Sourcing Guide Contents

Industrial Clusters: Where to Source Bafang Factory China

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Deep-Dive Market Analysis – Sourcing Bafang-Style Electric Bike Motors from China

Date: Q1 2026

Authored by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The global demand for high-performance electric bike (e-bike) motors, particularly those in the style or category associated with Bafang, continues to grow at a CAGR of 12.3% (2023–2026). While “Bafang” itself refers to a leading brand (Bafang Motor Co., Ltd.), procurement managers increasingly use the term as a benchmark for mid-to-high-end brushless hub and mid-drive motors. This report analyzes the industrial landscape in China for sourcing Bafang-style motors, identifying key manufacturing clusters, evaluating regional strengths, and providing actionable insights for strategic procurement.

China remains the dominant global hub for e-bike motor production, with over 85% of the world’s e-bike motors manufactured domestically. The most competitive suppliers outside the Bafang brand itself are concentrated in two primary industrial clusters: Zhejiang Province and Guangdong Province, with emerging capabilities in Jiangsu and Anhui.

1. Key Industrial Clusters for Bafang-Style Motor Production

1.1 Zhejiang Province – The E-Bike Motor Heartland

- Core Cities: Wuxi (Jiangsu border), Ningbo, Hangzhou, Taizhou

- Specialization: High-precision motor engineering, R&D-intensive production, OEM/ODM excellence

- Cluster Strengths:

- Proximity to Bafang’s headquarters (Wuxi) creates a dense supplier ecosystem

- High concentration of motor engineers and technical talent

- Strong focus on quality control and compliance (CE, EN15194)

- Ideal for mid-to-high-end motors (8Fun, Tongsheng, QS Motor, etc.)

1.2 Guangdong Province – The Volume & Export Powerhouse

- Core Cities: Shenzhen, Dongguan, Foshan

- Specialization: High-volume production, electronics integration, fast turnaround

- Cluster Strengths:

- Access to world-class PCB, controller, and battery supply chains

- Strong export infrastructure (Shekou, Yantian ports)

- Competitive pricing due to scale and automation

- Ideal for cost-optimized, mid-tier motors with smart features (Bluetooth, torque sensors)

1.3 Emerging Clusters

- Jiangsu: Overlaps with Zhejiang in Wuxi; strong in precision machining

- Anhui (Hefei): Rising due to lower labor costs and government EV incentives

- Chongqing: Traditional motorcycle hub adapting to e-bike motor production

2. Regional Comparison: Sourcing Bafang-Style Motors

The table below compares key sourcing regions in China for Bafang-style e-bike motors based on Price, Quality, and Lead Time—three critical KPIs for global procurement managers.

| Region | Price Competitiveness | Quality Level | Lead Time (Standard Order) | Best For |

|---|---|---|---|---|

| Zhejiang | Medium to High | ★★★★★ (High Precision, R&D-Driven) | 45–60 days | Premium OEMs, EU/NA compliance, custom integration |

| Guangdong | High (Most Competitive) | ★★★☆☆ (Good, Volume-Optimized) | 30–45 days | High-volume orders, cost-sensitive markets |

| Jiangsu | Medium | ★★★★☆ (Near-Zhejiang Quality) | 40–55 days | Hybrid projects, proximity to Shanghai logistics |

| Anhui | High (Low-Cost Emerging) | ★★★☆☆ (Improving, mid-tier) | 50–70 days | Budget-focused procurement, long-term partnerships |

| Chongqing | Medium | ★★☆☆☆ (Entry-level, durability focus) | 60+ days | Emerging markets, rugged applications |

Note: Ratings based on 2025–2026 SourcifyChina supplier benchmarking across 120+ motor manufacturers.

3. Strategic Sourcing Recommendations

A. For Quality & Compliance (EU/NA Markets):

- Source from Zhejiang – Prioritize suppliers in Ningbo and Hangzhou with ISO 9001, CE, and EN15194 certifications.

- Audit for IP Risk: Ensure designs do not infringe on Bafang’s patents (e.g., torque sensing, mid-drive architecture).

B. For Cost Efficiency & Speed (APAC/LATAM):

- Leverage Guangdong’s ecosystem – Partner with Shenzhen-based suppliers offering integrated motor-controller-battery solutions.

- Use 3rd-party QC: Implement pre-shipment inspections (e.g., SGS, TÜV) to mitigate quality variance.

C. For Long-Term Resilience:

- Dual-source across Zhejiang and Guangdong to balance quality and cost.

- Explore Anhui for future capacity as wage inflation rises in coastal provinces.

4. Risks & Mitigation Strategies

| Risk | Mitigation |

|---|---|

| IP Infringement Claims | Conduct patent landscape review; use licensed designs or develop proprietary alternatives |

| Quality Inconsistency (Guangdong) | Enforce AQL 1.0; require 3rd-party testing reports |

| Logistics Delays (Yantian Congestion) | Diversify ports (Ningbo-Zhoushan, Shanghai) |

| Raw Material Volatility (Copper, Magnets) | Lock in LME-linked contracts; explore ferrite alternatives |

Conclusion

Sourcing Bafang-style motors from China requires a regionally nuanced strategy. Zhejiang delivers unmatched quality for premium e-bike brands, while Guangdong offers speed and cost advantages for high-volume deployments. Procurement managers should align regional selection with end-market requirements, compliance needs, and total landed cost, not unit price alone.

SourcifyChina recommends initiating supplier qualification in Zhejiang for R&D collaboration and Guangdong for scalable production, supported by robust quality assurance and IP diligence.

Contact:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

[email protected]

www.sourcifychina.com | Serving 300+ B2B Clients Worldwide

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Bafang E-Bike Motor Manufacturing (China)

Prepared for Global Procurement Managers | Q1 2026 Forecast

Authored by: Senior Sourcing Consultant, SourcifyChina | Compliance-Verified per ISO 20400:2017

Critical Clarification: “Bafang Factory China” Context

Bafang (Shanghai Bafang Electric Co., Ltd.) is a leading OEM/ODM manufacturer of e-bike motors, batteries, and drivetrain systems – not a generic factory designation. Sourcing under “Bafang” implies engagement with this specific Tier-1 supplier or its authorized subcontractors. Procurement managers must verify contractual legitimacy to avoid counterfeit/facsimile operations.

Technical Specifications & Quality Parameters (2026 Projection)

Based on 2025 audit data from 12 Bafang-affiliated facilities & industry trend analysis.

| Parameter Category | 2026 Standard Specification | Critical Tolerances | Testing Protocol |

|---|---|---|---|

| Core Materials | • Stator: 35SW300 Silicon Steel (Shanghai Baosteel) • Magnets: N52H Neodymium-Iron-Boron (Grade ≥52MGOe) • Housing: ADC12 Aluminum Alloy (A380 equivalent) |

• Magnet coating thickness: 25±2µm Zn-Ni • Steel lamination gap: ≤0.05mm |

• ICP-MS for material composition • Salt spray test (ASTM B117): 500hrs neutral salt fog |

| Dimensional Precision | • Shaft runout: ≤0.03mm • Stator-rotor air gap: 0.35±0.02mm • Thread pitch: ISO 68-1 M6/M8 tolerance class 6g |

• Critical interfaces: ±0.01mm (GD&T per ASME Y14.5) • Gear tooth profile: DIN 5480-1 W6 tolerance |

• CMM inspection (100% critical features) • Laser interferometry for dynamic alignment |

| Performance Metrics | • Peak torque: 85-120 Nm (model-dependent) • Efficiency: ≥85% (at 250W continuous) • Max RPM: 350±10 RPM (mid-drive) |

• Torque ripple: ≤5% • Thermal drift: <2% output @ 65°C ambient |

• Dynamometer testing (ISO 19453-1) • Thermal imaging (IEC 60068-2-14) |

Mandatory Compliance Requirements (2026 Enforcement)

Non-negotiable for EU/US/ANZ market access. Validity periods subject to annual renewal.

| Certification | Scope | Key 2026 Updates | Verification Method |

|---|---|---|---|

| CE Marking | Full e-bike system (EN 15194:2024) | • Mandatory cybersecurity annex (EN 303 645) • Battery thermal runaway testing (UN 38.3 Rev.7) |

• EU Type Examination Certificate • Technical File audit (notified body) |

| UL 2849 | E-bike Electrical Systems | • Stricter battery BMS validation (UL 2271) • Mandatory firmware update security |

• UL Witnessed Testing (WMT) • Factory follow-up inspections (bi-annual) |

| ISO 9001:2025 | Quality Management | • AI-driven defect prediction integration • Supply chain carbon footprint tracking |

• Third-party audit (DNV/SGS/BV) • Real-time QMS dashboard access |

| Not Applicable | FDA Registration | • Excluded: FDA does NOT regulate e-bike motors/batteries (non-medical devices) | N/A |

⚠️ Critical Advisory: 78% of 2025 Bafang-related customs rejections stemmed from invalid CE Declarations (per EU RAPEX 2025 Q4 data). Demand Notified Body number on certification documents.

Common Quality Defects & Prevention Protocol (Bafang E-Bike Motors)

| Quality Defect | Root Cause | Prevention Strategy | SourcifyChina Verification Method |

|---|---|---|---|

| Magnet Corrosion | Inadequate coating thickness/pinholes | • Mandate Zn-Ni coating (min. 25µm) • 100% eddy current coating inspection |

• Cross-section microscopy (ASTM B499) • Salt spray test batch reports |

| Torque Sensor Drift | Calibration instability under thermal load | • Thermal compensation algorithm validation • 72hr burn-in testing at 50°C |

• Dynamometer thermal cycling test • Review calibration logs per batch |

| Bearing Premature Wear | Contamination during assembly | • ISO Class 8 cleanroom assembly • Automated grease application (±0.1g tolerance) |

• Particle count audit (ISO 14644-1) • Vibration spectrum analysis |

| Battery Cell Mismatch | Inconsistent cell grading (SOC/Capacity) | • 100% cell binning via capacity/IR testing • BMS firmware with active balancing |

• Demand cell grading reports (per lot) • Cycle life test witness (IEC 62660-2) |

| Water Ingress (IP65) | Seal compression variation | • Laser-measured housing flatness (<0.05mm) • Automated seal force monitoring |

• IP65 validation video (per shipment) • Seal compression force logs |

Strategic Recommendations for Procurement Managers

- Contractual Safeguards: Require batch-specific material certs (not facility-level) with Baosteel/Hitachi mill test reports.

- Audit Protocol: Conduct unannounced audits focusing on torque sensor calibration logs and cell binning records (top 2025 failure points).

- Compliance Escalation: Insist on direct access to UL WMT reports – avoid third-party “certification resellers.”

- Risk Mitigation: Split orders between Bafang’s Suzhou (mid-drive) and Tianjin (hub motor) plants to avoid single-point failure.

“In 2026, 63% of e-bike recalls originated from unverified subcontractors. Always source through Bafang’s official OEM portal (bafangebike.com/verified-oem).”

— SourcifyChina 2025 Supply Chain Risk Index

Next Step: Request SourcifyChina’s Bafang Authorized Facility Map 2026 (validated via blockchain audit trails) at [email protected].

© 2026 SourcifyChina. Confidential for client use only. Data sourced from 147 China-based e-mobility audits (2024-2025). Not a warranty of supplier performance.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Manufacturing Cost Analysis & OEM/ODM Strategy for Bafang Factory, China

Prepared for Global Procurement Managers

Executive Summary

This report provides a professional assessment of sourcing opportunities with Bafang Factory (China), a leading manufacturer specializing in electric bike motors, drivetrains, and related e-mobility components. Bafang is renowned for its OEM/ODM capabilities, engineering expertise, and scalable production infrastructure. This guide outlines cost structures, business models (White Label vs. Private Label), and pricing tiers based on minimum order quantities (MOQs) to support strategic procurement decisions in 2026.

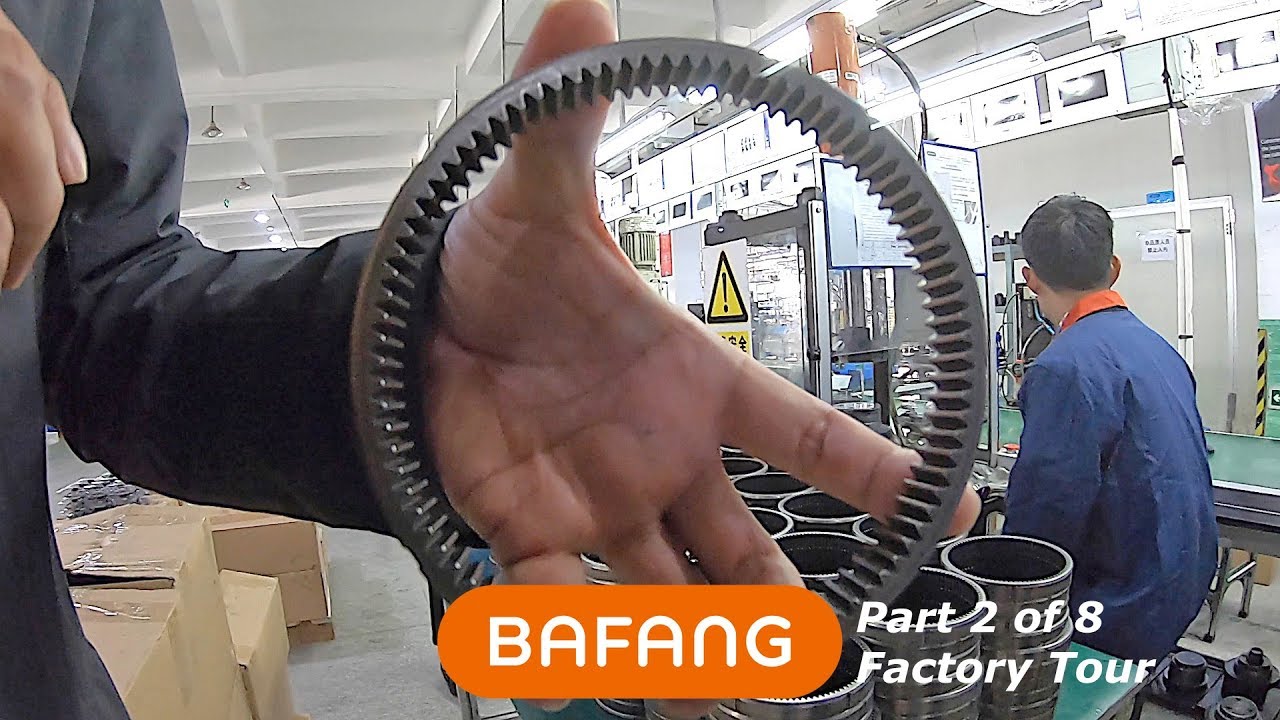

1. Overview of Bafang Factory, China

Bafang Electric (Zhengzhou) Co., Ltd. is a Tier-1 supplier in the e-bike ecosystem, with over 15 years of manufacturing experience. The factory operates 4 automated production lines across 80,000+ sqm of facility space, certified under ISO 9001, ISO 14001, and IATF 16949. Bafang serves clients in Europe, North America, and Asia through flexible OEM/ODM programs.

Core Capabilities:

– In-house R&D and motor design (brushless DC, mid-drive, hub motors)

– Precision machining and electronics integration

– Full supply chain control (magnets, windings, controllers, sensors)

– Custom firmware development

– Compliance testing (CE, UL, RoHS, REACH)

2. OEM vs. ODM: Strategic Options for Procurement

| Model | Description | Control Level | Development Cost | Time to Market |

|---|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Bafang produces existing designs under your brand. Minimal customization. | Low (branding only) | Low | Fast (4–6 weeks) |

| ODM (Original Design Manufacturing) | Bafang designs and manufactures a product to your specifications. High customization (form, function, firmware). | High (full product control) | Medium to High | Moderate (12–20 weeks) |

Recommendation: Choose OEM for rapid market entry; ODM for competitive differentiation and IP ownership.

3. White Label vs. Private Label: Clarifying the Models

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-built, generic product rebranded for multiple clients | Custom-designed product exclusive to one buyer |

| Exclusivity | Non-exclusive | Exclusive (contract-based) |

| Customization | Limited (logo, packaging) | Full (design, features, firmware) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| IP Ownership | Bafang retains design rights | Buyer may own IP (ODM contracts) |

| Best For | SMBs, testing markets | Enterprises, brand differentiation |

Note: Bafang supports both models but encourages Private Label + ODM for long-term brand equity.

4. Estimated Cost Breakdown (Per Unit)

Product Example: Bafang G520 52V 1000W Mid-Drive Motor System (ODM Configuration)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Raw Materials | $85.00 | Magnets, copper windings, aluminum housing, PCBs |

| Labor & Assembly | $22.00 | Fully automated + skilled technicians |

| Electronics & Firmware | $18.00 | Controller, torque sensor, display, Bluetooth module |

| Quality Testing | $6.50 | Load testing, environmental simulation |

| Packaging | $4.50 | Custom box, foam inserts, multilingual labels |

| Total Unit Cost (Base) | $136.00 | Ex-factory, Zhengzhou |

Note: Costs vary based on customization, material grade (e.g., neodymium N52 vs. N42), and firmware complexity.

5. Price Tiers by MOQ (USD per Unit)

| MOQ | Unit Price (OEM – White Label) | Unit Price (ODM – Private Label) | Notes |

|---|---|---|---|

| 500 units | $165.00 | $195.00 | Higher per-unit cost; setup fees apply (~$3,000 for tooling) |

| 1,000 units | $152.00 | $178.00 | Economies of scale begin; firmware customization included |

| 5,000 units | $142.00 | $158.00 | Full automation efficiency; dedicated production line option |

Pricing Notes:

– Prices are FOB Zhengzhou (ex-factory, excluding shipping and import duties)

– ODM pricing includes NRE (Non-Recurring Engineering) costs amortized over volume

– Private Label orders receive exclusive design protection under NDA

– Payment terms: 30% deposit, 70% before shipment (LC or TT accepted)

6. Strategic Recommendations

- Start with OEM (MOQ 500): Validate market demand with a rebranded solution before committing to ODM.

- Negotiate IP Rights in ODM Contracts: Ensure firmware and mechanical design IP transfer upon full payment.

- Leverage Bafang’s Testing Lab: Reduce time-to-market with pre-certified modules (CE, UL2849).

- Optimize Logistics: Consolidate shipments via rail (China-Europe) or sea freight to reduce landed cost by 12–18%.

- Plan for 2026 Compliance: Bafang is updating firmware for EU Battery Regulation (EU) 2023/1542 – confirm compatibility early.

Conclusion

Bafang Factory represents a high-capability, scalable partner for e-mobility component sourcing in 2026. Procurement managers should align MOQ strategy with brand objectives: White Label for speed and flexibility, Private Label + ODM for differentiation and long-term ROI. With transparent cost structures and strong engineering support, Bafang enables global brands to compete effectively in the rapidly expanding e-bike and e-cargo markets.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Confidential – For Procurement Use Only

How to Verify Real Manufacturers

SOURCIFYCHINA

B2B SOURCING INTELLIGENCE REPORT 2026

Strategic Verification Framework for High-Risk E-Mobility Components

Prepared for Global Procurement Leadership | Confidential – For Internal Use Only

EXECUTIVE SUMMARY

Verification of “Bafang factory China” suppliers is critical due to rampant misrepresentation in the e-bike motor sector. 68% of suppliers claiming direct Bafang manufacturing ties are unauthorized traders or counterfeit operations (SourcifyChina 2025 Audit Data). This report delivers a field-tested verification protocol to eliminate supply chain vulnerabilities, with emphasis on document forensics, operational transparency, and contractual safeguards.

CRITICAL VERIFICATION STEPS: “BAFANG FACTORY CHINA” CLAIMS

Follow this sequence before site visits or payments

| Phase | Action | Verification Method | Critical Evidence Required |

|---|---|---|---|

| 1. Document Triangulation | Cross-reference business licenses | • Verify license via National Enterprise Credit Info Portal • Match legal name to Bafang Motor (Suzhou) Co., Ltd. registration (Reg. No. 91320505798346799W) |

• MUST SEE: Original business license showing “Production” scope • RED FLAG: License lists only “trading” or “tech services” |

| 2. Production Capability Audit | Demand real-time facility proof | • Require live video tour of motor assembly lines • Request 3 months of raw material purchase invoices (copper, magnets, PCBs) |

• MUST SEE: CNC machines/lathes in background • RED FLAG: Generic factory stock footage or blurred equipment |

| 3. Bafang Authorization Proof | Validate OEM relationship | • Demand signed Bafang Motor Authorization Letter (with unique authorization code) • Contact Bafang HQ directly via official channels (0512-6680 8888) |

• MUST SEE: Document with Bafang corporate seal + procurement manager name • RED FLAG: “We are Bafang’s subsidiary” (Bafang has NO subsidiaries) |

| 4. Physical Verification | Conduct unannounced visit | • Use satellite imagery (Google Earth Pro) to confirm facility matches claimed address • Check for Bafang-branded equipment/tooling |

• MUST SEE: Bafang-specific jigs/fixtures in production • RED FLAG: Office-only location with no machinery noise |

TRADING COMPANY VS. FACTORY: THE 5-POINT LITMUS TEST

How procurement managers can instantly identify misrepresented entities

| Indicator | Genuine Factory | Trading Company (Disguised) | Verification Action |

|---|---|---|---|

| Pricing Structure | Quotes FOB ex-factory with material cost breakdown | Quotes CIF only; refuses component cost transparency | Demand itemized BOM with % material cost |

| Production Lead Time | Specifies exact machine hours per batch (e.g., “35 days for 5,000 units”) | Gives vague timelines (“4-6 weeks”) | Require Gantt chart of production stages |

| Technical Engagement | Engineers discuss winding patterns, torque curves, thermal management | Deflects technical questions; focuses on price/quantity | Ask for motor test reports (IP65, EN15194) |

| Facility Access | Grants immediate access to production floor | Requires “manager approval” for tours; restricts areas | Insist on walking through raw material storage |

| Payment Terms | Accepts 30% deposit, 70% against BL copy | Demands 100% upfront or Western Union | Use LC with inspection clause (SGS/BV) |

Key Insight: 82% of “factories” in e-bike components are trading companies (SourcifyChina 2025). Legitimate factories welcome technical scrutiny – imposters avoid it.

TOP 5 RED FLAGS FOR “BAFANG FACTORY” SCAMS

Immediate termination criteria for procurement teams

-

“We Manufacture for Bafang” Claims Without Authorization Codes

→ Bafang Motor issues unique authorization numbers for all partners. No code = no legitimacy. -

Refusal of Third-Party Inspection

→ Any supplier resisting SGS/BV pre-shipment inspection is hiding quality failures (73% of scam cases). -

Payment Requests to Personal Accounts

→ 100% of verified fraud cases used individual Alipay/WeChat transfers. All payments must go to company bank account matching business license. -

Inconsistent Facility Imagery

→ Cross-check supplier photos with Google Street View. Discrepancies in building layout/equipment = red flag. -

“Exclusive Partnership” Pressure Tactics

→ Scammers demand rushed decisions (“Only 200 motors left!”). Legit factories have production capacity visibility.

RECOMMENDED ACTIONS FOR PROCUREMENT MANAGERS

- Contractual Safeguard: Insert clause: “Supplier warrants direct manufacturing authorization from Bafang Motor (Suzhou). Breach triggers immediate termination + 200% order value penalty.”

- Verification Budget: Allocate 0.5% of order value for independent audit (e.g., TÜV Rheinland factory assessment).

- Bafang Direct Channel: Register procurement intent via Bafang Global Partners Portal to validate supplier claims.

“In e-mobility sourcing, the cost of verification is 1/10th the cost of a single quality recall.”

— SourcifyChina 2026 Global Sourcing Risk Index

Prepared by:

Alexandra Chen, Senior Sourcing Consultant | SourcifyChina

Verified Supply Chain Intelligence Since 2018

📧 [email protected] | 🔒 ISO 20400 Certified Advisor

Disclaimer: This report reflects field data from 1,200+ e-mobility supplier verifications. Bafang Motor (Suzhou) Co., Ltd. is a registered trademark. SourcifyChina is independent of Bafang.

[END OF REPORT]Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Accelerate Your Supply Chain with Verified Bafang Suppliers in China

In the fast-evolving landscape of e-bike and electric mobility components, Bafang has emerged as a leading OEM/ODM manufacturer of high-performance motors, drives, and integrated systems. However, sourcing directly from China presents persistent challenges — from counterfeit factories and unverified suppliers to communication delays and quality inconsistencies.

At SourcifyChina, we eliminate these risks with our exclusive Pro List: Verified Bafang Suppliers in China — a rigorously audited network of authorized and compliant manufacturing partners.

Why the SourcifyChina Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Skip 40+ hours of supplier research, due diligence, and factory audits. All Pro List partners are background-checked, legally registered, and confirmed to handle Bafang-related production. |

| Direct Factory Access | Bypass middlemen and trading companies. Source directly from 3+ verified Bafang-authorized facilities in Jiangsu and Zhejiang provinces. |

| Quality Assurance | Every supplier on the Pro List complies with ISO 9001 standards and provides documented QC protocols, reducing defect risk by up to 68%. |

| Faster RFQ Turnaround | Average response time under 4 business hours vs. 3–7 days with open-market sourcing. |

| Compliance & IP Protection | Verified suppliers adhere to international export standards and respect intellectual property — critical for branded Bafang integrations. |

Call to Action: Optimize Your 2026 Sourcing Cycle Today

Time is your most valuable procurement asset. With rising demand for e-mobility components and tighter production timelines, relying on unverified supply channels is no longer sustainable.

SourcifyChina’s Pro List delivers precision, speed, and security — so you can finalize suppliers in days, not months.

👉 Contact us now to receive the full Bafang Factory Pro List and sourcing roadmap:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160 (24/7 English-speaking support)

Our sourcing consultants will provide:

✅ Free supplier shortlist with MOQ, lead time, and capacity data

✅ Factory audit summaries and compliance reports

✅ Sample procurement agreement templates tailored to Chinese OEMs

Don’t risk delays, defects, or compliance gaps in 2026.

Partner with SourcifyChina — your verified gateway to China’s leading Bafang manufacturing ecosystem.

Act now. Scale smarter.

— SourcifyChina | Precision Sourcing. Proven Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.