The global barcode scanner market is experiencing robust growth, driven by increasing demand for automation and accuracy in retail, healthcare, logistics, and manufacturing sectors. According to Mordor Intelligence, the barcode scanner market was valued at USD 4.47 billion in 2023 and is projected to reach USD 6.38 billion by 2029, growing at a CAGR of 6.07% during the forecast period. A key trend fueling this expansion is the rising adoption of barcode scanners with integrated screens, which offer real-time data visibility, enhanced user interaction, and seamless integration with point-of-sale and inventory management systems. These devices combine scanning functionality with display capabilities, making them ideal for environments requiring instant verification and on-the-spot decision-making. As industries prioritize operational efficiency and digital transformation, manufacturers are responding with innovative, high-performance models. Based on production scale, technological capabilities, and market presence, the following analysis highlights the top 10 manufacturers leading the charge in barcode scanners with screens.

Top 10 Barcode Scanner With Screen Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AML Mobile Computers and Kiosks

Domain Est. 1996

Website: amltd.com

Key Highlights: AML is an American manufacturer of barcoding solutions including mobile computers, self-service kiosks, and forklift-mounted computers….

#2 1D/2D Barcode Scanners & NFC Readers for Retail & Industrial …

Domain Est. 2006

Website: socketmobile.com

Key Highlights: Mobile data capture with native OS integration. Barcode scanners and contactless reader writers providing control, speed, and accuracy….

#3 Newland AIDC

Domain Est. 2016

Website: newlandaidc.com

Key Highlights: Barcode Scanner. Superior 1D & 2D barcode scanning performance. · Mobile Terminal. Getting your business boosted with accurate real-time data communication….

#4 NetumScan Document Cameras, Barcode Scanner

Domain Est. 2019

Website: netumscan.com

Key Highlights: NetumScan Document Cameras & Barcode Scanner Manufacturer offers 1D, 2D, ccd, laser rfid, Wi-Fi, wirless, bluetooth, usb wired. Your Trusted Barcode Scanner ……

#5 General Purpose Handheld Scanners – Automation

Domain Est. 1988

Website: automation.honeywell.com

Key Highlights: The Voyager™ Extreme Performance (XP) 1470g scanner delivers accurate and reliable scanning capability on traditional barcodes and digital screens and wireless ……

#6 Products

Domain Est. 1994

Website: datalogic.com

Key Highlights: Our full range of barcode scanner products includes Fixed Retail Scanners, Hand Held Scanners, Mobile Computers, Sensors, Laser Marking Systems, Safety, Vision ……

#7 Barcode Scanners

Domain Est. 1995

Website: zebra.com

Key Highlights: Built for retail, healthcare, manufacturing and more, Zebra scanners are designed to meet real-world demands with unmatched versatility….

#8 2D Barcode Scanner (Gen 1)

Domain Est. 1996

Website: elotouch.com

Key Highlights: Improve self-service and price-checker applications with Elo’s 2D Barcode scanner that easily attaches to a variety of Elo touchscreen displays. Learn more….

#9 Barcode & Software Readers & Scanning

Domain Est. 1998

Website: codecorp.com

Key Highlights: Scan all barcode types with 99.9995% accuracy to empower exceptional care. Healthcare Barcode Scanners, Printers, Software & ID. Streamline workflows with ……

#10 Barcode and Vision

Domain Est. 1998

Website: bannerengineering.com

Key Highlights: Banner Engineering provides advanced barcode reading capabilities and vision sensors & smart cameras for traceability, inspection and quality control….

Expert Sourcing Insights for Barcode Scanner With Screen

2026 Market Trends for Barcode Scanners With Screens

Rising Demand in Retail and E-Commerce

The global expansion of e-commerce and omnichannel retail strategies is driving significant demand for barcode scanners with integrated screens. By 2026, these devices are expected to become essential tools for inventory management, point-of-sale (POS) operations, and order fulfillment. The need for real-time data visualization and instant transaction confirmation is pushing businesses to adopt scanners that combine scanning functionality with user-friendly displays, reducing dependency on external devices.

Integration with Mobile and Cloud Platforms

A key trend shaping the 2026 market is the deep integration of barcode scanners with screens into mobile operating systems and cloud-based enterprise software. Devices are increasingly designed to work seamlessly with inventory management systems, ERP platforms, and logistics software via Wi-Fi and Bluetooth connectivity. This enables real-time data syncing across distributed teams and warehouses, improving accuracy and operational efficiency.

Advancements in Display and User Interface Technology

By 2026, barcode scanners with screens are incorporating high-resolution color touchscreens, similar to smartphones. These enhanced interfaces allow users to navigate menus, view product details, confirm scans, and even process payments directly on the device. The shift toward intuitive UI design improves usability, especially in high-volume environments such as distribution centers and retail backrooms.

Growth in Emerging Markets

Emerging economies in Asia-Pacific, Latin America, and Africa are expected to see accelerated adoption of barcode scanners with screens due to digital transformation initiatives in small and medium enterprises (SMEs). Government support for digitizing retail and logistics, combined with decreasing hardware costs, is making these devices more accessible, fueling market expansion.

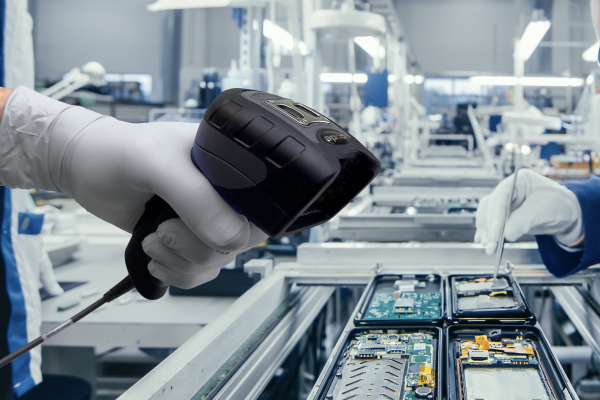

Focus on Rugged and Portable Designs

The 2026 market emphasizes durability and mobility. Manufacturers are introducing ruggedized models with long battery life, drop resistance, and IP-rated enclosures suitable for harsh industrial environments. These features cater to sectors like warehousing, manufacturing, and field service, where reliability and portability are critical.

Expansion into New Use Cases

Beyond traditional inventory and POS applications, barcode scanners with screens are being deployed in healthcare (for patient and medication tracking), logistics (for delivery confirmation), and event management (for ticketing and registration). The built-in screen enables interactive workflows, such as signature capture or form filling, broadening their utility.

Competitive Landscape and Innovation

The market is seeing increased competition from both established players and tech startups. Innovations such as AI-powered optical recognition, voice guidance, and multi-code scanning are differentiating next-gen models. Additionally, subscription-based models bundling hardware, software, and support services are gaining traction, especially among SMBs.

Sustainability and Lifecycle Management

Environmental concerns are influencing design choices, with manufacturers focusing on modular construction, recyclable materials, and energy-efficient components. By 2026, corporate procurement policies are expected to favor vendors offering sustainable lifecycle management, including take-back programs and device refurbishment.

In conclusion, the 2026 market for barcode scanners with screens is characterized by technological convergence, broader application scope, and global accessibility. Businesses that leverage these devices will benefit from improved operational visibility, faster workflows, and enhanced data accuracy across industries.

Common Pitfalls When Sourcing Barcode Scanners with Screens (Quality and IP Considerations)

Sourcing barcode scanners with integrated screens requires careful evaluation to ensure long-term reliability, performance, and suitability for the intended environment. Overlooking key quality and Ingress Protection (IP) rating factors can lead to increased downtime, higher maintenance costs, and operational inefficiencies. Below are common pitfalls to avoid:

1. Ignoring Build Quality and Durability

Many low-cost barcode scanners with screens are constructed using subpar materials that degrade quickly under regular use. Thin plastics, weak screen adhesives, and flimsy connectors can result in cracked screens, unresponsive touch interfaces, or internal component damage. Always assess the device’s physical robustness—especially if used in industrial, warehouse, or field service environments.

2. Overlooking IP Rating for the Operating Environment

Selecting a scanner without verifying its Ingress Protection (IP) rating against the operating environment is a frequent mistake. For example, a device rated IP54 may resist dust and splashes but is unsuitable for outdoor rain exposure or high-dust warehouse settings where IP65 or higher is needed. Mismatched IP ratings lead to premature failures due to water or particulate intrusion.

3. Assuming All Touchscreens Are Equal

Not all integrated screens offer the same usability. Resistive touchscreens may fail with gloved hands or in wet conditions, while capacitive screens may not respond reliably. Ensure the screen technology aligns with user needs—especially in cold storage, manufacturing, or healthcare settings where gloves or moisture are common.

4. Prioritizing Cost Over Long-Term Reliability

Choosing the cheapest option often results in poor component quality, limited software support, and shorter lifespans. Low-cost scanners may lack firmware updates, spare parts availability, or manufacturer support, increasing total cost of ownership. Investing in reputable brands with proven track records reduces the risk of field failures and service interruptions.

5. Neglecting Environmental Testing and Certifications

Some suppliers claim ruggedness without third-party validation. Always verify that the device has undergone drop, vibration, temperature, and sealing tests (e.g., MIL-STD-810, IP certification reports). Absence of certified testing results in unreliable performance under real-world conditions.

6. Underestimating Screen Visibility in Challenging Lighting

A high-resolution screen is ineffective if it cannot be read in direct sunlight or low-light areas. Scanners with poor screen brightness (measured in nits) or lack of anti-reflective coating lead to user errors and reduced productivity. Ensure the display offers adequate brightness and viewing angles for the deployment environment.

7. Failing to Verify Sealing Around Screen Edges

Even with a high IP rating, poor manufacturing can leave gaps between the screen and housing, creating entry points for dust and moisture. Inspect sample units for seamless bezels and proper gasketing. Poor sealing often leads to internal corrosion and touchscreen failure over time.

8. Overlooking Software and Firmware Stability

Integrated screens require stable operating systems and firmware. Devices with frequent crashes, slow response times, or incompatible software integrations disrupt workflows. Evaluate software reliability through pilot testing and check for regular updates from the manufacturer.

By proactively addressing these pitfalls—focusing on verified build quality, appropriate IP ratings, and real-world usability—organizations can source barcode scanners with screens that deliver durable, efficient, and cost-effective performance.

Logistics & Compliance Guide for Barcode Scanner With Screen

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for your barcode scanner with screen to ensure accurate customs declaration. This product typically falls under HS Code 8471.41 or 8471.49 (portable automatic data processing machines), depending on processing capabilities. Confirm with local customs authorities, as misclassification can lead to delays, fines, or shipment rejection.

Regulatory Compliance

Ensure the device meets regional regulatory standards prior to import or sale:

– FCC (USA): Comply with electromagnetic interference (EMI) standards under Part 15.

– CE (Europe): Meet requirements under the RED (Radio Equipment Directive), RoHS (Restriction of Hazardous Substances), and EMC (Electromagnetic Compatibility) directives.

– UKCA (UK): Equivalent to CE marking for products placed on the UK market.

– ISED (Canada): Certification for radio frequency devices.

– KC (South Korea), MIC (Japan), ANATEL (Brazil): Country-specific certifications may apply.

Documentation such as test reports and conformity certificates must be retained and provided upon request.

Battery Safety & Transportation

If the barcode scanner contains a built-in lithium-ion battery:

– Comply with UN 38.3 testing requirements for lithium batteries.

– Package devices according to IATA/IMDG/ADR regulations for air, sea, or ground transport.

– Clearly label shipments with proper Class 9 hazardous material markings when required.

– Include a Safety Data Sheet (SDS) and ensure shippers are trained in dangerous goods handling.

Labeling & Packaging Requirements

Ensure packaging includes:

– Clear product identification (model number, serial number).

– Compliance marks (FCC, CE, RoHS, etc.).

– Battery safety warnings (if applicable).

– Language-specific labels based on destination country (e.g., Spanish for Latin America, French for Canada).

– Barcodes or RFID tags for internal logistics tracking.

Import Duties & Taxation

Calculate and prepare for applicable import duties, VAT, or GST based on the destination country. Provide a detailed commercial invoice with:

– Accurate product description.

– Harmonized System (HS) code.

– Country of origin.

– Declared value (should reflect fair market value).

– Incoterms (e.g., FOB, DDP) to clarify responsibility for shipping and customs.

Software & Data Security Compliance

If the device stores or transmits data:

– Comply with data protection regulations such as GDPR (EU), CCPA (California), or PIPL (China).

– Ensure secure boot and firmware update mechanisms if used in regulated environments.

– Provide documentation on data handling practices and encryption standards.

Warranty & After-Sales Support Logistics

Plan for reverse logistics related to repairs, returns, or replacements:

– Establish authorized service centers or return locations in key markets.

– Include warranty terms and support contact information in local languages.

– Comply with local consumer protection laws regarding return periods and repair timelines.

Environmental & Disposal Regulations

Adhere to end-of-life disposal requirements:

– Comply with WEEE (Waste Electrical and Electronic Equipment) in Europe.

– Follow local e-waste recycling laws in the destination country.

– Provide take-back instructions or partner with certified e-waste recyclers.

Documentation & Record Keeping

Maintain accurate records for audits and customs inspections, including:

– Bill of lading/airway bill.

– Commercial invoice and packing list.

– Certificates of compliance (FCC, CE, etc.).

– Battery test reports (UN 38.3).

– Risk assessments and technical files.

Retain records for a minimum of 5–10 years depending on jurisdiction.

Conclusion:

After evaluating various options, sourcing a barcode scanner with an integrated screen proves to be a valuable investment for improving operational efficiency, accuracy, and user experience. These devices combine the functionality of scanning with real-time data visibility, enabling faster decision-making and reducing reliance on external devices such as smartphones or tablets. Key benefits include improved workflow in inventory management, retail point-of-sale systems, warehouse operations, and field services.

When selecting a barcode scanner with a screen, factors such as screen size and clarity, battery life, durability (especially in rugged environments), connectivity options (Bluetooth, Wi-Fi), ease of integration with existing software, and overall total cost of ownership should be carefully considered. Leading models from brands like Zebra, Honeywell, and Datalogic offer reliable performance and advanced features tailored to diverse business needs.

Ultimately, choosing the right barcode scanner with a screen depends on the specific requirements of your operations. By prioritizing usability, durability, and compatibility, businesses can enhance productivity, reduce errors, and achieve a strong return on investment. Therefore, it is recommended to pilot a shortlist of devices in real-world conditions before full-scale deployment to ensure optimal fit and performance.