Introduction: Navigating the Global Market for Beer Fermentation Tanks

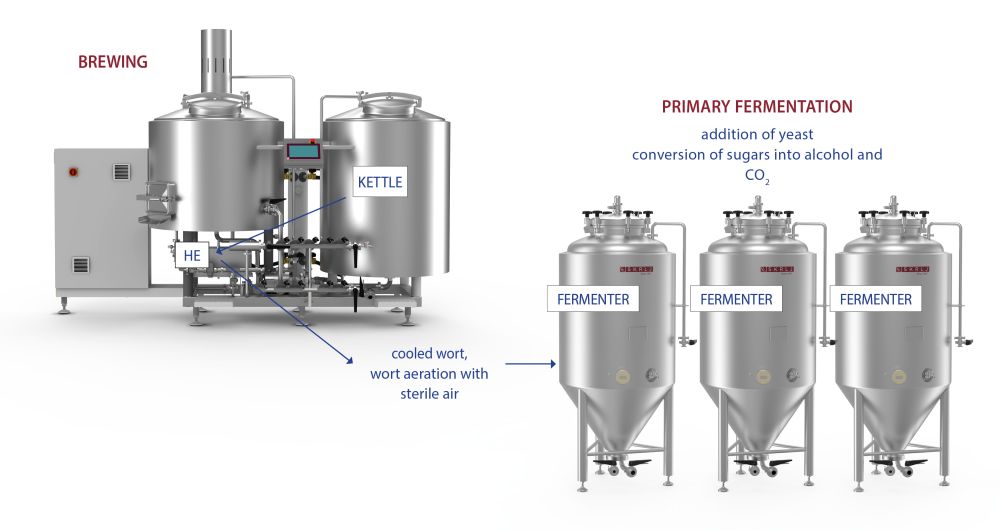

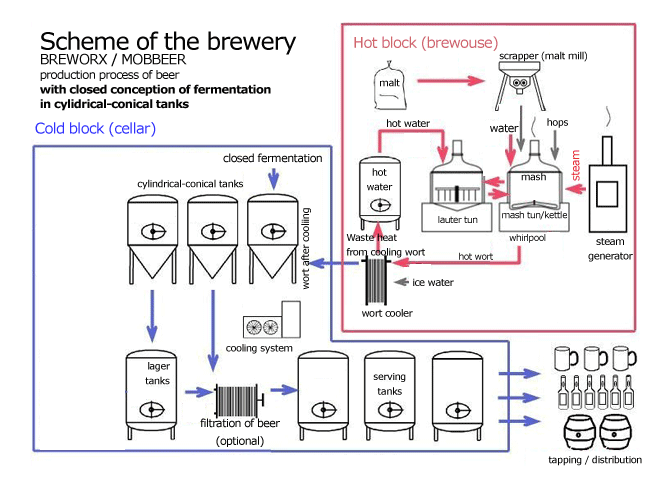

The beer fermentation tank represents the heart of any brewing operation—where wort transforms into beer through the precise biological processes that define your product’s quality, consistency, and profitability.

For brewery operators and procurement managers across the USA and Europe, selecting the right fermentation equipment has never been more complex. Today’s market offers everything from basic stainless steel unitanks to advanced conical fermenters with integrated wireless monitoring and temperature control systems. Each option carries significant implications for:

- Capital expenditure and ROI timelines

- Production capacity and scalability

- Product quality and batch consistency

- Operational efficiency and labor costs

- Regulatory compliance across jurisdictions

The challenge isn’t a lack of options—it’s navigating an oversaturated market where specifications vary widely, supplier claims require verification, and the wrong purchase decision can bottleneck production for years.

What This Guide Covers

This comprehensive B2B guide cuts through marketing noise to deliver actionable intelligence on beer fermentation tank procurement. You’ll find:

| Section | Focus Area |

|———|————|

| Market Overview | Current trends, pricing benchmarks, leading manufacturers |

| Technical Specifications | Capacity ranges, materials, pressure ratings, cooling systems |

| Supplier Evaluation | Qualification criteria, due diligence frameworks |

| Total Cost Analysis | Beyond purchase price—installation, maintenance, lifecycle costs |

| Compliance Requirements | FDA, EU regulations, certification standards |

Illustrative Image (Source: Google Search)

Whether you’re expanding an existing facility or launching a new brewing operation, this guide provides the framework for informed procurement decisions.

Article Navigation

- Top 10 Beer Fermentation Tank Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for beer fermentation tank

- Understanding beer fermentation tank Types and Variations

- Key Industrial Applications of beer fermentation tank

- 3 Common User Pain Points for ‘beer fermentation tank’ & Their Solutions

- Strategic Material Selection Guide for beer fermentation tank

- In-depth Look: Manufacturing Processes and Quality Assurance for beer fermentation tank

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘beer fermentation tank’

- Comprehensive Cost and Pricing Analysis for beer fermentation tank Sourcing

- Alternatives Analysis: Comparing beer fermentation tank With Other Solutions

- Essential Technical Properties and Trade Terminology for beer fermentation tank

- Navigating Market Dynamics and Sourcing Trends in the beer fermentation tank Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of beer fermentation tank

- Strategic Sourcing Conclusion and Outlook for beer fermentation tank

- Important Disclaimer & Terms of Use

Top 10 Beer Fermentation Tank Manufacturers & Suppliers List

1. Commercial Brewery Fermenters & Brite Tanks – GW Kent

Domain: gwkent.com

Registered: 1999 (26 years)

Introduction: 4-day delivery 30-day returnsAs a premier distributor of professional brewing equipment and supplies, GW Kent carries an outstanding selection of stainless brewery fermenters and brite ……

Illustrative Image (Source: Google Search)

2. Fermenting Tanks Manufacturers and Suppliers in the USA and …

Domain: thomasnet.com

Registered: 1996 (29 years)

Introduction: Fermenting Tanks Manufacturers and Suppliers in the USA and Canada · Lee Industries, Inc. · Lee Industries, Inc. · DCI, Inc. · DCI, Inc. · American Alloy Fabricators….

3. Stout Tanks & Kettles | Shop Beverage Making Equipment

Domain: stouttanks.com

Registered: 2013 (12 years)

Introduction: 7–10 day deliveryWe are the leading supplier of brewing equipment to the craft beverage industry. We have quality equipment for making Beer, Seltzer, Cider, Mead, Wine, Kombucha ……

4. Top 7 Beer Fermentation Tanks for Breweries 2025 – CHENMA

Domain: sdchenma.com

Registered: 2023 (2 years)

Introduction: Compare 2025’s best beer fermentation tanks – stainless steel, conical, unitank, wooden & hybrid systems. Essential features, benefits ……

5. Steinecker fermentation and storage tanks

Domain: steinecker.com

Registered: 1996 (29 years)

Introduction: We manufacture our pressure tanks to precisely suit your requirements – and in compliance with all current regulations….

Illustrative Image (Source: Google Search)

6. The 13 Best Manufacturers Specialized in Open Fermentation Tank

Domain: keychain.com

Registered: 1997 (28 years)

Introduction: Top US Manufacturers · 1. Patco brands · 2. Sierra Nevada Brewing Co. · 3. Blackforkfarms · 4. Rumsons · 5. New Belgium Brewing · 6. CH Distillery · 7. The Little ……

7. Fermentation Tank

Domain: carrybrew.com

Registered: 2021 (4 years)

Introduction: FERMENTATION TANK, find quality FERMENTATION TANK products,FERMENTATION TANK Manufacturers, FERMENTATION TANK Suppliers and Exporters at Carry Brewery Equipment…

8. Beer tanks | Stainless Steel Brewery Tanks

Domain: gpi-tanks.com

Registered: 2017 (8 years)

Introduction: Gpi makes beer tanks for the beer industry, ranging from smaller ones with a capacity of 250 litres for catering use to big 5000 hl CCTs for large breweries. We ……

9. Top quality fermenter and beer bright tank

Domain: wemacequipment.com

Registered: 2019 (6 years)

Introduction: Hgh quality beer brewing system,conical cooling jacketed fermentation vessels and beer bright tanks for sale….

Illustrative Image (Source: Google Search)

Understanding beer fermentation tank Types and Variations

Understanding Beer Fermentation Tank Types and Variations

Selecting the appropriate fermentation tank directly impacts production efficiency, beer quality, and operational costs. This section examines the primary tank types available to commercial breweries, outlining their specifications, optimal applications, and trade-offs.

Fermentation Tank Comparison Overview

| Tank Type | Key Features | Best Applications | Pros | Cons |

|---|---|---|---|---|

| Cylindroconical Tanks (CCTs) | Conical bottom (60-70°), integrated cooling jackets, CIP-compatible | Primary fermentation, conditioning, bright beer storage | Easy yeast harvesting, excellent temperature control, space-efficient | Higher capital investment, requires glycol system |

| Open Fermenters | Shallow, rectangular or round vessels; open-top design | Traditional ales, Belgian styles, top-cropping yeast strains | Lower cost, traditional flavor profiles, easy yeast collection | Contamination risk, limited temperature control, labor-intensive |

| Unitanks | Combined fermenter/conditioning vessel, pressure-rated, carbonation capability | Streamlined production, lagers, high-volume operations | Reduced transfers, faster turnaround, natural carbonation | Higher initial cost, less flexibility for specialty styles |

| Horizontal Tanks | Low-profile cylindrical design, large surface area | Facilities with height restrictions, lagering | Space optimization, gentle beer handling | Difficult yeast harvesting, uneven temperature distribution |

| Plastic/PET Fermenters | Lightweight, oxygen-resistant polymers, wide-mouth access | Pilot batches, small-scale operations, R&D | Low cost, easy handling, chemical-resistant | Limited lifespan, not suitable for high-volume production |

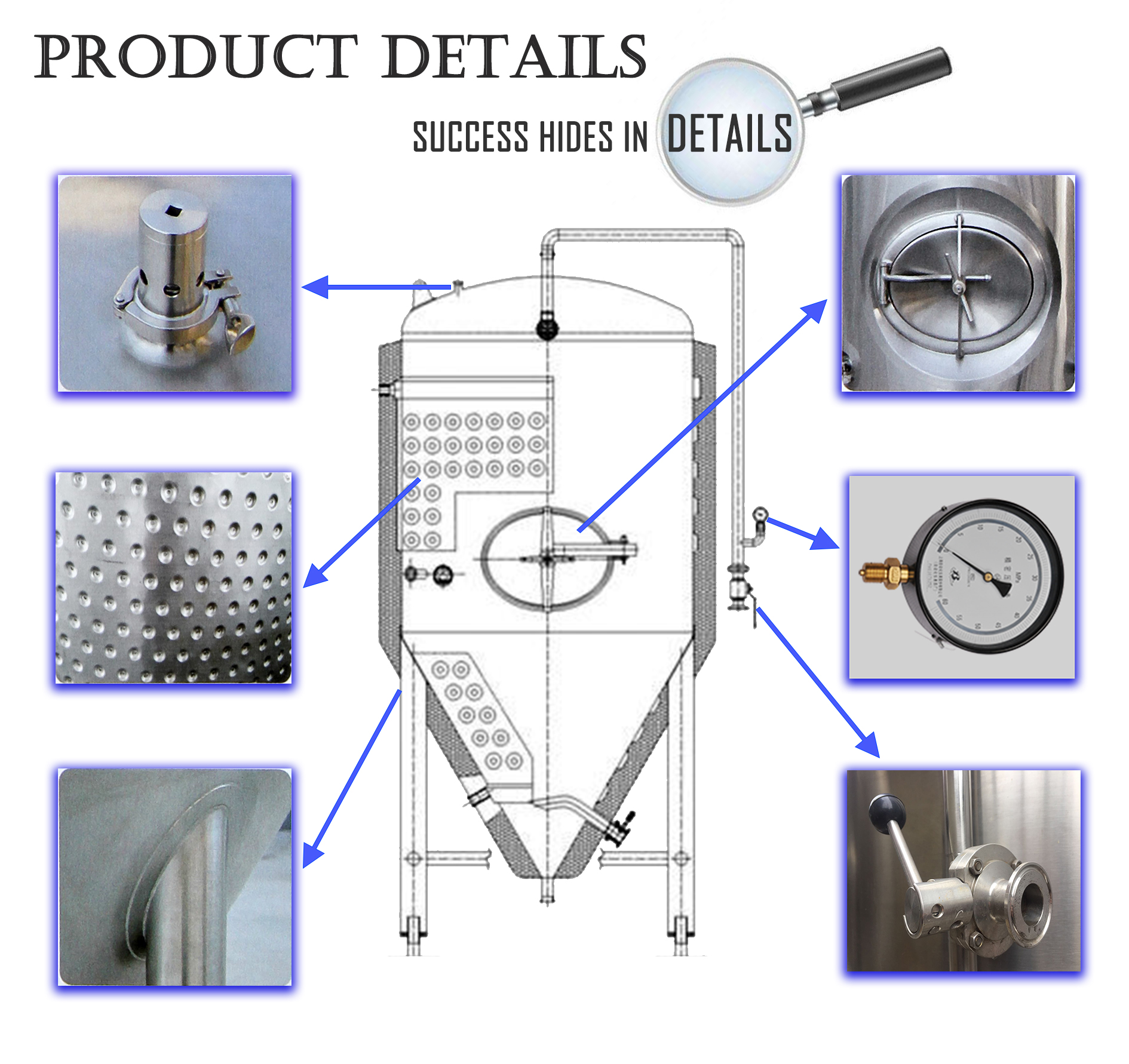

Cylindroconical Tanks (CCTs)

Cylindroconical tanks represent the industry standard for modern commercial brewing operations. The distinctive cone-shaped bottom—typically angled between 60 and 70 degrees—facilitates gravitational yeast settlement and collection through a bottom valve.

Technical Specifications:

– Constructed from 304 or 316L stainless steel

– Integrated glycol cooling jackets (typically 2-3 zones)

– Working pressure: 1-2 bar for standard models; up to 3 bar for unitank configurations

– CIP (Clean-in-Place) spray balls and sanitary fittings standard

Operational Advantages:

CCTs enable precise fermentation temperature management through multi-zone cooling jackets. The conical geometry allows brewers to harvest viable yeast for repitching, reducing raw material costs. Vertical orientation maximizes floor space utilization—a critical consideration for urban breweries.

Illustrative Image (Source: Google Search)

Ideal For: Breweries producing 10+ BBL batches seeking consistent quality and operational efficiency.

Open Fermenters

Open fermentation vessels remain essential for breweries producing traditional British ales, Belgian abbey styles, and other recipes requiring top-cropping yeast strains. These shallow, open-top tanks allow CO₂ to escape freely while providing access for manual yeast skimming.

Technical Specifications:

– Typically stainless steel or copper construction

– Depth: 1-2 meters to maintain appropriate hydrostatic pressure

– Often housed in dedicated temperature-controlled rooms

– Manual or semi-automated skimming systems available

Operational Considerations:

Open fermenters demand stringent environmental controls to prevent contamination. Positive-pressure fermentation rooms with HEPA filtration mitigate airborne contamination risks. Labor requirements exceed closed-system alternatives, but the resulting flavor complexity justifies the investment for specialty producers.

Illustrative Image (Source: Google Search)

Ideal For: Craft breweries emphasizing traditional methods, Belgian-style producers, and operations leveraging house yeast character as a brand differentiator.

Unitanks

Unitanks combine primary fermentation and conditioning functions within a single pressure-rated vessel, eliminating beer transfers between separate tanks. This configuration reduces oxygen exposure, minimizes product loss, and accelerates production cycles.

Technical Specifications:

– Pressure rating: 2-3 bar (29-44 PSI)

– Carbonation stones or spunding valve integration

– Racking arms at multiple heights for clear beer extraction

– Sample ports and sight glasses standard

Operational Advantages:

By fermenting and conditioning in one vessel, breweries reduce CIP cycles, water consumption, and labor hours. Natural carbonation through spunding eliminates or reduces forced carbonation requirements. Unitanks particularly benefit high-volume lager production where extended conditioning periods would otherwise tie up multiple vessels.

Ideal For: Production breweries prioritizing throughput, operations with limited tank inventory, and breweries seeking to reduce dissolved oxygen pickup.

Horizontal Tanks

Horizontal fermentation tanks address height-constrained facilities where vertical CCTs prove impractical. Common in converted industrial spaces, historic buildings, or regions with seismic building codes limiting vertical construction.

Technical Specifications:

– Length-to-diameter ratios typically 2:1 to 4:1

– Rolling or rotating mechanisms available for yeast resuspension

– Cooling jackets positioned along tank length

– Manway access on top or end

Operational Considerations:

The large surface-area-to-volume ratio can accelerate temperature fluctuations, requiring robust cooling infrastructure. Yeast collection proves more challenging than conical designs, often requiring manual intervention or specialized raking systems. However, gentle beer handling during transfers suits delicate styles.

Illustrative Image (Source: Google Search)

Ideal For: Breweries in buildings with ceiling height limitations, lagering operations, and facilities repurposing existing horizontal tank infrastructure.

Plastic and PET Fermenters

While not typical for full-scale production, food-grade plastic and PET (polyethylene terephthalate) fermenters serve legitimate commercial functions in pilot brewing, recipe development, and small-batch specialty production.

Technical Specifications:

– Oxygen barrier properties vary by material grade

– Capacities typically range from 3-30 gallons (11-114 liters)

– Wide-mouth designs facilitate cleaning and dry-hopping

– Some models feature integrated spigots for siphon-free transfers

Operational Considerations:

PET carboys offer oxygen resistance superior to standard HDPE buckets, making them suitable for extended aging trials. Their low cost enables parallel fermentation experiments without significant capital allocation. However, scratching compromises sanitation, limiting service life to 2-3 years under commercial use.

Illustrative Image (Source: Google Search)

Ideal For: Brewery R&D departments, taproom-exclusive small batches, and startup operations validating recipes before equipment investment.

Selection Criteria for Commercial Operations

When evaluating fermentation tank investments, consider these factors:

- Production Volume: Match tank capacity to batch size with 20-25% headspace allowance for kräusen

- Beer Portfolio: Diverse style offerings may require multiple tank types

- Facility Constraints: Ceiling height, floor load capacity, and utility access

- Budget Parameters: Balance capital expenditure against operational efficiency gains

- Growth Trajectory: Modular systems accommodate expansion; oversized initial investments strain cash flow

Engaging equipment suppliers early in facility planning ensures optimal tank selection aligned with production goals and physical constraints.

Key Industrial Applications of beer fermentation tank

Key Industrial Applications of Beer Fermentation Tanks

Beer fermentation tanks serve as the backbone of commercial brewing operations, but their applications extend well beyond traditional breweries. These specialized vessels deliver precise temperature control, sanitary processing environments, and scalable production capabilities across multiple industries.

Illustrative Image (Source: Google Search)

Primary Industry Applications

| Industry | Application | Tank Configuration | Typical Capacity Range |

|---|---|---|---|

| Craft Brewing | Primary/secondary fermentation, conditioning | Conical, unitank, cylindroconical | 1-100 BBL |

| Large-Scale Brewing | High-volume production, continuous fermentation | Cylindroconical, horizontal tanks | 100-1,000+ BBL |

| Beverage Manufacturing | Hard seltzer, kombucha, cider production | Stainless steel conical, jacketed vessels | 5-500 BBL |

| Pharmaceutical/Biotech | Yeast propagation, enzyme production | Specialized conical fermenters | Variable |

| Food Processing | Vinegar production, fermented foods | Modified fermentation vessels | 10-200 BBL |

| Research & Development | Pilot batches, strain development | Small-scale conical fermenters | 1-10 BBL |

Detailed Benefits by Application

Craft Brewing Operations

- Yeast harvesting efficiency: Conical bottom designs enable 95%+ yeast recovery rates, reducing ingredient costs by 15-20% annually

- Batch consistency: Glycol-jacketed temperature control maintains ±0.5°F accuracy throughout fermentation cycles

- Space optimization: Vertical cylindroconical configurations maximize floor space utilization in compact facilities

- Reduced oxidation: Sealed systems with pressure-rated construction minimize oxygen exposure during transfers

Large-Scale Commercial Brewing

- Production throughput: Unitank configurations combine fermentation and conditioning, reducing cycle times by 25-30%

- CIP compatibility: Integrated Clean-in-Place systems decrease sanitation labor by 40% while ensuring consistent hygiene standards

- Process automation: PLC-ready designs integrate with SCADA systems for real-time monitoring and data logging

- Energy efficiency: Advanced insulation and glycol management systems reduce cooling costs by 20-35%

Alternative Beverage Production

Hard seltzer, kombucha, and craft cider manufacturers increasingly adopt beer fermentation tank technology for:

- Pressure fermentation: Rated vessels (15-30 PSI) enable carbonation during fermentation, eliminating secondary carbonation steps

- Material compatibility: 304/316 stainless steel construction handles acidic fermentations without corrosion

- Flexible batch sizing: Modular tank farms accommodate seasonal demand fluctuations without capital overinvestment

Pharmaceutical and Biotechnology

Fermentation tanks adapted from brewing applications support:

- Yeast propagation: Controlled aerobic environments for starter culture development

- Enzyme production: Temperature-precise fermentation for industrial enzyme manufacturing

- Biofuel research: Ethanol fermentation trials utilizing brewing-derived vessel designs

Selection Criteria for Industrial Buyers

| Factor | Consideration | Impact on Operations |

|---|---|---|

| Material Grade | 304 vs. 316L stainless steel | Corrosion resistance, product purity, regulatory compliance |

| Pressure Rating | Atmospheric vs. pressure-rated | Carbonation options, transfer capabilities |

| Cooling System | Glycol jacket zones | Temperature control precision, energy consumption |

| Bottom Geometry | 60° vs. 70° cone angle | Yeast harvesting efficiency, sediment removal |

| Port Configuration | Sample, CIP, racking, carbonation | Process flexibility, maintenance accessibility |

| Certification | ASME, PED, 3-A Sanitary | Regulatory compliance, insurance requirements |

ROI Considerations

Industrial fermentation tank investments typically demonstrate:

- Payback period: 18-36 months for mid-scale operations

- Labor reduction: 30-50% decrease in manual handling through automated systems

- Product loss reduction: 5-10% improvement in yield through optimized vessel design

- Quality improvements: Measurable consistency gains supporting premium pricing strategies

Procurement teams should evaluate total cost of ownership, including installation, utilities infrastructure, maintenance schedules, and eventual capacity expansion requirements when specifying fermentation equipment for industrial applications.

Illustrative Image (Source: Google Search)

3 Common User Pain Points for ‘beer fermentation tank’ & Their Solutions

3 Common User Pain Points for Beer Fermentation Tanks & Their Solutions

Pain Point 1: Temperature Control Inconsistency

Scenario: A mid-sized craft brewery experiences batch-to-batch variation in their flagship IPA. Despite following identical recipes, fermentation temperatures fluctuate 3-5°F throughout the process, resulting in inconsistent flavor profiles and occasional off-flavors.

Problem: Standard fermentation tanks without integrated temperature management rely on ambient room conditions or external cooling jackets that respond slowly to temperature changes. Yeast activity generates heat during active fermentation, creating thermal spikes that can stress yeast and produce unwanted esters or fusel alcohols.

Solution: Invest in conical fermenters with built-in glycol jacket connections or integrated cooling systems. Modern options like the Grainfather Conical Fermenter Pro offer wireless temperature monitoring and precise control. For existing tanks, retrofit with:

| Solution Type | Investment Level | Temperature Accuracy |

|---|---|---|

| Glycol jacket system | High | ±0.5°F |

| Fermentation chamber | Medium | ±1°F |

| Temperature controller + cooling wrap | Low | ±2°F |

Pain Point 2: Difficult Cleaning and Sanitation Access

Scenario: A brewpub’s production team spends excessive labor hours cleaning narrow-mouth glass carboys and traditional fermenters. Despite thorough cleaning protocols, they experience sporadic contamination issues that ruin entire batches.

Illustrative Image (Source: Google Search)

Problem: Narrow openings and internal geometries with hard-to-reach corners harbor bacteria and wild yeast. Traditional carboys require specialized brushes and still leave potential contamination zones. This increases labor costs and contamination risk.

Solution: Transition to wide-mouth fermenters or conical designs with removable lids and sanitary tri-clamp fittings. Stainless steel conical fermenters (like the Reactor series) feature:

- Wide top openings for visual inspection and manual cleaning

- Smooth internal welds with no crevices

- CIP (Clean-in-Place) compatible ports

- Bottom dump valves for trub removal without opening the vessel

Pain Point 3: Inefficient Yeast Harvesting and Trub Separation

Scenario: A growing brewery wants to reduce costs by repitching yeast across multiple generations. Their flat-bottom fermenters make yeast collection messy and contamination-prone, forcing them to purchase fresh yeast for each batch.

Problem: Flat-bottom and bucket-style fermenters mix settled yeast with trub (hop debris, proteins, dead cells). Harvesting requires racking off beer first, then manually scooping yeast—introducing oxygen and contamination risks while yielding inconsistent yeast quality.

Illustrative Image (Source: Google Search)

Solution: Upgrade to true conical fermenters with bottom dump valves. The conical geometry naturally separates:

- Trub layer (bottom) — dump first and discard

- Healthy yeast layer (middle) — collect for repitching

- Clear beer (top) — transfer via side racking arm

This closed-system approach maintains sanitation, reduces oxygen exposure, and enables 5-10 yeast generations—delivering significant cost savings on yeast purchases while improving fermentation consistency.

Strategic Material Selection Guide for beer fermentation tank

Strategic Material Selection Guide for Beer Fermentation Tanks

Selecting the appropriate material for beer fermentation tanks directly impacts product quality, operational efficiency, total cost of ownership, and regulatory compliance. This guide provides a systematic analysis of available materials to support informed procurement decisions.

Material Analysis

Stainless Steel (304 and 316L Grades)

Stainless steel remains the industry standard for commercial beer fermentation, with 304 and 316L grades dominating the market.

Illustrative Image (Source: Google Search)

304 Stainless Steel

– Contains 18% chromium and 8% nickel

– Excellent corrosion resistance for standard brewing applications

– Suitable for most fermentation environments where chloride exposure is minimal

– Lower cost compared to 316L

– Widely available with established supply chains

316L Stainless Steel

– Contains molybdenum (2-3%) for enhanced pitting resistance

– Superior performance in high-chloride environments and aggressive cleaning protocols

– Required for facilities using chlorinated sanitizers or located in coastal regions

– Higher initial investment with extended service life

– Preferred for pharmaceutical-grade brewing operations

Key Considerations:

– Surface finish (Ra value) affects cleanability and biofilm formation

– Electropolished surfaces (Ra ≤ 0.5 μm) recommended for premium applications

– Weld quality critical—full penetration welds with proper passivation required

– Both grades meet FDA, EU 1935/2004, and 3-A Sanitary Standards

PET (Polyethylene Terephthalate) Plastic

PET carboys and fermenters serve specific applications in smaller-scale and pilot operations.

Illustrative Image (Source: Google Search)

Advantages:

– Lightweight construction reduces handling injuries and shipping costs

– Shatter-resistant compared to glass alternatives

– Lower capital expenditure for startup operations

– Transparent walls enable visual fermentation monitoring

Limitations:

– Oxygen permeability limits aging applications beyond 2-3 months

– Temperature ceiling of approximately 60°C (140°F) restricts hot-side use

– Scratch susceptibility creates sanitation challenges over time

– Not suitable for pressurized fermentation above 2 PSI

– Limited scalability for production volumes exceeding 20 gallons

Application Fit:

Best suited for R&D facilities, pilot batches, and small-batch specialty production where frequent recipe iteration outweighs long-term durability requirements.

Food-Grade HDPE (High-Density Polyethylene)

HDPE fermentation buckets remain prevalent in entry-level commercial and brewpub applications.

Illustrative Image (Source: Google Search)

Advantages:

– Lowest acquisition cost per gallon of capacity

– Impact-resistant and virtually unbreakable

– Lightweight for manual handling

– Easy modification for spigots and sampling ports

Limitations:

– Porous surface develops micro-scratches harboring bacteria

– Recommended replacement cycle of 12-24 months in commercial use

– Limited chemical resistance to certain caustic cleaners

– Not recommended for extended conditioning or lagering

– Oxygen barrier properties inferior to stainless steel and glass

Glass Carboys

Traditional glass fermenters maintain niche applications despite handling challenges.

Advantages:

– Zero oxygen permeability—ideal for extended aging

– Chemically inert with no flavor transfer

– Indefinite service life with proper care

– Complete visibility for fermentation monitoring

Illustrative Image (Source: Google Search)

Limitations:

– Breakage risk creates significant safety liability

– Weight (40+ lbs when full for 6-gallon units) increases handling injuries

– Thermal shock sensitivity requires careful temperature management

– Narrow neck designs complicate cleaning and dry-hopping

– Not viable for pressurized applications

Conical Fermenter Configurations

Regardless of material, conical geometry provides operational advantages:

- Yeast harvesting from cone bottom without beer transfer

- Trub separation improves beer clarity

- Reduced oxidation during yeast removal

- Compatible with CIP (Clean-in-Place) systems

- Enables single-vessel fermentation and conditioning

Premium stainless conical units increasingly incorporate:

– Integrated temperature control jackets

– Pressure-rated designs (15-30 PSI) for spunding

– Sanitary tri-clamp fittings throughout

– Rotating racking arms

– Digital monitoring connectivity

Regulatory and Compliance Factors

United States:

– FDA 21 CFR compliance for food-contact materials

– 3-A Sanitary Standards certification for dairy-equivalent cleanliness

– State-specific requirements vary—verify local health department standards

Illustrative Image (Source: Google Search)

European Union:

– EU Regulation 1935/2004 (Framework Regulation)

– EU 10/2011 for plastic materials

– EHEDG (European Hygienic Engineering & Design Group) guidelines

– CE marking requirements for pressurized vessels

Total Cost of Ownership Considerations

Material selection extends beyond purchase price:

- Cleaning chemical compatibility affects operational costs

- Replacement frequency for plastic materials adds cumulative expense

- Energy efficiency of jacketed stainless vessels reduces utility costs

- Resale value favors stainless steel equipment

- Insurance premiums may vary based on material-related risks

Material Comparison Table

| Attribute | 304 Stainless Steel | 316L Stainless Steel | PET Plastic | HDPE Plastic | Glass |

|---|---|---|---|---|---|

| Initial Cost | High | Very High | Low | Very Low | Low-Moderate |

| Service Life | 20+ years | 25+ years | 2-5 years | 1-2 years | Indefinite (if unbroken) |

| Oxygen Barrier | Excellent | Excellent | Moderate | Poor | Excellent |

| Pressure Rating | Up to 30+ PSI | Up to 30+ PSI | <2 PSI | Not rated | Not rated |

| Max Temperature | 150°C+ | 150°C+ | 60°C | 80°C | Limited by thermal shock |

| Weight (empty) | Heavy | Heavy | Light | Light | Heavy |

| CIP Compatible | Yes | Yes | Limited | No | No |

| Chloride Resistance | Moderate | Excellent | Good | Good | Excellent |

| Scratch Resistance | Excellent | Excellent | Poor | Poor | Excellent |

| Scalability | Unlimited | Unlimited | <20 gal practical | <15 gal practical | <15 gal practical |

| FDA/EU Compliant | Yes | Yes | Yes | Yes | Yes |

| Recommended Use | Production | Production/High-spec | Pilot/R&D | Entry-level | Specialty aging |

Selection Recommendations by Operation Type

Large-Scale Production Breweries (>10,000 bbl/year):

316L stainless steel conical fermenters with glycol jackets and full CIP integration

Mid-Size Craft Breweries (1,000-10,000 bbl/year):

304 stainless steel conical fermenters; 316L for high-chloride environments

Illustrative Image (Source: Google Search)

Brewpubs and Taprooms (<1,000 bbl/year):

304 stainless steel unitanks or conicals; HDPE acceptable for limited specialty batches

R&D and Pilot Facilities:

PET or small stainless conicals for flexibility and rapid iteration

Contract Brewing Considerations:

Specify material requirements in contracts—316L preferred for quality-sensitive brands

In-depth Look: Manufacturing Processes and Quality Assurance for beer fermentation tank

In-depth Look: Manufacturing Processes and Quality Assurance for Beer Fermentation Tanks

Understanding how beer fermentation tanks are manufactured is essential for B2B buyers evaluating suppliers. The production quality directly impacts tank longevity, sanitation capabilities, and ultimately, your brewing operations. This section examines the critical manufacturing stages and quality standards that distinguish professional-grade equipment.

Manufacturing Process Overview

1. Material Preparation

The manufacturing process begins with raw material selection and preparation:

| Material | Application | Key Specifications |

|---|---|---|

| 304 Stainless Steel | Standard fermentation tanks | 18% chromium, 8% nickel; suitable for most brewing applications |

| 316L Stainless Steel | Premium/corrosive environments | Added molybdenum for superior corrosion resistance; lower carbon content |

| PET Plastic | Entry-level/small-batch fermenters | Food-grade, oxygen-resistant polymers |

Preparation steps include:

– Material certification verification (mill test reports)

– Surface inspection for defects

– Cutting and sizing using CNC plasma or laser cutting

– Edge preparation for welding

2. Forming and Fabrication

Tank components undergo precision forming processes:

Shell Formation

– Sheet rolling using hydraulic plate rollers

– Conical bottom forming via hydraulic pressing or spinning

– Dished head fabrication for top closures

Critical Tolerances

– Wall thickness consistency: ±0.1mm

– Roundness deviation: <1% of diameter

– Cone angle precision: ±0.5°

3. Welding and Assembly

Professional fermentation tanks require certified welding procedures:

- TIG (GTAW) welding for all product-contact seams

- Orbital welding for consistent, repeatable pipe connections

- Full penetration welds on structural joints

- Purge welding with argon to prevent oxidation

Assembly sequence:

1. Shell-to-cone joint welding

2. Jacket attachment (for glycol-cooled units)

3. Port and fitting installation

4. Leg/support structure mounting

5. Accessory integration (sample valves, CIP arms, temperature probes)

4. Surface Finishing

Interior surface quality directly affects cleaning efficiency and product quality:

| Finish Type | Ra Value | Application |

|---|---|---|

| Mill Finish | 3.2–6.3 µm | Non-contact surfaces |

| Mechanical Polish | 0.8–1.6 µm | Standard product contact |

| Electropolish | 0.4–0.8 µm | Premium sanitary applications |

Quality Control and Assurance

Testing Protocols

Pressure Testing

– Hydrostatic testing at 1.5× operating pressure

– Pneumatic leak testing for jacketed vessels

– Documentation of test parameters and results

Weld Inspection

– Visual inspection per AWS D18.1/D18.2

– Dye penetrant testing for surface cracks

– Radiographic testing for critical welds (when specified)

Dimensional Verification

– CMM (Coordinate Measuring Machine) inspection

– Capacity verification

– Port location and alignment checks

Applicable Quality Standards

| Standard | Scope | Relevance |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Ensures consistent manufacturing processes |

| ISO 22000 | Food Safety Management | Critical for beverage equipment |

| ASME BPE | Bioprocessing Equipment | Defines sanitary design and surface finish requirements |

| 3-A Sanitary Standards | Dairy/Food Equipment | Widely accepted in North American brewing |

| PED 2014/68/EU | Pressure Equipment Directive | Required for pressurized vessels sold in Europe |

Documentation Requirements

Reputable manufacturers provide:

– Material certificates (EN 10204 3.1 or equivalent)

– Weld procedure specifications (WPS)

– Welder qualification records

– Pressure test certificates

– Surface finish verification reports

– CE marking documentation (for EU markets)

Supplier Evaluation Checklist

When assessing fermentation tank manufacturers, verify:

- [ ] ISO 9001 certification (current and audited)

- [ ] Documented welding procedures and certified welders

- [ ] In-house quality testing capabilities

- [ ] Traceability systems for materials and components

- [ ] Reference installations in commercial brewing operations

- [ ] Compliance with regional pressure vessel regulations

Practical Sourcing Guide: A Step-by-Step Checklist for ‘beer fermentation tank’

Practical Sourcing Guide: A Step-by-Step Checklist for Beer Fermentation Tanks

This checklist provides B2B buyers with a systematic approach to sourcing beer fermentation tanks, from initial assessment through final procurement.

Phase 1: Requirements Definition

| Step | Action Item | Key Considerations |

|---|---|---|

| 1.1 | Define batch size requirements | Current production volume + 3-5 year growth projections |

| 1.2 | Determine tank quantity needed | Primary vs. secondary fermentation; simultaneous batch capacity |

| 1.3 | Specify material requirements | 304 vs. 316 stainless steel; food-grade certification |

| 1.4 | Identify feature requirements | Conical bottom, glycol jacket, pressure rating, CIP compatibility |

| 1.5 | Establish budget parameters | Equipment cost, installation, accessories, maintenance |

Phase 2: Supplier Identification

- [ ] Research domestic manufacturers (USA/EU compliance advantages)

- [ ] Identify international suppliers with export experience

- [ ] Request referrals from industry associations (Brewers Association, SIBA)

- [ ] Review trade publication supplier directories

- [ ] Verify supplier certifications (ISO 9001, PED for EU, ASME for USA)

Phase 3: Technical Evaluation

Essential Specifications to Verify:

- [ ] Working volume vs. total volume ratio

- [ ] Pressure rating (PSI/bar)

- [ ] Surface finish (Ra value for interior)

- [ ] Weld quality and documentation

- [ ] Glycol jacket coverage percentage

- [ ] Port configurations and tri-clamp sizing

- [ ] Temperature probe and PRV provisions

Phase 4: Supplier Qualification

| Evaluation Criteria | Documentation Required |

|---|---|

| Manufacturing capability | Facility certifications, production capacity |

| Quality assurance | QC procedures, material traceability |

| Regulatory compliance | CE marking (EU), NSF certification (USA) |

| Financial stability | Business references, years in operation |

| After-sales support | Warranty terms, spare parts availability |

Phase 5: RFQ Process

- [ ] Prepare detailed technical specifications document

- [ ] Request quotes from minimum 3-5 qualified suppliers

- [ ] Specify delivery terms (FOB, CIF, DDP)

- [ ] Include installation and commissioning requirements

- [ ] Request lead times and production schedules

- [ ] Clarify payment terms and milestone structure

Phase 6: Sample/Reference Validation

- [ ] Request customer references (similar scale operations)

- [ ] Arrange facility visits or virtual tours where possible

- [ ] Review sample welds or request test coupons

- [ ] Verify actual vs. claimed specifications on existing installations

Phase 7: Contract Finalization

Key Contract Elements:

- [ ] Detailed technical specifications as exhibit

- [ ] Quality acceptance criteria and inspection rights

- [ ] Delivery schedule with penalties for delays

- [ ] Warranty terms (minimum 2-year structural recommended)

- [ ] Spare parts pricing locked for defined period

- [ ] Installation support and training provisions

Phase 8: Pre-Shipment & Delivery

- [ ] Schedule factory acceptance testing (FAT)

- [ ] Verify documentation package (material certs, pressure test reports, manuals)

- [ ] Confirm shipping dimensions and site access compatibility

- [ ] Arrange rigging and installation contractors

- [ ] Coordinate utility connections (glycol, CO2, drainage)

Quick Reference: Red Flags to Avoid

| Warning Sign | Risk |

|---|---|

| No material traceability documentation | Substandard materials |

| Unusually low pricing vs. market | Quality compromises |

| Vague warranty terms | Limited recourse for defects |

| No reference customers available | Unproven capability |

| Resistance to third-party inspection | Quality concerns |

Document version for internal procurement use. Adapt checklist items based on specific operational requirements and regulatory jurisdiction.

Comprehensive Cost and Pricing Analysis for beer fermentation tank Sourcing

Comprehensive Cost and Pricing Analysis for Beer Fermentation Tank Sourcing

Understanding the full cost structure of beer fermentation tank procurement is essential for making informed purchasing decisions. This analysis breaks down the key cost components and provides actionable strategies to optimize your investment.

Cost Breakdown by Tank Type

| Tank Type | Price Range (USD) | Best For | Key Cost Drivers |

|---|---|---|---|

| PET Plastic Carboys (5-6 gal) | $35 – $45 | Small-batch, secondary fermentation | Material grade, oxygen resistance |

| Fermentation Buckets | $15 – $50 | Entry-level, primary fermentation | Food-grade certification, accessories |

| Basic Conical Fermenters | $300 – $700 | Serious homebrewers, nano-breweries | Stainless steel grade, weld quality |

| Pro-Grade Conical Fermenters | $700 – $1,500+ | Commercial pilot batches, advanced control | Integrated tech, wireless connectivity |

| Commercial Fermenters (7-30 BBL) | $5,000 – $50,000+ | Craft breweries, production facilities | Capacity, cooling systems, automation |

Materials Cost Analysis

Stainless Steel (304 vs. 316L)

– 304 SS: Standard for most applications; lower cost

– 316L SS: Required for high-chloride environments; 15-25% premium

– Thickness: 2mm-4mm walls significantly impact durability and price

Plastic/PET Options

– Food-grade PET: Cost-effective for smaller operations

– BPA-free certification adds 5-10% to baseline cost

– UV resistance and oxygen barrier properties affect longevity

Labor and Manufacturing Costs

| Cost Component | Percentage of Total | Notes |

|---|---|---|

| Raw Materials | 40-55% | Steel prices fluctuate with global markets |

| Fabrication/Welding | 20-30% | Sanitary welds command premium pricing |

| Quality Control | 5-10% | Pressure testing, certification |

| Finishing | 5-10% | Electropolishing, passivation |

| Assembly | 5-10% | Fittings, valves, instrumentation |

Logistics and Shipping Considerations

Domestic Sourcing (USA/Europe)

– Lead times: 2-6 weeks

– Shipping: $200-$2,000 depending on size and distance

– Advantages: Faster delivery, easier warranty claims, no import duties

International Sourcing (Asia)

– Lead times: 8-16 weeks (including ocean freight)

– Shipping: $1,500-$8,000+ per container

– Import duties: 0-6.5% (USA), variable in EU

– Hidden costs: Customs brokerage, port fees, inland transport

Total Cost of Ownership (TCO) Factors

Beyond purchase price, factor these ongoing costs:

- Installation: $500-$5,000 for commercial units

- Glycol/Cooling Systems: $2,000-$15,000 additional investment

- Maintenance: 2-5% of purchase price annually

- Replacement Parts: Gaskets, valves, sensors

- Energy Consumption: Temperature control systems

Cost-Saving Strategies

1. Volume Purchasing

– Negotiate 10-20% discounts on orders of 3+ units

– Coordinate purchases with other breweries for bulk pricing

2. Strategic Timing

– Order during off-peak seasons (Q1, early Q2)

– Monitor steel commodity prices for optimal purchasing windows

3. Specification Optimization

– Avoid over-engineering; match specs to actual requirements

– Standard port sizes and fittings reduce customization costs

4. Supplier Negotiation Tactics

– Request itemized quotes to identify markup areas

– Leverage competing quotes for price matching

– Negotiate extended payment terms (Net 60/90)

5. Consider Refurbished Equipment

– Certified pre-owned tanks: 40-60% savings

– Verify sanitary condition and pressure certifications

6. Regional Sourcing

– EU buyers: Source within EU to avoid import VAT complications

– USA buyers: Domestic suppliers often competitive when factoring total landed cost

Red Flags in Pricing

- Quotes significantly below market rate (quality concerns)

- Vague material specifications

- No pressure testing certification included

- Shipping costs quoted separately without detail

- No warranty or limited warranty terms

Recommended Budget Allocation

For a comprehensive fermentation setup, allocate your budget as follows:

| Component | Budget Percentage |

|---|---|

| Fermentation Tanks | 60-70% |

| Temperature Control | 15-20% |

| Fittings/Accessories | 5-10% |

| Installation/Contingency | 10-15% |

Alternatives Analysis: Comparing beer fermentation tank With Other Solutions

Alternatives Analysis: Comparing Beer Fermentation Tanks With Other Solutions

Selecting the right fermentation vessel directly impacts production efficiency, product quality, and long-term operational costs. This analysis compares dedicated beer fermentation tanks against two common alternatives: open-top fermentation vessels and multi-purpose food-grade containers.

Comparison Overview

| Factor | Dedicated Beer Fermentation Tanks | Open-Top Fermentation Vessels | Multi-Purpose Food-Grade Containers |

|---|---|---|---|

| Initial Investment | $300–$10,000+ (scale-dependent) | $150–$2,000 | $50–$500 |

| Contamination Control | Excellent (sealed systems with airlocks) | Poor to Moderate (requires constant monitoring) | Moderate (not optimized for fermentation) |

| Temperature Management | Built-in or compatible with glycol systems | Requires external solutions | Limited options |

| Yeast Harvesting | Conical designs enable efficient collection | Manual removal required | Not designed for harvesting |

| Oxygen Exposure | Minimal (PET, stainless steel options) | High risk during active fermentation | Variable by material |

| Scalability | High (1-gallon to commercial volumes) | Limited | Limited |

| Cleaning/Sanitation | CIP-compatible designs available | Labor-intensive | Standard cleaning only |

| Lifespan | 10–20+ years (stainless steel) | 3–7 years | 2–5 years |

Detailed Analysis

Dedicated Beer Fermentation Tanks

Purpose-built fermentation tanks—whether PET carboys, stainless steel conicals, or advanced systems like the Grainfather Conical Fermenter Pro—offer integrated features that streamline operations. Conical bottoms facilitate yeast harvesting and sediment removal without transferring beer. Stainless steel construction ensures durability, chemical resistance, and consistent sanitation. Higher-end models include wireless monitoring, pressure-rated designs, and glycol jacket compatibility for precise temperature control.

Open-Top Fermentation Vessels

Traditional open fermenters remain common in specific brewing styles (Belgian lambics, British cask ales) where wild yeast exposure is desirable. However, for standard production, they present significant contamination risks, require dedicated climate-controlled spaces, and demand intensive manual oversight. Labor costs and batch inconsistency often offset lower equipment prices.

Multi-Purpose Food-Grade Containers

Standard food-grade buckets and containers offer the lowest entry cost but lack fermentation-specific features. Absence of proper airlock systems, suboptimal geometry for yeast management, and material limitations (oxygen permeability, chemical compatibility) compromise batch quality and consistency. These solutions may suit experimental or ultra-small-scale operations but create bottlenecks when scaling production.

Recommendation

For B2B operations prioritizing batch consistency, operational efficiency, and scalability, dedicated beer fermentation tanks deliver superior total cost of ownership despite higher upfront investment. Stainless steel conical fermenters provide the optimal balance of durability, functionality, and long-term value for growing craft breweries and contract brewing operations.

Essential Technical Properties and Trade Terminology for beer fermentation tank

Essential Technical Properties and Trade Terminology for Beer Fermentation Tanks

Understanding the technical specifications and industry terminology is critical when sourcing beer fermentation tanks for commercial operations. This section covers the key properties that influence purchasing decisions and the standard trade terms used in B2B transactions.

Critical Technical Properties

Material Specifications

| Material | Grade | Applications | Key Considerations |

|---|---|---|---|

| Stainless Steel | 304 SS | Standard fermentation | Cost-effective, adequate corrosion resistance |

| Stainless Steel | 316L SS | High-chloride environments, acidic washes | Superior corrosion resistance, higher cost |

| PET Plastic | Food-grade | Small-batch, pilot systems | Lightweight, oxygen-resistant, limited lifespan |

Dimensional and Capacity Parameters

- Working Volume vs. Total Volume: Working volume typically represents 75-80% of total tank capacity to accommodate krausen formation

- Height-to-Diameter Ratio: Standard cylindroconical tanks maintain 2:1 to 4:1 ratios; higher ratios increase hydrostatic pressure and CO₂ retention

- Cone Angle: 60° to 70° standard; steeper angles facilitate yeast harvesting and sediment removal

Pressure and Temperature Ratings

| Parameter | Typical Range | Critical Notes |

|---|---|---|

| Working Pressure | 1.0-2.0 bar (14.5-29 psi) | Must accommodate carbonation requirements |

| Design Pressure | 2.5-3.0 bar | Safety margin above working pressure |

| Temperature Range | -5°C to 25°C (23°F to 77°F) | Glycol jacket compatibility required |

| Surface Finish (Ra) | 0.4-0.8 µm | Interior polish affects CIP effectiveness |

Jacketing and Cooling Systems

- Glycol Jacket Coverage: Minimum 30% surface coverage for adequate temperature control

- Jacket Design Types: Dimple plate, half-pipe, or laser-welded pillow plate

- Heat Transfer Coefficient: Target 500-800 W/m²K for efficient cooling

- Glycol Inlet/Outlet Size: Standard DN25-DN50 depending on tank volume

Port and Fitting Configurations

Standard port requirements for commercial fermentation tanks:

- Sample Valve: Typically DN15, positioned above cone

- Racking Arm: Adjustable or fixed, DN25-DN50

- CIP Spray Ball Port: Top-mounted, DN40-DN50

- Pressure Relief Valve (PRV): Sized to tank pressure rating

- Thermowell: For temperature probe insertion

- Carbonation Stone Port: Bottom-mounted for forced carbonation

- Manway: 400mm-500mm diameter for access and dry-hopping

Standard Trade Terminology

Order and Pricing Terms

| Term | Definition | Typical Application |

|---|---|---|

| MOQ | Minimum Order Quantity | Often 1-5 units for standard sizes; higher for custom fabrication |

| OEM | Original Equipment Manufacturer | Custom branding, private-label tank production |

| ODM | Original Design Manufacturer | Supplier designs to buyer specifications |

| FOB | Free On Board | Price includes delivery to port of origin; buyer assumes shipping |

| CIF | Cost, Insurance, Freight | Price includes shipping and insurance to destination port |

| EXW | Ex Works | Buyer responsible for all transport from factory |

Lead Time Considerations

- Stock Units: 2-4 weeks typical

- Standard Custom: 8-12 weeks

- Fully Engineered Custom: 16-24 weeks

- Installation and Commissioning: Additional 1-2 weeks on-site

Quality and Compliance Certifications

Essential certifications for USA and European markets:

| Certification | Region | Purpose |

|---|---|---|

| ASME | USA | Pressure vessel code compliance |

| PED (2014/68/EU) | Europe | Pressure Equipment Directive |

| CE Marking | Europe | Conformity with EU safety standards |

| 3-A Sanitary Standards | USA | Dairy and food equipment hygiene |

| FDA Compliance | USA | Food-contact material safety |

| ISO 9001 | Global | Quality management system |

Warranty and Service Terms

- Standard Warranty: 1-2 years on fabrication defects

- Extended Warranty: Available for 3-5 years at additional cost

- Spare Parts Availability: Confirm 10+ year parts support

- Service Level Agreement (SLA): Response time guarantees for technical support

Specification Checklist for RFQ Preparation

When preparing a Request for Quotation, include:

- Batch size and annual production volume

- Working pressure and temperature requirements

- Material grade preference (304 vs. 316L)

- Glycol system specifications (temperature, flow rate)

- Required ports and fittings with sizes

- Surface finish requirements (interior/exterior)

- Certification requirements for your jurisdiction

- Delivery terms preference (FOB, CIF, DDP)

- Installation support requirements

- Spare parts and documentation needs

Navigating Market Dynamics and Sourcing Trends in the beer fermentation tank Sector

Navigating Market Dynamics and Sourcing Trends in the Beer Fermentation Tank Sector

Market Overview and Growth Trajectory

The global beer fermentation tank market continues to expand, driven by craft brewery proliferation, automation demands, and evolving consumer preferences. For B2B buyers in the USA and Europe, understanding current dynamics is essential for strategic procurement decisions.

Key Market Drivers:

– Craft beer segment growth requiring flexible, smaller-batch fermentation solutions

– Increasing demand for stainless steel conical fermenters across production scales

– Integration of smart monitoring and wireless connectivity in fermentation equipment

– Rising emphasis on equipment that supports quality consistency and process control

Current Sourcing Trends

| Trend | Implication for Buyers |

|---|---|

| Premiumization of Equipment | Shift toward feature-rich conical fermenters with built-in temperature control and wireless monitoring capabilities |

| Scalable Solutions | Demand for modular systems that accommodate production expansion without full equipment replacement |

| Material Innovation | PET plastic carboys gaining traction for secondary fermentation; stainless steel remains standard for primary commercial operations |

| Automation Integration | Pro-edition fermenters with digital connectivity becoming industry standard for mid-size operations |

Sustainability Considerations

European and North American buyers increasingly prioritize:

- Durability and longevity — Stainless steel tanks offering 20+ year operational lifespans reduce replacement cycles

- Energy efficiency — Integrated temperature management systems minimizing external cooling/heating requirements

- Material recyclability — Food-grade stainless steel and PET plastics supporting end-of-life recycling programs

- Reduced water consumption — CIP-compatible designs enabling efficient cleaning protocols

Historical Context

Fermentation tank technology has evolved from open wooden vessels to sealed stainless steel conical designs that now dominate commercial operations. The shift toward conical fermenters—enabling yeast harvesting and sediment removal without transfer—represents the most significant advancement in modern brewing infrastructure.

Procurement Recommendations

- Assess production trajectory before selecting tank capacity

- Prioritize connectivity features for operations requiring batch documentation

- Evaluate total cost of ownership including maintenance, cleaning efficiency, and durability

- Verify food-grade certifications and regional compliance standards

Frequently Asked Questions (FAQs) for B2B Buyers of beer fermentation tank

Frequently Asked Questions (FAQs) for B2B Buyers of Beer Fermentation Tanks

1. What sizes of beer fermentation tanks are available for commercial operations?

Commercial beer fermentation tanks range from small-batch units (1-5 BBL) suitable for brewpubs and pilot systems, to mid-size tanks (7-30 BBL) for craft breweries, up to large-scale vessels (60+ BBL) for regional and industrial operations. Tank selection depends on your production volume, batch frequency, and facility space constraints.

2. What materials are used in commercial fermentation tanks, and which is best for our operation?

| Material | Advantages | Best For |

|---|---|---|

| 304 Stainless Steel | Durable, corrosion-resistant, industry standard | Most commercial breweries |

| 316 Stainless Steel | Superior corrosion resistance | High-acid environments, coastal locations |

| PET Plastic | Lightweight, lower cost | Small-batch operations, secondary fermentation |

Stainless steel conical fermenters remain the industry standard for commercial B2B applications due to durability, sanitation compliance, and longevity.

3. What is the typical lead time for commercial fermentation tank orders?

Lead times vary significantly:

– Domestic manufacturers: 4-12 weeks

– International suppliers: 8-20 weeks (plus shipping)

– Custom fabrication: 12-24 weeks

Factor in installation, commissioning, and potential port delays when planning capacity expansion.

4. What certifications and compliance standards should we verify?

Ensure tanks meet:

– ASME pressure vessel standards (if jacketed/pressurized)

– 3-A Sanitary Standards for dairy/food equipment

– CE marking (required for European operations)

– FDA-compliant materials for food-contact surfaces

– Local health department requirements

Request certification documentation before purchase.

5. What features differentiate basic tanks from advanced fermentation systems?

Standard Features:

– Conical bottom with dump valve

– Cooling jacket

– Sample port

– CIP (Clean-in-Place) spray ball

Advanced Features:

– Integrated temperature control with wireless monitoring

– Pressure-rated designs for carbonation

– Glycol manifold connections

– Data logging and fermentation tracking

– Automated pressure relief systems

6. What is the expected ROI and lifespan of commercial fermentation tanks?

Quality stainless steel fermentation tanks typically last 20-30 years with proper maintenance. ROI considerations include:

– Increased production capacity

– Reduced labor through automation features

– Lower contamination/batch loss rates

– Energy efficiency of modern cooling systems

Most operations achieve payback within 2-5 years depending on utilization rates.

7. What support and warranty terms should we expect from suppliers?

Standard B2B terms include:

– Warranty: 1-5 years on welds and construction; 1-2 years on components

– Technical support: Installation guidance, troubleshooting

– Spare parts availability: Minimum 10-year commitment

– Training: Operator training for advanced systems

Request service response time guarantees and local technician availability.

8. What are the key considerations for installation and facility requirements?

Pre-purchase assessment checklist:

– Floor load capacity (filled tanks are heavy)

– Ceiling height and doorway dimensions for tank delivery

– Glycol chiller capacity and piping infrastructure

– Drainage and floor slope requirements

– Electrical requirements for controllers/sensors

– Ventilation for CO2 management

– Access space for cleaning and maintenance

Consult with suppliers early to identify facility modifications needed before ordering.

Strategic Sourcing Conclusion and Outlook for beer fermentation tank

Strategic Sourcing Conclusion: Beer Fermentation Tanks

Selecting the right fermentation tank directly impacts your brewery’s operational efficiency, product consistency, and long-term profitability. The market offers solutions across every scale—from entry-level PET carboys under $50 to professional-grade stainless steel conical fermenters exceeding $700.

Key Takeaways for B2B Buyers

| Factor | Consideration |

|---|---|

| Material | Stainless steel for durability and sanitation; PET plastic for cost-conscious operations |

| Capacity | Match batch size requirements with 10-15% headspace allowance |

| Features | Wireless monitoring, conical bottoms, and siphonless designs reduce labor costs |

| Supplier | Prioritize vendors offering satisfaction guarantees and technical support |

Market Outlook

The fermentation equipment sector continues advancing toward:

– Smart monitoring integration for remote fermentation tracking

– Modular systems enabling scalable production

– Enhanced sanitation features reducing contamination risks

Recommended Next Steps

- Audit current fermentation capacity against projected demand

- Request quotes from multiple suppliers for comparison

- Evaluate total cost of ownership, including maintenance and replacement cycles

- Consider pilot testing before full fleet procurement

Strategic investment in quality fermentation equipment yields measurable returns through improved batch consistency, reduced product loss, and streamlined operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.