The global valve lockout devices market is experiencing steady growth, driven by increasing emphasis on workplace safety and compliance with OSHA and other industrial safety regulations. According to Grand View Research, the global energy lockout/tagout (LOTO) devices market was valued at USD 892.8 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising industrial automation, rigorous safety protocols in sectors such as oil & gas, chemical processing, and manufacturing, and the need for reliable isolation solutions during equipment maintenance. Ball valve lockout devices, in particular, represent a critical segment of this market due to their widespread use in controlling fluid flow systems. With demand on the rise, several manufacturers have emerged as leaders in innovation, durability, and compliance. Based on market presence, product offerings, and industry reputation, here are the top 9 ball valve lockout device manufacturers shaping the current safety landscape.

Top 9 Ball Valve Lockout Device Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Valve Lockouts

Domain Est. 1995

Website: masterlock.com

Key Highlights: Adjustable Ball Valve Lockout Device. List Price: $60.89. Compare Compare. S3080. 4-leg … Supplier Code of Conduct | Site Map….

#2 V500 Universal Ball Valve Lockout Device

Domain Est. 1995

Website: abus.com

Key Highlights: This cable lock establishes a connection between the valve handle and a fixed point, effectively immobilizing the ball valve and fortifying it….

#3 Brady® Ball Valve Lockout

Domain Est. 1995

Website: seton.com

Key Highlights: In stock $9.95 deliveryThese valve lockouts lock valves in closed position Seton’s top-quality Ball Valve Lockout will ship quickly, backed by our 100% Satisfaction Guarantee!…

#4 Ball Valve Lockout Devices

Domain Est. 1997

Website: emedco.com

Key Highlights: 1–7 day deliveryEnsure safe LOTO with ball valve lockout kits. Shop universal, Prinzing, steel, and PVC devices for all valve sizes. OSHA-compliant selection….

#5 Brady Official Product

Domain Est. 1998

Website: bradyid.com

Key Highlights: 1-day delivery 7-day returnsThis single-piece lockout device has an adjustable design that provides a secure fit when locking out T-handle ball valves on PVC pipes….

#6 STOPOUT® Ball Valve Lockouts

Domain Est. 2002

Website: accuform.com

Key Highlights: In stock Rating 5.0 (1) Unique and easy-to-use lockout has two wingspan halves that hinge to quickly and simply secure over any closed ball valve handle….

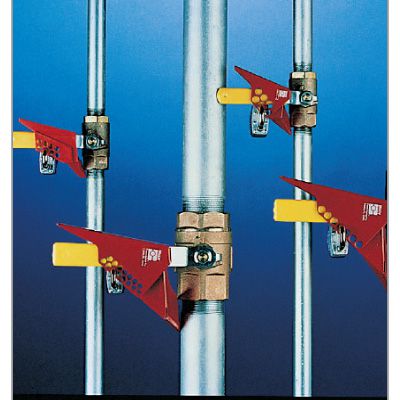

#7 Ball Valve Lockout

Domain Est. 2003

Website: safetylock.net

Key Highlights: Ball Valve Lockout Devices are used to lock ball valves during LOTO. Buy Ball valve lockouts in different materials Steel, PVC, non-metallic, semi-metallic….

#8 Ball Valve Lockout For 12 to 114

Domain Est. 2012

#9 Valve Lockouts

Domain Est. 2024

Website: epsafe.com

Key Highlights: We provide a full range of valve locking solutions, covering various types such as ball valves, gate valves, and butterfly valves….

Expert Sourcing Insights for Ball Valve Lockout Device

H2: 2026 Market Trends for Ball Valve Lockout Devices

The market for Ball Valve Lockout Devices (BVLDs) in 2026 is poised for steady growth, driven primarily by heightened global safety standards, regulatory enforcement, and the expansion of industrial automation. Key trends shaping the landscape include:

1. Regulatory Pressure and Compliance Focus:

Stringent occupational health and safety regulations, particularly OSHA (US), EU-OSHA (Europe), and similar bodies in emerging markets, continue to mandate robust Lockout/Tagout (LOTO) procedures. Companies are investing heavily in compliant safety equipment to avoid penalties and reduce liability. By 2026, stricter enforcement and updates to ISO 45001 and ANSI Z244.1 standards will further accelerate demand for certified BVLDs across manufacturing, oil & gas, and utilities sectors.

2. Growth in Industrial Automation and Smart Safety Integration:

The rise of Industry 4.0 is influencing LOTO practices. In 2026, there is increased interest in integrating traditional mechanical lockout devices with digital systems. Trends include QR-coded or RFID-enabled BVLDs that interface with safety management software for digital record-keeping, audit trails, and real-time monitoring. This enhances accountability and streamlines compliance reporting.

3. Expansion in Emerging Economies:

Industrial growth in Asia-Pacific (especially India and Southeast Asia), the Middle East, and parts of Latin America is driving infrastructure and energy projects. As these regions adopt formal safety protocols, demand for affordable and standardized BVLDs is rising. Local manufacturing and distribution partnerships are emerging to meet this demand.

4. Product Innovation and Material Advancements:

To address diverse operating environments, manufacturers are introducing BVLDs made from corrosion-resistant materials (e.g., reinforced polymers, stainless steel) suitable for extreme temperatures, chemical exposure, and outdoor use. Modular and universal designs that fit a wider range of valve sizes and types are gaining popularity to reduce inventory complexity.

5. Emphasis on Ergonomics and User Safety:

Human factors are increasingly influential. BVLDs in 2026 feature improved ergonomics—easier installation, clear visual indicators, and compatibility with multiple lock types (padlocks, hasps)—to reduce human error and ensure consistent use. Training-focused kits and color-coded systems are also being adopted to enhance worker understanding.

6. Sustainability and Durability:

With a growing focus on sustainability, manufacturers are offering longer-lasting, recyclable BVLDs that reduce waste. Durable designs lower total cost of ownership and align with corporate ESG (Environmental, Social, Governance) goals.

Conclusion:

By 2026, the Ball Valve Lockout Device market will be characterized by smarter, more durable, and globally compliant solutions. The convergence of regulatory demands, digital integration, and industrial growth—especially in emerging markets—will underpin sustained market expansion, with innovation focused on enhancing safety, efficiency, and traceability in high-risk environments.

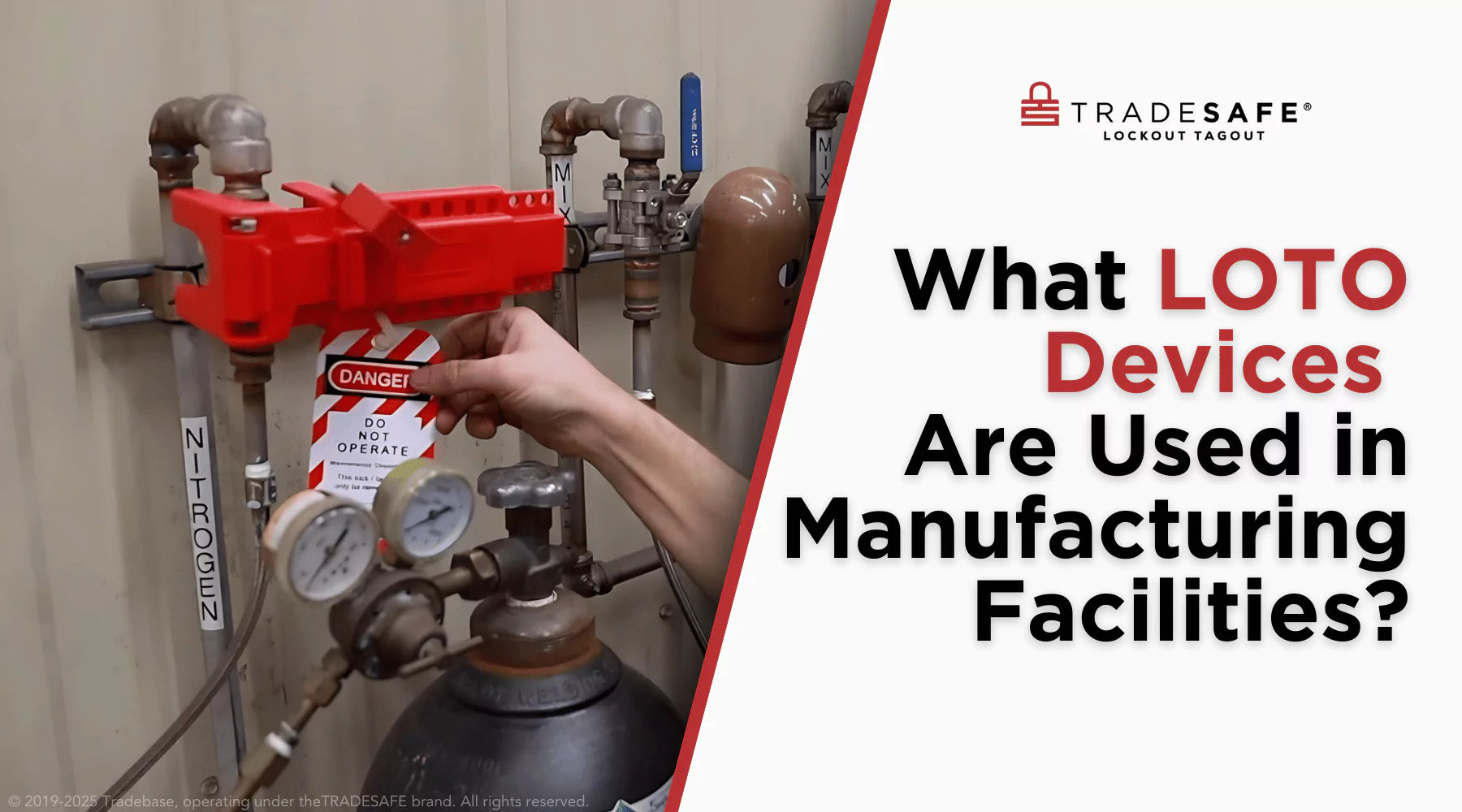

Common Pitfalls When Sourcing Ball Valve Lockout Devices (Quality & IP)

Sourcing the right Ball Valve Lockout Device is critical for ensuring workplace safety during maintenance and repair operations. However, several common pitfalls related to quality and Ingress Protection (IP) ratings can compromise safety and compliance. Avoiding these issues is essential for effective lockout/tagout (LOTO) procedures.

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting low-cost lockout devices without evaluating their construction and durability. Cheaply made devices often use brittle plastics or substandard metals that can crack, deform, or fail under stress. This compromises worker safety and may not meet OSHA or other regulatory standards. Always assess material quality—look for UV-resistant, impact-resistant polymers or corrosion-resistant metals like stainless steel or anodized aluminum.

2. Ignoring Ingress Protection (IP) Ratings

Many ball valve lockouts are used in harsh environments—outdoors, in chemical plants, or areas with high dust and moisture. Failing to verify the IP rating can result in selecting a device that is not adequately protected. For example:

- IP65 or higher is recommended for outdoor or washdown environments to prevent water and dust ingress.

- Devices without proper IP certification may degrade quickly, leading to mechanical failure or difficulty in locking/unlocking.

Always match the IP rating to the environmental conditions of the installation site.

3. Incompatible Valve Handle Sizes

Ball valves come in various handle shapes and sizes. A common pitfall is purchasing a one-size-fits-all lockout that does not securely accommodate all intended valve types. Devices that are too loose may slip off, while overly tight ones can damage the handle or be difficult to install. Ensure the lockout is adjustable or available in multiple sizes to fit round, lever, or extended handles properly.

4. Lack of Universal Compatibility

Some lockout devices are designed only for specific valve brands or models. This limits flexibility and increases inventory costs. Opt for universal designs that can be used across multiple valve types and manufacturers. Verify compatibility with common standards and check for modular or adaptable features.

5. Poor Locking Mechanism Design

The lockout must accept standard padlocks (typically up to 16mm shackle diameter). Devices with poorly designed hasps or flimsy locking points can be easily bypassed or broken. Look for robust, tamper-resistant locking points that ensure the device remains secured until intentionally removed by authorized personnel.

6. Overlooking Certification and Compliance

Always verify that the lockout device complies with relevant safety standards such as OSHA 29 CFR 1910.147, ANSI/ASSE Z244.1, or ISO standards. Devices without proper certification may not provide the required level of protection and could expose employers to liability in case of an incident.

7. Inadequate Supplier Due Diligence

Sourcing from unreliable suppliers increases the risk of receiving counterfeit or non-compliant products. Conduct due diligence: check customer reviews, request product samples, and verify the supplier’s track record in industrial safety equipment. Reputable suppliers should provide detailed specifications, test reports, and compliance documentation.

By addressing these common pitfalls—particularly around material quality, environmental protection (IP rating), compatibility, and compliance—you can ensure the ball valve lockout devices you source enhance safety, meet regulatory requirements, and perform reliably in real-world conditions.

Logistics & Compliance Guide for Ball Valve Lockout Device

Overview

This guide outlines the logistics and compliance requirements for the procurement, handling, storage, distribution, and regulatory adherence related to Ball Valve Lockout Devices. These devices are critical components of energy control programs (Lockout/Tagout – LOTO) used to ensure worker safety during equipment maintenance and servicing.

Regulatory Compliance

Ball Valve Lockout Devices must comply with relevant occupational health and safety standards, including but not limited to:

– OSHA 29 CFR 1910.147 (Control of Hazardous Energy) – Mandates the use of lockout procedures and appropriate lockout devices to isolate energy sources.

– ANSI Z244.1 – 2016 (Control of Hazardous Energy – Lockout, Tagout, and Alternative Methods) – Provides consensus standards for lockout device design and use.

– ISO 14118:2017 (Safety of machinery – Prevention of unexpected start-up) – International standard relevant for machinery safety, including energy isolation.

Ensure all devices are certified for use in applicable environments (e.g., non-conductive materials for electrical safety, corrosion-resistant materials for outdoor or chemical exposure).

Procurement & Sourcing

- Source Ball Valve Lockout Devices from suppliers compliant with ISO 9001 and OSHA-approved safety standards.

- Verify product specifications meet application requirements (e.g., valve handle size, material compatibility, extreme temperature resistance).

- Maintain documentation of supplier certifications, product test reports, and compliance statements.

- Implement a vendor assessment process to ensure ongoing regulatory and quality adherence.

Packaging & Labeling

- Devices must be individually packaged or grouped in protective packaging to prevent damage during transit.

- Each package must include:

- Product name and model number

- Compliance markings (e.g., OSHA-compliant, ANSI Z244.1)

- Material composition

- Manufacturer and part traceability

- Safety warnings and usage instructions (in local language if exported)

- Barcodes or QR codes for inventory and traceability tracking are recommended.

Storage & Inventory Management

- Store in a dry, temperature-controlled environment away from direct sunlight and corrosive agents.

- Follow FIFO (First In, First Out) inventory rotation to ensure product effectiveness.

- Conduct regular audits to verify stock levels, expiration dates (if applicable), and compliance with safety standards.

- Maintain a digital inventory system with records of purchase date, lot number, location, and compliance status.

Shipping & Distribution

- Use durable, tamper-evident outer packaging for shipments.

- Comply with international shipping regulations (e.g., IATA, IMDG) if transporting across borders, particularly for devices with metallic or conductive components.

- Include safety data sheets (SDS) if required by jurisdiction or material composition.

- Provide end-user documentation (installation guide, compliance certificate, LOTO procedure template).

End-User Compliance & Training

- Distribute lockout devices only to trained personnel or with mandatory training materials.

- Provide guidelines on proper application, inspection, and maintenance of the lockout device.

- Encourage integration into site-specific LOTO programs with documented procedures.

- Recommend annual inspection and retirement of damaged or worn devices.

Recordkeeping & Audits

- Retain records of compliance certifications, shipping documents, and customer training acknowledgments for a minimum of five years.

- Conduct annual internal audits to verify adherence to logistics and regulatory requirements.

- Prepare for external inspections by OSHA or other regulatory bodies with complete documentation.

Environmental & Disposal Considerations

- Follow local, state, and federal regulations for disposal of lockout devices, especially those containing plastics or metals.

- Encourage recycling programs where feasible.

- Avoid landfill disposal when materials are recyclable or hazardous.

Conclusion

Proper logistics and compliance management of Ball Valve Lockout Devices ensures both operational safety and adherence to legal requirements. By following this guide, organizations can maintain a safe workplace, avoid regulatory penalties, and ensure product reliability from procurement to end-use.

Conclusion:

After a thorough evaluation of sourcing options for ball valve lockout devices, it is evident that selecting the right supplier involves balancing quality, compliance, cost, and reliability. Ball valve lockout devices play a critical role in maintaining workplace safety by ensuring energy isolation during maintenance and repair operations, thus complying with OSHA and other safety standards.

Key considerations in the sourcing decision include material durability (such as UV-resistant plastics or rugged polymers), universal compatibility with various valve types and stem sizes, ease of installation, and certification to safety standards. Suppliers offering customizable or multi-position lockout devices can provide additional flexibility for diverse operational needs.

Sourcing from reputable manufacturers with proven track records in industrial safety equipment ensures reliable product performance and regulatory compliance. Additionally, evaluating lead times, customer support, and bulk pricing can further enhance cost-efficiency and supply chain resilience.

In conclusion, investing in high-quality ball valve lockout devices from trusted suppliers not only safeguards personnel and equipment but also strengthens overall safety culture and operational compliance. A strategic sourcing approach will ensure long-term value, reliability, and adherence to safety best practices across industrial environments.