The global bath and body products market has experienced steady expansion over the past decade, driven by rising consumer interest in self-care, aromatherapy, and natural personal care formulations. According to Grand View Research, the global bath and shower products market size was valued at USD 23.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. This uptick in demand has directly fueled the need for efficient production equipment—particularly bath bomb presses—capable of meeting scalability, consistency, and customization requirements for both artisanal brands and large manufacturers.

As DIY skincare and eco-conscious bathing rituals gain popularity, the demand for automated and semi-automated bath bomb pressing machines has surged. Mordor Intelligence projects continued growth in the personal care manufacturing equipment sector, citing increased investments in small-scale production lines and private-label product development. In this evolving landscape, selecting the right bath bomb press manufacturer is critical for ensuring product quality, operational efficiency, and long-term ROI. Below are the top six manufacturers leading innovation, reliability, and performance in the bath bomb press space.

Top 6 Bath Bomb Press Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

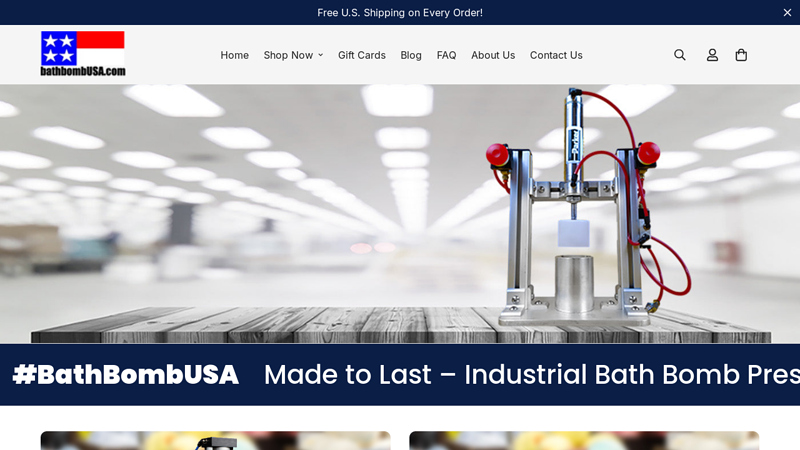

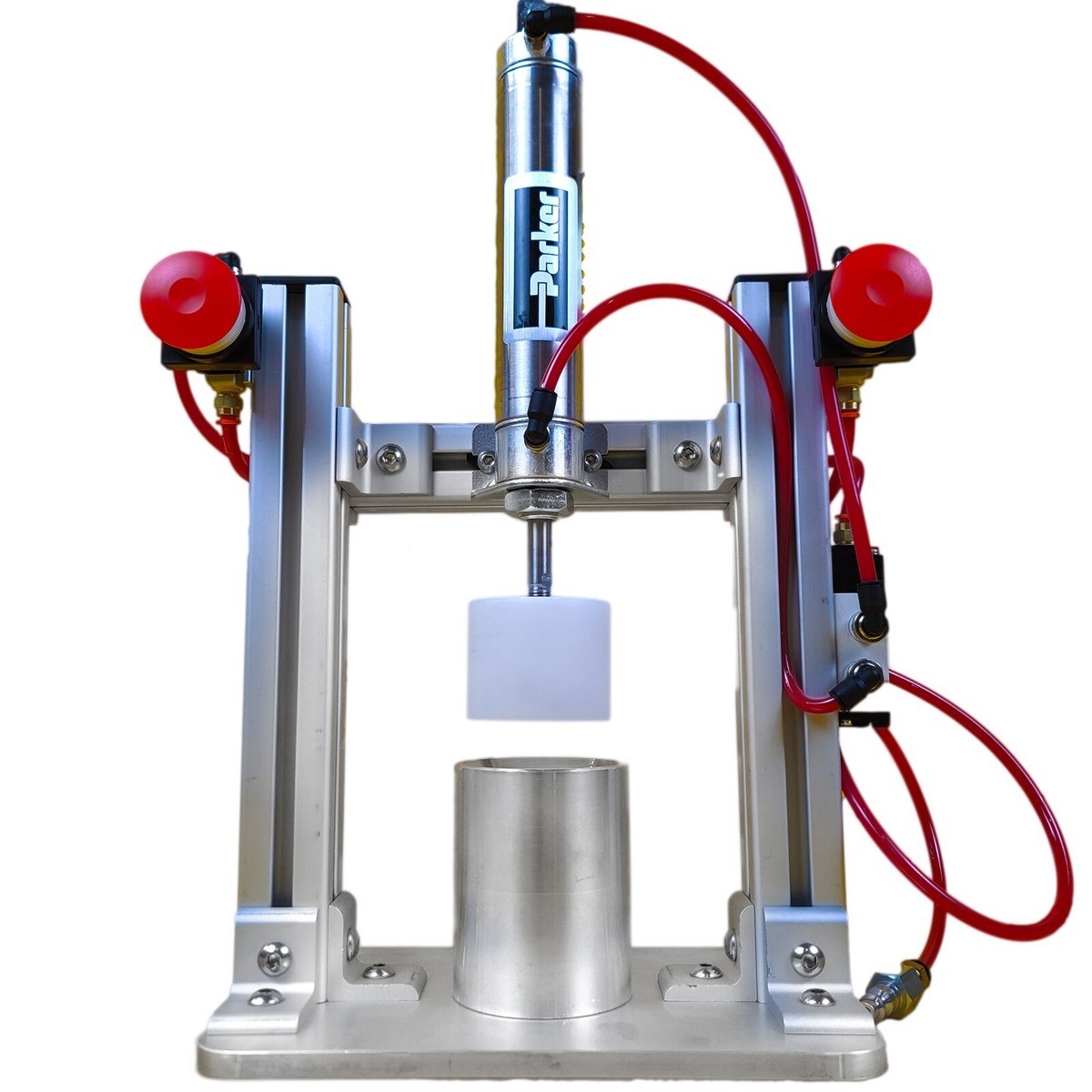

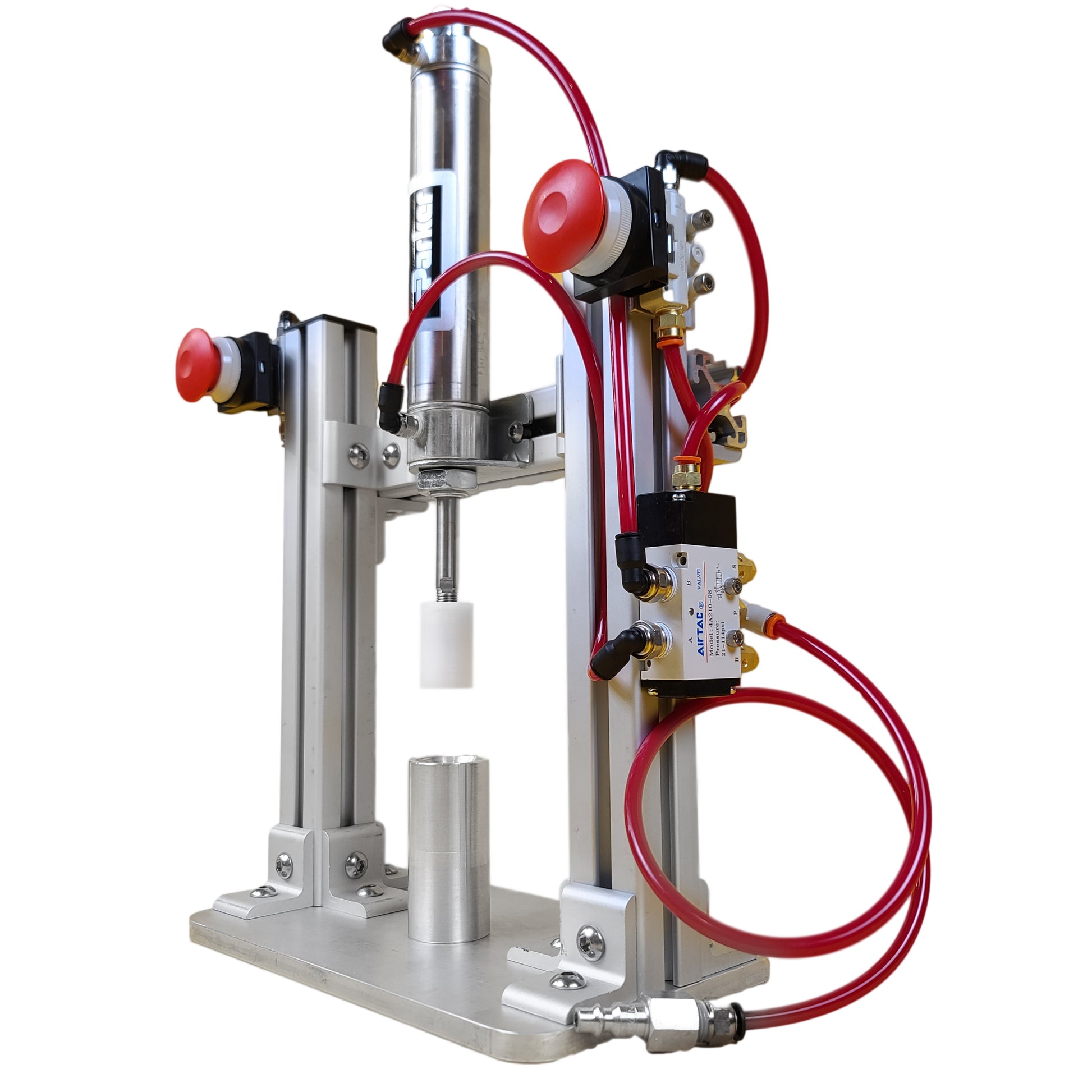

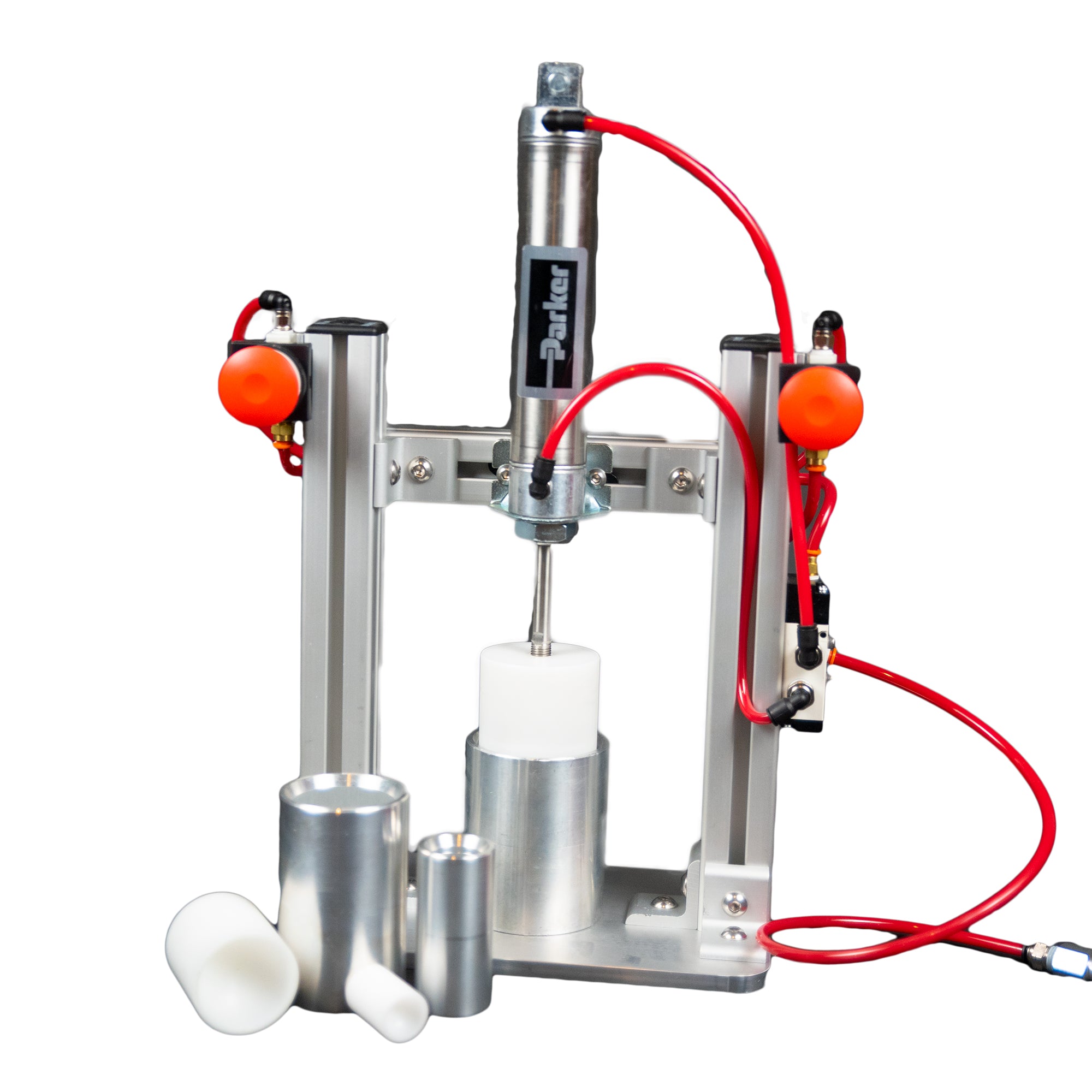

#1 Bath Bomb USA

Domain Est. 2018

Website: bathbombusa.com

Key Highlights: Industrial bath bomb press machines & molds made in the USA. Faster production, premium quality, and free U.S. shipping on every order….

#2 BathbombMachine

Domain Est. 2024

Website: utbathbombpress.com

Key Highlights: Our bath bomb making machines come in various models to meet various production needs. With cutting-edge technology and superior mold workmanship….

#3 SV Labs

Domain Est. 2004

Website: s-vlabs.com

Key Highlights: SV Labs is your partner for growth. We offer a unique combination of custom innovation, concierge-level service, multi-site capabilities, and MOQ flexibility to ……

#4 Bath Bomb Press

Domain Est. 2010

Website: bathbombpress.com

Key Highlights: The Bath Bomb Press is made of anodized aluminum and is light weight. It has no welded parts, takes up a small foot print in your work area and requires ……

#5 Learn About the Bath Bomb Machine Team

Domain Est. 2010 | Founded: 2010

Website: bathbombmachine.com

Key Highlights: Since 2010, BathBombMachine.com has crafted safe, durable machines for bath bomb production. Scale your business with innovative, high-capacity solutions….

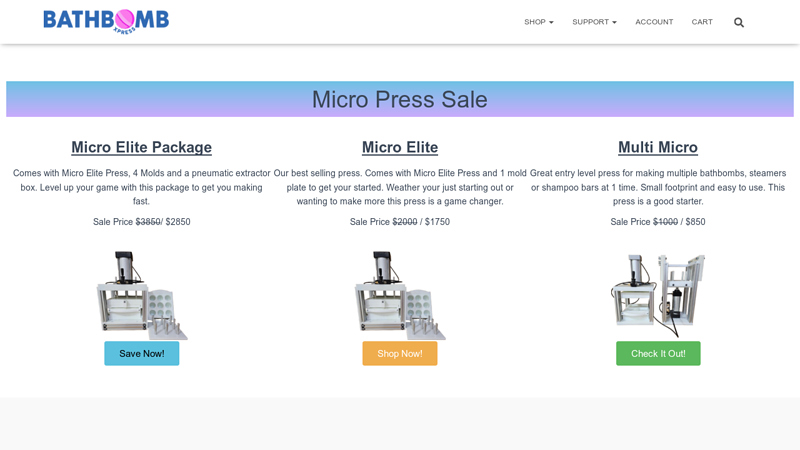

#6 Bath Bomb Presses and Molds: Bath Bomb X

Domain Est. 2016

Website: bathbombxpress.com

Key Highlights: From the wide variety of presses and molds, we are sure you will find the right product to fit your growing business needs….

Expert Sourcing Insights for Bath Bomb Press

H2: 2026 Market Trends for Bath Bomb Press

The bath bomb press market is poised for significant evolution by 2026, driven by increasing consumer demand for natural and personalized bath and body products, advancements in manufacturing technology, and the expansion of e-commerce platforms. As the global wellness and self-care industry continues to grow, bath bombs remain a popular product due to their sensory appeal, ease of use, and perceived therapeutic benefits. This has led to heightened interest in efficient, scalable, and customizable bath bomb production tools—such as bath bomb presses—among small businesses, artisans, and emerging brands.

One major trend shaping the 2026 market is the rise of automation and precision in bath bomb pressing equipment. Manufacturers are integrating smart controls, adjustable pressure settings, and modular dies into their machines to allow for consistent output and intricate designs. These features cater to the growing demand for premium, aesthetically pleasing bath products that stand out in competitive retail and online markets.

Additionally, sustainability is becoming a core consideration. By 2026, bath bomb press producers are expected to prioritize eco-friendly materials and energy-efficient designs. Biodegradable components, recyclable construction, and low-power operation are becoming key selling points as environmentally conscious consumers influence brand decisions up the supply chain.

Another notable trend is the democratization of production. With the proliferation of DIY beauty movements and home-based businesses, compact, affordable, and user-friendly bath bomb presses are gaining popularity. These entry-level models enable hobbyists and micro-entrepreneurs to produce professional-quality bath bombs with minimal investment—fueling innovation and niche market development.

Furthermore, the integration of digital platforms for customization is emerging. By 2026, some bath bomb press systems may offer companion apps or cloud-based design libraries, allowing users to download molds, track production metrics, or share formulations—creating a connected ecosystem for creators.

In conclusion, the 2026 bath bomb press market reflects broader shifts toward personalization, sustainability, and technological integration. As consumer demand for high-quality, unique bath products intensifies, the bath bomb press will evolve from a simple tool into a smart, scalable, and eco-conscious component of modern beauty manufacturing.

Common Pitfalls Sourcing a Bath Bomb Press: Quality and Intellectual Property Risks

Sourcing a bath bomb press—whether for in-house production or contract manufacturing—comes with significant risks, particularly concerning product quality and intellectual property (IP) protection. Overlooking these factors can lead to supply chain disruptions, legal disputes, or damage to brand reputation. Below are critical pitfalls to avoid.

Quality Inconsistencies and Substandard Equipment

One of the most frequent issues when sourcing bath bomb presses is receiving machinery that fails to meet performance or durability standards. Many suppliers, especially overseas, offer lower-cost presses made with inferior materials or imprecise engineering. This can result in inconsistent compression, uneven tablet formation, excessive wear and tear, or frequent mechanical failures. Without rigorous vetting—including factory audits, sample testing, and review of certifications—buyers risk investing in equipment that reduces output efficiency and increases long-term maintenance costs.

Lack of Standardized Manufacturing Processes

Even if the press appears functional, discrepancies in manufacturing processes across suppliers can impact the final product. Variations in mold tolerances, pressure calibration, or automation integration may lead to bath bombs that differ in density, shape, or disintegration rate. These inconsistencies affect product quality and customer experience. Ensuring the supplier adheres to standardized engineering practices and is willing to customize the machine to your exact specifications is essential for maintaining batch-to-batch consistency.

Intellectual Property Infringement Risks

Sourcing from manufacturers with weak IP compliance can expose your business to legal liabilities. Some suppliers may copy patented press designs or use components that violate existing intellectual property rights. If your purchased equipment incorporates infringing technology, you could face cease-and-desist orders, fines, or be forced to halt production. Always verify that the supplier owns the design rights or has proper licensing, and consider including IP indemnification clauses in your procurement contract.

Inadequate Protection of Your Own IP

When customizing a bath bomb press—especially with unique molds, automation features, or branding elements—there’s a risk the supplier could replicate or resell your design to competitors. Without strong non-disclosure agreements (NDAs) and clear contractual ownership of custom tooling and designs, your proprietary innovations may be compromised. Ensure that contracts explicitly state that all custom-developed components are your exclusive property and restrict the supplier from using them for other clients.

Poor After-Sales Support and Spare Parts Availability

A bath bomb press is a long-term investment, and ongoing support is crucial. Some suppliers offer attractive upfront pricing but lack reliable customer service, technical support, or access to replacement parts. This can lead to extended downtime during breakdowns. Confirm the supplier’s service capabilities, availability of spare parts, and willingness to provide training before finalizing the purchase.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence on potential suppliers, prioritize transparency and documentation, and engage legal counsel when drafting IP and procurement agreements. Investing time upfront to verify quality standards and protect intellectual property will safeguard your production process and brand integrity in the long run.

Logistics & Compliance Guide for Bath Bomb Press

This guide outlines essential logistics and compliance considerations for manufacturing, packaging, distributing, and selling bath bomb presses. Adhering to these guidelines ensures safety, legal compliance, and smooth operations.

Product Safety & Regulatory Compliance

Bath bomb presses are industrial equipment, often used in cosmetic or spa product manufacturing. Compliance with safety and regulatory standards is critical.

Ensure your bath bomb press meets applicable machinery safety standards such as:

– OSHA (Occupational Safety and Health Administration) regulations for workplace equipment

– ANSI B11 Series standards for machine tool safety (if applicable)

– CE Marking requirements if exporting to the European Union, including compliance with the Machinery Directive (2006/42/EC)

Conduct regular risk assessments and provide safety guards, emergency stop functions, and clear warning labels. Maintain technical documentation and a Declaration of Conformity for regulatory audits.

Electrical & Mechanical Standards

Verify that all electrical components meet national and international safety codes:

– UL (Underwriters Laboratories) or ETL Listing for North American markets

– IEC (International Electrotechnical Commission) standards for motors and control systems

– Proper grounding, insulation, and overload protection must be implemented

Ensure mechanical designs follow engineering best practices and are tested for durability, load capacity, and operator safety. Use materials compatible with humid or chemical exposure if used in cosmetic production environments.

Packaging & Shipping Logistics

Proper packaging protects the press during transit and ensures customer satisfaction.

- Use heavy-duty wooden crates or reinforced cardboard with internal bracing for shock absorption

- Include protective covers for moving parts and control panels

- Label packages with “Fragile,” “This Side Up,” and handling instructions

- Include assembly manuals, safety warnings, and compliance documentation inside the shipment

Coordinate with freight carriers experienced in handling industrial machinery. Use tracked shipping with insurance, especially for international deliveries.

Import/Export Compliance

If shipping across borders, follow all import and export regulations:

– Obtain correct HS (Harmonized System) codes for customs classification (e.g., 8479.89 for machines of a kind used in industrial production)

– Prepare commercial invoices, packing lists, and certificates of origin

– Comply with ITAR, EAR, or other trade controls if components are subject to export restrictions

– Ensure adherence to destination country’s electrical and safety standards

Work with a licensed customs broker if necessary to avoid delays or penalties.

Workplace & Operational Compliance

When the bath bomb press is installed, ensure compliance with operational safety:

– Provide operator training and safety manuals in the local language

– Follow local regulations for machine guarding, noise levels, and workplace ergonomics

– Maintain records of maintenance, inspections, and employee training

Regularly audit equipment performance and safety protocols to prevent accidents and ensure uptime.

Environmental & Disposal Considerations

Address end-of-life equipment responsibly:

– Design with recyclable materials where possible

– Provide guidance for proper disposal of electrical and mechanical components

– Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions

Minimize environmental impact through energy-efficient motors and sustainable manufacturing practices.

Recordkeeping & Documentation

Maintain organized records for compliance and traceability:

– Technical design files and risk assessments

– Certificates of compliance (CE, UL, etc.)

– Shipping logs, warranty claims, and customer communications

– Maintenance and repair histories

Retain documentation for a minimum of 10 years, or as required by local regulations.

By following this guide, manufacturers and distributors of bath bomb presses can ensure safe, legal, and efficient operations across the supply chain.

In conclusion, sourcing a bath bomb press requires careful consideration of several key factors including production needs, budget, machine quality, and supplier reliability. Whether opting for a manual, semi-automatic, or fully automatic press, it is essential to align the equipment specifications with your manufacturing scale and long-term business goals. Conducting thorough research, requesting product demonstrations, and evaluating after-sales support can significantly reduce risks and ensure a sound investment. By partnering with reputable suppliers and prioritizing durability and ease of maintenance, businesses can enhance production efficiency, maintain product consistency, and support sustainable growth in the competitive bath and body market.