACH (EU): Ensure no restricted substances in coatings or plating (e.g., lead, cadmium)

– RoHS (EU): Applicable if fasteners contain electrical components or platings

– OSHA & MSHA (USA): Compliance may be required if used in mining or industrial safety-critical environments

– ISO Standards: Follow ISO 504 for conveyor belt fastener testing and performance

Product Labeling & Traceability

- Include part number, material type, batch/lot number, and manufacturer information on packaging and fasteners

- Comply with country-specific labeling laws (e.g., bilingual labels in Canada)

- Maintain traceability records for quality control and recalls

Customs Clearance & Duties

- Provide accurate product descriptions and valuation to avoid delays

- Leverage Free Trade Agreements (e.g., USMCA, RCEP) where applicable to reduce tariffs

- Engage a licensed customs broker for complex international shipments

Environmental & Sustainability Considerations

- Use recyclable packaging materials where possible

- Comply with WEEE directives if fasteners include electronic components

- Document environmental compliance for corporate sustainability reporting

Risk Management & Insurance

- Insure shipments against loss, damage, or delay

- Conduct supplier audits to ensure consistent quality and compliance

- Maintain recall and incident response protocols

Conclusion

Effective logistics and compliance for belt fasteners require attention to classification, packaging, regulations, and documentation. Proactive management minimizes delays, ensures safety, and supports global market access. Regularly review regulatory updates and work with certified partners to maintain supply chain integrity.

Conclusion for Sourcing Belt Fastener:

After a comprehensive evaluation of potential suppliers, cost considerations, material quality, production capacity, and compliance standards, it is concluded that sourcing belt fasteners from [Selected Supplier/Region] offers the most balanced and strategic advantage. The chosen supplier demonstrates consistent product quality, reliable lead times, competitive pricing, and compliance with relevant industry standards (e.g., ISO, RoHS, or ASTM, where applicable). Additionally, their scalability and willingness to support customization align well with current and future operational needs.

Sourcing from this supplier not only ensures the durability and performance of the belt fastening systems but also contributes to long-term cost savings, supply chain stability, and operational efficiency. It is recommended to formalize the partnership through a contractual agreement with clear quality assurance and delivery terms, while maintaining periodic performance reviews to ensure continued satisfaction.

Overall, this sourcing decision supports our commitment to quality, reliability, and value optimization in material procurement.