The global demand for cricket equipment has seen a notable surge, driven by the sport’s expanding popularity and increasing investments in player development—particularly across South Asia and emerging markets. According to a 2023 report by Mordor Intelligence, the global cricket equipment market is projected to grow at a CAGR of over 5.8% from 2023 to 2028. A critical component within this ecosystem is the bat roller machine, an essential tool used to compress and prepare willow cricket bats for optimal performance and durability. As manufacturers and training academies prioritize bat conditioning, the demand for high-quality, durable bat roller machines has intensified. This growth is further bolstered by rising participation in professional and amateur cricket, prompting both established and emerging players in the sports equipment manufacturing space to innovate in design, materials, and mechanical efficiency. Against this backdrop, we examine the top 5 bat roller machine manufacturers leading the charge in technological advancement, market reach, and customer trust.

Top 5 Bat Roller Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Big Dawg Bat Rolling: Expert Bat Performance Enhancement

Domain Est. 2009

Website: bigdawgbatrolling.com

Key Highlights: Unlock peak performance with expert bat optimization at Big Dawg Bat Rolling. Unmatched services, cutting-edge tech, and customer satisfaction. Explore now.Missing: machine manufa…

#2 BAT SCANDINAVIA

Domain Est. 2003

Website: batgroup.com

Key Highlights: BAT Group has been operating for over 30 years in the production of accessories and components for solar systems. BAT designs and manufactures systems and ……

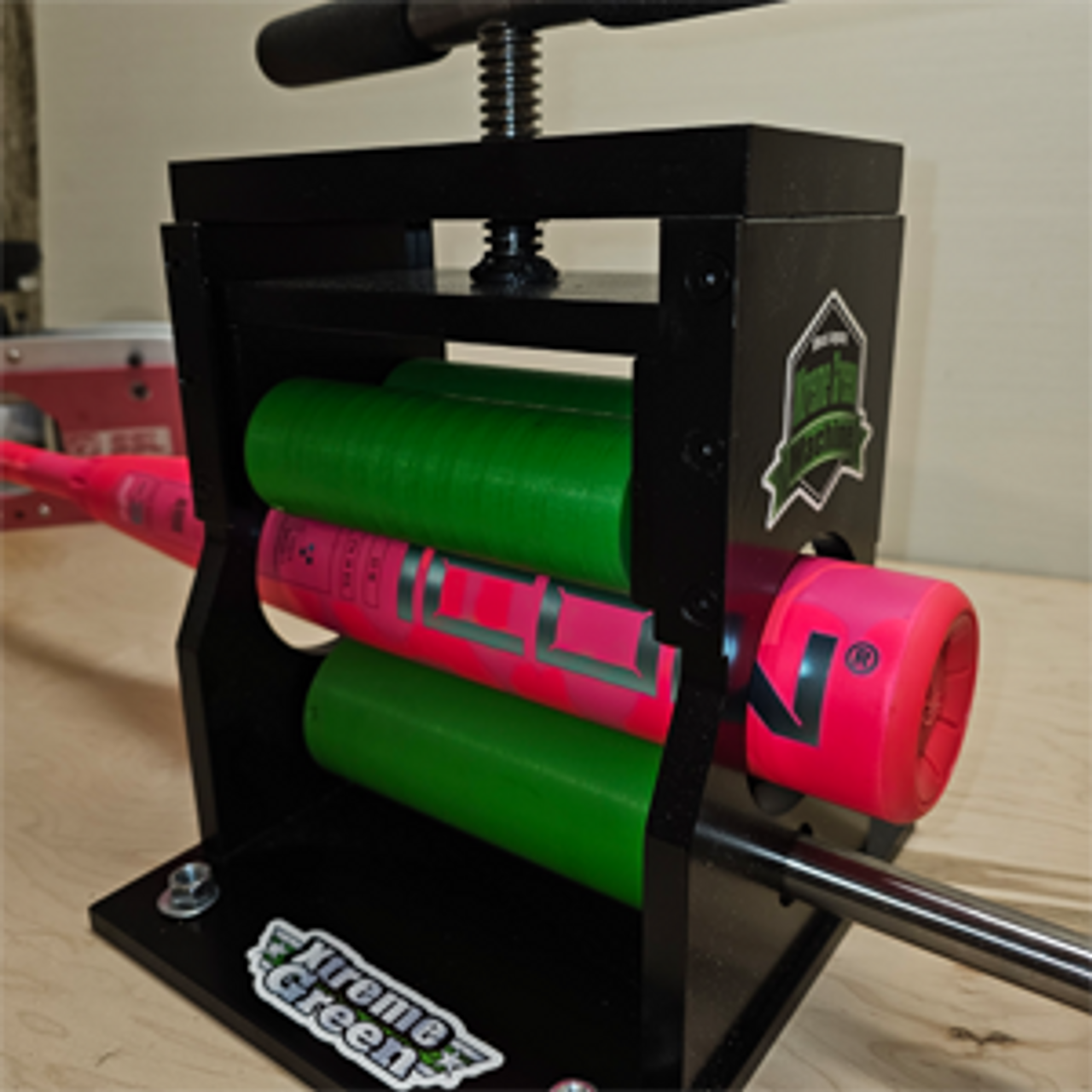

#3 BatRolling4u ProMax2 Bat Rolling & Shaving New Baseball Bats

Domain Est. 2008

#4 ProRollers Heated Baseball & Softball Bat Rolling Game Ready …

Domain Est. 2009

#5 Unleash your bat’s full potential!

Domain Est. 2014

Website: bat-rolling.ca

Key Highlights: We are your complete solution for your bat rolling needs. Bat-rolling.ca offers competitive pricing, flexible appointments and quick turnarounds….

Expert Sourcing Insights for Bat Roller Machine

2026 Market Trends for Bat Roller Machine: Key Dynamics Shaping the Industry

The bat roller machine market, a niche but vital segment within the custom baseball and softball bat tuning industry, is poised for notable evolution by 2026. Driven by technological advancements, shifting consumer behaviors, and regulatory scrutiny, the market landscape is expected to become more sophisticated and segmented. Here are the dominant trends shaping the future:

H2: Increasing Demand for High-Precision, Automated Roller Machines

By 2026, the market will see a significant shift towards advanced, computer-controlled bat roller machines. Operators and professional tuning services are increasingly demanding machines that offer unparalleled consistency, repeatability, and data tracking. Machines equipped with digital pressure sensors, programmable rolling profiles (for different bat models and materials), and automated rolling cycles will dominate the premium segment. This trend is fueled by the need to minimize human error, ensure uniform performance enhancement across multiple bats, and provide verifiable tuning logs—critical for competitive players and high-volume tuning businesses. Expect integration with mobile apps for profile management and performance analytics.

H2: Rise of Multi-Functional and Dual-Purpose Machines

To maximize value and cater to users who service both baseball and softball, manufacturers are developing multi-functional roller machines. By 2026, dual-mode machines capable of efficiently rolling both youth/adult baseball bats and fastpitch/slowpitch softball bats will gain market share. These machines feature adjustable roller configurations, interchangeable pressure settings, and modular components that allow quick conversion between bat types. This trend responds to the growing number of tuning businesses aiming to diversify their customer base without investing in separate equipment, enhancing operational efficiency and ROI.

H2: Emphasis on Portability and Compact Design for Mobile Services

With the proliferation of mobile bat rolling services—especially at tournaments, schools, and local events—there is a rising demand for lightweight, compact, and easily transportable machines. By 2026, leading manufacturers will focus on ergonomic designs that maintain performance while improving portability. Features such as foldable frames, integrated carrying handles, and reduced power requirements (enabling battery or generator operation) will become standard in mid-tier models. This trend supports the growing gig economy model in bat performance services and democratizes access to tuning for amateur leagues and individual players.

H2: Growing Regulatory and Warranty Compliance Awareness

As bat manufacturers continue to void warranties on rolled bats and governing bodies (e.g., NCAA, USSSA) enforce stricter bat performance standards (BPF, BBCOR), consumer awareness around compliance will intensify. In 2026, reputable roller machine providers will emphasize transparency, offering machines calibrated to operate within “legal performance limits” for specific leagues. Some manufacturers may partner with third-party testing labs to certify machine output, providing operators with compliance documentation. This trend reflects a maturing market where credibility and risk mitigation are paramount, especially as detection technologies for altered bats improve.

H2: Expansion of Direct-to-Consumer (DTC) and Online Sales Channels

The bat roller machine market will increasingly shift online by 2026, with manufacturers leveraging e-commerce platforms, social media marketing, and digital tutorials to reach DIY enthusiasts and small business owners. Subscription-based models for software updates (e.g., new rolling profiles), remote diagnostics, and online training courses will emerge. This digital transformation lowers entry barriers, enables global reach, and supports after-sales service, fostering a more connected and informed user community. However, it may also intensify competition, particularly from lower-cost international suppliers.

H2: Sustainability and Long-Term Durability as Purchase Drivers

Environmental and economic sustainability concerns will influence purchasing decisions. Buyers will prioritize machines built with durable, recyclable materials and energy-efficient motors. Extended warranties, modular designs for easy repairs, and availability of replacement parts will distinguish premium brands. By 2026, lifecycle cost analysis—factoring in maintenance, longevity, and energy use—will become a key differentiator, especially for commercial operators seeking reliable, long-term investments amid rising equipment costs.

In summary, the 2026 bat roller machine market will be defined by technological sophistication, user-centric design, regulatory awareness, and digital engagement. Success will depend on manufacturers’ ability to innovate while addressing compliance, portability, and sustainability—key concerns of an increasingly discerning customer base.

Common Pitfalls When Sourcing a Bat Roller Machine (Quality and Intellectual Property)

Sourcing a bat rolling machine—especially for performance enhancement in sports like cricket or baseball—can present significant challenges, particularly concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls is crucial for making informed, legally sound, and cost-effective procurement decisions.

Poor Build Quality and Performance Inconsistencies

Many low-cost bat roller machines, particularly those sourced from unverified suppliers or generic manufacturers, suffer from substandard materials and inconsistent engineering. This can lead to uneven pressure application, misalignment of rollers, or premature mechanical failure. Poorly built machines may damage bats instead of enhancing performance and require frequent maintenance or replacement, increasing long-term costs.

Lack of Precision Calibration

High-performance bat rolling requires precise control over roller pressure, speed, and alignment. Machines lacking proper calibration mechanisms often deliver inconsistent results, reducing the effectiveness of the rolling process. Buyers may assume all machines offer the same level of precision, but cheaper models frequently omit critical adjustment features, leading to unreliable outcomes.

Inadequate Safety Features

Some budget-friendly or DIY-style bat roller machines lack essential safety mechanisms such as emergency stop functions, protective guards, or secure clamping systems. This poses risks to operators and can result in equipment or bat damage. Overlooking safety in favor of cost savings can lead to liability issues and operational downtime.

Misrepresentation of Capabilities

Suppliers may exaggerate the machine’s capabilities—such as compatibility with various bat types, rolling speed, or durability—without providing verifiable testing data. Claims like “professional-grade” or “used by elite players” are often unverified marketing tactics. Due diligence, including third-party reviews or live demonstrations, is essential to avoid overpaying for underperforming equipment.

Intellectual Property Infringement Risks

A major legal pitfall involves sourcing machines that infringe on patented designs or proprietary technology. Some manufacturers replicate features from well-known branded rollers (e.g., specific roller configurations, loading mechanisms, or control systems) without licensing. Purchasing such equipment may expose the buyer to legal liability, especially if used commercially, and could result in seizures or lawsuits.

Use of Counterfeit or Unbranded Components

To cut costs, some machines use counterfeit bearings, motors, or control systems that fail prematurely or operate inefficiently. These components may not meet safety or performance standards, and their use can void warranties or compromise machine reliability. Transparent sourcing of parts and supplier certifications help mitigate this risk.

Limited After-Sales Support and Warranty

Low-cost machines often come with minimal or no after-sales service, technical support, or warranty coverage. When issues arise, sourcing replacement parts or qualified technicians can be difficult and expensive. Reliable customer support is critical for minimizing downtime and ensuring long-term usability.

Inadequate Documentation and Compliance

Machines sourced from non-reputable suppliers may lack proper user manuals, safety certifications (such as CE or UL), or compliance with regional electrical and mechanical standards. This not only creates operational risks but can also hinder legal use in commercial or public facilities.

Avoiding these pitfalls requires thorough vetting of suppliers, requesting references or demos, verifying IP status, and prioritizing quality and safety over initial cost savings. Investing in a reputable, compliant, and well-supported bat roller machine ultimately protects both performance goals and legal integrity.

Logistics & Compliance Guide for Bat Roller Machine

This guide outlines the essential logistics and compliance considerations for the transportation, import/export, and safe operation of Bat Roller Machines—equipment commonly used in the sport of cricket to maintain or alter the condition of cricket bats. Adherence to these guidelines ensures legal compliance, efficient shipping, and user safety.

Regulatory Compliance

Bat Roller Machines may be subject to various national and international regulations depending on their electrical specifications, materials, and intended use. Key compliance areas include:

- Electrical Safety Standards: Ensure the machine complies with relevant electrical safety certifications such as CE (Europe), UKCA (United Kingdom), or UL/ETL (United States). This includes voltage compatibility (e.g., 110V vs. 230V) and grounding requirements.

- Import/Export Regulations: When shipping across borders, verify tariff classifications (HS Code – typically under 8479.89 for general-purpose machinery). Declare the machine accurately to customs authorities to avoid delays or penalties.

- Prohibited Use in Competitive Play: Note that rolling cricket bats beyond permissible limits may violate cricket regulations (e.g., ICC or ECB rules). Include disclaimers stating that the machine is for training, maintenance, or personal use only, not to gain unfair advantage in sanctioned matches.

Packaging and Handling

Proper packaging is critical to prevent damage during transit:

- Use a robust wooden crate or heavy-duty cardboard box with internal foam or padding to secure moving parts, especially the roller mechanism and motor housing.

- Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” to guide handlers.

- Include assembly instructions and safety warnings inside the package.

Shipping and Transportation

Plan logistics based on machine size, weight, and destination:

- Domestic Shipping: Use freight carriers experienced with heavy machinery. For machines over 70 lbs (32 kg), palletized shipping with liftgate service is recommended.

- International Shipping: Work with a licensed freight forwarder to manage customs clearance, documentation (commercial invoice, packing list, bill of lading), and compliance with destination country standards.

- Shipping Documentation: Provide a detailed product description, value, country of origin, and end-user information to prevent customs delays.

Safety and User Compliance

Ensure end-users operate the machine safely and legally:

- Include a user manual with operational instructions, maintenance tips, and safety warnings (e.g., keep hands away from rollers during operation).

- Recommend use of personal protective equipment (PPE), such as safety glasses and closed-toe shoes.

- Advise against excessive rolling that could damage the bat or violate sports regulations.

Warranty and Support Logistics

- Clearly state warranty terms, including coverage duration, claim process, and return procedures for defective units.

- Offer technical support via email or phone; consider providing video tutorials for setup and troubleshooting.

- For international customers, specify whether spare parts and service are available locally or must be shipped from the manufacturer.

Adhering to this guide ensures smooth logistics operations and regulatory compliance while promoting safe and responsible use of Bat Roller Machines globally.

Conclusion for Sourcing a Bat Roller Machine:

Sourcing a bat roller machine requires careful consideration of several key factors including quality, durability, technical specifications, after-sales support, and cost-effectiveness. After evaluating various suppliers and models, it is evident that investing in a reliable, well-constructed machine from a reputable manufacturer ensures long-term performance and consistent results in bat preparation. Prioritizing machines with robust engineering, user-friendly design, and comprehensive warranty and service options will ultimately enhance efficiency and reduce downtime. Additionally, verifying compliance with relevant industry standards and obtaining feedback from existing users can further validate the decision. In conclusion, a strategic sourcing approach focused on quality, support, and value will lead to the acquisition of a bat roller machine that meets operational needs and supports the production of high-performance bats.