The global battery hold down clamp market is experiencing steady growth, driven by rising automotive production, increasing demand for aftermarket vehicle parts, and the expansion of electric vehicle (EV) infrastructure. According to Grand View Research, the global automotive battery market was valued at USD 63.1 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. This growth indirectly fuels demand for essential battery retention components such as hold down clamps, which ensure safety, reduce vibration damage, and maintain optimal battery performance across diverse vehicle types. Additionally, Mordor Intelligence projects that the automotive fasteners and mounting systems market—including components like battery clamps—will expand significantly, supported by stricter regulatory standards for vehicle durability and safety. As OEMs and aftermarket suppliers seek reliable, high-performance solutions, the competitive landscape for battery hold down clamp manufacturers is evolving rapidly. This list highlights the top seven manufacturers leading innovation, quality, and market reach in this growing niche.

Top 7 Battery Hold Down Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Battery Hold Down

Domain Est. 2002

Website: parts.infinitiusa.com

Key Highlights: Order Your OEM Battery Hold Down (f48665namh) For Your 2019-2025 INFINITI Vehicle From The Official Infiniti Parts Store!…

#2 C5AZ

Domain Est. 1995

Website: holley.com

Key Highlights: In stock Free delivery over $149Heavy duty stamped steel construction with black vinyl coating like the original to prevent corrosion. About Scott Drake. Shop the official site of …

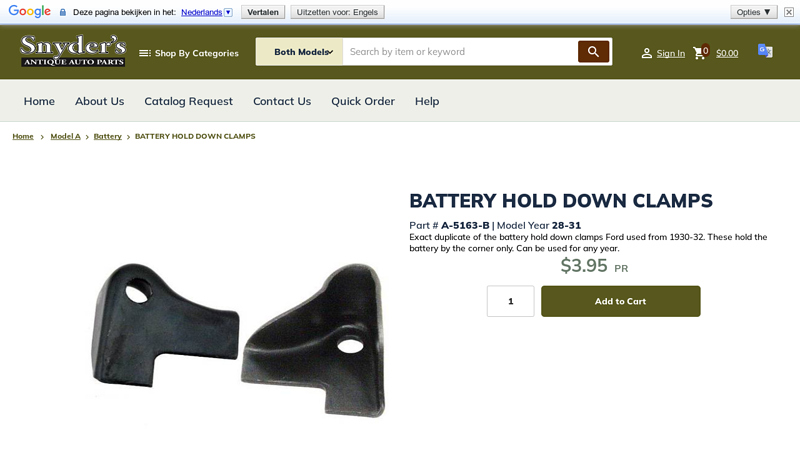

#3 Product Battery BATTERY HOLD DOWN CLAMPS A

Domain Est. 1998

Website: snydersantiqueauto.com

Key Highlights: 7–10 day delivery 30-day returnsExact duplicate of the battery hold down clamps Ford used from 1930-32. These hold the battery by the corner only. Can be used for any year….

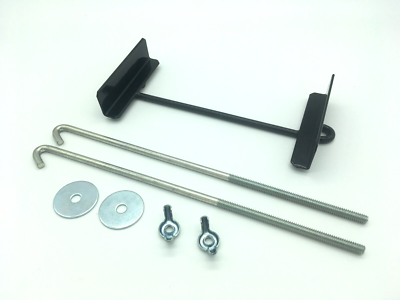

#4 Battery Hold

Domain Est. 1998

Website: 4statetrucks.com

Key Highlights: Designed for use with 2 Group 30 Or Group 31 Batteries. Includes – 4 U-Bolts, 8 Jamb Nuts, 8 Washer Plates, 4 J Hooks, 4 Flat Washers, 2 Poly Battery Clamps, ……

#5 Battery Hold Down

Domain Est. 2001

Website: dormanproducts.com

Key Highlights: Battery hold down corroded or missing? This hold down replaces your original equipment to keep your battery properly secured and maintain its longevity….

#6 ODYSSEY Battery Hold Down Kit

Domain Est. 2002

Website: odysseybattery.com

Key Highlights: Prevents battery movement in any configuration and/or location. Includes all components required for an easy install. Designed and precision-machined ……

#7 No Limit Fabrication Battery Hold Downs

Domain Est. 2011

Expert Sourcing Insights for Battery Hold Down Clamp

H2: 2026 Market Trends for Battery Hold Down Clamp

The global Battery Hold Down Clamp market is projected to experience steady growth through 2026, driven by increasing demand across automotive, industrial, and renewable energy sectors. Key trends shaping the market include the rise of electric vehicles (EVs), advancements in battery technology, stricter safety regulations, and the expansion of off-grid energy systems.

-

Growth in Electric Vehicle Adoption

The rapid expansion of the EV market is a primary driver for battery hold down clamps. As automakers globally transition toward electrification, the need for secure, vibration-resistant battery mounting solutions intensifies. Battery hold down clamps ensure stable battery positioning in EVs, enhancing safety and durability. This trend is expected to accelerate through 2026, especially in regions like North America, Europe, and China. -

Stringent Safety and Regulatory Standards

Governments and regulatory bodies are imposing stricter safety requirements for battery installations in vehicles and energy storage systems. These standards mandate secure fastening mechanisms to prevent battery displacement during accidents or heavy vibration. As a result, manufacturers are investing in high-performance, compliant clamp designs, boosting market demand. -

Advancements in Material and Design Innovation

By 2026, the market will see increased adoption of lightweight, corrosion-resistant materials such as reinforced polymers and aluminum alloys. These materials improve clamp durability and reduce overall vehicle weight—key factors in EV efficiency. Additionally, modular and adjustable clamp designs are gaining traction, offering compatibility with various battery sizes and configurations. -

Expansion of Renewable Energy and Energy Storage Systems (ESS)

The growing deployment of solar and wind energy systems, coupled with the need for reliable energy storage, is fueling demand for battery hold down clamps in stationary applications. As grid-scale and residential battery storage systems proliferate, secure mounting solutions become essential to ensure long-term performance and safety. -

Regional Market Dynamics

Asia-Pacific, led by China and India, is expected to dominate the market due to booming automotive production and government support for clean energy. Meanwhile, North America and Europe will see growth driven by EV infrastructure development and sustainability initiatives. -

Sustainability and Recycling Considerations

Environmental concerns are prompting manufacturers to explore recyclable and eco-friendly clamp materials. By 2026, sustainability is likely to become a differentiating factor in product offerings, influencing procurement decisions among environmentally conscious buyers.

In summary, the Battery Hold Down Clamp market in 2026 will be shaped by technological innovation, regulatory pressures, and the global shift toward electrification and renewable energy. Companies that align with these trends through R&D and strategic partnerships are poised to capture significant market share.

Common Pitfalls When Sourcing Battery Hold Down Clamps (Quality & IP)

Sourcing Battery Hold Down Clamps may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to significant operational, safety, and legal risks. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost clamps use substandard materials such as brittle plastics or inadequately coated metals that degrade quickly under heat, vibration, and exposure to battery acid. This can result in clamp failure, battery movement, and potential short circuits or damage to vehicle electronics.

Inadequate Mechanical Strength and Fit

Clamps that are not engineered to match OEM specifications may lack the necessary tensile strength or clamping force. An improper fit—either too loose or too tight—can lead to battery shifting during operation or damage to the battery case, increasing the risk of leaks or electrical faults.

Non-Compliance with Environmental and Safety Standards

Some sourced clamps fail to meet essential environmental resistance standards (e.g., UV resistance, temperature range, vibration testing). Additionally, they may not comply with industry-specific certifications (such as ISO, SAE, or UL), compromising safety and reliability in demanding conditions.

Lack of Intellectual Property Due Diligence

Sourcing clamps from suppliers that replicate patented OEM designs without licensing can expose your company to IP infringement claims. This includes copying distinctive shapes, mounting mechanisms, or integrated features protected under utility or design patents. Legal disputes can result in costly recalls, fines, or supply chain disruptions.

Insufficient Traceability and Documentation

Suppliers may provide clamps without proper material certifications, test reports, or traceability data. This lack of documentation makes it difficult to validate quality, respond to audits, or address field failures effectively—especially critical in regulated industries like automotive or marine.

Overlooking Long-Term Supply Chain Reliability

Selecting suppliers based solely on low initial cost often neglects their capacity for consistent quality and long-term availability. Unreliable suppliers may alter materials or manufacturing processes without notice, leading to inconsistent clamp performance and potential production delays.

H2: Logistics & Compliance Guide for Battery Hold Down Clamp

Overview

This guide provides essential information for the safe, efficient, and compliant logistics handling, transportation, and regulatory compliance of Battery Hold Down Clamps. While the clamp itself is a mechanical component and not classified as hazardous, proper logistics planning and adherence to international and regional regulations are crucial to ensure product integrity, avoid delays, and maintain compliance throughout the supply chain.

1. Packaging & Handling

Packaging Requirements:

– Use durable, moisture-resistant packaging (e.g., corrugated cardboard boxes, polyethylene bags) to protect against corrosion and physical damage.

– Individual units should be wrapped or separated to prevent scratching, especially if made of coated or plated steel.

– Use void fill (e.g., foam inserts, bubble wrap) to minimize movement during transit.

– Clearly label packages with:

– Product name: “Battery Hold Down Clamp”

– Part number and quantity

– Handling instructions (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”)

– Supplier and destination information

Handling Precautions:

– Store and handle in dry, temperature-controlled environments to prevent rust or degradation of surface coatings.

– Avoid exposure to corrosive substances (acids, salts, chemicals) commonly found in battery compartments or industrial settings.

– Use appropriate manual or mechanical handling equipment (e.g., pallet jacks, forklifts) to prevent damage during loading/unloading.

2. Storage Conditions

- Temperature: Store between 10°C and 30°C (50°F to 86°F)

- Humidity: Maintain relative humidity below 65% to prevent oxidation

- Ventilation: Ensure adequate airflow in storage areas

- Shelf Life: No expiration date; however, inspect periodically for signs of corrosion or deformation

- Stacking: Do not exceed manufacturer-recommended stacking heights to avoid crushing lower layers

3. Transportation

Domestic (e.g., US, EU):

– Can be shipped via standard freight (LTL, FTL, parcel) without hazardous material restrictions.

– Secure loads using straps or dunnage to prevent shifting.

– Follow carrier-specific packaging and labeling requirements.

International Shipping:

– Comply with International Maritime Dangerous Goods (IMDG) Code, IATA Dangerous Goods Regulations (air), and ADR (road in Europe) — Note: Battery hold down clamps are not classified as dangerous goods when shipped standalone.

– Use ISPM 15-compliant wooden pallets if applicable (heat-treated and marked).

– Complete standard shipping documents: Commercial Invoice, Packing List, Bill of Lading/Air Waybill.

– Include Harmonized System (HS) Code: Typically 7326.90 (Other articles of iron or steel) — verify based on material composition and regional tariff schedules.

4. Regulatory Compliance

Environmental & Material Compliance:

– RoHS (EU): Ensure compliance with Restriction of Hazardous Substances Directive (2011/65/EU) for lead, cadmium, mercury, etc., particularly if coatings or plating are used.

– REACH (EU): Register and communicate substances of very high concern (SVHC) if applicable; most clamps fall under articles and may require communication if SVHC content exceeds 0.1%.

– Proposition 65 (California, USA): If the clamp contains listed substances (e.g., lead in certain alloys), provide appropriate warning labels.

Customs & Trade:

– Provide accurate product descriptions and country of origin.

– Ensure compliance with trade regulations (e.g., Uyghur Forced Labor Prevention Act – UFLPA if manufactured in Xinjiang, China).

– Monitor for changes in tariffs or import restrictions under US Section 301 or EU trade policies.

5. Documentation Requirements

Mandatory documentation includes:

– Commercial Invoice: With value, quantity, weight, and HS code

– Packing List: Itemized contents per package

– Certificate of Origin: Required by some countries for tariff determination

– RoHS/REACH Compliance Declaration (if requested by customer or distributor)

– SDS (Safety Data Sheet): Not typically required for mechanical components unless coated with hazardous substances — confirm with manufacturer

6. Special Considerations

- Kitting with Batteries: If the clamp is shipped as part of a battery kit or assembly, the entire shipment may be subject to battery-specific regulations (e.g., UN3480, IATA PI965). Ensure proper classification and packaging in such cases.

- Aftermarket vs. OEM: Distribution channels may impose additional labeling or traceability requirements (e.g., barcode, serial number tracking).

- Recycling: Design for disassembly and recyclability; steel clamps are typically 100% recyclable.

Conclusion

Battery Hold Down Clamps are low-risk components from a logistics and compliance standpoint, but attention to packaging, environmental protection, and regulatory documentation ensures smooth global distribution. Always verify regional requirements and maintain communication with freight forwarders, customs brokers, and regulatory experts to stay compliant.

Conclusion for Sourcing Battery Hold-Down Clamp:

After evaluating various suppliers, material options, cost considerations, and compatibility requirements, sourcing a reliable battery hold-down clamp is essential to ensure the safety, stability, and longevity of the battery within its application. The ideal clamp should offer a secure fit, resistance to environmental factors such as vibration, moisture, and corrosion, and be compatible with the battery size and mounting configuration.

Sourcing from reputable suppliers who provide consistent quality, adhere to industry standards, and offer scalable pricing ensures long-term performance and cost-efficiency. Additionally, considering factors such as material durability (e.g., steel, stainless steel, or reinforced plastic), ease of installation, and inventory availability helps minimize downtime and maintenance costs.

In conclusion, a strategic sourcing approach—balancing quality, cost, and reliability—will result in the selection of a battery hold-down clamp that enhances operational safety and system integrity across automotive, industrial, or marine applications. Regular supplier performance reviews and demand forecasting will further support sustainable procurement and supply chain resilience.