The global barcode reader market is experiencing robust growth, driven by increasing adoption of automation across retail, healthcare, logistics, and manufacturing sectors. According to Mordor Intelligence, the barcode scanner market was valued at USD 4.98 billion in 2023 and is projected to reach USD 7.45 billion by 2029, growing at a CAGR of 6.87% during the forecast period. A significant contributor to this expansion is the rising demand for wireless barcode readers, which offer enhanced mobility, real-time data capture, and seamless integration with inventory and point-of-sale systems. Advancements in Bluetooth technology, longer battery life, and ruggedized designs have further fueled the shift from wired to wireless solutions. As businesses prioritize operational efficiency and accuracy, the competitive landscape has seen a surge in innovative manufacturers specializing in wireless barcode reading technology. Based on market presence, product performance, technological innovation, and global reach, the following are the top 10 wireless barcode reader manufacturers shaping the industry.

Top 10 Barcode Reader Wireless Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 1D/2D Barcode Scanners & NFC Readers for Retail & Industrial …

Domain Est. 2006

Website: socketmobile.com

Key Highlights: Mobile data capture with native OS integration. Barcode scanners and contactless reader writers providing control, speed, and accuracy….

#2 General Purpose Handheld Scanners – Automation

Domain Est. 1988

Website: automation.honeywell.com

Key Highlights: Handheld barcode scanners: wired and wireless Bluetooth® scanners that can read even poor quality or damaged ones. Designed for POS and day-to-day ……

#3 Products

Domain Est. 1994

Website: datalogic.com

Key Highlights: Our full range of barcode scanner products includes Fixed Retail Scanners, Hand Held Scanners, Mobile Computers, Sensors, Laser Marking Systems, Safety, Vision ……

#4 Barcode Scanners

Domain Est. 1995

Website: zebra.com

Key Highlights: Built for retail, healthcare, manufacturing and more, Zebra scanners are designed to meet real-world demands with unmatched versatility….

#5 Barcode & Software Readers & Scanning

Domain Est. 1998

Website: codecorp.com

Key Highlights: Scan all barcode types with 99.9995% accuracy to empower exceptional care. Healthcare Barcode Scanners, Printers, Software & ID. Streamline workflows with ……

#6 Barcode Scanner For 2D, Bluetooth Wireless, iPhone & Android

Domain Est. 1998

#7 Barcode and Vision

Domain Est. 1998

Website: bannerengineering.com

Key Highlights: Banner Engineering provides advanced barcode reading capabilities and vision sensors & smart cameras for traceability, inspection and quality control….

#8

Domain Est. 2002

Website: koamtac.com

Key Highlights: Our mission is simple: to make the best, easy-to-use, competitively-priced Bluetooth barcode scanners, RFID readers, mPOS companions, and power solutions….

#9 Barcode Scanner,Barcode Reader,Barcode Solutions

Domain Est. 2018

Website: syblecode.com

Key Highlights: We are professional manufacture of barcode scanner, to produce Laser ,Linear ,2D barcode scanner,wireless ,Bluetooth barcode scanner etc….

#10 Wireless & Bluetooth Barcode Scanners

Domain Est. 2021

Website: barcode-usa.com

Key Highlights: Free delivery 30-day returnsWireless, Bluetooth, and Cordless Barcode Scanners and Bar code readers. Pair to Tablets, Computers, ipads, Android, Windows, Surface Pro, iphones and m…

Expert Sourcing Insights for Barcode Reader Wireless

2026 Market Trends for Wireless Barcode Readers

The wireless barcode reader market is poised for significant evolution by 2026, driven by technological advancements, shifting industry demands, and the increasing need for real-time data integration. Key trends shaping the landscape include:

Accelerated Adoption of Advanced Imaging and AI Integration

By 2026, wireless barcode readers will increasingly leverage high-resolution imaging sensors and artificial intelligence (AI) to enhance performance. Unlike traditional laser scanners, imager-based readers can decode damaged, poorly printed, or 2D barcodes (like QR and Data Matrix) with greater accuracy. AI-powered decoding algorithms will enable faster and more reliable scans in challenging conditions—such as low light, extreme angles, or on curved surfaces—especially in logistics, warehousing, and retail environments where operational efficiency is critical.

Expansion of IoT and Cloud Connectivity

Integration with the Internet of Things (IoT) and cloud-based platforms will become standard. Wireless barcode readers will not only transmit scanned data via Bluetooth or Wi-Fi but also connect directly to enterprise resource planning (ERP), warehouse management systems (WMS), and cloud analytics platforms in real time. This seamless connectivity allows businesses to monitor inventory levels, track asset movement, and gain actionable insights, improving supply chain visibility and decision-making across sectors like manufacturing, healthcare, and e-commerce fulfillment.

Growing Demand in E-Commerce and Last-Mile Delivery

The continued growth of e-commerce, particularly in emerging markets, will fuel demand for portable and rugged wireless barcode readers. By 2026, logistics companies and delivery services will rely heavily on handheld and wearable wireless scanners to manage high-volume order processing, returns, and real-time package tracking. Devices with long battery life, durable designs, and ergonomic form factors will be in high demand to support mobile workforces and improve last-mile delivery accuracy.

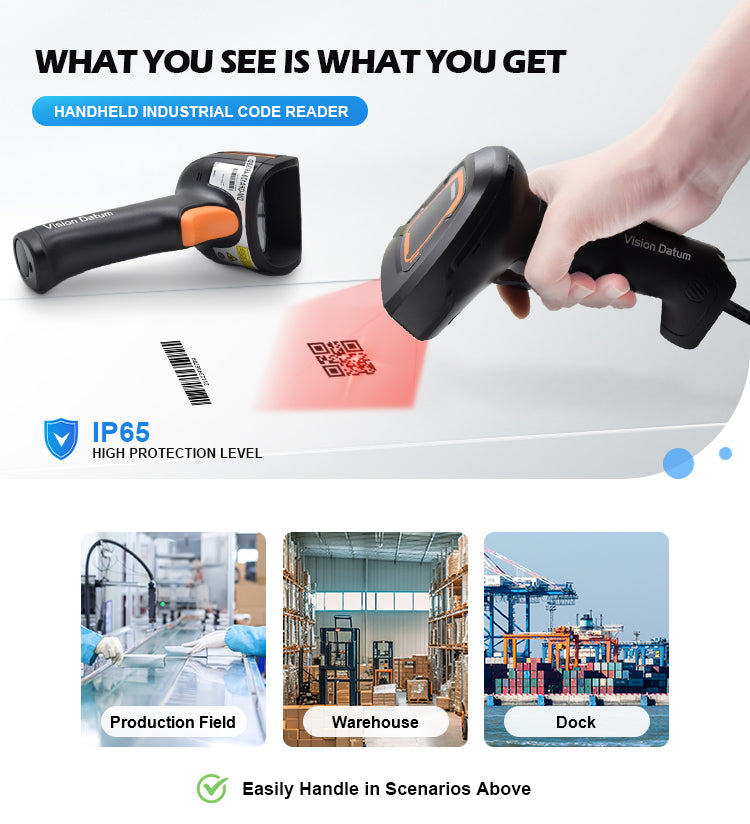

Shift Toward Rugged and Hygienic Designs in Specialized Industries

Industries such as healthcare, food & beverage, and pharmaceuticals will drive demand for wireless barcode readers with antimicrobial coatings, IP65+ ratings for dust and water resistance, and easy-to-clean surfaces. In healthcare, wireless devices will support patient safety initiatives by enabling accurate medication administration and specimen tracking without tethered constraints. Similarly, ruggedized models will dominate in manufacturing and field service applications where equipment must withstand harsh environments.

Increased Focus on Security and Data Encryption

As wireless data transmission becomes more ubiquitous, security will be a paramount concern. By 2026, leading manufacturers will incorporate end-to-end encryption, secure pairing protocols (e.g., Bluetooth 5.3+), and compliance with data protection regulations (such as GDPR and HIPAA). This is especially critical in sectors handling sensitive information, ensuring that barcode data cannot be intercepted or tampered with during transit.

Emergence of Wearable and Hands-Free Solutions

Wearable wireless barcode readers—such as ring scanners and smart glasses—will gain traction, particularly in warehouse and retail settings where hands-free operation improves productivity. These devices allow workers to scan items without holding a traditional scanner, enabling faster order picking, cycle counting, and inventory management. Advances in miniaturization and battery efficiency will make wearables more practical and cost-effective by 2026.

Sustainability and Battery Innovation

Environmental concerns will influence product design, with manufacturers focusing on energy-efficient components and recyclable materials. Battery technology will improve to support longer operational life (multi-shift usage) and faster charging, reducing downtime and total cost of ownership. Solar-assisted charging and energy-harvesting technologies may begin to appear in niche applications.

In summary, the 2026 wireless barcode reader market will be defined by smarter, more connected, and more resilient devices. Businesses that adopt these advanced solutions will benefit from improved operational efficiency, enhanced data accuracy, and greater agility in an increasingly digital economy.

Common Pitfalls When Sourcing Wireless Barcode Readers (Quality, IP Rating)

Sourcing wireless barcode readers requires careful evaluation to ensure reliability, durability, and performance in real-world environments. Overlooking critical factors—especially quality and Ingress Protection (IP) ratings—can lead to operational inefficiencies, increased costs, and system downtime. Below are common pitfalls to avoid:

Underestimating Build Quality and Component Reliability

Many low-cost wireless barcode readers use subpar materials and components to reduce price, leading to frequent failures. Poorly constructed scanners may suffer from fragile triggers, weak antennas, or unreliable internal circuitry. Always evaluate the manufacturer’s reputation, warranty terms, and customer reviews. Prioritize devices from established brands known for industrial-grade durability, especially if used in demanding environments like warehouses or manufacturing.

Ignoring IP Rating Requirements for the Operating Environment

The IP (Ingress Protection) rating indicates resistance to dust and moisture. A common mistake is selecting a reader with insufficient protection for its intended use. For example, using an IP52-rated device in a washdown environment or a dusty warehouse can result in rapid degradation. Always match the IP rating to the environment:

– IP54 or higher for indoor industrial settings with dust

– IP65 or higher for areas exposed to water jets or cleaning

– IP67 or higher for full dust tightness and temporary water submersion

Overlooking Battery Life and Charging Infrastructure Compatibility

Wireless readers depend on battery performance. Poor battery life leads to frequent recharging, disrupting workflow. Additionally, some models use proprietary charging docks or batteries that are costly to replace. Ensure the scanner offers sufficient runtime for a full shift and consider standard battery types or hot-swappable options. Verify compatibility with existing charging stations or IT infrastructure.

Assuming All Wireless Technologies Perform Equally

Bluetooth, Wi-Fi (802.11), and proprietary RF each have trade-offs in range, latency, and network load. Choosing the wrong wireless protocol can lead to connection drops, interference, or data loss. For instance, standard Bluetooth may struggle in high-interference areas, while Wi-Fi models require robust network coverage. Assess your facility’s wireless infrastructure and select a reader with the appropriate technology and roaming support.

Neglecting Scan Engine Quality and Compatibility

Not all scan engines perform equally across barcode types (1D, 2D, damaged, or low-contrast codes). A low-quality imager may fail to read common barcodes, causing delays. Ensure the reader supports the symbologies used in your operations and has strong motion tolerance and depth of field. Test the scanner with your actual barcode types before bulk purchasing.

Failing to Verify Software and System Integration

Wireless readers must integrate seamlessly with existing software (WMS, ERP, etc.). Proprietary SDKs or lack of support for common interfaces (HID, SPP, or keyboard wedge) can complicate deployment. Confirm compatibility with your operating systems (Windows, Android, iOS) and middleware requirements early in the sourcing process.

Skipping Environmental and Drop Testing Validation

Even with a high IP rating, real-world durability depends on drop resistance and operating temperature range. Readers used in cold storage or outdoor logistics must function in extreme temperatures. Check for MIL-STD-810G certification or similar standards to ensure the device can withstand drops, vibrations, and thermal stress.

Avoiding these pitfalls ensures you source a wireless barcode reader that delivers long-term value, minimizes downtime, and supports efficient operations. Always conduct pilot testing in your actual working environment before full deployment.

Logistics & Compliance Guide for Barcode Reader Wireless

Product Overview

The Wireless Barcode Reader is a portable, battery-powered scanning device designed for efficient data capture in retail, warehousing, and logistics environments. It communicates via Bluetooth or Wi-Fi to compatible host systems, enabling real-time inventory tracking and point-of-sale operations. This guide outlines logistics handling, transportation, and regulatory compliance requirements.

Packaging and Labeling Requirements

Ensure all units are shipped in manufacturer-sealed packaging with anti-static protection. Include the following on external packaging:

– Product name and model number

– FCC ID, CE mark, and RoHS compliance symbols

– Battery safety warnings (if applicable)

– Wireless compliance statements (e.g., “Complies with 47 CFR Part 15”)

– Handling icons (e.g., “Fragile,” “Do Not Stack”)

Shipping and Transportation

Ship via ground or air freight in accordance with IATA/IMDG regulations if lithium-ion batteries are included. Use temperature-controlled environments when shipping in extreme climates. Units must be secured to prevent movement during transit. Avoid exposure to moisture, dust, or electromagnetic interference. Maintain a logistics chain with humidity below 80% and temperatures between 10°C and 40°C.

Regulatory Compliance

The Wireless Barcode Reader complies with the following international standards:

– FCC Part 15 (USA): Ensures electromagnetic compatibility and limits radio frequency emissions.

– CE Marking (EU): Meets EU directives for Radio Equipment (RED), EMC, and RoHS.

– IC RSS-247 (Canada): Complies with radio standards for license-free devices.

– ISED Certification: Required for wireless operation in Canada.

– REACH and RoHS (EU): Restricts hazardous substances in electronic components.

Ensure all documentation, including Declaration of Conformity (DoC), is available for customs and regulatory audits.

Import and Customs Documentation

Provide the following for international shipments:

– Commercial invoice with HS code (typically 8471.90 for data input devices)

– Packing list detailing contents and weights

– Certificate of Origin

– FCC/ISED/CE compliance documentation

– Battery safety data sheet (if applicable)

Verify country-specific import regulations—some regions may require local certification (e.g., KC mark for South Korea, ANATEL for Brazil).

Battery Safety and Handling

If the device contains a rechargeable lithium-ion battery:

– Comply with UN 38.3 testing requirements

– Limit battery state of charge to ≤30% during shipping

– Package to prevent short circuits and physical damage

– Include proper Class 9 lithium battery labels on outer packaging

Environmental and Disposal Compliance

Dispose of end-of-life units in accordance with WEEE (EU) and local e-waste regulations. Do not dispose of in regular trash. Partner with certified electronic recyclers to ensure responsible material recovery and data security.

Quality Assurance and Traceability

Maintain batch-level traceability through serial number tracking. Conduct pre-shipment inspections to verify packaging integrity, functionality, and label accuracy. Retain compliance records for a minimum of five years.

Contact and Support

For compliance inquiries or logistics support, contact:

Compliance Department

Email: [email protected]

Phone: +1 (800) 555-0199

Documentation Portal: https://docs.example.com/wireless-barcode-reader

Conclusion: Sourcing a Wireless Barcode Reader

After evaluating various options and considerations, sourcing a wireless barcode reader proves to be a strategic decision for improving operational efficiency, mobility, and data accuracy across inventory management, warehousing, retail, and logistics environments. Wireless barcode readers eliminate the constraints of cords, allowing for greater flexibility and productivity in dynamic work settings.

Key factors such as compatibility with existing systems, battery life, scanning performance, durability, and connectivity options (e.g., Bluetooth, Wi-Fi) should guide the selection process. Additionally, assessing total cost of ownership—including maintenance, scalability, and vendor support—ensures long-term value.

By choosing a reliable and high-performing wireless barcode reader from a reputable supplier, businesses can streamline workflows, reduce human error, and enhance overall operational effectiveness. Investing in the right solution today sets the foundation for scalable, future-ready data capture processes.