The global commercial bakery oven market is experiencing robust growth, driven by rising demand for baked goods in foodservice outlets, central kitchens, and large-scale bakeries. According to Grand View Research, the global bakery equipment market was valued at USD 7.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by increasing urbanization, a surge in café and bakery chains, and the growing preference for artisanal and specialty breads. Additionally, technological advancements—such as energy-efficient designs, automated controls, and IoT-enabled monitoring systems—are reshaping how commercial ovens are selected and utilized. As operators prioritize throughput, consistency, and operational efficiency, the choice of bakery oven manufacturer becomes a critical factor in maintaining competitive advantage. In this landscape, ten manufacturers have emerged as industry leaders, combining innovation, durability, and scalability to meet the evolving demands of commercial baking worldwide.

Top 10 Bakery Ovens Commercial Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Ovens

Domain Est. 1996

Website: wisoven.com

Key Highlights: Wisconsin Oven Corporation has been designing, engineering, and manufacturing industrial ovens and other heating equipment for over 40 years….

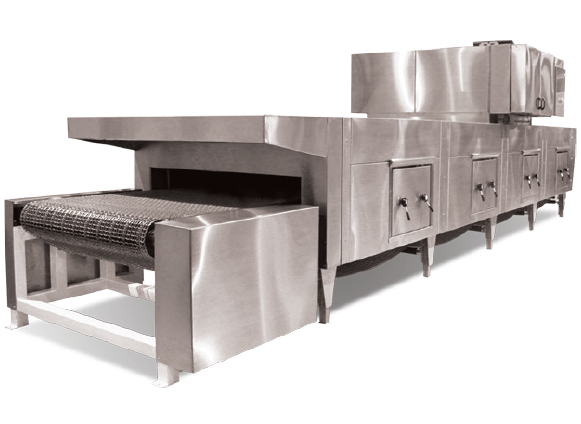

#2 Belshaw

Domain Est. 1995

Website: belshaw.com

Key Highlights: Belshaw donut machines are renowned in the world of donut production. Adamatic is a leading manufacturer of divider-rounders and bread lines….

#3 Bakers Pride

Domain Est. 1996

Website: bakerspride.com

Key Highlights: Bakers Pride manufacturers commercial cooking equipment for the food service industry. Deck ovens, conveyor and speed ovens, ranges and charbroilers….

#4 Revent

Domain Est. 1996

Website: revent.com

Key Highlights: Today we are one of the world’s largest producers of rack ovens. We are proud of our history yet understand that there will be no future without a commitment….

#5 Bakery Ovens

Domain Est. 1997

Website: sveba.com

Key Highlights: We manufacture rack ovens of all sizes for bakeries. Ovens for cafes, instore bakeries, bakeries and industrial bakeries….

#6 Blodgett Ovens

Domain Est. 2001

Website: blodgett.com

Key Highlights: Blodgett is the leading manufacturer of commercial convection, Hydrovection, baking & roasting and pizza deck and Combi ovens in the world….

#7 LBC Bakery Equipment Manufacturer

Domain Est. 2006

Website: lbcbakery.com

Key Highlights: LBC Bakery designs and manufactures large-scale rack ovens and proofers for supermarkets, independent bakeries, franchises, and food service departments at ……

#8 Commercial Ovens

Domain Est. 2004

Website: fbmbakingmachines.com

Key Highlights: With our selection of hearth deck ovens and convection commercial ovens, mixers, sheeters, blast freezers and more, FBM will fill all of your baking ……

#9 Moffat

Domain Est. 2012

Website: moffatusa.com

Key Highlights: Moffat specializes in the design, manufacture, distribution and after-sales support of commercial convection ovens, proofers and holding cabinets….

#10 Doyon Baking

Domain Est. 2013

Website: doyonbaking.com

Key Highlights: Doyon Baking offers commercial bakery equipment built for performance, precision, and durability. Trusted by baking professionals worldwide….

Expert Sourcing Insights for Bakery Ovens Commercial

H2: 2026 Market Trends for Commercial Bakery Ovens

The global commercial bakery ovens market is poised for significant transformation by 2026, driven by technological innovation, shifting consumer preferences, and sustainability demands. As foodservice operators and large-scale bakeries adapt to evolving market dynamics, several key trends are shaping the commercial bakery oven landscape.

-

Increased Adoption of Smart and Connected Ovens

By 2026, smart ovens equipped with IoT (Internet of Things) capabilities are expected to dominate the commercial sector. These ovens offer remote monitoring, automated baking cycles, predictive maintenance, and integration with bakery management systems. Cloud-based analytics enable operators to optimize energy use, ensure recipe consistency, and reduce labor costs—critical advantages in a competitive environment. -

Growth in Energy-Efficient and Eco-Friendly Models

Sustainability is a major driver in equipment purchasing decisions. Manufacturers are responding with energy-efficient ovens that reduce gas and electricity consumption. Induction heating, improved insulation, heat recovery systems, and convection optimization are becoming standard. Additionally, demand for ovens compatible with renewable energy sources is rising, especially in regions with strict carbon emission regulations. -

Expansion of Modular and Multi-Functional Ovens

To maximize space and versatility, especially in urban bakeries and hybrid cafes, modular and multi-functional ovens are gaining traction. These units can perform convection, steam, rotary, and deck baking within a single footprint. Their flexibility allows bakeries to produce a diverse range of products—from artisan breads to pastries—without requiring multiple dedicated machines. -

Rise in Demand for Artisan and Specialty Baking Equipment

The growing consumer preference for artisanal, sourdough, and organic baked goods is fueling demand for ovens that replicate traditional baking methods. Deck ovens with stone hearths, wood-fired options, and steam-injected models are seeing increased adoption. These ovens provide superior crust development and texture, aligning with the premiumization trend in the bakery sector. -

Regional Market Diversification and Emerging Market Growth

While North America and Europe remain dominant markets, Asia-Pacific and Latin America are expected to register the highest growth rates by 2026. Urbanization, rising disposable incomes, and the expansion of café culture are driving bakery sector development in countries like India, China, Brazil, and Indonesia. Localized manufacturing and tailored product offerings are becoming essential for global oven suppliers. -

Labor Shortage Mitigation Through Automation

Labor challenges in the foodservice industry are pushing bakeries to invest in automated ovens with programmable logic controllers (PLCs), auto-loading systems, and AI-driven recipe management. These features reduce dependency on skilled labor, ensure consistency, and streamline production—making automation a key selling point for new installations. -

Focus on Hygiene and Easy Maintenance

Post-pandemic, hygiene remains a top priority. Commercial ovens with seamless stainless steel construction, self-cleaning functions, and antimicrobial surfaces are increasingly preferred. Designs that simplify disassembly and cleaning are helping bakeries meet stringent health regulations and reduce downtime.

In conclusion, the 2026 commercial bakery oven market will be characterized by intelligent, sustainable, and adaptable solutions. Manufacturers that prioritize innovation, energy efficiency, and user-centric design will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Commercial Bakery Ovens (Quality and IP)

Sourcing commercial bakery ovens involves navigating several critical challenges, particularly concerning product quality and intellectual property (IP) risks. Overlooking these pitfalls can lead to operational inefficiencies, safety hazards, and legal complications.

Poor Build Quality and Material Standards

Many suppliers, especially from less-regulated markets, use substandard materials such as thin-gauge stainless steel or low-grade insulation. This compromises durability, energy efficiency, and food safety. Ovens may warp, corrode, or fail prematurely under high-temperature bakery conditions, leading to costly downtime and maintenance.

Inadequate Temperature Control and Heat Distribution

Low-quality ovens often suffer from inconsistent heat distribution and inaccurate thermostats. This results in uneven baking, inconsistent product quality, and wasted ingredients—critical issues for bakeries relying on precision and repeatability.

Lack of Certification and Compliance

Commercial ovens must meet regional safety and energy standards (e.g., CE, UL, NSF). Sourcing from non-compliant manufacturers may result in equipment that cannot be legally operated, fails inspections, or poses fire or electrical hazards.

Misrepresentation of Technical Specifications

Some suppliers exaggerate oven performance metrics such as heat-up time, energy consumption, or capacity. Buyers may end up with underperforming equipment that doesn’t meet production demands, affecting throughput and profitability.

Intellectual Property Infringement Risks

Purchasing ovens that copy patented designs or branded technologies—especially from unverified manufacturers—can expose businesses to IP litigation. Even unintentional use of counterfeit or cloned equipment may result in seizure, fines, or reputational damage.

Limited After-Sales Support and Spare Parts Availability

Ovens sourced from distant or unknown suppliers often come with poor technical support and limited access to replacement parts. This leads to extended downtime during breakdowns, disrupting bakery operations and increasing long-term ownership costs.

Inadequate Warranty and Service Agreements

Generic or vague warranty terms may not cover critical components or labor. Without clear service agreements, bakeries face unexpected repair costs and delays, undermining the total cost of ownership.

Avoiding these pitfalls requires due diligence: vetting suppliers, verifying certifications, inspecting sample units, and consulting legal experts when IP concerns arise.

Logistics & Compliance Guide for Commercial Bakery Ovens

Product Classification and Regulations

Commercial bakery ovens are classified as industrial food processing equipment and must comply with multiple regulatory standards. These include electrical safety codes (e.g., UL 197 in the U.S.), energy efficiency standards (such as those set by the Department of Energy), and food safety regulations (e.g., FDA and NSF/ANSI 2). Ensuring compliance with local, national, and international standards is critical before shipment or installation.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit. Commercial ovens should be crated or palletized with adequate cushioning and corner protectors. Use weather-resistant wrapping for ocean or outdoor transport. Clearly label all units with handling instructions (e.g., “This Side Up,” “Fragile”) and include shipping documentation listing model numbers, serial numbers, and compliance certifications.

Import and Export Compliance

When shipping internationally, verify compliance with destination country regulations. This includes obtaining CE marking for the EU, CCC certification for China, or other local certifications. Provide accurate Harmonized System (HS) codes (e.g., 8417.20 for industrial ovens) for customs clearance. Prepare commercial invoices, packing lists, and certificates of origin to avoid delays.

Transportation and Handling

Use freight carriers experienced in handling heavy industrial equipment. Most commercial ovens exceed standard parcel size and weight limits, requiring LTL (Less Than Truckload) or full truckload shipping. Ensure delivery sites have appropriate access—check door widths, elevator capacities, and floor load limits. Include rigging and liftgate requirements in logistics planning.

Installation and Site Preparation

Verify that the installation site meets utility requirements: proper voltage (typically 208V or 240V single/three-phase), gas line specifications (if gas-powered), and ventilation systems per local building codes. Confirm clearances around the oven for safety and maintenance access. Retain installation manuals and compliance documents on-site for inspection purposes.

Post-Delivery Compliance and Documentation

After delivery, complete commissioning checks and maintain records of installation, calibration, and safety inspections. Provide facility staff with operation manuals and training documentation. Retain all compliance certificates (electrical, gas, sanitation) for audits and insurance purposes. Register equipment with relevant authorities if required by local regulations.

Maintenance and Ongoing Compliance

Schedule routine maintenance per manufacturer guidelines to ensure ongoing safety and efficiency. Keep logs of servicing, part replacements, and performance checks. Stay updated on regulatory changes—especially energy efficiency or emissions standards—that may affect continued operation. Non-compliant units may face fines or operational shutdowns.

Conclusion: Sourcing Commercial Bakery Ovens

Sourcing commercial bakery ovens is a critical decision that directly impacts the efficiency, consistency, and scalability of bakery operations. After evaluating various types of ovens—such as convection, deck, rotary, rack, and combi ovens—along with factors like fuel type (electric vs. gas), capacity, energy efficiency, build quality, and brand reliability, it becomes clear that the right choice depends on the specific needs of the bakery, including production volume, product type, available space, and budget.

A thorough sourcing process should include comparing reputable manufacturers, reviewing energy certifications, assessing after-sales service and warranty options, and considering total cost of ownership over time. Additionally, engaging with suppliers early, requesting demos, and obtaining customer references can significantly reduce risks and ensure long-term satisfaction.

Ultimately, investing in the right commercial bakery oven is not just a purchase—it’s a strategic move that supports product quality, operational efficiency, and business growth. By aligning oven specifications with operational goals and leveraging market research and expert insights, bakery owners can make informed decisions that deliver lasting value and competitive advantage.