The global baseball equipment market has experienced steady growth over the past decade, driven by rising participation in youth and amateur leagues, increased investment in sports infrastructure, and growing demand for high-performance gear. According to a 2023 report by Mordor Intelligence, the global baseball equipment market was valued at USD 5.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028. A key segment within this market is baseball bats, where innovation in materials—such as composite, aluminum, and wood hybrids—has fueled demand across recreational and professional tiers. North America remains the largest regional market, supported by the enduring popularity of Major League Baseball (MLB) and robust school-level baseball programs. This growth trajectory has intensified competition among manufacturers, leading to rapid advancements in bat technology, performance analytics integration, and customization options. As consumer preferences shift toward lightweight, durable, and compliant equipment, a select group of manufacturers has emerged as industry leaders. Based on market presence, technological innovation, and customer reach, the following are the top 10 baseball bat companies shaping the future of the sport.

Top 10 Baseball Bat Companies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

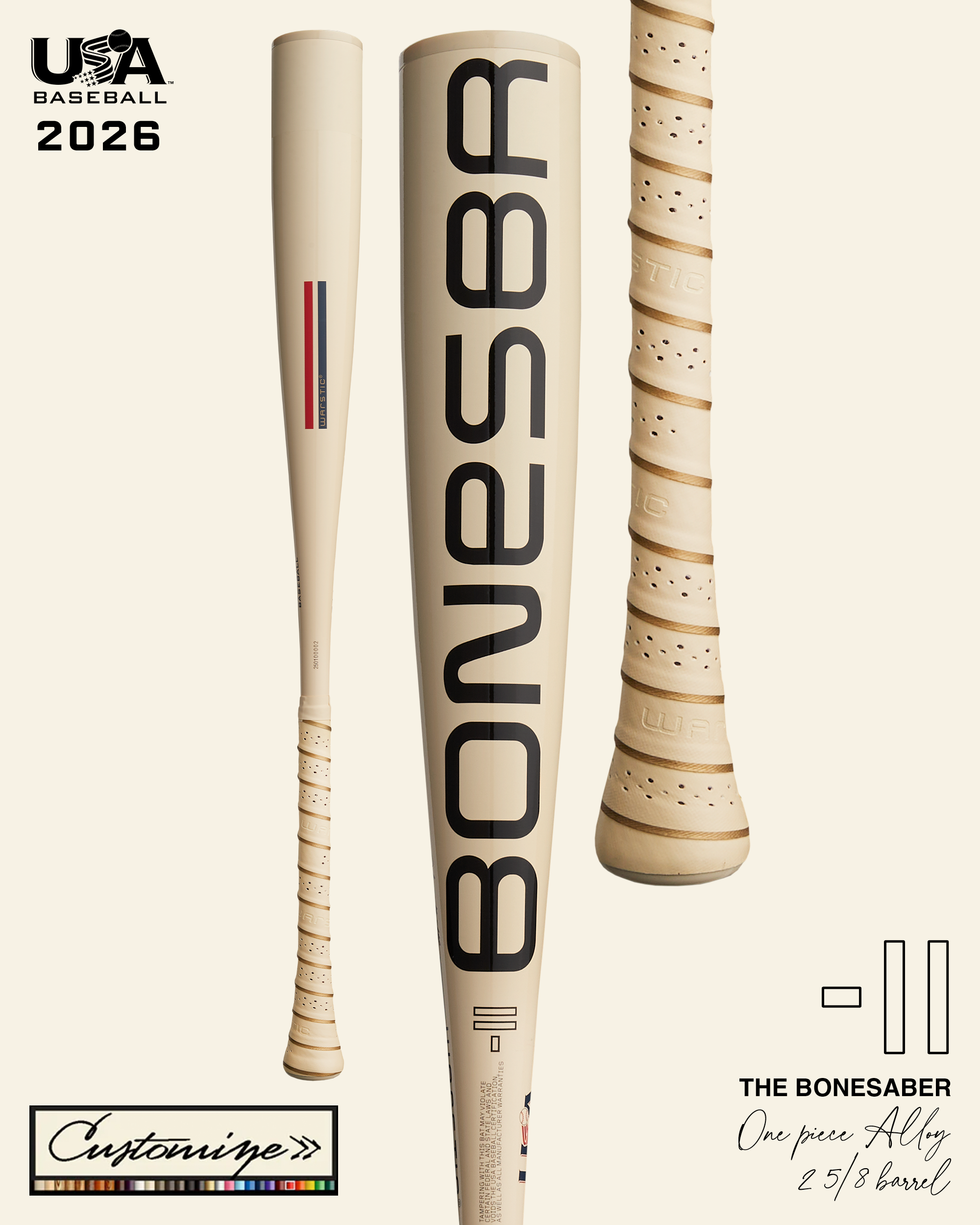

#1 Warstic

Domain Est. 2010 | Founded: 2011

Website: warstic.com

Key Highlights: Warstic Sports, Inc. is an independent, USA-based, direct-to-consumer focused sporting goods brand established in 2011. We make high-caliber hitting gear ……

#2 Rawlings Baseball & Softball Bats

Domain Est. 1995

Website: rawlings.com

Key Highlights: Free delivery over $35Rawlings is an industry leader in baseball & softball bats with options available for players of all ages. Champions choose Rawlings, find your new bat ……

#3 Wood Baseball Bats

Domain Est. 1995

Website: slugger.com

Key Highlights: Shop the latest and greatest from the authority on wooden baseball bats. Made from only the finest quality ash, birch, and maple….

#4 Old Hickory Bat Company

Domain Est. 1999

#5 Phoenix Baseball Bats

Domain Est. 1999

Website: phoenixbats.com

Key Highlights: 1–7 day delivery · 10-day returnsWood baseball and softball bats for every level from little league to pro. Highest quality ash, maple and birch baseball bats 100% made in USA….

#6 Maple Baseball Bats

Domain Est. 2001

Website: maxbats.com

Key Highlights: We live to produce the best custom wood bats on the market. We supply all players, of all levels, the bats they depend on to perform when they step in….

#7 Axe™

Domain Est. 2009

Website: axebat.com

Key Highlights: SHOP BY CATEGORY · a group of baseball bats. Built for power, precision, and peak performance. · a group of baseball bats. Featuring the Patented Axe Handle ……

#8 Victus Sports

Domain Est. 2012

Website: victussports.com

Key Highlights: Victus Sports produces handmade, pro-quality custom wood baseball bats. All Victus bats are design-driven, handcrafted, high quality wood bats….

#9 TUCCI

Domain Est. 2015

Website: tuccilimited.com

Key Highlights: Baseball’s next evolution is here. TUCCI is a premium baseball/softball brand that offers wood bats, metal/composite bats, batter protective equipment, ……

#10 Walter Bat Company

Domain Est. 2021

Website: walterbats.com

Key Highlights: American made wood baseball and softball bats for youth, college, and professional athletes. Custom and in stock bats available….

Expert Sourcing Insights for Baseball Bat Companies

2026 Market Trends for Baseball Bat Companies

The baseball bat industry is poised for significant evolution by 2026, shaped by technological innovation, shifting consumer behaviors, and growing emphasis on performance analytics. Companies that adapt to these emerging trends will gain a competitive edge in a market increasingly focused on customization, sustainability, and data-driven design.

1. Advanced Materials and Manufacturing Innovation

By 2026, bat manufacturers will increasingly utilize next-generation composite materials and hybrid alloys to enhance performance, durability, and feel. Expect wider adoption of nano-enhanced composites, 3D-printed internal structures, and AI-optimized barrel designs. These innovations will allow for lighter, stronger bats with larger sweet spots and improved energy transfer. Investment in proprietary material science and manufacturing processes will become a key differentiator, especially in the premium youth and amateur adult segments.

2. Data-Driven Personalization and Smart Bats

The integration of sensor technology and performance analytics will accelerate. Smart bats equipped with embedded sensors to track swing speed, launch angle, and contact quality will move beyond professional training into mainstream amateur and youth markets. Companies will leverage this data to offer personalized bat recommendations, custom tuning, and real-time feedback apps. By 2026, data connectivity and digital ecosystems will be central to brand value, fostering deeper customer engagement and repeat purchases.

3. Sustainability and Eco-Conscious Production

Environmental responsibility will become a major market driver. Consumers—particularly younger demographics—will favor brands that prioritize sustainable sourcing, recyclable materials, and reduced carbon footprints. Bat companies will respond by developing biodegradable composites, using reclaimed wood (especially for maple and ash), and adopting eco-friendly packaging. Transparency in supply chains and third-party sustainability certifications will be critical for brand credibility and market positioning.

4. Expansion in Youth and Amateur Markets

Youth baseball remains a core growth segment, with increasing parental investment in high-performance gear. By 2026, segmentation within youth bats will deepen, with specialized models for skill level, league regulations (e.g., USA Baseball standards), and position-specific needs. Customization options—such as grip color, length, and weight—will expand, driven by e-commerce platforms offering direct-to-consumer personalization. Additionally, the rise of amateur adult leagues will boost demand for advanced recreational bats.

5. E-Commerce and Direct-to-Consumer (DTC) Dominance

Online sales channels will continue to grow, with DTC models allowing brands to capture higher margins, collect valuable customer data, and control branding. Virtual try-on tools, augmented reality (AR) swing simulations, and AI-powered sizing guides will enhance the online shopping experience. Social media and influencer marketing will play a pivotal role in launching new models and engaging younger audiences, particularly in the high school and travel ball markets.

6. Regulatory and Safety Considerations

Ongoing rule changes by governing bodies (e.g., NCAA, NFHS, USA Baseball) around bat performance standards (BBCOR, USSSA) will require continuous R&D adaptation. Companies must remain agile to comply with evolving regulations while maintaining competitive performance. Additionally, enhanced safety standards—particularly in youth bats—will drive innovation in vibration dampening and impact resistance to reduce injury risks.

In summary, baseball bat companies in 2026 will need to balance cutting-edge technology with sustainability, personalization, and digital engagement. Success will depend on agility, data integration, and a customer-centric approach that meets the demands of a more informed and environmentally conscious consumer base.

Common Pitfalls When Sourcing Baseball Bat Companies: Quality and Intellectual Property Risks

Sourcing baseball bats from manufacturers, especially overseas, can be cost-effective but comes with significant risks if not managed carefully. Two of the most critical areas where companies stumble are quality control and intellectual property (IP) protection. Understanding these pitfalls is essential to avoid costly recalls, legal disputes, and reputational damage.

Quality Consistency and Material Defects

One of the most frequent issues when sourcing baseball bats is inconsistent product quality. Many manufacturers, particularly lower-tier suppliers, may lack rigorous quality assurance processes, resulting in bats that vary in weight, balance, and durability. Common problems include:

- Inconsistent wood grain or composite layering, leading to premature breakage during use.

- Poor finishing or rough edges, which can affect player safety and performance.

- Failure to meet league certification standards (e.g., BBCOR, USSSA, or USA Baseball), rendering the bats unusable in official games.

To mitigate this, buyers should conduct factory audits, require third-party inspections, and secure detailed product specifications in contracts.

Intellectual Property Infringement

Another major risk is unintentionally sourcing bats that infringe on existing trademarks, patents, or designs. Many manufacturers—especially in regions with lax IP enforcement—produce “knock-off” versions of popular bat models from well-known brands like Louisville Slugger, Rawlings, or Easton.

Key IP pitfalls include:

- Unauthorized use of brand names or logos, which can lead to customs seizures and legal action.

- Replication of patented bat technologies, such as proprietary barrel designs or composite materials.

- Design patent violations, even in subtle aesthetic details.

Sourcing from a supplier who cannot provide proof of IP ownership or licensing agreements exposes your business to litigation and supply chain disruption.

Lack of Transparency and Supplier Verification

Many sourcing failures stem from inadequate due diligence. Some suppliers misrepresent their capabilities, claim false certifications, or subcontract work to unapproved facilities. This opacity makes it difficult to trace quality issues or IP violations back to the source.

Best practices include verifying business licenses, visiting production facilities, and requiring documentation of material sourcing and design rights.

Conclusion

Avoiding these pitfalls requires a proactive approach: vet suppliers thoroughly, insist on quality certifications, and confirm full IP compliance before production. Investing time upfront in due diligence can save substantial legal and financial costs down the line.

Logistics & Compliance Guide for Baseball Bat Companies

Understanding International Trade Regulations

Baseball bat manufacturers and distributors must comply with international trade laws when importing or exporting products. Key considerations include country-specific import restrictions, tariffs, and customs documentation. Ensure compliance with the Harmonized System (HS) codes—typically under HS 9506.62 for baseball bats—to correctly classify goods and determine applicable duties. Work with customs brokers to streamline clearance and avoid delays.

Material Compliance and Restrictions

Baseball bats may be constructed from wood, aluminum, composite materials, or hybrids. Each material type is subject to different regulatory standards:

– Wooden bats generally face fewer restrictions but must comply with phytosanitary regulations (e.g., ISPM 15) if made from solid wood and shipped internationally.

– Metal and composite bats may be subject to safety and environmental regulations, such as REACH (EU) or CPSIA (U.S.), especially if components contain restricted substances.

Ensure all raw materials meet regional chemical and safety standards before production.

Product Certification and League Approvals

To sell bats commercially, especially in organized leagues, compliance with league-specific performance standards is essential:

– USA Baseball certification is required for youth bats in the U.S. (USA Baseball stamp).

– BBCOR (Batted Ball Coefficient of Restitution) certification is mandatory for high school and collegiate play.

– USSSA (United States Specialty Sports Association) has its own performance standard for youth leagues.

Maintain documentation of certification and ensure packaging and labeling clearly display required logos and compliance marks.

Labeling and Packaging Requirements

Proper labeling is critical for compliance and consumer transparency:

– Include manufacturer name, country of origin, material type, and model information.

– Display required certification marks (e.g., BBCOR, USA, USSSA).

– Comply with FTC “Made in USA” guidelines if claiming domestic production.

– Follow FALCPA (Food Allergen Labeling Act) if bats include any wood treatments with allergenic residues (rare, but possible).

Shipping and Distribution Logistics

Efficient logistics require planning for:

– Mode of transport: Air freight for time-sensitive orders; ocean freight for bulk shipments.

– Warehousing: Use climate-controlled facilities if storing composite bats, as extreme temperatures may affect performance.

– Inventory management: Track batch numbers and certifications to facilitate recalls if necessary.

– Last-mile delivery: Partner with reliable carriers experienced in handling sports equipment.

Import/Export Documentation

Ensure all shipments include:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of origin (if claiming preferential tariffs under trade agreements)

– Test reports or certificates of compliance (e.g., for BBCOR or safety standards)

Maintain records for a minimum of five years for audit purposes.

Environmental and Safety Compliance

- Follow OSHA regulations for workplace safety in manufacturing facilities.

- Comply with EPA and local regulations for waste disposal, especially from machining metals or composites.

- Address battery regulations if bats include electronic sensors (e.g., swing analyzers), which may be subject to IATA and DOT hazardous materials rules for transport.

Recalls and Product Liability

Establish a recall plan in case of non-compliance or safety issues:

– Register with the U.S. Consumer Product Safety Commission (CPSC) if selling in the U.S.

– Monitor customer feedback and field reports for performance or safety concerns.

– Report defects promptly and coordinate with retailers for product retrieval.

Recordkeeping and Audits

Maintain comprehensive records including:

– Supplier certifications

– Material test reports

– Compliance documentation (certifications, test results)

– Shipping and customs records

Regular internal audits help ensure ongoing compliance with regulatory and contractual requirements.

Working with Third Parties

When outsourcing manufacturing or logistics:

– Vet suppliers for compliance with labor, environmental, and safety standards.

– Include compliance clauses in contracts.

– Conduct periodic audits of third-party facilities to ensure alignment with your standards.

By adhering to this logistics and compliance framework, baseball bat companies can mitigate risks, enhance market access, and build trust with customers and regulators.

In conclusion, sourcing baseball bat companies requires a strategic approach that balances quality, cost, compliance, and reliability. By evaluating potential suppliers based on their manufacturing capabilities, materials used (such as aluminum, composite, or wood), industry certifications (like BBCOR or USA Baseball compliance), and reputation for consistency and customer service, businesses can identify trustworthy partners. It is essential to consider both domestic and international suppliers, weighing factors such as lead times, shipping costs, minimum order quantities, and communication efficiency. Conducting due diligence—through factory audits, sample testing, and reviewing client feedback—further mitigates risk. Ultimately, establishing strong partnerships with reputable baseball bat manufacturers ensures access to high-quality products that meet market demands and performance standards, supporting long-term success in the sports equipment industry.