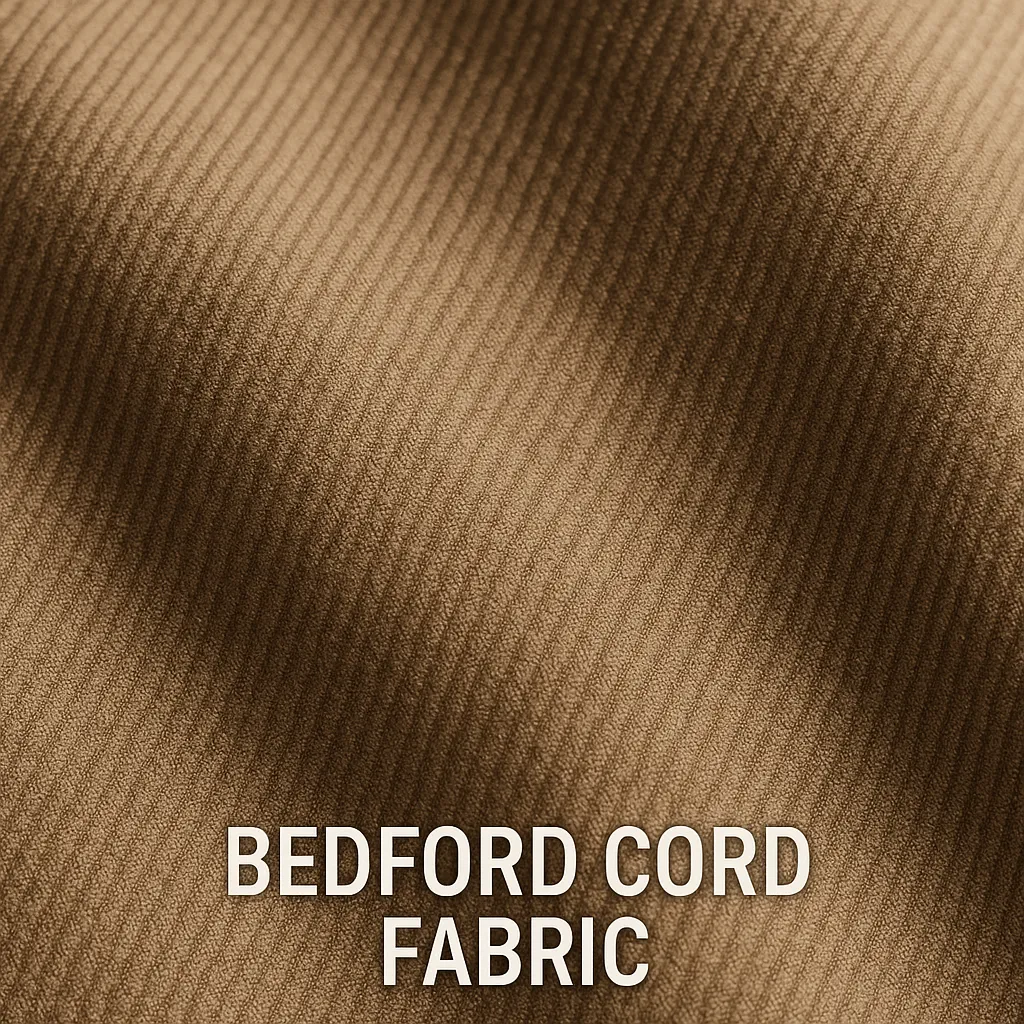

The global specialty textile market has seen steady expansion, driven by rising demand for durable, versatile fabrics in fashion, upholstery, and industrial applications. According to Grand View Research, the global textile market was valued at USD 963.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Bedford cord—a durable woven fabric characterized by lengthwise ridges similar to corduroy but without the pile—has gained traction due to its strength, texture, and aesthetic appeal. With increasing demand in both apparel and home furnishings, manufacturers specializing in Bedford cord are strategically scaling production and innovation. Fueled by advancements in weaving technology and sustainable textile practices, the niche market for structured cotton and blended fabrics continues to evolve. As industry demand grows, a select group of manufacturers have emerged as leaders in quality, consistency, and supply chain efficiency. Here are the top 6 Bedford cord fabric manufacturers shaping the market today.

Top 6 Bedford Cord Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brisbane Moss

Domain Est. 1999

Website: brisbanemoss.co.uk

Key Highlights: The original British Corduroy and Moleskin manufacturer since 1858 · A unique collection of stock supported Corduroy, Moleskin, Flat Cotton, Velvet and Linen ……

#2 Jain Cord Industries

Domain Est. 2013

Website: jaincord.com

Key Highlights: Jain Cord is a vertically integrated company committed to excellence in sustainable manufacturing and processing of premium fabrics and garments….

#3 Mies

Domain Est. 1997

Website: pallastextiles.com

Key Highlights: Traditional Bedford cord fabric is much like a blank canvas – functional and rough around the edges. Inspired by its namesake, Bedford plays up the chunky ……

#4 Bedford Cord Five Pocket Pants

Domain Est. 1997

Website: wythe.com

Key Highlights: Free deliveryIt breaks in and molds to your body like raw denim, and is easy to see why this was a favored fabric for workwear. 100% Cotton; Hair-on-hide patch; Straight fit ……

#5 Fabric

Domain Est. 2008

Website: grownandsewn.com

Key Highlights: 9oz 100% cotton. Developed hundreds of years ago Bedford cord has truly stood the test of time, but is surprisingly under-used in garments today. It’s ……

#6 Bedford Cord

Domain Est. 2009

Expert Sourcing Insights for Bedford Cord Fabric

H2 2026 Market Trends for Bedford Cord Fabric

As the global textile industry evolves in response to shifting consumer preferences, sustainability demands, and technological advancements, Bedford Cord fabric—a durable, ribbed textile historically used in workwear, upholstery, and outerwear—is experiencing a measured resurgence and transformation. The second half of 2026 (H2 2026) reveals several key trends shaping the market for Bedford Cord fabric, driven by innovation, regional demand shifts, and strategic positioning within niche and mainstream applications.

1. Revival in Sustainable Fashion

In H2 2026, Bedford Cord fabric is gaining traction in the sustainable fashion sector. Brands focused on eco-conscious production are increasingly turning to Bedford Cord due to its durability, which aligns with the “slow fashion” movement. Manufacturers are incorporating organic cotton and recycled polyester blends into Bedford Cord weaves, reducing environmental footprints. This shift is particularly evident in Europe and North America, where consumers prioritize long-lasting garments and transparent supply chains.

2. Innovation in Textile Engineering

Advancements in weaving and finishing technologies have enhanced the performance characteristics of Bedford Cord. In 2026, new moisture-wicking, UV-protective, and wrinkle-resistant treatments are being applied to Bedford Cord, expanding its use beyond traditional applications. These technical improvements are increasing its appeal in the outdoor and performance apparel markets, traditionally dominated by synthetic fabrics.

3. Growth in Home Furnishings and Automotive Interiors

Bedford Cord is experiencing renewed demand in home décor and automotive upholstery segments. Its textured appearance, durability, and resistance to abrasion make it ideal for high-traffic areas. In H2 2026, luxury automotive brands in Germany and Japan are incorporating Bedford Cord into interior trim options, emphasizing tactile quality and vintage-inspired design. Similarly, interior designers are using Bedford Cord for accent chairs and drapery, driven by the popularity of retro and industrial aesthetics.

4. Regional Market Shifts

Asia-Pacific, particularly India and China, is emerging as a key production and consumption hub for Bedford Cord fabric in 2026. Local manufacturers are investing in modern looms to produce high-quality Bedford Cord at competitive prices. Meanwhile, demand in North America remains steady, supported by heritage workwear brands reintroducing Bedford Cord in limited-edition collections. Europe shows moderate growth, with a focus on premium and bespoke applications.

5. Challenges and Competitive Pressures

Despite positive momentum, the Bedford Cord market faces challenges. Competition from cheaper synthetic alternatives like microsuede and corduroy substitutes remains strong. Additionally, the niche nature of the fabric limits mass-market scalability. However, strategic branding and positioning as a premium, vintage-inspired textile are helping manufacturers differentiate in a crowded marketplace.

6. Supply Chain and Raw Material Trends

Cotton price volatility in 2026 has prompted some producers to explore alternative fiber blends. Lenzing’s TENCEL™ and other biodegradable fibers are being tested in Bedford Cord weaves to improve softness and sustainability. Supply chain resilience has improved post-pandemic, with diversified sourcing reducing dependency on single regions.

Conclusion

In H2 2026, Bedford Cord fabric is undergoing a quiet renaissance, supported by sustainability trends, technological innovation, and growing demand in niche markets. While not a mainstream textile, its unique texture, durability, and heritage appeal position it favorably within premium and specialty segments. Continued investment in eco-friendly production and versatile applications will be critical for long-term growth.

Common Pitfalls When Sourcing Bedford Cord Fabric (Quality & IP)

Sourcing Bedford cord fabric—known for its durable, ribbed texture—requires careful attention to both quality consistency and intellectual property (IP) concerns. Overlooking these areas can lead to production delays, increased costs, or legal complications. Below are key pitfalls to avoid:

Inconsistent Fabric Quality

Variations in weave density, cord height, and yarn quality are common when working with low-tier suppliers. Poor dye lot consistency or weak tensile strength can compromise the final product’s appearance and durability. Always request physical swatches and lab test reports for abrasion resistance, shrinkage, and colorfastness before bulk ordering.

Misrepresentation of Fiber Content

Some suppliers may falsely advertise Bedford cord as 100% cotton or high-grade polyester when it contains lower-quality blends or recycled fibers. This affects both performance and compliance. Verify fiber content through third-party lab testing and ensure certifications (e.g., Oeko-Tex, GOTS) match claims.

Lack of IP Due Diligence

Using branded or patented textile patterns, finishes, or weaves without authorization can result in infringement claims. For example, certain textured finishes or proprietary treatments may be protected. Always confirm that the fabric design and manufacturing process do not violate existing patents or trademarks, especially when sourcing for branded apparel or upholstery.

Inadequate Supply Chain Transparency

Opaque sourcing channels increase the risk of unethical labor practices or counterfeit materials. This not only affects brand reputation but may also trigger compliance issues in regulated markets. Partner with suppliers who offer full traceability and conduct regular audits of their production facilities.

Overlooking Minimum Order Quantities (MOQs) and Lead Times

Some manufacturers impose high MOQs or extended lead times that don’t align with your production schedule. This can lead to overstocking or rushed sourcing decisions that compromise quality. Clearly define your requirements upfront and assess supplier flexibility.

By addressing these pitfalls early—through vetting, testing, and legal review—brands can ensure reliable, compliant, and high-performing Bedford cord fabric sourcing.

Logistics & Compliance Guide for Bedford Cord Fabric

This guide outlines key logistics considerations and compliance requirements for the import, export, storage, and handling of Bedford Cord fabric, a durable cotton or cotton-blend textile known for its distinctive corded texture and commonly used in apparel, upholstery, and workwear.

Import & Export Regulations

Bedford Cord fabric is subject to international trade regulations based on fiber content, country of origin, and intended end-use. Key compliance factors include:

- Harmonized System (HS) Code Classification: Typically falls under HS Code 5516.93 (woven fabrics of other synthetic staple fibers, cotton blends) or 5210.51 (cotton fabrics, unbleached/bleached). Accurate classification is essential for customs clearance and duty assessment.

- Country of Origin Labeling: Must comply with destination country rules (e.g., FTC labeling in the U.S., EU Textile Regulation 1007/2011). Proper documentation and labeling of origin are mandatory.

- Textile Content Disclosure: Regulations such as the U.S. Textile Fiber Products Identification Act require accurate fiber composition labeling (e.g., 80% cotton, 20% polyester).

- Import Restrictions and Quotas: Some countries may impose quotas or anti-dumping duties on textiles from specific regions. Verify current trade agreements and restrictions with customs authorities.

Environmental & Safety Compliance

Handling and transporting Bedford Cord fabric must adhere to environmental and safety standards:

- REACH & SVHC Compliance (EU): Ensure fabric is free from Substances of Very High Concern (SVHCs), particularly dyes and chemical finishes. Suppliers must provide updated Safety Data Sheets (SDS).

- Proposition 65 (California, USA): Confirm absence of listed carcinogens or reproductive toxins in dyes, finishes, or treatments applied to the fabric.

- Oeko-Tex Standard 100: While voluntary, certification ensures the fabric is free from harmful levels of toxic substances and supports sustainable branding.

- Fire Safety Standards: For upholstery or workwear applications, fabric may need to meet flammability requirements such as CAL 117 (U.S.) or BS 5852 (UK).

Packaging & Handling

Proper packaging ensures product integrity during transit:

- Roll Protection: Store and ship fabric on sturdy cardboard cores, wrapped in polyethylene or kraft paper to prevent moisture, dust, and abrasion.

- Labeling: Each roll must be clearly labeled with content, weight, width, color, batch/lot number, and care instructions.

- Palletization: Secure rolls on wooden or recyclable pallets using stretch wrap or strapping. Avoid overhang to prevent damage during handling.

- Climate Control: Store in dry, temperature-controlled environments to prevent mildew or fiber degradation, especially in humid regions.

Transportation & Storage

Optimize logistics for efficiency and compliance:

- Mode of Transport: Choose between ocean (cost-effective for bulk), air (urgent/low volume), or land freight (regional distribution). Ensure containers are clean, dry, and pest-free.

- Documentation: Provide commercial invoice, packing list, bill of lading, certificate of origin, and any required textile declarations.

- Warehousing: Use GOTS- or ISO-compliant warehouses if handling organic or certified fabrics. Implement FIFO (First In, First Out) inventory practices.

- Customs Clearance: Employ licensed customs brokers familiar with textile classifications to avoid delays or penalties.

Sustainability & Ethical Standards

Increasing regulatory and consumer demand for responsible sourcing:

- Supply Chain Transparency: Maintain records of raw material sources and manufacturing processes. Compliance with initiatives like the Uyghur Forced Labor Prevention Act (UFLPA) may require proof that cotton is not sourced from restricted regions.

- Certifications: Consider certifications such as GOTS (Global Organic Textile Standard), BCI (Better Cotton Initiative), or OEKO-TEX to demonstrate ethical and environmental responsibility.

- Waste Management: Recycle packaging materials and manage off-cuts according to local environmental regulations.

Adhering to this logistics and compliance framework ensures smooth operations, minimizes legal risks, and supports sustainable and ethical practices across the Bedford Cord fabric supply chain.

In conclusion, sourcing Bedford cord fabric requires a strategic approach that balances quality, cost, sustainability, and reliability. This durable and versatile textile, known for its distinct ridged surface and strength, is ideal for apparel, upholstery, and workwear. When sourcing, it is essential to identify reputable suppliers who can provide consistent quality and meet required specifications in terms of composition, weight, and finish. Evaluating factors such as minimum order quantities, lead times, and compliance with environmental and ethical standards further ensures a successful procurement process. Exploring both domestic and international markets—such as manufacturers in Asia, Europe, or specialty mills—can offer competitive pricing and material variety. Ultimately, building strong supplier relationships, conducting sample testing, and staying informed about market trends will support effective and sustainable sourcing of Bedford cord fabric for any application.