The global brewing equipment market is experiencing steady expansion, driven by rising craft beer consumption and increasing investments in microbreweries and homebrewing. According to Mordor Intelligence, the brewing equipment market was valued at USD 7.6 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. A critical component in this ecosystem is the beer mash tun—a vessel essential for the mashing process, where starches are converted into fermentable sugars. As demand for high-efficiency, scalable brewing solutions grows, manufacturers of mash tuns are innovating with advanced materials, temperature control systems, and automation. In this evolving landscape, eight manufacturers have emerged as leaders, combining engineering excellence, market reach, and customer-centric design to meet the needs of commercial and craft brewers alike.

Top 8 Beer Mash Tun Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electric, Insulated & Stainless Steel Mash Tuns

Domain Est. 2006

Website: glaciertanks.com

Key Highlights: 5-day delivery · 30-day returnsExtensive range of stainless steel mash tuns, including insulated & electric. Ideal for craft brewers to commercial & industrial applications. Buy O…

#2 Mash Tun – Brewing

Domain Est. 1995

Website: sp.paulmueller.com

Key Highlights: Ideal for single infusion mashing, this mash mixer and lauter tun hybrid combines two essential pieces of brewhouse equipment to create a vessel that operates ……

#3 ShakesBeer mash tun

Domain Est. 1996

Website: steinecker.com

Key Highlights: Improved extract yield with reduced mashing times. Maximum flexibility, best quality and efficiency are required in each individual step of the brewing process….

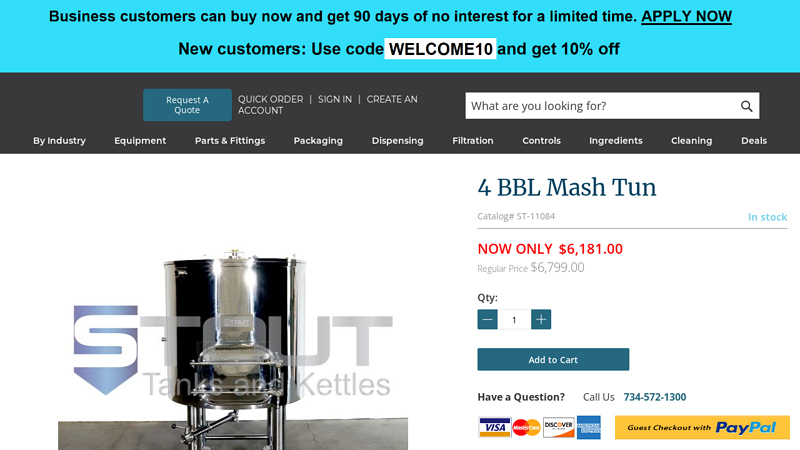

#4 4 BBL Mash Tun for sale

Domain Est. 1999

Website: gwkent.com

Key Highlights: In stock $2,000 deliveryIt is designed to give you an optimum combination of good extraction, high gravities, and efficient lautering. It has many professional grade features inclu…

#5 Hot Side

Domain Est. 2013

Website: ssbrewtech.com

Key Highlights: 4–7 day delivery Free 30-day returnsOur InfuSsion Mash Tun is the perfect choice for brewer’s looking to upgrade their aging plastic cooler. Learn More. Ss Brew Kettle BME. Ss Brew…

#6 10 Gallon Tri

Domain Est. 2014

#7 Commercial Beer Mash Tun Tanks for Sale

Domain Est. 2015

Website: abs-commercial.com

Key Highlights: 3 BBL Mash tun tank. Fully equipped and ready for service. Height: 7’1″ Width: 3’10” Weight: 496Lbs Download PDF Request A Quote…

#8 Stainless Steel Mash Tuns

Domain Est. 2017

Website: craftmasterstainless.com

Key Highlights: Designed to carefully mix ground grist with your supply of temperature-controlled water, this process is particular and key to the final product’s quality….

Expert Sourcing Insights for Beer Mash Tun

H2: 2026 Market Trends for Beer Mash Tun

The global beer mash tun market is poised for notable transformation by 2026, driven by evolving brewing practices, technological advancements, and shifting consumer preferences. As craft brewing continues to expand and industrial efficiency becomes a priority, mash tuns—essential equipment for mashing grains during beer production—are undergoing innovation to meet the demands of both small-scale and large-scale breweries.

1. Growth in Craft Brewing Sector

The sustained rise of the craft beer movement is a key driver shaping the mash tun market. By 2026, an increasing number of microbreweries and brewpubs are expected to invest in compact, efficient, and modular mash tuns that offer flexibility in batch sizes and recipe experimentation. This trend favors manufacturers producing scalable and user-friendly systems tailored to artisanal brewers.

2. Technological Integration and Automation

Automation and smart brewing technologies are becoming standard in modern brewing facilities. By 2026, mash tuns are likely to feature integrated sensors, programmable logic controllers (PLCs), and Internet of Things (IoT) connectivity for real-time monitoring of temperature, pH levels, and mash efficiency. This enhances consistency, reduces human error, and improves scalability—particularly attractive to mid- to large-sized breweries.

3. Emphasis on Sustainability and Energy Efficiency

Environmental concerns are pushing breweries to adopt energy-efficient equipment. Future mash tuns are expected to incorporate improved insulation, heat recovery systems, and eco-friendly materials. Manufacturers focusing on low water and energy consumption designs will gain a competitive edge, aligning with global sustainability goals and regulatory standards.

4. Regional Market Expansion

While North America and Europe remain dominant markets due to established brewing traditions and high craft beer consumption, regions like Asia-Pacific and Latin America are projected to show the fastest growth by 2026. Emerging markets in countries such as China, India, and Brazil are witnessing a surge in both domestic and imported craft beer demand, driving the need for brewing infrastructure, including mash tuns.

5. Customization and Modular Design

Brewers increasingly demand customizable solutions. By 2026, mash tuns with modular construction—allowing integration with other brewing vessels like lauter tuns and brew kettles—are expected to be in high demand. This allows for easier upgrades, space optimization, and streamlined brewing processes, especially in urban microbreweries with limited floor space.

6. Consolidation and Competitive Landscape

The market may see increased consolidation among equipment suppliers, with larger companies acquiring niche innovators to expand product portfolios. At the same time, specialized startups offering turnkey brewing systems with advanced mash tuns will continue to disrupt the market, particularly in the craft segment.

In summary, by 2026, the beer mash tun market will be shaped by innovation in automation, sustainability, and scalability, with strong growth supported by the global craft beer revolution and expanding brewing capacity in emerging economies. Manufacturers that align with these trends will be best positioned for success.

Common Pitfalls Sourcing a Beer Mash Tun (Quality, IP)

Sourcing a beer mash tun—especially for commercial brewing—requires careful consideration of both quality and intellectual property (IP) concerns. Overlooking these aspects can lead to operational inefficiencies, safety hazards, legal issues, and compromised product quality. Below are key pitfalls to avoid:

Poor Material Quality and Construction

One of the most frequent mistakes is selecting a mash tun made from substandard materials. Stainless steel is the industry standard, but not all grades are suitable. Using low-grade stainless (e.g., 304 instead of 316L) increases the risk of corrosion, especially when exposed to acidic wort or cleaning agents. Thin-walled vessels or poorly welded seams can lead to structural failure, contamination, or difficulty maintaining temperature—jeopardizing both beer quality and safety.

Inadequate Insulation and Temperature Control

A mash tun must maintain a stable temperature throughout the mashing process. Poorly insulated vessels result in significant heat loss, leading to inconsistent enzyme activity and incomplete starch conversion. This directly affects fermentability and final beer flavor. Buyers often underestimate the importance of proper cladding, insulation thickness, and jacket design, especially in environments with fluctuating ambient temperatures.

Non-Compliant Design and Missing Certifications

Commercial mash tuns must meet regulatory standards such as ASME (American Society of Mechanical Engineers), PED (Pressure Equipment Directive) in Europe, or local food safety codes (e.g., FDA, CE). Sourcing a vessel without proper certification can lead to failed inspections, insurance complications, or even shutdowns. Additionally, lack of compliance with 3-A Sanitary Standards affects cleanability and may violate health regulations.

Ignoring Intellectual Property (IP) in Design and Technology

Many advanced mash tun systems incorporate proprietary technologies—such as specialized false bottoms, recirculation systems, or integrated control software. Sourcing equipment that replicates patented designs can expose the buyer to IP infringement claims. This is particularly common when purchasing from low-cost manufacturers who reverse-engineer branded systems. Always verify the originality of design features and ensure documentation supports legal use.

Lack of Scalability and Future-Proofing

Breweries often select a mash tun based on current batch sizes without considering growth. A system that lacks modularity or compatibility with future automation may become obsolete quickly. Additionally, proprietary control systems or non-standard fittings can limit integration with new equipment, increasing long-term costs and complexity.

Incomplete or Missing Documentation

Quality sourcing includes obtaining full technical documentation: material test reports (MTRs), weld logs, pressure test results, and user manuals. Without these, verifying quality, performing maintenance, or proving compliance during audits becomes difficult. Missing documentation can also hinder warranty claims or resale value.

Overlooking After-Sales Support and Service

Even high-quality mash tuns require maintenance and occasional repairs. Sourcing from a supplier with poor customer support or limited spare parts availability can lead to extended downtime. This is especially critical for IP-protected components that may only be serviced by the original manufacturer.

By recognizing these pitfalls early, brewers can make informed decisions that ensure quality, compliance, and long-term operational success when sourcing a beer mash tun.

Logistics & Compliance Guide for Beer Mash Tun

Overview

A beer mash tun is a critical vessel in the brewing process, used to mix milled grain (typically malted barley) with hot water to convert starches into fermentable sugars. Proper logistics and compliance are essential for safe, legal, and efficient operation, particularly in commercial brewing environments.

Regulatory Compliance

Food Safety Standards

Mash tuns must comply with food-grade material standards. In the U.S., this typically means adherence to FDA 21 CFR regulations for food-contact surfaces. Materials must be non-toxic, corrosion-resistant (e.g., 304 or 316 stainless steel), and designed to prevent bacterial harborage. Regular cleaning and sanitation protocols (e.g., CIP – Clean-in-Place systems) must align with current Good Manufacturing Practices (cGMP).

Pressure and ASME Certification

If the mash tun is designed to operate under pressure or vacuum, it may require ASME (American Society of Mechanical Engineers) certification, particularly if it meets the criteria for a pressure vessel. Consult local jurisdiction requirements—some regions mandate ASME U or U2 stamps for commercial brewing equipment.

Electrical and Mechanical Safety

All electrical components (e.g., temperature sensors, pumps, control panels) must comply with OSHA and NFPA 70 (National Electrical Code) standards. Grounding, proper enclosures, and explosion-proof ratings (if applicable) are required. Equipment should carry relevant certifications such as UL, CE, or CSA.

Environmental and Waste Disposal

Spent grain and cleaning effluent (caustic or acidic waste from CIP) must be managed in accordance with EPA and local wastewater regulations. Discharge limits for pH, BOD, and solids may apply. Many facilities partner with farms for spent grain reuse, which supports sustainability compliance.

Import and Export Logistics

International Shipping Requirements

When importing or exporting mash tuns, ensure compliance with destination country regulations. Documentation should include:

– Commercial invoice

– Packing list

– Certificate of Conformity (for CE, UKCA, or other regional standards)

– Material test reports (e.g., for stainless steel)

– Sanitary design certification (e.g., 3-A Sanitary Standards if applicable)

Customs Classification

Mash tuns typically fall under HS Code 8438.60 (“Machines for the industrial preparation or manufacture of food or drink, not elsewhere specified or included”). Accurate classification ensures correct duty rates and avoids customs delays.

Packaging and Handling

Use robust wooden crates or steel-reinforced pallets to prevent damage during transit. Waterproof wrapping and desiccants help prevent corrosion. Clearly label with handling instructions (e.g., “This Side Up,” “Fragile,” “Do Not Stack”).

Installation and Operational Compliance

Facility Requirements

Ensure adequate floor loading capacity, utility connections (water, steam, electricity, drainage), and ventilation. Local building and fire codes may dictate clearances, gas line installations, and emergency shutoffs.

Validation and Documentation

Maintain records of:

– Equipment installation qualification (IQ)

– Operational qualification (OQ)

– Preventive maintenance schedules

– Calibration logs for temperature and pressure sensors

These records support audits and regulatory inspections (e.g., TTB in the U.S. for alcohol production compliance).

Training and Personnel Safety

Operator Training

Personnel must be trained in:

– Safe operation procedures

– Lockout/Tagout (LOTO) for maintenance

– Chemical handling (caustic soda, acids, sanitizers)

– Emergency response for steam, scalding, or electrical hazards

Training records should be kept up to date and comply with OSHA 29 CFR 1910 standards.

Summary

Adhering to logistics and compliance standards for beer mash tuns ensures operational safety, regulatory approval, and product quality. Key considerations include food safety, pressure vessel regulations, environmental compliance, proper shipping documentation, and thorough staff training. Always consult local authorities and industry standards to ensure full compliance.

In conclusion, sourcing a beer mash tun requires careful consideration of several key factors including material quality, capacity, insulation, temperature control, ease of cleaning, and compatibility with your brewing system. Whether you are a craft brewer or scaling up production, selecting the right mash tun directly impacts the efficiency, consistency, and quality of your beer. Evaluating suppliers based on reputation, warranty, customer support, and total cost of ownership will ensure a reliable and long-term investment. Ultimately, a well-chosen mash tun not only supports optimal starch conversion and lautering efficiency but also contributes to the overall success and scalability of your brewing operation.