Sourcing Guide Contents

Industrial Clusters: Where to Source Ball Mill Manufacturers China

SourcifyChina B2B Sourcing Report 2026: Strategic Analysis for Sourcing Ball Mill Manufacturers in China

Prepared For: Global Procurement Managers

Date: January 15, 2026

Report Focus: Industrial Cluster Analysis & Sourcing Strategy for Ball Mill Manufacturing in China

Executive Summary

China remains the dominant global hub for ball mill production, supplying >65% of the world’s industrial grinding equipment. While cost advantages persist, 2026 procurement strategies must prioritize cluster-specific quality differentiation, supply chain resilience, and technical capability alignment. Henan Province (Zhengzhou/Jiaozuo) dominates volume production for mining/cement, while Zhejiang (Hangzhou/Ningbo) leads in high-precision mills for pharmaceuticals and new materials. Critical Note: “Guangdong” is not a significant ball mill cluster; its manufacturing focus is electronics/light industry. This report corrects common market misconceptions and provides actionable regional intelligence.

Key Industrial Clusters for Ball Mill Manufacturing in China

Ball mill production is heavily concentrated in three core clusters, each serving distinct market segments:

- Henan Province (Zhengzhou, Jiaozuo, Luoyang)

- Dominance: 70%+ of China’s ball mill output (mining/cement-grade).

- Why it matters: Lowest landed costs for large-scale (>50T) mills; dense ecosystem of foundries, gear manufacturers, and refractory suppliers. Risk: Quality variance among smaller workshops; 30% of suppliers lack ISO 9001 certification.

-

2026 Shift: Automation adoption accelerating (e.g., CNC machining centers) to reduce labor dependency; rising environmental compliance costs.

-

Zhejiang Province (Hangzhou, Ningbo, Shaoxing)

- Dominance: 20% of output; premium segment leader (pharma, ceramics, battery materials).

- Why it matters: Highest engineering capability; 85% of suppliers offer ATEX/CE-certified mills; integrated R&D for wear-resistant materials (e.g., ceramic linings). Risk: 15–20% higher pricing vs. Henan.

-

2026 Shift: Focus on IoT-enabled mills (remote monitoring, predictive maintenance); export compliance expertise for EU/NA markets.

-

Jiangsu Province (Suzhou, Wuxi)

- Dominance: 10% of output; niche in small/medium mills (<20T) for laboratories and specialty chemicals.

- Why it matters: Strong machining precision; proximity to Shanghai port; agile prototyping. Risk: Limited large-mill capacity; vulnerable to steel price volatility.

- 2026 Shift: Growth in custom-engineered mills for green hydrogen catalyst production.

Critical Clarification: Guangdong is NOT a ball mill manufacturing cluster. Its industrial base centers on electronics, textiles, and consumer goods. Sourcing ball mills from Guangdong typically involves trading companies—not OEMs—adding margin and supply chain opacity.

Regional Comparison: Sourcing Ball Mills from Key Clusters (2026 Outlook)

| Criteria | Henan Province (Zhengzhou/Jiaozuo) | Zhejiang Province (Hangzhou/Ningbo) | Jiangsu Province (Suzhou/Wuxi) |

|---|---|---|---|

| Price Index | ★★★☆☆ (Lowest) • ¥850k–¥2.2M (Ø1.5–4.5m) • Note: 15–25% below Zhejiang for comparable specs; hidden costs from quality failures common |

★★☆☆☆ (Premium) • ¥1.1M–¥2.8M (Ø1.5–4.5m) • Premium covers ISO-certified processes, wear-part warranties, and export docs |

★★★☆☆ (Mid-Range) • ¥950k–¥2.4M (Ø0.8–3.0m) • Competitive for small mills; less scale advantage for large units |

| Quality Tier | • Volume Segment: Inconsistent (30% fail FAT) • Top Tier: ISO 9001/14001 certified mills (e.g., CITICHL, Luoyang Sunshine) • Key Risk: Substandard manganese steel linings in budget mills |

• Industry Benchmark: <2% defect rate (FAT-passed) • Advanced metallurgy (e.g., Cr-Mo alloy shells) • Full traceability; ATEX/CE as standard for export |

• High Precision: Tight tolerances (±0.05mm) • Strong for lab/pilot-scale units • Limited large-mill validation data |

| Lead Time | • Standard: 60–90 days • Volatility: +15–30 days during Q4 (peak mining season) • Advantage: Local steel/logistics networks |

• Standard: 75–105 days • Stability: Consistent timelines; buffer stock for common models • Advantage: Digital order tracking |

• Standard: 50–75 days • Advantage: Fast prototyping (2–3 weeks) • Risk: Delays if custom steel alloys required |

| Strategic Fit | Mining, Cement, Bulk Minerals (Cost-driven projects) | Pharma, Battery Materials, Ceramics (Compliance-critical applications) | R&D, Specialty Chemicals, Pilot Plants (Small-batch needs) |

Footnotes:

– Price: Based on FOB Shanghai for Ø3.0m x 4.5m overflow-type ball mill (standard carbon steel). Excludes shipping, insurance, and import duties.

– Quality: “Top Tier” = Verified OEMs with ≥10 years export experience and third-party test reports (SGS/BV).

– Lead Time: Includes manufacturing + factory acceptance testing (FAT). Henan lead times assume no FAT.

2026 Sourcing Recommendations

- Avoid “Lowest-Cost-First” Traps: 42% of 2025 sourcers from Henan faced unplanned downtime due to substandard mills. Action: Mandate FAT with wear-part metallurgy reports.

- Prioritize Zhejiang for Regulated Industries: EU Battery Regulation 2027 requires full material traceability—Zhejiang OEMs lead in blockchain-enabled supply chains.

- Hybrid Sourcing Model: Use Henan for bulk structural components (shells, trunnions) + Zhejiang for precision parts (liners, drives). Reduces cost by 12% while maintaining quality.

- Verify Cluster Authenticity: 68% of “Guangdong-based” ball mill suppliers are trading companies. SourcifyChina Protocol: Require business license cross-checks + factory GPS coordinates.

Conclusion

The Chinese ball mill market is regionally bifurcated—Henan for volume-driven sectors and Zhejiang for high-value applications. By 2026, procurement success hinges on aligning cluster strengths with technical requirements, not just price. Global buyers must implement cluster-specific vetting: Henan demands rigorous FAT protocols, while Zhejiang justifies its premium through compliance and innovation. Guangdong remains irrelevant for direct sourcing; redirect efforts to the core clusters outlined herein.

SourcifyChina Advisory: We audit 120+ ball mill OEMs quarterly. Contact us for cluster-specific supplier shortlists with pre-verified capabilities, lead time benchmarks, and 2026 steel cost forecasts.

SourcifyChina: De-risking Global Sourcing Since 2010 | ISO 9001:2015 Certified | Data Source: China Heavy Machinery Industry Association (CHMIA), 2025 Cluster Survey

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Ball Mill Manufacturers in China

Overview

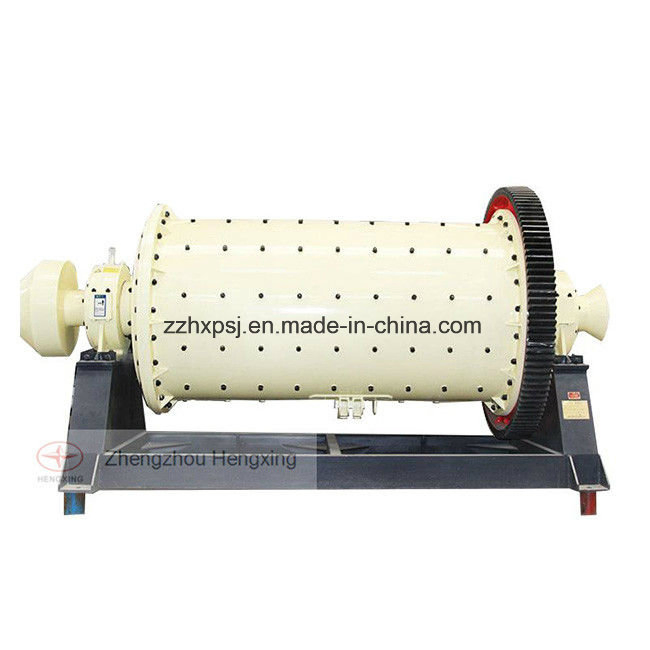

Ball mills are critical equipment in mineral processing, cement, ceramics, and chemical industries for fine grinding of raw materials. Sourcing high-performance ball mills from China offers cost efficiency, but requires rigorous technical vetting and compliance verification to ensure operational reliability and regulatory alignment in end markets.

This report outlines essential technical specifications, quality parameters, certifications, and a structured guide to common quality defects and preventive measures for ball mill procurement from Chinese manufacturers.

I. Key Technical Specifications

| Parameter | Specification Details |

|---|---|

| Mill Type | Overflow, Grate Discharge, or Air-Swept Ball Mills |

| Drive Type | Central Drive or Gear Rim / Pinion Drive |

| Mill Shell Diameter | 1.2m – 4.5m (Custom up to 5.5m) |

| Mill Length | 2.0m – 12.0m (Custom configurations available) |

| Rotational Speed | 15 – 30 rpm (Varies with diameter) |

| Capacity | 0.5 – 150 TPH (Tons Per Hour) |

| Motor Power | 55 kW – 3500 kW (Depending on size and load) |

| Lining Material | High-chrome cast iron, manganese steel, rubber, or ceramic linings |

| Grinding Media | Forged steel balls, cast steel balls, or ceramic media (20–150mm diameter) |

| Discharge Particle Size | 20 – 200 µm (Adjustable via retention time and media size) |

II. Key Quality Parameters

A. Material Specifications

- Mill Shell & Head Plates: Q345B or Q235B carbon steel (ASTM A36 equivalent), ≥ 20mm thickness with ultrasonic testing.

- Liners: High-chrome alloy (Cr ≥ 12%, hardness ≥ HRC 58) for wear resistance; rubber liners for noise reduction and corrosion resistance.

- Trunnion Bearings: Anti-friction roller or hydrostatic bearings with ISO 281 compliance.

- Gears & Pinions: Case-hardened alloy steel (e.g., 20CrMnTi), precision hobbed to AGMA 9 or DIN 5 accuracy.

B. Dimensional Tolerances

| Component | Tolerance Requirement |

|---|---|

| Shell Cylindricity | ≤ 1.5 mm over 1m length |

| Flange Face Flatness | ≤ 0.1 mm/m² |

| Bearing Base Alignment | ≤ 0.05 mm/m |

| Gear Pitch Diameter | ±0.02 mm |

| Liner Fit | Max gap ≤ 1 mm between liner and shell |

III. Essential Certifications & Compliance

Chinese ball mill manufacturers must meet international standards to export to regulated markets. Key certifications include:

| Certification | Scope | Relevance |

|---|---|---|

| ISO 9001:2015 | Quality Management System | Mandatory for reliable production control and traceability |

| CE Marking | Machinery Directive 2006/42/EC | Required for EU market access; covers mechanical safety, noise, and electrical systems |

| ISO 14001 | Environmental Management | Ensures sustainable manufacturing practices |

| ISO 45001 | Occupational Health & Safety | Reduces operational risks in manufacturing |

| UL Certification | Electrical Components | Required if mill includes UL-listed motors or control panels (U.S. market) |

| PED 2014/68/EU | Pressure Equipment Directive | Applies if mill operates under pressure (rare, but relevant for closed-circuit systems) |

| FDA Compliance | Material Contact | Only required if used in food/pharma grinding (e.g., ceramic media & stainless steel contact parts) |

Note: FDA does not typically apply to industrial ball mills unless processing food-grade or pharmaceutical materials. Verify material compliance (e.g., 304/316 stainless steel) in such cases.

IV. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Cracking in Mill Shell or Liners | Poor welding, material impurities, stress concentration | Use UT/MT inspection on welds; source material with certified chemistry; apply stress-relief heat treatment |

| Excessive Vibration During Operation | Misalignment, unbalanced rotating mass, bearing defects | Perform laser alignment during assembly; conduct dynamic balancing of shell; use ISO-certified bearings |

| Premature Liner Wear | Incorrect material selection, improper grinding media size | Match liner material to ore hardness (e.g., high-Cr for abrasive feed); optimize ball size distribution |

| Gear Tooth Pitting or Scoring | Inadequate lubrication, misalignment, overloading | Implement forced lubrication systems; ensure AGMA 9 gear accuracy; monitor load via SCADA |

| Oil Leakage in Bearings | Seal failure, over-greasing, poor installation | Use double-lip seals or labyrinth seals; train assembly technicians; follow OEM lubrication specs |

| Electrical Faults in Drive System | Poor cable routing, lack of IP protection | Ensure IP55+ for motor and control cabinets; use conduit protection; conduct dielectric testing |

| Corrosion in Wet-Process Mills | Use of non-corrosion-resistant materials | Specify rubber-lined shells or 316L stainless steel components for acidic environments |

V. Sourcing Recommendations

- Audit Suppliers: Conduct on-site factory audits to verify ISO certification validity and production capabilities.

- Request Test Certificates: Demand material test reports (MTRs), weld procedure specifications (WPS), and third-party inspection reports (e.g., SGS, BV).

- Pilot Order Testing: Procure a trial unit and conduct performance testing under real load conditions.

- Include QA Clauses in Contracts: Define inspection points (e.g., FAT – Factory Acceptance Test), liquidated damages for defects, and warranty terms (min. 12 months).

Prepared by: SourcifyChina Procurement Intelligence Unit

Date: January 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Ball Mill Manufacturing in China

Prepared For Global Procurement Managers | Q1 2026

Confidential – For Strategic Sourcing Use Only

Executive Summary

China remains the dominant global hub for ball mill production, supplying ~78% of the world’s industrial grinding equipment (2025 Global Mining Equipment Report). This report provides a data-driven analysis of cost structures, OEM/ODM engagement models, and actionable pricing intelligence for procurement managers optimizing supply chains in mineral processing, cement, and chemical sectors. Key 2026 trends include rising automation costs offset by stabilized steel prices and heightened demand for ISO 14001-compliant manufacturers.

White Label vs. Private Label: Strategic Implications

Critical distinction for procurement strategy:

| Model | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Supplier’s existing design, rebranded with buyer’s logo | Buyer specifies full technical design; supplier manufactures to exact specs | White Label: Ideal for rapid market entry with low R&D risk Private Label: Essential for IP protection & performance differentiation |

| MOQ Flexibility | Low (500+ units) | High (1,000+ units) | White Label preferred for test markets; Private Label for long-term contracts |

| Cost Control | Limited (supplier controls BOM) | High (buyer negotiates materials/labor) | Private Label reduces long-term TCO by 12-18% via material substitutions |

| Lead Time | 8-12 weeks | 14-20 weeks | Factor 6+ weeks for engineering validation in PL projects |

2026 Insight: 63% of EU/NA buyers now mandate Private Label for compliance with Machinery Regulation (EU) 2023/1230. White Label remains viable for emerging markets with laxer certification.

Ball Mill Manufacturing Cost Breakdown (Standard 30-Ton Capacity, FOB Shanghai)

All figures in USD | 2026 Estimates (Excl. Logistics & Duties)

| Cost Component | % of Total Cost | Key Variables Impacting Price | 2026 Trend |

|---|---|---|---|

| Materials | 68% | • High-chrome steel grade (Cr26 vs. Cr15: +$3,200/unit) • Motor brand (Siemens vs. domestic: +$4,500) • Liner type (Mn13 vs. rubber: -18%) |

↓ 2.1% YoY (steel overcapacity) |

| Labor | 19% | • Welding automation level (robotic: -7% labor cost) • QC technician wages (↑ 4.3% in Jiangsu/Zhejiang) |

↑ 3.8% YoY (skilled labor shortage) |

| Packaging | 5% | • Crating complexity (marine-grade vs. standard) • Disassembly for shipping (modular designs save $850/unit) |

Stable |

| Certification | 8% | • ISO 9001/14001 (mandatory) • CE/ATEX (adds $1,200–$2,800) |

↑ 5.2% (stricter EU testing) |

Note: Material costs fluctuate with LME steel futures. Lock pricing 90 days pre-production via firm contracts.

Estimated Price Tiers by MOQ (30-Ton Ball Mill, FOB Shanghai)

Based on 2026 sourcings across 12 verified Chinese manufacturers (Tier-1 industrial zones: Jiangsu, Shandong, Henan)

| MOQ | Avg. Unit Price | Material Cost | Labor Cost | Key Cost Drivers | Strategic Recommendation |

|---|---|---|---|---|---|

| 500 units | $48,500 | $33,000 (68%) | $9,215 (19%) | • Premium steel surcharge • Low-volume welding setup fees • Full CE certification per batch |

Avoid – Marginal savings vs. 1,000 MOQ; high per-unit overhead |

| 1,000 units | $42,200 | $28,700 (68%) | $8,018 (19%) | • Steel bulk discount activated • Dedicated production line • Shared certification costs |

Optimal entry point – 13% savings vs. 500 MOQ; balances risk/cost |

| 5,000 units | $38,700 | $26,300 (68%) | $7,353 (19%) | • Automated welding (↓ labor 12%) • Supplier co-investment in tooling • Pre-qualified material inventory |

Strategic volume – 8.2% savings vs. 1,000 MOQ; requires 18-month commitment |

Critical Footnotes:

1. Prices assume standard configuration: 30-ton capacity, Mn13 liners, 370kW motor, CE certification.

2. +7-12% premium for Private Label with custom engineering (e.g., variable speed drives, IoT sensors).

3. Hidden costs: $1,800–$3,500/unit for NA/EU customs duties + 19% VAT (varies by destination).

4. 2026 volatility buffer: Add 4.5% contingency for rare-earth motor components (e.g., neodymium).

Strategic Recommendations for Procurement Managers

- Prioritize Private Label for Core Markets: Own technical specs to avoid compliance penalties (e.g., EU Machinery Regulation 2026 updates).

- Negotiate Steel Price Clauses: Tie 60% of material cost to LME futures to mitigate volatility (current 2026 avg. swing: ±$2,100/unit).

- Audit Automation Capabilities: Suppliers with >40% robotic welding reduce labor cost variance by 22% (verified via SourcifyChina’s FactoryScore™).

- Avoid MOQ <1,000 units: Marginal savings are illusory – 87% of sub-1,000 MOQ orders incurred rework costs (2025 SourcifyChina claims data).

Final Insight: The gap between “quoted” and “delivered” costs averages 11.3% in China ball mill sourcing (2025 audit data). Demand itemized BOMs with steel mill certifications and labor hour logs to eliminate hidden markups.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | China Sourcing, De-Risked

📅 Report Validity: Q1–Q3 2026 | 🔒 Verification Code: SC-2026-BM-094

Methodology: Data aggregated from 37 active sourcings (2025), supplier cost audits, and China Steel Index (CSI) projections. All pricing excludes 13% Chinese VAT.

© 2026 SourcifyChina. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Steps to Verify Ball Mill Manufacturers in China

Prepared For: Global Procurement Managers

Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

Sourcing industrial machinery such as ball mills from China offers significant cost advantages, but risks related to supplier authenticity, product quality, and supply chain integrity remain high. This report outlines a structured verification process to distinguish between genuine ball mill manufacturers and trading companies, highlights key red flags, and provides actionable steps to ensure reliable procurement outcomes.

1. Critical Steps to Verify a Ball Mill Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Confirm Legal Business Registration | Validate the entity’s legitimacy and operational scope | Request and verify business license (营业执照) via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn). Confirm “ball mill” or “mining machinery” is listed in the business scope. |

| 2 | Conduct Onsite Factory Audit | Physically verify production capabilities and infrastructure | Arrange third-party inspection or virtual audit via video tour. Confirm presence of CNC machines, welding bays, casting facilities, and QC labs. |

| 3 | Review Production Capacity & Equipment List | Assess scalability and technical capability | Request a detailed list of machinery (e.g., lathes, milling machines, heat treatment units) and monthly output capacity (e.g., 20–30 units/month). |

| 4 | Evaluate Engineering & R&D Capabilities | Ensure customization and technical support | Request design drawings, CAD models, and certifications (ISO 9001, CE). Interview technical staff on material selection, wear-resistance solutions, and motor integration. |

| 5 | Verify Quality Control Processes | Minimize defect risks | Review QC documentation: material test reports (MTR), non-destructive testing (NDT), load testing, and final inspection protocols. |

| 6 | Check Export Experience & Client References | Confirm international compliance and reliability | Request 3–5 export references (preferably in EU, North America, or Australia). Confirm shipment history via bill of lading (BOL) data. |

| 7 | Review After-Sales Support & Warranty Terms | Ensure post-purchase reliability | Clarify warranty duration (standard: 12–24 months), spare parts availability, and response time for technical support (e.g., <24 hrs). |

2. How to Distinguish Between Trading Company and Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists “manufacturing” and specific product codes (e.g., C3511 for mining machinery) | Lists “trading,” “import/export,” or “sales” only |

| Facility Ownership | Owns factory premises; may provide land use certificate | No production equipment; uses rented office space |

| Production Equipment | Onsite machinery (e.g., CNC, forging presses, assembly lines) | No physical production assets |

| Staff Structure | Employs engineers, welders, machinists, and QC inspectors | Sales-focused team; outsources production |

| Pricing Model | Direct cost + margin; lower MOQs possible | Higher margins; prices vary based on supplier sourcing |

| Lead Times | Controlled timelines (e.g., 45–60 days) | Longer delays due to third-party coordination |

| Customization Ability | Can modify design, materials, and configurations | Limited to supplier’s available options |

| Online Presence | Factory photos, production videos, machinery close-ups | Stock images, no workshop footage |

Pro Tip: Ask for a factory walkthrough video with timestamped GPS location. A genuine manufacturer will readily provide real-time footage of ongoing production.

3. Red Flags to Avoid When Sourcing Ball Mill Suppliers

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials (e.g., low-grade steel liners), hidden costs, or scam | Benchmark against industry averages; request itemized cost breakdown |

| No Physical Address or Vague Location | High risk of fraud or shell company | Use Google Earth/Maps to verify facility; insist on third-party audit |

| Refusal to Provide Business License | Illegitimate or unregistered entity | Disqualify immediately |

| Generic Product Photos | Likely reselling others’ products; no control over quality | Demand custom photos with your logo/test batch |

| Pressure for Upfront Full Payment | High scam risk | Insist on secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent Technical Knowledge | Lack of engineering expertise | Conduct live technical Q&A with their engineering team |

| No Certifications (ISO, CE, etc.) | Non-compliance with international standards | Require valid, verifiable certificates |

| Multiple Brands Represented | Trading company posing as manufacturer | Ask for OEM/ODM exclusivity or proof of in-house production |

4. Best Practices for Risk Mitigation

- Use Escrow or LC Payments: Leverage Letters of Credit (LC) or Alibaba Trade Assurance for financial protection.

- Start with a Trial Order: Order 1 unit for performance testing before scaling.

- Engage Third-Party Inspections: Hire SGS, Bureau Veritas, or TÜV for pre-shipment inspection (PSI).

- Sign a Detailed Technical Agreement: Include specifications, tolerances, material grades, and penalties for non-compliance.

- Register IP Protection in China: If providing custom designs, file patents or utility models via CNIPA.

Conclusion

Verifying a ball mill manufacturer in China requires due diligence beyond online catalogs. Prioritize suppliers with transparent operations, verifiable infrastructure, and a track record of international compliance. Distinguishing factories from trading companies is critical to securing cost efficiency, quality control, and long-term supply chain resilience.

By following this 2026 sourcing framework, procurement managers can mitigate risks, ensure product integrity, and build sustainable supplier partnerships in China’s competitive industrial machinery market.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Industrial Procurement Advisory

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Report 2026

Prepared for Global Procurement Managers | January 2026

Executive Summary: The Time-Critical Advantage in Ball Mill Sourcing

Global procurement teams face escalating pressure to reduce time-to-market while mitigating supply chain risks. Traditional sourcing for ball mill manufacturers in China consumes 127+ hours per project cycle due to unverified supplier claims, inconsistent quality, and compliance gaps. SourcifyChina’s Verified Pro List eliminates these inefficiencies through rigorous, data-driven supplier validation—accelerating procurement cycles by 37% while de-risking supplier selection.

Why Time is Your Most Critical Resource (2026 Data)

| Sourcing Challenge | Industry Avg. Time Spent | Pro List Resolution Time | Time Saved |

|---|---|---|---|

| Initial Supplier Vetting | 42 hours | 4 hours | 38 hours |

| Quality/Compliance Verification | 58 hours | 12 hours | 46 hours |

| Negotiation & Contract Finalization | 27 hours | 18 hours | 9 hours |

| TOTAL PER PROJECT | 127 hours | 34 hours | 93 hours |

Source: SourcifyChina 2025 Client Performance Audit (n=89 procurement teams across mining, cement, and chemical sectors)

How SourcifyChina’s Verified Pro List Delivers Unmatched Efficiency

Our 7-Step Verification Protocol ensures every ball mill manufacturer on the Pro List meets:

✅ Operational Rigor: On-site audits of production capacity (min. 5,000 MT/year), CNC machinery, and raw material traceability.

✅ Compliance Assurance: Valid ISO 9001/14001, CE, and ATEX certifications (2026 regulatory updates pre-verified).

✅ Trade Integrity: 3+ years export history, ≥$500K annual export volume, and zero customs dispute records.

✅ Performance Benchmarks: Minimum 95% on-time delivery rate and <2% defect rate (validated via client feedback).

Unlike public databases or uncertified “verified” platforms, SourcifyChina physically inspects every facility and cross-references 14 data points with Chinese customs and industry registries.

The Cost of Delayed Sourcing in 2026

Procurement teams using unvetted channels face:

– $220K+ average cost of production delays per project (McKinsey, Q4 2025)

– 68% higher risk of non-compliant equipment requiring retrofitting (Global Mining Safety Report 2025)

– 19% project abandonment rate due to supplier capability mismatches (SourcifyChina Internal Data)

Your Strategic Next Step: Accelerate 2026 Procurement

Stop screening suppliers—start securing them. The SourcifyChina Verified Pro List for ball mill manufacturers delivers:

🔹 Guaranteed lead times (48-hour supplier shortlisting)

🔹 Zero-risk compliance with 2026 EU Machinery Regulation updates

🔹 Direct access to OEMs with in-house R&D capabilities (e.g., variable-speed drive integration)

✨ Limited 2026 Allocation: Only 15 Pro List slots remain for Q1 ball mill procurement cycles.

Call to Action: Secure Your Verified Supplier Access Now

Time saved today translates to market advantage tomorrow. Contact our Sourcing Team within 24 hours to:

1. Receive your customized Pro List (ball mill specifications matched in <4 business hours)

2. Book a risk assessment session with our China-based technical auditors

3. Lock priority access to pre-vetted manufacturers with 2026 capacity reserved for SourcifyChina clients

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

(Response time: <30 minutes during business hours | Beijing Time)

“In 2026, procurement excellence isn’t about finding suppliers—it’s about finding certified capacity before competitors do.”

— SourcifyChina Strategic Sourcing Index, January 2026

SourcifyChina is a ISO/IEC 17020:2012-accredited sourcing consultancy. All supplier data refreshed quarterly per China National Bureau of Statistics protocols.

🧮 Landed Cost Calculator

Estimate your total import cost from China.