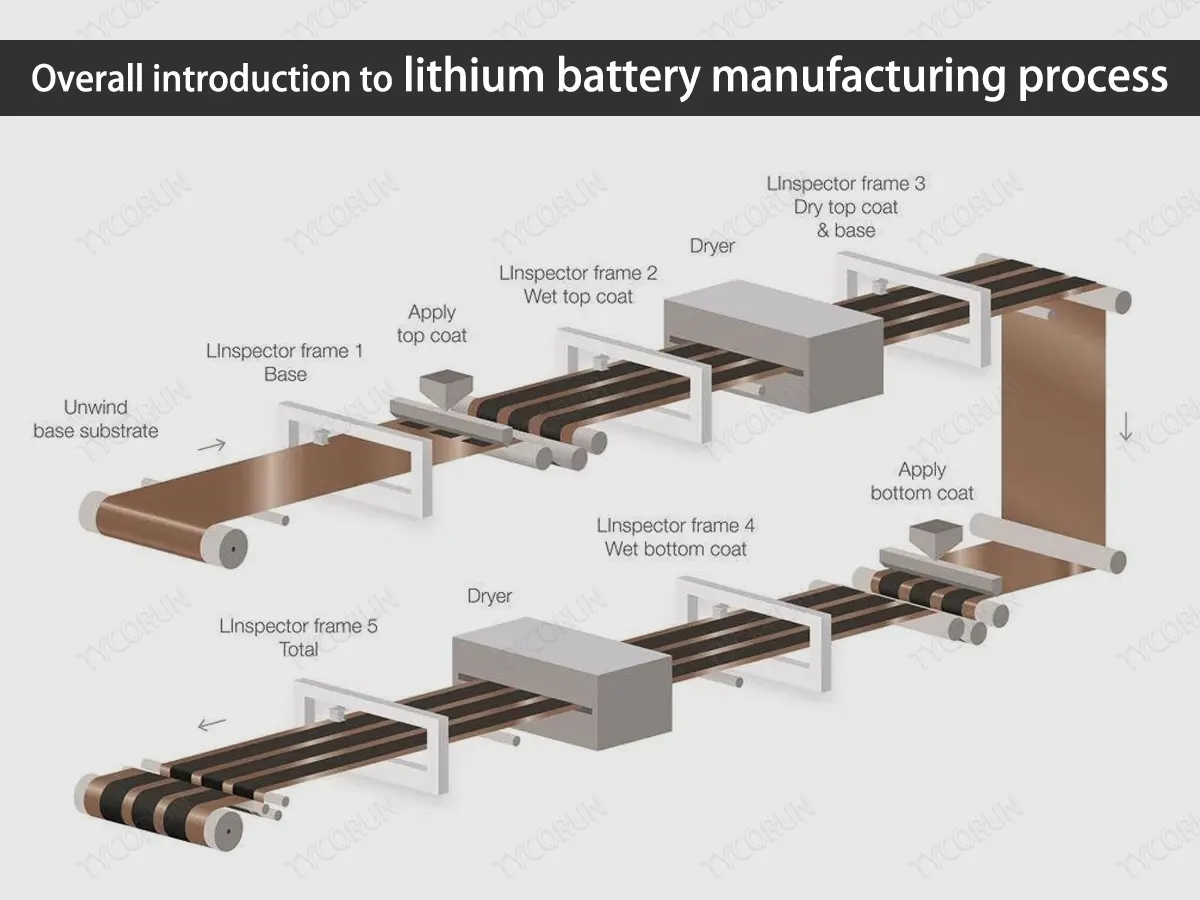

The global lithium polymer (LiPo) battery market is experiencing robust expansion, driven by rising demand in consumer electronics, electric vehicles (EVs), and portable medical devices. According to a report by Mordor Intelligence, the LiPo battery market was valued at USD 6.87 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2030. Similarly, Grand View Research estimates that the broader lithium-ion battery market, which includes LiPo variants, is expected to expand at a CAGR of 14.4% over the same period, underpinned by advancements in energy density and safety features. As industries increasingly prioritize lightweight, flexible, and high-performance power solutions, a select group of manufacturers have emerged as leaders in innovation, scale, and reliability. These top eight lithium polymer battery producers are shaping the future of energy storage by leveraging cutting-edge technology and strategic global supply chain integration.

Top 8 Batterie Li Polymer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About LiPoly Batteries

Domain Est. 2016

Website: lipolybatteries.com

Key Highlights: Lipoly Batteries Co., Ltd. is a li polymer battery manufacturer in Shenzhen, China and was found in 2008. With over 10 years of experience in power industrial, ……

#2 About us

Domain Est. 2010

Website: lipolbattery.com

Key Highlights: We are LiPol Battery Co., Ltd, a lithium polymer battery manufacturer in Shenzhen, China and was found in 2002. With over 8 years of experience the power ……

#3

Domain Est. 2018

Website: batterylipo.com

Key Highlights: Asia important rechargeable lithium polymer battery manufacturer. We served the world market with high end LIPO battery cells and packs….

#4 About Us. www.li

Domain Est. 2019

Website: li-polymer-battery.com

Key Highlights: Li-Polymer-Battery.com is a new website of LiPol Battery Co., Ltd. We one of China’s earliest private enterprises devoted to Creative Power For Future Energy ……

#5 Lithium Polymer Battery

Domain Est. 1997

Website: eemb.com

Key Highlights: EEMB Lithium Polymer Battery is designed for greater energy density, safer, wide temperature range, ultra thin, high power delivery, flexible form factors….

#6 Lipo Battery, Lithium Polymer Battery, Li-po Battery

Domain Est. 1999

Website: grepow.com

Key Highlights: Grepow lipo battery and lithium polymer battery packs provide the highest energy density. Widely used in applications such as UAV, FPV, drone and RC hobby….

#7 CNHL LiPo Batteries for RC Cars, FPV Drones & Planes …

Domain Est. 2010

Website: chinahobbyline.com

Key Highlights: $9.99 delivery · 30-day returnsExplore CNHL’s lipo batteries and lithium polymer battery packs for RC cars, drones, and planes. Rechargeable power with local warehouse shipping….

#8 Lithium polymer battery products

Domain Est. 2018

Website: lithium-polymer-battery.com

Key Highlights: The NCM lithium polymer battery is a lithium ion battery with muliple materials synthesized by nickel manganese cobalt oxide as a positive electrode material….

Expert Sourcing Insights for Batterie Li Polymer

H2: 2026 Market Trends for Lithium Polymer (Li-Po) Batteries

The global lithium polymer (Li-Po) battery market is poised for significant evolution by 2026, driven by advancements in technology, rising demand across key industries, and increasing emphasis on energy density and safety. Below is an analysis of the major market trends shaping the Li-Po battery sector in 2026:

1. Surge in Demand from Consumer Electronics

Li-Po batteries remain the preferred power source for smartphones, tablets, wearables, and ultra-thin laptops due to their high energy density, lightweight design, and flexible form factor. In 2026, the proliferation of foldable devices and next-generation wearables will further boost demand, with manufacturers pushing for thinner, safer, and faster-charging battery solutions.

2. Expansion in Drones and UAVs

The unmanned aerial vehicle (UAV) market continues to grow rapidly in sectors such as agriculture, logistics, surveillance, and entertainment. Li-Po batteries are favored in drones for their high discharge rates and power-to-weight ratio. By 2026, enhanced thermal stability and longer cycle life in new Li-Po variants will support longer flight times and improved reliability, fueling market expansion.

3. Growth in Electric Mobility Niche Applications

While lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) dominate the EV mainstream, Li-Po batteries are gaining traction in niche electric mobility segments—such as electric scooters, e-bikes, and personal mobility devices—where compact size and design flexibility are crucial. Innovations in polymer electrolytes are improving safety and reducing swelling risks, making Li-Po more viable for these applications.

4. Advancements in Solid-State and Hybrid Polymer Technologies

By 2026, research into solid-state lithium polymer batteries is expected to reach commercialization milestones. These next-gen batteries promise higher energy densities, improved thermal stability, and reduced flammability. Hybrid polymer systems combining gel and solid electrolytes are also emerging, offering a transitional solution with better performance and safety than traditional Li-Po cells.

5. Focus on Sustainability and Recycling

Environmental regulations and corporate sustainability goals are pushing battery manufacturers to improve recyclability and reduce reliance on cobalt and other conflict minerals. In 2026, closed-loop recycling initiatives and eco-design principles will be increasingly adopted across the Li-Po supply chain, particularly in Europe and North America.

6. Regional Market Dynamics

Asia-Pacific, led by China, South Korea, and Japan, remains the dominant manufacturing hub for Li-Po batteries. However, by 2026, North America and Europe are expected to increase domestic production capacity in response to supply chain security concerns and incentives under green energy policies (e.g., U.S. Inflation Reduction Act, EU Battery Regulation).

7. Price Stabilization Amid Raw Material Volatility

After fluctuations in lithium and cobalt prices in the early 2020s, improved supply chain resilience and alternative material formulations (e.g., lithium manganese oxide blends) are expected to stabilize Li-Po battery costs by 2026. This will support broader adoption across price-sensitive applications.

Conclusion

By 2026, the lithium polymer battery market will be characterized by technological innovation, expanded applications beyond consumer electronics, and stronger sustainability practices. While facing competition from other lithium-ion chemistries, Li-Po batteries will maintain a strategic position in markets requiring flexibility, light weight, and high performance. Continued R&D in solid-state polymers and recycling technologies will define the next phase of growth and competitiveness in the sector.

Common Pitfalls When Sourcing Li-Polymer Batteries (Quality & IP)

Sourcing Li-Polymer (Lithium-Polymer) batteries involves significant risks related to both quality and intellectual property (IP) protection. Overlooking these pitfalls can lead to product failures, safety hazards, legal disputes, and reputational damage. Here’s a breakdown of the most common issues:

H2: Quality-Related Pitfalls

-

Counterfeit or Substandard Cells:

- Pitfall: Suppliers may offer batteries labeled as high-grade brands (e.g., Samsung, LG, Murata) but deliver counterfeit, recycled, or rewrapped cells. These often use inferior-grade internal components (anode, cathode, electrolyte).

- Impact: Reduced capacity, shorter cycle life, inconsistent performance, and increased risk of swelling, overheating, or thermal runaway.

- Mitigation: Require genuine manufacturer certifications, conduct third-party lab testing (e.g., capacity, internal resistance, cycle testing), and audit supplier facilities.

-

Inaccurate or Exaggerated Specifications:

- Pitfall: Suppliers may overstate key parameters such as capacity (mAh), energy density (Wh/kg), discharge rate (C-rate), or cycle life.

- Impact: Product underperformance, premature failure, customer dissatisfaction, and safety risks under high-load conditions.

- Mitigation: Verify specs through independent testing, request detailed datasheets with test conditions, and include performance warranties in contracts.

-

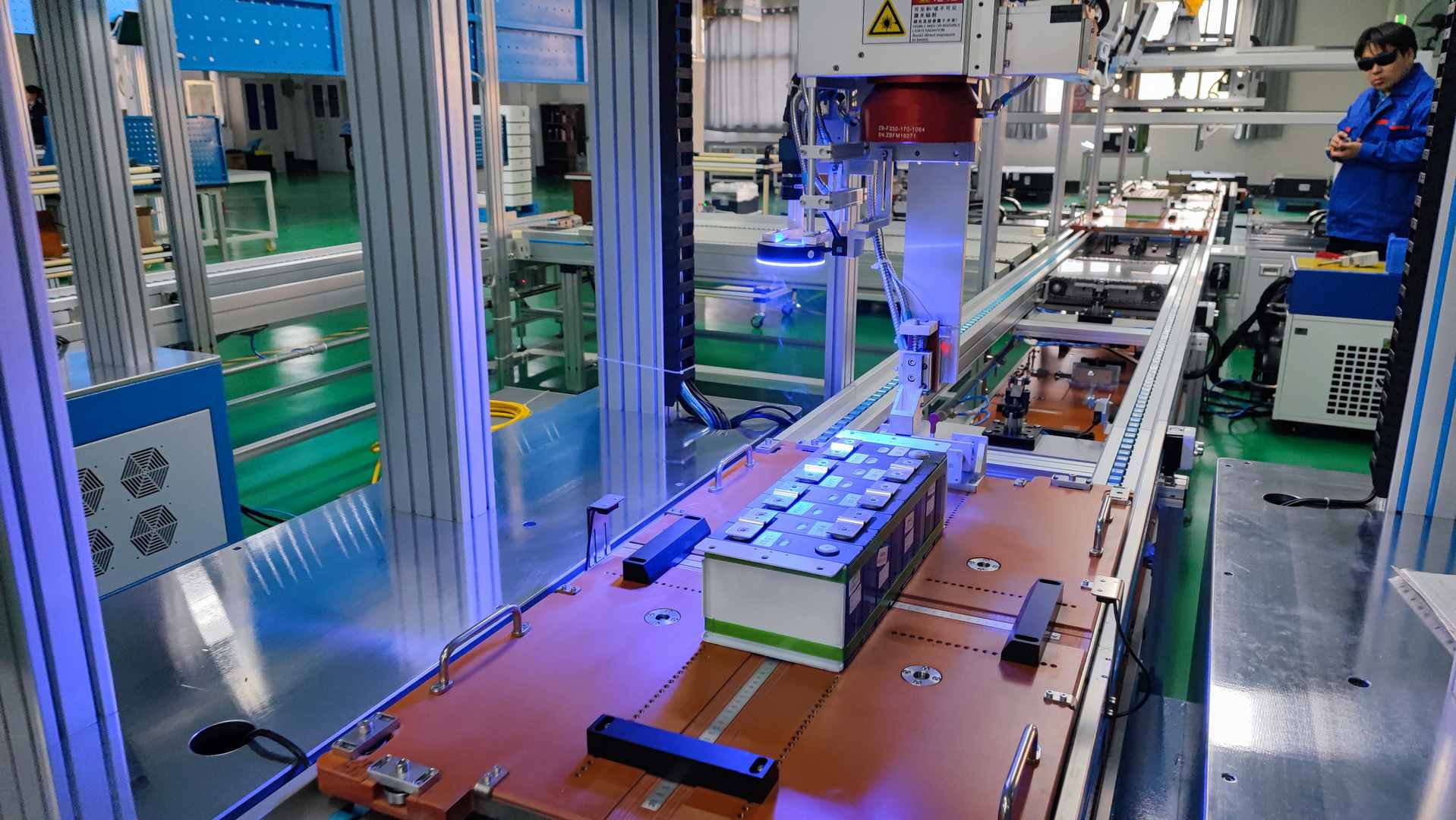

Poor Manufacturing Consistency and QC:

- Pitfall: Low-cost manufacturers may lack rigorous quality control processes, leading to high variance in cell performance, internal defects (e.g., micro-shorts), or inconsistent electrolyte filling.

- Impact: Field failures, high return rates, and safety incidents due to undetected flaws.

- Mitigation: Audit production lines, require statistical process control (SPC) data, and perform batch sampling and testing before shipment.

-

Lack of Safety Certification and Compliance:

- Pitfall: Batteries may not meet required safety standards like UL 1642, IEC 62133, UN 38.3, or regional regulations (e.g., CE, FCC).

- Impact: Legal non-compliance, shipment rejections, product recalls, and liability in case of fire or injury.

- Mitigation: Demand valid, up-to-date test reports from accredited labs and verify certification marks.

-

Inadequate Protection Circuit Module (PCM) Design:

- Pitfall: Even with good cells, a poorly designed or low-quality PCM can fail to prevent overcharge, over-discharge, short circuits, or over-temperature.

- Impact: Catastrophic battery failure, fire hazard, damage to connected devices.

- Mitigation: Review PCM design and BOM, require component certifications (e.g., TI, Seiko), and test under fault conditions.

H2: Intellectual Property (IP)-Related Pitfalls

-

Reverse Engineering and Design Theft:

- Pitfall: Suppliers or their subcontractors may copy proprietary battery pack designs, PCM layouts, firmware, or form factors to produce and sell identical or similar products to competitors.

- Impact: Loss of competitive advantage, market dilution, reduced pricing power.

- Mitigation: Use strong NDAs, limit design information to “need-to-know,” and consider modular or obfuscated designs.

-

Unauthorized Use of Trademarks and Branding:

- Pitfall: Suppliers may use your brand name, logo, or product name on batteries not authorized for sale, especially in gray markets.

- Impact: Brand damage, customer confusion, potential liability for substandard products bearing your mark.

- Mitigation: Include strict branding and trademark clauses in contracts, conduct market monitoring, and enforce IP rights.

-

Lack of IP Ownership Clauses in Contracts:

- Pitfall: Failure to explicitly define who owns the IP for custom designs, firmware, or tooling developed during manufacturing.

- Impact: Disputes over ownership, inability to switch suppliers, or being forced to pay royalties.

- Mitigation: Clearly state in contracts that all IP developed for your product belongs to your company. Specify tooling ownership and access rights.

-

Weak or Unenforceable NDAs and Agreements:

- Pitfall: Using generic or poorly drafted non-disclosure agreements that lack jurisdiction-specific enforceability or clear scope.

- Impact: Difficulty proving breach or pursuing legal action, especially in cross-border sourcing.

- Mitigation: Use jurisdiction-specific, well-drafted legal agreements reviewed by IP counsel. Include clear definitions, exclusions, and remedies.

-

Third-Party IP Infringement by Supplier:

- Pitfall: The supplier may use components (e.g., ICs in the PCM) or manufacturing processes that infringe on third-party patents.

- Impact: Your company may be held liable for contributory infringement, leading to lawsuits or import bans.

- Mitigation: Require suppliers to warrant they do not infringe third-party IP and indemnify you against such claims. Conduct IP due diligence on key components.

Conclusion:

Successfully sourcing Li-Polymer batteries requires a dual focus on rigorous quality assurance and proactive IP protection. Due diligence, clear contractual terms, independent verification, and ongoing monitoring are essential to mitigate the risks associated with both substandard products and intellectual property theft. Partnering with reputable, transparent suppliers and involving legal and technical experts early in the sourcing process can prevent costly setbacks.

H2: Logistics & Compliance Guide for Lithium Polymer (Li-Po) Batteries

Lithium Polymer (Li-Po) batteries are widely used in consumer electronics, drones, electric vehicles, and portable medical devices due to their high energy density and lightweight design. However, their transport and handling are subject to strict international regulations due to safety risks such as fire, thermal runaway, and explosion. This guide outlines the key logistics and compliance requirements for shipping Lithium Polymer batteries under Hazard Class 9 (UN3480 or UN3481), based on international standards.

1. Classification & Identification (H2.1)

- UN Number:

- UN3480 – Lithium-ion batteries (including Li-Po), packed by themselves.

-

UN3481 – Lithium-ion batteries contained in or packed with equipment.

-

Proper Shipping Name:

- Lithium ion batteries, including lithium ion polymer batteries

- Lithium ion batteries, including lithium ion polymer batteries, contained in equipment

-

Lithium ion batteries, including lithium ion polymer batteries, packed with equipment

-

Hazard Class: Class 9 – Miscellaneous Dangerous Goods

- Packing Group: Typically PG II (medium danger)

2. Regulatory Framework (H2.2)

Li-Po batteries are regulated under the following international guidelines:

- IATA Dangerous Goods Regulations (DGR) – Air transport

- IMDG Code – Sea transport

- ADR – Road transport in Europe

- 49 CFR – U.S. Department of Transportation (DOT) regulations

- UN Manual of Tests and Criteria, Part III, Sub-section 38.3 – Required safety testing

Note: All regulations are harmonized with the UN Model Regulations but may have specific regional variations.

3. Packaging Requirements (H2.3)

- Robust Packaging: Must withstand vibration, pressure changes, and shocks.

- Prevent Short Circuits: Terminals must be protected (e.g., by caps, tape, or individual packaging).

- Prevent Movement: Batteries must be secured to avoid shifting during transit.

- Separation from Other Dangerous Goods: Do not pack with explosives, flammable materials, or oxidizers.

- Stacking Strength: Packages must support at least 1.2 meters of identical packages.

Special Provisions:

– PI 965–970 (IATA) apply depending on shipment type:

– Section IA or IB for larger quantities (requires Class 9 label, shipper’s declaration, and training).

– Section II for smaller quantities (may be exempt from full documentation if under limits).

4. Labeling & Marking (H2.4)

All packages must display:

- Proper Shipping Name & UN Number

- Class 9 Hazard Label (black 9 on white upper half, seven vertical stripes on lower half)

- Lithium Battery Handling Label (new design as per IATA 2019+)

- Orientation Arrows (if liquid present or required by mode)

- Shipper/Consignee Information

Note: For Section II shipments under IATA, some labeling may be reduced, but the lithium battery mark is still required.

5. Documentation (H2.5)

- Shipper’s Declaration for Dangerous Goods – Required for IATA PI 965 IA/IB, PI 966, PI 967, etc.

- Dangerous Goods Note (DGN) – For IMDG/ADR shipments.

- Safety Data Sheet (SDS) – Recommended, though not always mandatory for transport.

6. Quantity Limits & Exceptions (H2.6)

- Passenger Aircraft:

- Devices with batteries: allowed in carry-on or checked baggage (typically ≤ 100 Wh per battery).

-

Spare batteries: only in carry-on, max 2 spares (if ≤ 100 Wh). Batteries > 100 Wh require airline approval.

-

Cargo Aircraft:

-

Higher quantities permitted with proper packaging and documentation.

-

Small Batteries (Section II):

- Batteries ≤ 20 Wh (or ≤ 100 Wh for some equipment) may qualify for reduced requirements.

7. Testing & Certification (H2.7)

All Li-Po batteries must pass UN 38.3 testing:

– Altitude simulation

– Thermal cycling

– Vibration

– Shock

– External short circuit

– Impact/Crush (for cells)

– Overcharge

– Forced discharge

Certificates of compliance must be available upon request.

8. Training & Competency (H2.8)

- Personnel involved in preparing, offering, or transporting Li-Po batteries must be dangerous goods trained and certified.

- Training must be refreshed every 2 years (IATA/IMDG/ADR).

- Records of training must be maintained.

9. Carrier-Specific Requirements (H2.9)

- IATA Members, FedEx, UPS, DHL all have additional restrictions:

- Pre-approval for high-capacity batteries.

- Advance notification.

- Prohibitions on certain routes or modes.

Always consult the carrier’s latest dangerous goods manual before shipping.

10. Emergency Response (H2.10)

- Provide Emergency Response Information (e.g., phone number for 24/7 assistance).

- Include fire-fighting instructions: Use Class D extinguishers or large amounts of water.

- Avoid inhalation of toxic fumes during fire.

Summary Checklist (H2.11)

✅ UN 38.3 test summary available

✅ Correct classification (UN3480/UN3481)

✅ Proper packaging & terminal protection

✅ Class 9 label + lithium battery handling mark

✅ Required documentation completed

✅ Personnel trained and certified

✅ Carrier-specific rules verified

✅ Quantity limits observed

Important: Regulations are updated annually. Always refer to the latest edition of IATA DGR, IMDG Code, or ADR/49 CFR before shipment.

For compliance assurance, consider working with a certified dangerous goods safety consultant or freight forwarder experienced in lithium battery logistics.

This guide provides general information and is not a substitute for legal or regulatory advice. Always consult official sources and regulatory bodies.

Conclusion for Sourcing Lithium-Polymer Batteries

Sourcing lithium-polymer (Li-Po) batteries requires a strategic and diligent approach, balancing performance, safety, cost, and reliability. As high-energy-density power sources widely used in consumer electronics, drones, medical devices, and portable applications, Li-Po batteries demand careful supplier evaluation and supply chain management.

Key considerations in the sourcing process include verifying supplier certifications (such as ISO, UN38.3, CE, RoHS), assessing manufacturing capabilities, and ensuring compliance with international safety and transportation standards. Partnering with reputable manufacturers—particularly those with proven quality control processes—helps mitigate risks related to battery failure, thermal runaway, and regulatory non-compliance.

Additionally, factors such as customization needs, minimum order quantities, lead times, and logistical requirements should align with project timelines and volume demands. Establishing long-term relationships with suppliers enables better pricing, consistent quality, and collaborative innovation.

In conclusion, successful sourcing of lithium-polymer batteries hinges on thorough due diligence, an emphasis on safety and compliance, and strategic supplier selection. By prioritizing these elements, organizations can secure reliable, high-performance battery solutions that support product integrity and market competitiveness.