The global zinc-chloride battery market is experiencing steady growth, driven by rising demand for reliable, cost-effective primary batteries in consumer electronics, medical devices, and industrial applications. According to Grand View Research, the global primary battery market was valued at USD 12.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with zinc-based chemistries maintaining a significant share due to their affordability and widespread usability. Mordor Intelligence further highlights that the increasing deployment of low-power portable devices and the continued preference for zinc-chloride batteries in emerging markets are key growth catalysts. As demand surges, a select group of manufacturers has emerged as leaders in innovation, scale, and global distribution, shaping the competitive landscape of the zinc-chloride battery sector.

Top 9 Batteries Zinc Chloride Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Zinc Chloride Manufacturers, Suppliers

Domain Est. 1996

Website: pcc-chemical.com

Key Highlights: Taiwan zinc chloride manufacturers, Pan-Continental Chemical, offers quality zinc chloride liquid and zinc chloride solid to meet your demands….

#2 ZINC CHLORIDE ( ZnCl2 )

Domain Est. 2003

Website: altichem.com

Key Highlights: Zinc Chloride is a salt with the chemical formula ZnCl2, it is a compound of zinc cations and chloride anions. It is highly soluble in water….

#3 Zinc Chloride

Domain Est. 2019

Website: hansonchemicals.com

Key Highlights: Hanson Chemicals is a trusted manufacturer, supplier and distributor of Zinc Chloride, serving industries across USA & Canada with reliable quality and….

#4 Your Trusted Supplier of High Quality Battery Grade Zinc Chloride

Domain Est. 2020

Website: coastalzinc.com

Key Highlights: As the world’s leading zinc chloride producer, Coastal Zinc Group has been providing the highest quality battery zinc chloride for many years….

#5 Zinc Chloride Pure supplier – manufacturer

Domain Est. 2022

Website: vinipulchemicals.com

Key Highlights: It is used in the manufacture of batteries, particularly as an electrolyte. … This makes it suitable for applications like zinc-carbon batteries and zinc- ……

#6 Zinc Chloride Supplier & Distributor

Domain Est. 2010

Website: connectionchemical.com

Key Highlights: Connection Chemical LP is your trusted source for high-quality Zinc Chloride. We provide dependable supply chain solutions to partners and customers across ……

#7 Zinc Chloride

Domain Est. 2012

Website: galvanizingchemicals.com

Key Highlights: Zinc Chloride is used in Dry Cell Batteries as an electrolyte and also as a moisture absorbent and corrosion inhibitor. Dry Cell Batteries. It is used in ……

#8 Zinc Chloride

Domain Est. 2014

Website: flaureachemicals.com

Key Highlights: Zinc Chloride’s constant quality allows the production of “green batteries”, which have no mercury content. Zinc Chloride is also used by various chemical ……

#9 Zinc Chloride Batteries

Domain Est. 2020

Website: batterydivision.com

Key Highlights: $19.95 delivery · 30-day returnsAt BatteryDivision, you’ll find an array of Zinc Chloride cells ranging from AA, AAA, C, D, and 9V sizes….

Expert Sourcing Insights for Batteries Zinc Chloride

H2: Emerging Market Trends for Zinc-Chloride Batteries in 2026

As the global energy storage landscape evolves, zinc-chloride batteries—a subset of zinc-based primary (non-rechargeable) batteries—are experiencing renewed interest due to their safety, environmental profile, and cost-effectiveness. By 2026, several key market trends are shaping the trajectory of zinc-chloride battery adoption and development:

-

Growing Demand in Low-Power Consumer Electronics

Zinc-chloride batteries continue to dominate in low-drain applications such as remote controls, clocks, flashlights, and basic household devices. In 2026, the proliferation of smart home devices and IoT sensors in emerging markets is sustaining demand for affordable, reliable power sources. Despite competition from alkaline batteries, zinc-chloride variants remain preferred in price-sensitive regions due to their lower manufacturing costs. -

Environmental and Regulatory Drivers

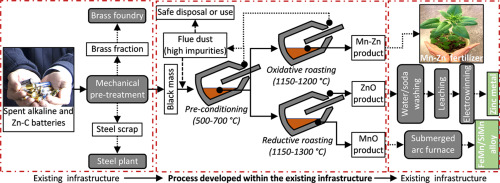

Environmental regulations, particularly in the EU and North America, are increasingly favoring battery chemistries with lower toxicity and easier recyclability. Zinc-chloride batteries, which contain fewer hazardous materials compared to lithium or nickel-cadmium alternatives, benefit from favorable regulatory treatment. By 2026, extended producer responsibility (EPR) schemes and stricter disposal guidelines are encouraging manufacturers to enhance recycling infrastructure for zinc-based systems. -

Innovation in Hybrid and Modified Chemistries

While traditional zinc-chloride batteries are non-rechargeable, research into modified zinc-chloride systems with limited rechargeability is gaining momentum. By 2026, early-stage hybrid zinc-chloride batteries with improved cycle life are being tested for niche applications in industrial sensors and backup systems. These developments are driven by academic-industry partnerships, particularly in Asia and Europe. -

Regional Market Shifts

Asia-Pacific remains the largest consumer and producer of zinc-chloride batteries, driven by high-volume electronics manufacturing in China, India, and Southeast Asia. However, by 2026, localized production is increasing in regions like Africa and Latin America to reduce import dependency and meet rising demand for affordable energy solutions in off-grid applications. -

Competition from Alternative Technologies

The zinc-chloride battery market faces pressure from advancements in alkaline, lithium primary, and rechargeable lithium-ion batteries. However, their cost advantage and adequate performance in low-drain roles ensure continued relevance. In 2026, zinc-chloride batteries hold a stable, albeit niche, market share—particularly in developing economies where price sensitivity is paramount. -

Supply Chain and Raw Material Stability

Zinc is abundant and widely mined, with stable global supply chains. In 2026, fluctuations in zinc prices have minimal impact on battery production costs compared to lithium or cobalt-dependent technologies. This stability enhances the long-term viability of zinc-chloride batteries in mass-market applications.

In summary, while zinc-chloride batteries are not at the forefront of high-performance energy storage innovation, their role in 2026 remains significant in cost-effective, safe, and environmentally acceptable power solutions for low-drain devices. Market growth is incremental, supported by regulatory trends, regional demand, and ongoing material science improvements.

When sourcing Zinc Chloride (ZnCl₂) batteries—commonly known as zinc-carbon or heavy-duty batteries—using the H2 framework (Hazardous Chemicals under REACH/CLP regulations), several critical pitfalls related to quality and intellectual property (IP) must be carefully managed to ensure compliance, performance, and legal safety. Below are the common pitfalls categorized under H2 considerations:

1. Quality-Related Pitfalls (Under H2 – Hazard Classification)

Zinc chloride batteries contain hazardous substances classified under EU Regulation (EC) No 1272/2008 (CLP), where ZnCl₂ itself may fall under certain hazard classes (e.g., Skin Corrosion/Irritation, Serious Eye Damage/Eye Irritation, Specific Target Organ Toxicity).

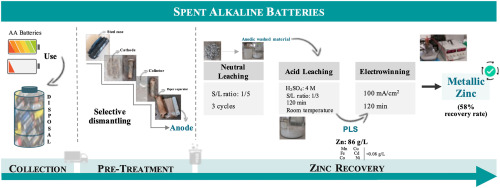

Pitfall 1: Poor Electrolyte Purity

- Issue: Low-grade ZnCl₂ may contain impurities like lead, cadmium, or iron, which degrade performance and increase internal corrosion.

- H2 Impact: Impure ZnCl₂ can alter the hazard profile, potentially increasing toxicity or reactivity and violating REACH SVHC (Substances of Very High Concern) restrictions.

- Mitigation: Require material declarations (e.g., REACH SVHC compliance) and certificates of analysis (CoA) specifying trace metal content.

Pitfall 2: Inconsistent Battery Performance

- Issue: Variability in ZnCl₂ concentration or electrolyte formulation leads to inconsistent discharge rates, shelf life, and leakage risks.

- H2 Impact: Poor quality increases the risk of leakage (classified under H314: Causes severe skin burns and eye damage), raising safety and regulatory reporting obligations.

- Mitigation: Audit suppliers’ quality control processes; insist on standardized manufacturing (e.g., IEC 60086 compliance).

Pitfall 3: Non-Compliant Packaging & Labeling

- Issue: Batteries not properly labeled with H2 hazard warnings (e.g., corrosive content).

- H2 Impact: Non-compliance with CLP labeling requirements (Regulation (EC) No 1272/2008) can result in customs rejection, fines, or product recalls.

- Mitigation: Ensure all packaging includes correct GHS pictograms, signal words, and hazard statements (e.g., H314, H335).

2. Intellectual Property (IP) Pitfalls

Pitfall 4: Infringement of Patented Battery Designs

- Issue: Some ZnCl₂ battery chemistries or structural designs (e.g., leak-resistant seals, cathode formulations) may be protected by patents.

- H2 Link: While not directly a hazard, using patented IP without authorization may lead to legal action, disrupting supply.

- Mitigation: Conduct freedom-to-operate (FTO) analysis; source from licensed manufacturers.

Pitfall 5: Proprietary Electrolyte Formulations

- Issue: Suppliers may claim trade secrets over ZnCl₂ blend ratios or additives (e.g., NH₄Cl mixtures, gelling agents).

- H2 Impact: Lack of full disclosure complicates safety data sheet (SDS) accuracy under REACH, particularly Section 3 (composition) and Section 11 (toxicological info).

- Mitigation: Require full SDS with disclosure of hazardous components above threshold limits (≥1% for non-chronic hazards); negotiate data sharing where needed.

Pitfall 6: Counterfeit or Grey Market Goods

- Issue: Unauthorized resellers may offer “compatible” batteries that mimic branded products but use substandard or mislabeled ZnCl₂ electrolytes.

- H2 Impact: Counterfeit products often lack valid SDS, missing H2 hazard info, leading to non-compliance and user exposure risks.

- Mitigation: Source only from authorized distributors; verify batch traceability and SDS authenticity.

Best Practices to Avoid Pitfalls (H2-Aligned)

- Verify SDS Compliance: Ensure Safety Data Sheets classify ZnCl₂ per CLP (e.g., H314, H335) and are updated per REACH Article 31.

- Audit Supply Chain: Assess suppliers for ISO 9001 and ISO 14001 certification; confirm hazardous substance management systems.

- Demand Transparency: Require full disclosure of ZnCl₂ purity, impurities, and exact formulation percentages where relevant to hazard classification.

- Check IP Status: Review patent databases (e.g., EPO, USPTO) for active patents on zinc-chloride battery tech before sourcing.

- Test Incoming Goods: Perform independent lab testing for ZnCl₂ content, leakage resistance, and electrical performance.

Conclusion

Sourcing Zinc Chloride batteries under H2 (hazardous chemicals) obligations requires rigorous attention to both quality control and IP integrity. Failure to address impurities, labeling, or patent risks can result in regulatory penalties, safety incidents, or legal disputes. By aligning procurement practices with REACH/CLP requirements and conducting thorough due diligence, organizations can mitigate these common pitfalls effectively.

H2: Logistics & Compliance Guide for Zinc-Chloride Batteries

Zinc-chloride batteries are a common type of primary (non-rechargeable) battery widely used in household and industrial applications. While generally safe, they contain materials that require careful handling, transportation, and disposal in accordance with international and national regulations. This guide outlines key logistics and compliance considerations for the safe and legal management of zinc-chloride batteries across the supply chain.

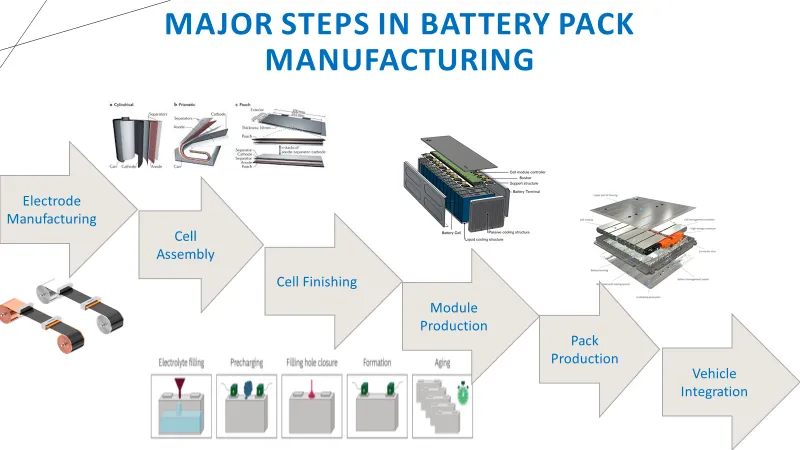

1. Battery Description & Classification

- Chemistry: Zinc (anode), manganese dioxide (cathode), zinc chloride (electrolyte)

- Type: Primary (non-rechargeable) battery

- Common Forms: AA, AAA, C, D, 9V, and button cells

- UN Number: Typically UN 1370 – “Batteries, dry” (when shipped without equipment)

- Proper Shipping Name: Batteries, dry

- Class: Class 9 – Miscellaneous Dangerous Goods (under UN Model Regulations)

✅ Note: Zinc-chloride batteries are not classified as hazardous under most transport regulations when shipped by themselves, provided they are non-spillable and packaged to prevent short circuits and damage.

2. Transportation Regulations

A. International Air Transport (IATA DGR)

- Applicable Regulation: IATA Dangerous Goods Regulations (current edition)

- UN ID: UN 1370

- Packing Instruction: PI 966, Section IB (if packed with equipment) or PI 969, Section IB (if packed alone)

- Hazard Class: Class 9

- Labeling: Class 9 Miscellaneous Dangerous Goods label required if shipment meets criteria

- Exceptions: Small quantities of batteries (e.g., consumer quantities) may be exempt under Special Provision A123 or limited quantity rules

✅ Key Compliance Tips:

– Prevent short circuits by insulating terminals (e.g., tape or individual packaging)

– Pack securely to avoid movement or damage

– Do not mix with lithium batteries unless compliant with segregation rules

B. International Road/Rail (ADR/RID)

- Regulations: ADR (road), RID (rail)

- UN ID: UN 1370

- Class: 9

- Packing Group: Not assigned (PG III or not limited)

- Packaging: Must prevent short circuits and physical damage

- Documentation: Dangerous goods declaration required if above threshold quantities

❗ Note: Shipments under 10 kg net weight may be exempt under limited quantity provisions (LQ).

C. Maritime Transport (IMDG Code)

- UN ID: UN 1370

- Class: 9

- Packing Instruction: P903 (for dry batteries)

- Stowage: No specific stowage requirements beyond general segregation

- Documentation: Dangerous Goods Declaration if required by quantity

3. Packaging & Handling Requirements

- Terminal Protection: Each battery must have terminals insulated (e.g., plastic caps, shrink wrap, or tape)

- Inner Packaging: Use non-conductive material to separate batteries

- Outer Packaging: Strong, rigid packaging to prevent crushing or puncture

- Marking: Outer package must be marked with:

- Proper shipping name: “Batteries, dry”

- UN number: UN 1370

- Shipper/Consignee information

- Quantity Limits: Follow IATA/ADR/IMDG limits per package and per consignment

4. Storage & Warehousing

- Environment: Store in dry, cool, well-ventilated areas

- Shelving: Use non-conductive shelving; avoid stacking heavy items on battery cartons

- Segregation: Keep away from:

- Water or damp environments

- Flammable materials

- Reactive chemicals (especially oxidizers)

- Fire Safety: No special firefighting procedures required; use water or standard extinguishers if fire occurs

5. Regulatory Compliance & Documentation

- SDS (Safety Data Sheet): Required under GHS (Globally Harmonized System)

- Section 14: Transport information must include UN number, class, packing group, and regulations

- Customs Declarations: Declare accurately using correct HS code (e.g., 8506.80.xx for primary batteries)

- REACH & RoHS (EU): Confirm compliance with:

- RoHS Directive 2011/65/EU: Restricts hazardous substances (zinc-chloride batteries typically compliant)

- REACH: No SVHCs (Substances of Very High Concern) above threshold

- WEEE Directive (EU): Producers must register and finance end-of-life recycling

6. End-of-Life & Recycling Compliance

- Disposal: Not classified as hazardous waste under U.S. EPA or EU Waste Framework Directive in most cases

- Recycling: Encourage recycling through designated battery take-back programs

- Labeling: Include “Do not dispose in household waste” and recycling symbol (e.g., crossed-out wheelie bin)

- U.S. (EPA): Follow state-specific regulations (e.g., California requires recycling)

- EU: Comply with Battery Directive 2006/66/EC – mandates collection and recycling targets

7. Emergency Response

- Leakage: If electrolyte leaks (white powder), avoid inhalation or skin contact

- Clean with damp cloth; ventilate area

- Dispose of contaminated material as non-hazardous waste

- Ingestion/Exposure: Rare, but if occurs:

- Rinse mouth; seek medical advice

- Refer to SDS for first aid measures

- Fire: Use standard firefighting methods; no toxic fumes expected under normal conditions

8. Best Practices Summary

| Area | Best Practice |

|——|—————-|

| Packaging | Insulate terminals, use rigid boxes, prevent movement |

| Transport | Follow IATA/ADR/IMDG rules; declare if required |

| Labeling | Mark with UN 1370, “Batteries, dry”, and contact info |

| Documentation | Include SDS, shipping papers, compliance statements |

| Storage | Dry, cool, separated from incompatible materials |

| Recycling | Partner with certified recyclers; comply with WEEE/Battery Directive |

9. References

- IATA Dangerous Goods Regulations (current edition)

- ADR 2023 (European Agreement concerning Road Transport)

- IMDG Code (International Maritime Dangerous Goods)

- EU Battery Directive 2006/66/EC

- RoHS Directive 2011/65/EU

- GHS Rev. 9 (Globally Harmonized System)

- OSHA Hazard Communication Standard (29 CFR 1910.1200)

Ensure all personnel involved in handling, shipping, or storing zinc-chloride batteries are trained in relevant regulations and emergency procedures. Regular audits and compliance checks are recommended to maintain safety and regulatory adherence.

⚠️ Disclaimer: Regulations vary by country and mode of transport. Always consult local authorities and the latest regulatory texts before shipping.

Conclusion for Sourcing Zinc Chloride Batteries

In conclusion, sourcing zinc chloride batteries requires a careful evaluation of quality, cost, reliability, and supplier credibility. These batteries, commonly used in low-drain devices such as clocks, remote controls, and flashlights, offer an economical alternative to alkaline batteries. When selecting suppliers, it is essential to consider product consistency, compliance with safety and environmental standards (such as RoHS and REACH), and the ability to ensure stable supply chains.

Establishing relationships with reputable manufacturers—particularly those in established battery-producing regions—can help secure competitive pricing and dependable inventory. Additionally, conducting regular performance testing and reviewing certifications ensures that the batteries meet required specifications and deliver reliable service life.

Ultimately, successful sourcing of zinc chloride batteries hinges on balancing cost-efficiency with quality assurance, while maintaining flexibility to adapt to market fluctuations and evolving technological or regulatory demands. A strategic, well-informed procurement approach will support long-term operational efficiency and customer satisfaction.