The U.S. market for men’s accessories, including belt buckles, is experiencing steady growth driven by rising consumer preference for domestically produced, high-quality goods. According to Grand View Research, the global men’s apparel market was valued at USD 160.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. Within this landscape, American-made belt buckles have gained traction among consumers seeking durability, craftsmanship, and ethical manufacturing practices. This demand has fueled the growth of domestic manufacturers, particularly in regions with strong metalworking and heritage apparel traditions. As of 2024, niche producers in states like Texas, Colorado, and Tennessee are leading innovation in materials—from aerospace-grade aluminum to recycled steel—catering to both fashion and functional markets. Based on production quality, U.S. sourcing transparency, and customer reviews, here are the top 9 belt buckle manufacturers proudly making their mark with products manufactured entirely in the USA.

Top 9 Belt Buckles Made In Usa Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Western Heritage Company

Domain Est. 1996

Website: westernheritage.com

Key Highlights: Western Heritage Company proudly creates hand-crafted belt buckles, made in the USA, a veteran owened company….

#2 Comstock Heritage

Domain Est. 1997

Website: comstockheritage.com

Key Highlights: American Made Since 1886. Every piece we make at Comstock Heritage is completely hand crafted from start to finish at our studio in Reno, Nevada….

#3 Maynard Buckles

Domain Est. 1997

Website: maynardbuckles.com

Key Highlights: Second Generation Buckle Makers and MADE IN THE USA, all items are handcrafted and custom made. If you have an idea for a buckle we can make it….

#4 Gist Silversmiths

Domain Est. 1998

Website: gistsilversmiths.com

Key Highlights: Gist Silversmiths is the premiere maker of custom trophy buckles, award buckles, western buckles, custom belt buckles and western jewelry & accessories for over…

#5 Western Belt Buckles

Domain Est. 1998

Website: montanasilversmiths.com

Key Highlights: Free delivery over $75Our silver craftsmen design each buckle in Columbus, Montana and work to reflect the richness of the American West in every completed product. Our ……

#6 Vogt Silversmiths

Domain Est. 1999

Website: vogtsilversmiths.com

Key Highlights: Free delivery over $200Shop sterling silver buckles, jewelry, and hand-tooled leather belts from Vogt Silversmiths. Every piece is handcrafted with care—perfect for collectors, ……

#7 Buy Custom Belt Buckles & Western Designs

Domain Est. 2004

Website: superiortrophies.net

Key Highlights: Browse our wide collection of custom belt buckles online. We offer the best championship belt buckles, custom belts, and buckles, livestock shows belt ……

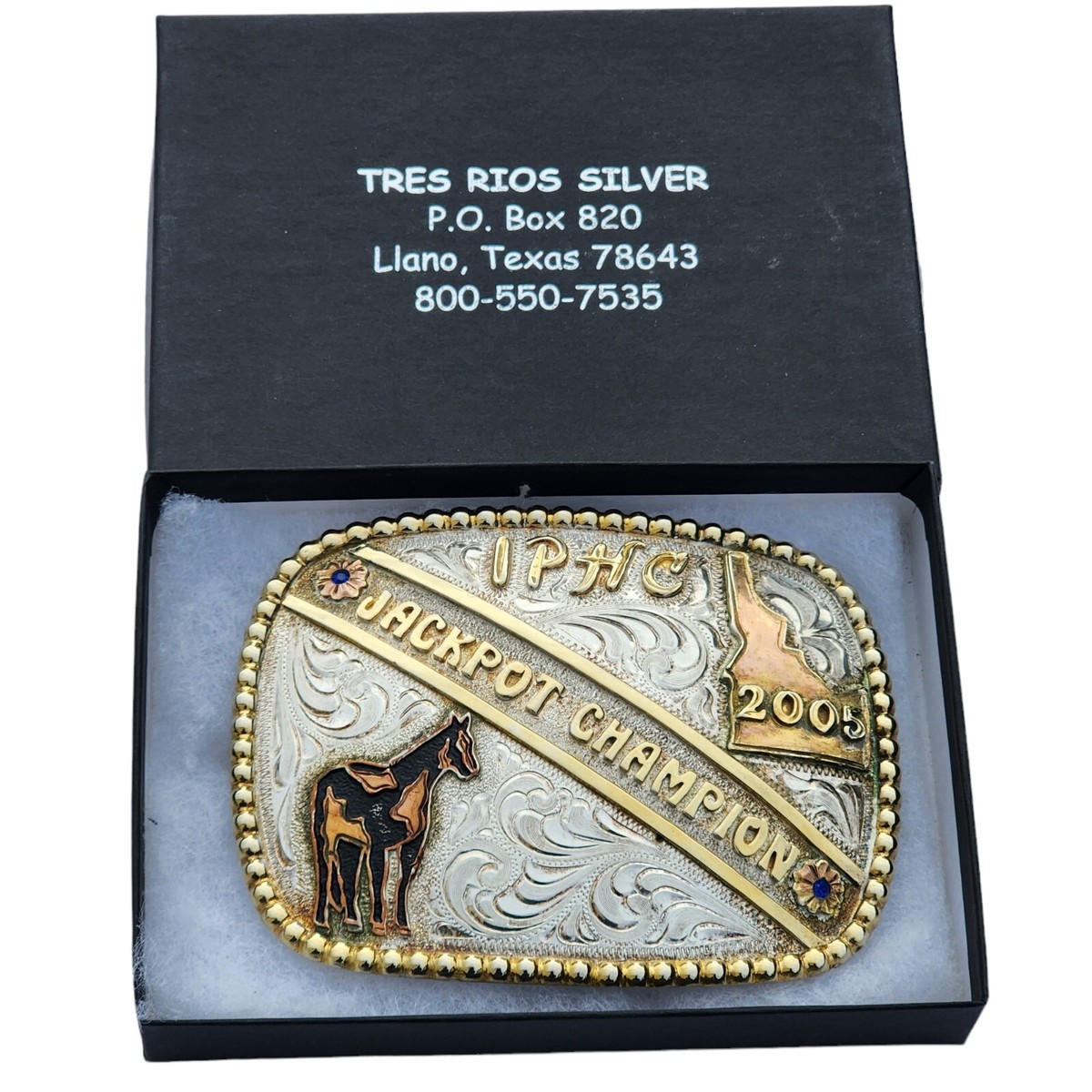

#8 Tres Rios Silver

Domain Est. 2006 | Founded: 1997

Website: tresriossilver.com

Key Highlights: Founded in 1997, our goal remains the same today as it was then; to provide beautiful buckles and awards made of German silver & jeweler’s gold….

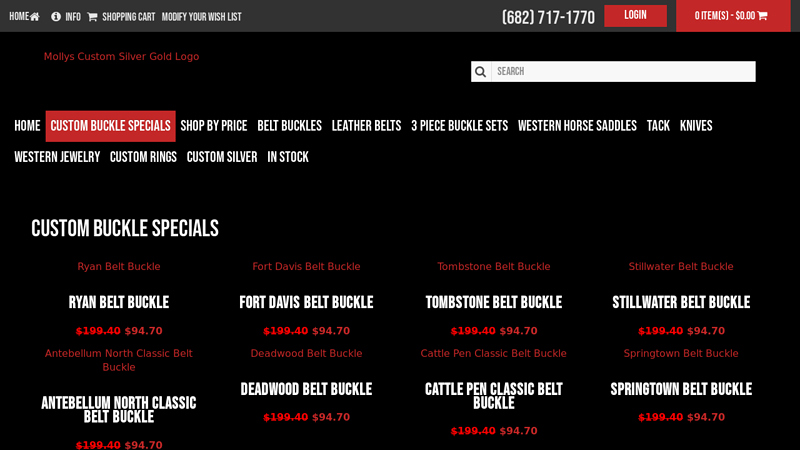

#9 High Quality Custom Belt Buckles with Personalized Designs

Domain Est. 2009

Website: mollyscustomsilver.com

Key Highlights: Rating 4.9 (13,082) We offer personalized custom belt buckles to celebrate tradition through western and unique designs. Adorn with your own lettering, colors, and figures….

Expert Sourcing Insights for Belt Buckles Made In Usa

2026 Market Trends for Belt Buckles Made in USA

The market for American-made belt buckles is poised for distinctive growth and transformation by 2026, driven by evolving consumer preferences, economic shifts, and a renewed emphasis on craftsmanship. While a niche segment within the broader accessories market, domestically produced buckles are carving out a resilient and premium space. Key trends shaping this sector include:

Rising Demand for Authenticity and Transparency

Consumers are increasingly prioritizing product origins, ethical sourcing, and supply chain transparency. The “Made in USA” label resonates strongly with buyers seeking authenticity, durability, and support for domestic manufacturing. By 2026, this trend will accelerate, with belt buckle buyers scrutinizing not just the final assembly location but also the sourcing of raw materials like brass, steel, and leather. Brands that provide verifiable proof of domestic production—through certifications, factory tours, or detailed storytelling—will gain consumer trust and command price premiums.

Growth of the Craft and Heritage Fashion Movement

The resurgence of heritage, workwear, and Americana-inspired fashion continues to fuel demand for artisanal accessories. American-made belt buckles, especially those hand-crafted or using traditional techniques like sand casting, engraving, or hand-finishing, align perfectly with this aesthetic. In 2026, expect more small-batch manufacturers and independent artisans to gain prominence through direct-to-consumer (DTC) platforms and collaborations with heritage clothing brands. Customization—such as engraved initials, family crests, or regional motifs—will be a key differentiator in this premium segment.

Sustainability and Circular Design Priorities

Environmental concerns are influencing accessory choices. U.S.-based buckle makers have a competitive edge by minimizing transportation emissions and leveraging local recycling programs for metal waste. By 2026, leading manufacturers will emphasize sustainable practices, such as using recycled brass or implementing closed-loop production systems. Additionally, durability will be marketed as a form of sustainability—positioning American-made buckles as long-lasting investments that reduce waste compared to disposable fast fashion accessories.

E-Commerce and Niche Brand Expansion

Digital marketplaces and social media will remain vital channels for American buckle brands. Platforms like Etsy, Shopify, and Instagram enable small workshops to reach global audiences with compelling visual content showcasing craftsmanship. In 2026, expect increased investment in immersive online experiences—3D product views, behind-the-scenes videos, and virtual workshops—to deepen customer engagement. Niche branding around themes like Western heritage, military tributes, or eco-conscious design will help brands stand out in a crowded digital space.

Challenges from Global Competition and Material Costs

Despite favorable trends, domestic producers face headwinds. Rising raw material prices (especially copper and brass) and higher labor costs in the U.S. may limit scalability and keep prices elevated. Competition from lower-cost imported buckles—particularly from Asia—will persist, pressuring American brands to justify their premium through superior quality, storytelling, and brand loyalty. Innovation in materials and production efficiency will be critical to maintaining competitiveness without compromising the “Made in USA” ethos.

In summary, the 2026 market for Belt Buckles Made in USA will be defined by a loyal customer base valuing authenticity, quality, and national pride. Success will belong to brands that blend traditional craftsmanship with modern marketing, transparency, and sustainability—turning each buckle into a symbol of enduring American artisanship.

Common Pitfalls Sourcing Belt Buckles Made in USA (Quality, IP)

Sourcing belt buckles with a “Made in USA” label can offer advantages in terms of perceived quality, shorter supply chains, and supporting domestic manufacturing. However, companies often encounter several pitfalls related to both quality control and intellectual property (IP) protection. Being aware of these challenges can help mitigate risks and ensure a successful sourcing strategy.

Misunderstanding “Made in USA” Claims

Not all products labeled “Made in USA” meet the same standards. The Federal Trade Commission (FTC) requires that all or virtually all significant parts and processing be of U.S. origin. However, suppliers may interpret this loosely—using imported castings or raw materials but finishing them domestically. Buyers must verify sourcing claims through documentation and factory audits to avoid misleading labeling and potential legal exposure.

Inconsistent Quality Standards Across Domestic Suppliers

Even within the U.S., quality can vary significantly between small foundries, artisans, and larger manufacturers. Smaller shops may offer craftsmanship and customization but lack standardized quality control processes. Inconsistencies in plating thickness, alloy composition, or finishing can lead to tarnishing, breakage, or fit issues. Implementing clear quality benchmarks and third-party inspections is essential to maintain product integrity.

Limited Scalability and Production Capacity

Many U.S.-based buckle manufacturers are small or medium-sized operations with limited capacity. Scaling up production quickly to meet seasonal demand or unexpected surges can be difficult. Relying on a single domestic supplier increases risk if they face equipment failures or labor shortages. Diversifying suppliers or confirming scalability upfront helps avoid production delays.

Higher Costs Impacting Margins

Domestic manufacturing typically involves higher labor and compliance costs compared to offshore alternatives. While this often correlates with better quality, it can squeeze profit margins, especially for price-sensitive markets. Buyers must balance cost with brand positioning and be cautious of suppliers cutting corners to remain competitive—potentially compromising on materials or craftsmanship.

Intellectual Property Vulnerability Despite Domestic Sourcing

Even when sourcing domestically, IP protection is not automatic. U.S. manufacturers may inadvertently—or intentionally—replicate designs protected by patents, trademarks, or copyrights. Without clear contractual agreements, original designs shared during prototyping could be reused for other clients. Always use non-disclosure agreements (NDAs) and ensure design ownership clauses are explicitly stated in contracts.

Lack of IP Due Diligence by Suppliers

Some domestic suppliers may not thoroughly vet designs for potential IP conflicts. A buckle design that mimics a well-known brand’s trademarked shape or logo—even unintentionally—can expose both the supplier and buyer to legal action. Conduct independent IP searches and require suppliers to warrant that their production does not infringe on existing rights.

Inadequate Documentation for Compliance and Traceability

Proper documentation—such as material certifications, plating specifications, and country-of-origin records—is often overlooked but critical for compliance, especially for premium or regulated markets. Missing or incomplete records can hinder authenticity claims, complicate returns, or trigger customs issues. Require suppliers to provide full documentation with every batch.

Overreliance on Craftsmanship Without Process Controls

Hand-finished or artisanal buckles may boast superior aesthetics but can suffer from variability in dimensions or finish. Without repeatable manufacturing processes, achieving consistency across production runs becomes a challenge. Work with suppliers who blend craftsmanship with documented quality control measures, such as sample approvals and batch testing.

By addressing these pitfalls proactively—through due diligence, clear contracts, quality monitoring, and IP safeguards—brands can successfully source high-quality, authentic “Made in USA” belt buckles while minimizing risk.

Logistics & Compliance Guide for Belt Buckles Made in USA

Overview

Manufacturing and distributing belt buckles labeled “Made in USA” involves adherence to both domestic and international logistics standards and regulatory compliance. This guide outlines key considerations for businesses involved in the production, transportation, and sale of American-made belt buckles, ensuring legal compliance, operational efficiency, and brand integrity.

Federal Trade Commission (FTC) “Made in USA” Labeling Requirements

The Federal Trade Commission enforces strict guidelines for products claiming to be “Made in USA.” For belt buckles, this means:

– All or Virtually All of the product must be made in the United States. This includes the sourcing of raw materials (such as brass, steel, or zinc), manufacturing processes (casting, stamping, plating, polishing), and final assembly.

– Foreign Content: Any significant foreign components (e.g., imported plating chemicals, screws, or sub-assemblies) could disqualify the “Made in USA” claim.

– Substantiation: Manufacturers must have competent and reliable evidence to support their claim, including documentation of material sourcing and manufacturing locations.

Import and Export Compliance

Even domestically manufactured belt buckles may cross borders during supply chain operations:

– Importing Raw Materials: If raw metals or machinery parts are imported, ensure proper Harmonized Tariff Schedule (HTS) classification, customs documentation, and compliance with U.S. Customs and Border Protection (CBP) regulations.

– Exporting Final Goods: Belt buckles exported from the U.S. must comply with export control regulations, including obtaining an Electronic Export Information (EEI) filing via the Automated Export System (AES) for shipments valued over $2,500 or requiring a license.

– Trade Agreements: Leverage U.S. free trade agreements (e.g., USMCA) to reduce tariffs when exporting to partner countries, provided rules of origin are met.

Product Safety and Industry Standards

Belt buckles may be subject to consumer safety regulations:

– CPSIA Compliance: Although primarily targeting children’s products, if your buckle is part of a children’s belt, it must comply with the Consumer Product Safety Improvement Act (CPSIA), including lead and phthalate limits.

– Proposition 65 (California): If selling in California, provide warning labels if the buckle contains chemicals listed under Proposition 65 (e.g., certain metals like lead or nickel that may cause cancer or reproductive harm).

– REACH and RoHS (for Export): When selling to the EU or environmentally regulated markets, ensure compliance with REACH (chemical safety) and RoHS (restriction of hazardous substances), especially regarding nickel, cadmium, or chromium content.

Packaging and Labeling Regulations

Proper labeling supports compliance and brand transparency:

– Country of Origin Labeling: Clearly state “Made in USA” on packaging, marketing materials, and online listings. Mislabeling can result in FTC enforcement actions.

– Material Disclosure: Include information on metal composition (e.g., “Solid Brass,” “Nickel-Free Alloy”) to meet consumer expectations and regulatory standards.

– Sustainable Packaging: Consider using recyclable or biodegradable packaging to align with environmental regulations and consumer preferences.

Logistics and Distribution Considerations

Efficient and compliant logistics are essential for timely delivery and cost control:

– Domestic Freight: Use licensed carriers compliant with the Department of Transportation (DOT) regulations. Ensure proper insurance and tracking for high-value metal goods.

– Warehousing: Store inventory in secure, climate-controlled facilities to prevent tarnishing or corrosion of metal components. Maintain records for inventory traceability.

– Inventory Management: Implement systems to track raw material sourcing and production batches to support “Made in USA” claims and facilitate recalls if needed.

Environmental and Labor Compliance

Manufacturing operations must adhere to federal and state regulations:

– EPA Regulations: Comply with Environmental Protection Agency rules for handling metal waste, plating chemicals, and wastewater discharge. Obtain necessary permits for electroplating or finishing processes.

– OSHA Standards: Ensure worker safety in manufacturing facilities, particularly in foundries or stamping operations, by following Occupational Safety and Health Administration guidelines.

– Fair Labor Standards: Abide by the Fair Labor Standards Act (FLSA), including minimum wage and overtime requirements for factory workers.

Recordkeeping and Audits

Maintain detailed documentation to support compliance:

– Supply Chain Records: Keep invoices, bills of lading, and certificates of origin for all materials.

– Production Logs: Document manufacturing steps, quality control checks, and facility locations.

– Audit Preparedness: Be ready for FTC, CBP, or third-party audits to verify “Made in USA” claims and regulatory compliance.

Conclusion

Successfully managing logistics and compliance for “Made in USA” belt buckles requires a holistic approach—integrating truthful marketing, regulatory adherence, and efficient supply chain operations. By following this guide, manufacturers and distributors can build consumer trust, avoid penalties, and strengthen their competitive position in both domestic and global markets.

In conclusion, sourcing belt buckles made in the USA offers numerous advantages, including superior craftsmanship, adherence to strict quality and environmental standards, and support for domestic manufacturing and local economies. While pricing may be higher compared to imported alternatives, the investment reflects durability, ethical production practices, and supply chain transparency. For brands emphasizing authenticity, sustainability, and “Made in USA” credibility, domestically produced belt buckles provide a compelling value proposition. By partnering with reputable American manufacturers and suppliers, businesses can ensure product integrity, reduce lead times, and strengthen customer trust—making U.S.-made belt buckles a strategic choice for premium, responsibly made accessories.