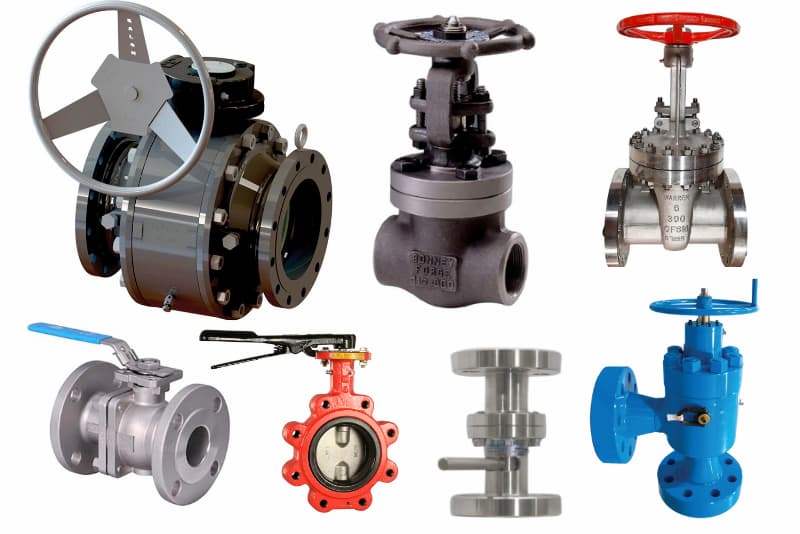

The global ball valve market is experiencing robust growth, driven by increasing demand across industries such as oil & gas, chemical processing, water treatment, and power generation. According to a 2023 report by Grand View Research, the global ball valve market size was valued at USD 8.67 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This expansion is fueled by infrastructure development, rising energy consumption, and the need for efficient flow control systems in industrial automation. Additionally, Mordor Intelligence projects steady growth, citing advancements in valve materials and actuation technologies as key contributors to market evolution. In this dynamic landscape, identifying leading manufacturers becomes crucial for sourcing high-performance, reliable ball valves. Based on market presence, product innovation, global reach, and compliance with international standards, here are the top 10 ball valve manufacturers shaping the industry today.

Top 10 Ball Valve Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powell Valves: Industrial Valve Manufacturer

Domain Est. 1998

Website: powellvalves.com

Key Highlights: Powell Valves has been a leading industrial manufacturer, providing high-quality gate, globe, check, bellow-seal & non-return valves. Contact a valve expert ……

#2 Control Valve Suppliers, Industrial Valve Manufacturer & Distributors

Domain Est. 2001

Website: valtorc.com

Key Highlights: Comprehensive Solutions – Ball valves, butterfly valves, control valves, actuators, fittings, and more; Customer-Focused Service – Quick Ship options, on-site ……

#3 Bonney Forge

Domain Est. 1996

Website: bonneyforge.com

Key Highlights: Bonney Forge is a leading manufacturer of Forged and Cast Steel Valves,Olets*/Pipets*, Forged Steel Fittings and Unions, and Specialty Products….

#4 American Valve

Domain Est. 1997

Website: americanvalve.com

Key Highlights: Replace your stuck, crusty gate valves with valves that actually work. Our 4000 Series ball valves are the most reliable on the market, and trusted by ……

#5 Cooper® Valves

Domain Est. 2005

Website: coopervalves.com

Key Highlights: American original manufacturer of high alloy valves and nickel valves in a global market. We offer a large assortment of valve types….

#6 Valve Manufacturer and Supplier

Domain Est. 2009

Website: valveman.com

Key Highlights: ValveMan delivers reliable valve solutions for every industry. Find top-quality ball valves, check valves, and more with fast shipping and expert support….

#7 Valves

Domain Est. 2012

Website: klinger-international.com

Key Highlights: KLINGER offers a wide range of industrial valves, including ball valves, butterfly valves, piston valves, gate valves, globe valves, check valves, knife gate ……

#8 Jamesbury™ ball valves

Domain Est. 1991

Website: valmet.com

Key Highlights: Jamesbury ball valves are reliable and long-lasting valves. Their cycle life of can be as much as 100 times longer than with competitive products….

#9 KITZ

Domain Est. 1996

Website: kitz.com

Key Highlights: Through the manufacture and sale of valves that control the flow of water, air, oil and gas, the KITZ Group contributes to today’s affluent society….

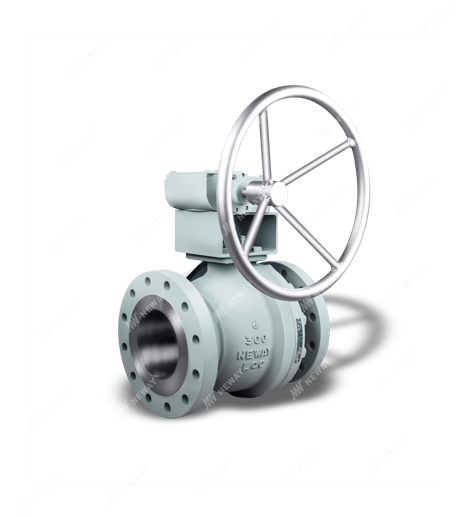

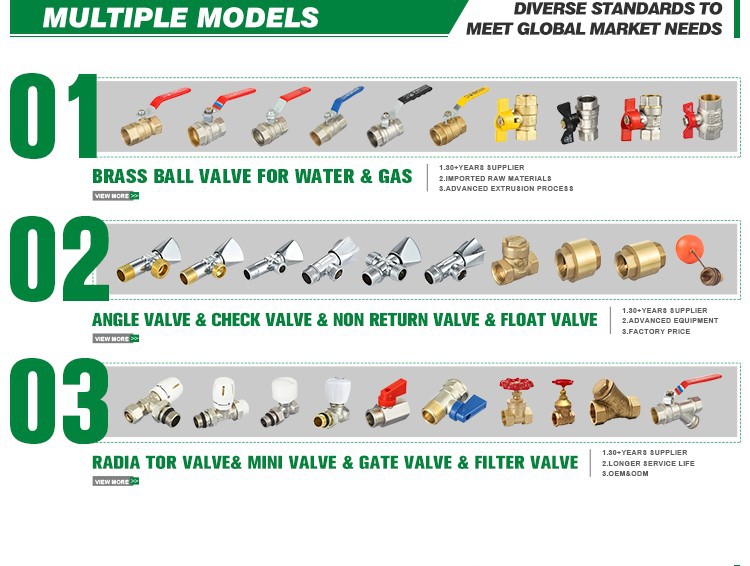

#10 Product Catalogsnewayvalve

Domain Est. 2002

Website: newayvalve.com

Key Highlights: Forged Valve · Ball Valve · Floating Ball Valve · Trunnion Mounted Ball Valve · Double Ball · Other Type Ball Valve · Butterfly Valve · Concentric Butterfly ……

Expert Sourcing Insights for Ball Valve Types

H2: 2026 Market Trends for Ball Valve Types

By 2026, the global ball valve market is poised for significant transformation driven by technological advancements, evolving industry demands, and sustainability imperatives. Key trends shaping specific ball valve types include:

1. Dominance of Trunnion-Mounted Ball Valves in High-Pressure Applications:

Trunnion-mounted ball valves are expected to maintain strong growth, particularly in oil & gas (upstream, midstream, and LNG), petrochemicals, and high-pressure power generation. Their superior stability and lower operating torque under extreme pressures (above 600 psi) make them indispensable. The expansion of deepwater drilling and pipeline infrastructure in regions like the Middle East, North America, and Asia-Pacific will further boost demand for trunnion-mounted designs with enhanced materials (e.g., super duplex stainless steel, alloy 625) and fire-safe certifications.

2. Rising Adoption of Metal-Seated Ball Valves for Harsh Environments:

Metal-seated ball valves will see accelerated adoption in applications involving high temperatures, abrasive media, or stringent fugitive emission requirements—such as refining, chemical processing, and power plants. Innovations in hard-facing technologies (Stellite, tungsten carbide) and advanced sealing systems will improve cycle life and reliability. Regulatory tightening on emissions (e.g., EPA, ISO 15848) will push industries toward metal-seated valves capable of zero leakage performance, especially in critical services.

3. Growth in Cryogenic Ball Valves Driven by LNG and Hydrogen Economy:

The global push toward cleaner energy will significantly expand the LNG sector and emerging hydrogen infrastructure, driving demand for cryogenic ball valves. These specialized valves, designed for temperatures as low as -196°C, will benefit from material enhancements (cryogenic-treated stainless steel) and extended bonnets to protect packing. By 2026, increased investments in hydrogen production, storage, and transport will create new opportunities for cryogenic and hydrogen-compatible ball valves with ISO 21010 and KTA 3404 certifications.

4. Smart and Automated Ball Valves Gaining Traction:

Integration of digitalization and Industry 4.0 principles will elevate demand for automated ball valves (pneumatic, electric, hydraulic actuators) with smart capabilities. Valves equipped with positioners, sensors, and IIoT connectivity will enable predictive maintenance, remote monitoring, and improved process control. The water & wastewater, pharmaceutical, and food & beverage sectors will increasingly adopt smart ball valve solutions to enhance efficiency and compliance.

5. Compact and Lightweight Designs for Space-Constrained Applications:

In offshore platforms, modular plants, and retrofit projects, compact and lightweight ball valve designs (e.g., reduced-port, segment ball valves) will gain preference. Manufacturers will focus on reducing valve weight through advanced alloys and optimized body designs without compromising performance, contributing to lower installation and logistics costs.

In conclusion, by 2026, the ball valve market will be characterized by specialization and performance optimization. Trunnion-mounted and metal-seated valves will dominate critical industrial applications, while cryogenic and smart valve technologies will expand rapidly in response to energy transition and digital transformation trends.

Common Pitfalls Sourcing Ball Valve Types (Quality, IP)

When sourcing ball valves, especially for critical applications, overlooking key quality and Ingress Protection (IP) factors can lead to system failures, safety hazards, and costly downtime. Below are common pitfalls to avoid:

Inadequate Material Quality and Certification

Sourcing ball valves without verifying material certifications (e.g., ASTM, ISO, or EN standards) can result in valves made from substandard alloys. This compromises corrosion resistance, pressure ratings, and longevity—especially in harsh environments like chemical processing or offshore installations.

Misunderstanding IP Ratings for Enclosures

Many buyers assume all ball valves have weatherproof or dust-tight actuators. However, the IP rating applies primarily to the actuator (electric/pneumatic), not the valve body. Failing to confirm the IP65, IP67, or higher rating for the actuator can lead to moisture or dust ingress, causing electrical faults or mechanical failure.

Overlooking Seat and Seal Material Compatibility

Valve performance heavily depends on seat materials (e.g., PTFE, RTFE, metal). Sourcing without checking chemical compatibility between the seal material and the process media can result in rapid degradation, leaks, or contamination.

Ignoring Pressure and Temperature Ratings

Selecting a ball valve based only on nominal pipe size without verifying its pressure (PSI/Bar) and temperature ratings for the specific application can lead to catastrophic failure under operating conditions, particularly in high-pressure steam or cryogenic systems.

Procuring from Non-Reputable Suppliers

To cut costs, some buyers source from uncertified or unknown manufacturers. This increases the risk of counterfeit products, inconsistent quality, and lack of traceability—jeopardizing compliance with industry standards like API 6D or ISO 5211.

Neglecting End Connection Standards

Mismatched end connections (e.g., threaded, flanged, socket weld) due to sourcing valves without confirming ANSI, DIN, or JIS standards can lead to installation issues, leaks, or the need for costly adapters.

Assuming All “Stainless Steel” Valves Are Equal

Not all stainless steel valves offer the same corrosion resistance. For example, 304 SS may suffice for water, but 316 SS or duplex grades are needed for chloride-rich environments. Sourcing without specifying the correct grade risks premature failure.

Failing to Verify Third-Party Testing and Traceability

Lack of documentation such as Material Test Reports (MTRs), Pressure Test Certificates (e.g., ANSI B16.34), or NDT reports undermines quality assurance, especially in regulated industries like oil & gas or pharmaceuticals.

Avoiding these pitfalls requires clear technical specifications, supplier vetting, and attention to both valve body performance and actuator IP protection.

Logistics & Compliance Guide for Ball Valve Types

This guide outlines key logistics considerations and compliance requirements for various types of ball valves used in industrial applications. Proper handling, transportation, documentation, and regulatory adherence are essential to ensure safety, performance, and legal compliance throughout the supply chain.

Full Port vs. Reduced Port Ball Valves

Logistics Considerations:

– Weight and Dimensions: Full port ball valves are typically larger and heavier than reduced port versions due to the oversized bore. Ensure packaging and palletization accommodate size differences.

– Storage: Store both types in dry, temperature-controlled environments to prevent corrosion. Use protective caps on ends to avoid debris ingress.

– Transportation: Secure valves with adequate bracing during transit. Full port valves may require special lifting equipment due to increased mass.

Compliance Requirements:

– Material Certifications: Provide Mill Test Certificates (MTCs) per EN 10204 3.1 or 3.2 for body and trim materials.

– Pressure Ratings: Ensure valves comply with ASME B16.34 or ISO 10497 for fire testing and pressure-temperature ratings.

– Marking: Permanent valve body marking must include manufacturer name, size, class, material grade, and applicable standards.

Floating vs. Trunnion Mounted Ball Valves

Logistics Considerations:

– Packaging: Trunnion-mounted valves, often used in high-pressure applications, require robust wooden crates with internal cushioning to protect stem and bearing assemblies.

– Handling: Use lifting lugs if provided; never lift by the actuator or stem. Floating ball valves may be lighter but still require careful handling to avoid seat damage.

– Inventory Management: Clearly label trunnion valves as high-pressure equipment to prevent misuse in low-pressure systems.

Compliance Requirements:

– Design Standards: Conform to API 6D for pipeline valves, especially for trunnion-mounted types used in oil & gas.

– Testing: Perform shell and seat leakage tests per API 598 or ISO 5208. Fire-safe testing per API 607/API 6FA may be required.

– Export Controls: Trunnion valves used in critical infrastructure may be subject to ITAR or EAR regulations—verify export classification.

Top-Entry, Side-Entry, and Three-Piece Ball Valves

Logistics Considerations:

– Modularity: Three-piece valves allow disassembly for cleaning or repair—ensure all bolts, gaskets, and components are packed together with identification tags.

– Fragile Components: Top-entry valves have precision-machined top caps; use padded dividers in shipping containers.

– Custom Crating: Side-entry valves with offset designs may require custom crates to prevent stress on the body during transport.

Compliance Requirements:

– Hygiene Standards (if applicable): For three-piece valves used in food, beverage, or pharmaceutical industries, ensure compliance with 3-A Sanitary Standards and EHEDG guidelines.

– Material Traceability: Full traceability (heat numbers) for wetted parts required under FDA 21 CFR or EU 1935/2004 for sanitary applications.

– Assembly Documentation: Provide assembly and reassembly instructions with torque specifications to ensure compliance with operational safety standards.

V-Port (V-Ball) and Multi-Port Ball Valves

Logistics Considerations:

– Precision Handling: V-ball valves have machined V-shaped balls—protect from impact to maintain flow control accuracy.

– Orientation: Multi-port valves (e.g., 4-way) must be shipped in correct orientation; include clear labeling and installation diagrams.

– Actuator Compatibility: If shipped with actuators, verify mounting interface (ISO 5211) and protect actuator components during transit.

Compliance Requirements:

– Flow Characterization: V-ball valves used in control applications may require flow coefficient (Cv) certification per ISA-75.01.01.

– Functional Safety: If used in SIS (Safety Instrumented Systems), comply with IEC 61508/61511 for valve assembly certification (SIL rating).

– Custom Design Approvals: Multi-port configurations may need third-party validation (e.g., DNV, Lloyd’s Register) for offshore or marine use.

General Compliance & Documentation

- Certificates of Conformance (CoC): Must accompany each shipment, listing standards met, test results, and material compliance.

- REACH & RoHS: Confirm valve materials (e.g., brass, coatings) comply with EU REACH (SVHC) and RoHS directives.

- PED Compliance: For valves in pressurized systems within the EU, ensure conformity with Pressure Equipment Directive 2014/68/EU and affix CE marking with notified body involvement if applicable.

- Customs Documentation: Provide accurate HS codes (e.g., 8481.80 for ball valves), country of origin, and valuation for smooth international clearance.

Storage & Handling Best Practices

- Store valves upright with end caps installed.

- Avoid exposure to moisture, salts, and extreme temperatures.

- Rotate stock using FIFO (First In, First Out) to prevent long-term storage issues.

- Inspect packaging upon receipt and report damages immediately.

Adhering to this logistics and compliance guide ensures ball valves maintain integrity from manufacturer to end-user and meet global regulatory expectations.

Conclusion on Sourcing Ball Valve Types

In conclusion, sourcing the appropriate ball valve type requires a thorough understanding of application requirements, including pressure, temperature, media compatibility, flow control needs, and regulatory standards. Different ball valve designs—such as full port vs. reduced port, floating vs. trunnion-mounted, and one-piece, two-piece, or three-piece bodies—offer distinct advantages depending on the use case. Material selection (e.g., brass, stainless steel, PVC) and end connections (threaded, welded, flanged) further influence performance and longevity.

When sourcing, it is essential to balance cost, quality, and reliability by partnering with reputable suppliers who provide certifications, test reports, and compliance with industry standards (e.g., ISO, API, ANSI). Evaluating factors such as maintenance requirements, actuation options, and environmental conditions ensures optimal valve performance and system efficiency.

Ultimately, selecting the right ball valve involves a strategic approach that aligns technical specifications with operational demands, leading to improved safety, reduced downtime, and long-term cost savings across industrial, commercial, and residential applications.