The global industrial machinery components market, including precision-engineered parts like B16 heads, is witnessing steady expansion driven by growing demand across oil & gas, chemical processing, and power generation sectors. According to a 2023 report by Mordor Intelligence, the global valve market—closely tied to B16 head applications—is projected to grow at a CAGR of 5.8% from 2023 to 2028, reaching a valuation of over USD 105 billion. Similarly, Grand View Research estimates a CAGR of 5.6% from 2022 to 2030, citing increased infrastructure investments and stringent safety regulations as key drivers. As critical components compliant with ASME B16.5 standards for pipeline connections, B16 heads require high precision and material integrity, placing a premium on manufacturer expertise. With rising demand for leak-proof, high-pressure-rated fittings, the importance of reliable, certified producers has never been greater. Based on production capabilities, global footprint, compliance certifications, and market presence, here are the top 8 B16 head manufacturers leading the industry in quality and innovation.

Top 8 B16 Head Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Honda B20B, with B16A head. Head Stud Kit. 208-4306. Honda/Acura B16A Head Stud … Home | Company Information | Contact Us | Trademarks and Legal | Mobile Site…

#2 Skunk2 Racing

Domain Est. 1999

#3 B

Domain Est. 1999

Website: theoldone.com

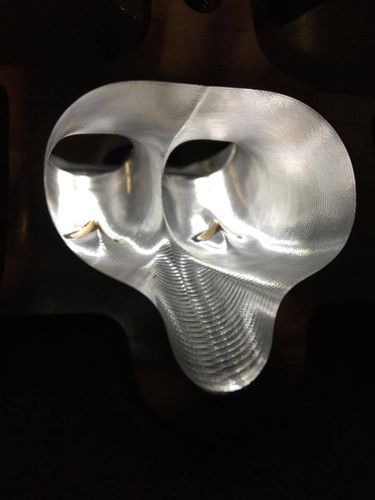

Key Highlights: This is an semi-complete view of cylinder head modifications for the B-16 Honda engines. It’s meant to be a guide of sorts to some of the folks who have ……

#4 B Series GSR/B16 CNC head package

Domain Est. 2007

Website: prayoontoracing.com

Key Highlights: The Prayoonto Racing GSR/B16 head package can do it all. From 1200 + whp 60 psi SFWD trim to 300 + whp all motor. with a STD size valve both gsr and b16 heads ……

#5 Supertech Honda B20 Block B16 Head 84.5mm Bore +1.4cc Dome

Domain Est. 2009

Website: throtl.com

Key Highlights: 30-day returnsSupertech Honda B20 Block B16 Head 84.5mm Bore +1.4cc Dome – H845-P1 ; Earn $29.94 ; W/VIP 8985 ; No VIP 1797 ; Ship to · 29401 ; Supertech Engine products (1)….

#6 B16A/B18C

Domain Est. 2010

Website: headgamesmotorworks.com

Key Highlights: We specialize in high-performance cylinder head porting that delivers real power gains. Trusted by racers and performance enthusiasts alike….

#7 Supertech Honda B20 Block B16 Head 84mm Bore +5.5cc Dome …

Domain Est. 2014

Website: onlinetsm.com

Key Highlights: Out of stockSupertech Honda B20 Block B16 Head 84mm Bore +5.5cc Dome 12.5:1 CR Pistons – Set of 4 (Excl Rings) … Pay over time with Affirm. See if you qualify at checkout….

#8 Supertech Honda B20 Block B16 Head 85mm Bore +5.5cc Dome …

Domain Est. 2016

Website: tristatemotorsports.com

Key Highlights: Supertech Honda B20 Block B16 Head 85mm Bore +5.5cc Dome 12.5:1 CR Pistons – Set of 4 (Excl Rings) … Pay over time with Affirm. See if you qualify at checkout….

Expert Sourcing Insights for B16 Head

H2 2026 Market Trends for B16 Head

As the industrial and manufacturing sectors evolve through 2026, the market for B16 heads—commonly referring to ASME B16.5 or B16.47 standardized pipe flanges and associated components—reflects significant shifts driven by technological innovation, regulatory changes, and global economic dynamics. The second half of 2026 (H2 2026) showcases several key trends shaping demand, supply, and application of B16 heads across critical industries such as oil & gas, petrochemicals, power generation, and renewable energy infrastructure.

1. Increased Demand from Energy Transition Projects

H2 2026 sees a surge in demand for ASME B16-compliant heads, particularly in hydrogen and carbon capture, utilization, and storage (CCUS) projects. As governments and corporations accelerate decarbonization efforts, high-pressure piping systems using B16 flange standards are being adapted for hydrogen transport. The need for leak-proof, high-integrity connections in hydrogen service is driving specifications toward enhanced B16 head designs with improved materials (e.g., stainless steel and low-temperature alloys).

2. Advancement in Material and Coating Technologies

Material innovation is a dominant trend, with increased adoption of corrosion-resistant alloys (CRAs) such as duplex and super duplex stainless steels in B16 head manufacturing. Manufacturers are responding to harsher operating environments—especially in offshore and sour service applications—by integrating advanced coatings and cladding technologies. This ensures longer service life and compliance with increasingly stringent safety standards, particularly in regions like the Middle East and the North Sea.

3. Digitalization and Smart Manufacturing Integration

The B16 head supply chain is undergoing digital transformation. In H2 2026, more manufacturers employ digital twins, predictive analytics, and AI-driven quality control in production. Smart sensors embedded during manufacturing track flange integrity and provide real-time data for predictive maintenance in downstream applications. This shift supports Industry 4.0 adoption and enhances traceability—critical for compliance with ISO and ASME certification requirements.

4. Regional Supply Chain Reconfiguration

Geopolitical factors and trade policies continue to influence regional manufacturing hubs. In H2 2026, North America and India emerge as key production centers for B16 heads, driven by nearshoring trends and government incentives for domestic manufacturing (e.g., U.S. Infrastructure Investment and Jobs Act). Meanwhile, Southeast Asia sees growth in fabrication capacity, serving ASEAN and Australian energy markets.

5. Sustainability and Circular Economy Pressures

Environmental regulations are pushing manufacturers toward sustainable practices. Recycled raw materials, energy-efficient forging processes, and modular design for reusability are becoming standard. Some B16 head producers now offer take-back programs and lifecycle assessments, aligning with ESG (Environmental, Social, and Governance) goals of major engineering, procurement, and construction (EPC) firms.

6. Price Volatility and Raw Material Fluctuations

Despite stabilization compared to earlier years, nickel and chromium prices remain volatile due to geopolitical tensions and mining output variability. This impacts the cost of stainless steel B16 heads, prompting buyers to lock in long-term supply contracts and explore alternative materials where code-compliant.

7. Regulatory Harmonization and Global Standards Alignment

There is growing alignment between ASME B16 standards and international equivalents (e.g., EN 1092-1, JIS B2220), facilitating global project interoperability. In H2 2026, multinational projects increasingly specify dual-certified B16 heads to streamline procurement and reduce lead times, especially in LNG export terminals and cross-border pipeline networks.

Conclusion

The H2 2026 market for B16 heads is characterized by innovation, sustainability, and adaptability. Driven by the energy transition, digitalization, and supply chain resilience, the segment is poised for steady growth, particularly in high-specification and next-generation infrastructure. Stakeholders who invest in advanced materials, digital capabilities, and sustainable manufacturing are best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing B16 Head (Quality, IP)

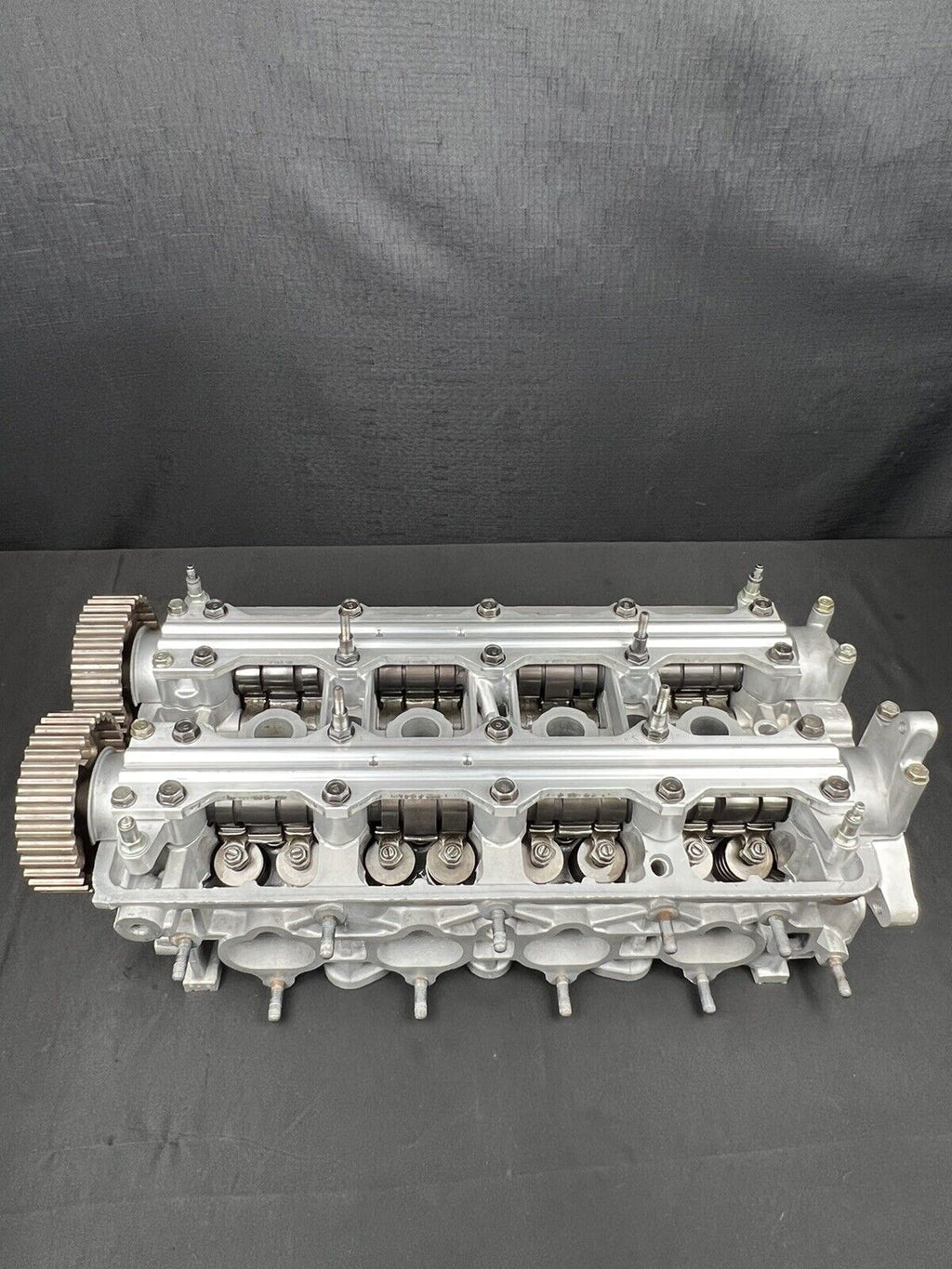

Sourcing B16 heads—commonly referring to the Honda B16 engine cylinder head—can be a complex process, especially in the used or aftermarket market. Buyers often encounter challenges related to quality assurance and intellectual property (IP) concerns. Below are some common pitfalls to watch out for.

Quality-Related Pitfalls

Inconsistent or Unknown Maintenance History

Many B16 heads on the market come from salvaged engines with no documented service history. This raises concerns about potential overheating, improper tuning, or prior damage such as cracked heads, warped decks, or worn valve guides. Without verification, buyers risk installing a compromised component.

Poor Reconditioning or Machining

Used heads are sometimes resurfaced or rebuilt by unqualified technicians. Inadequate deck resurfacing, incorrect valve seat angles, or improper valve stem seal replacement can lead to compression leaks, oil consumption, or premature failure.

Counterfeit or Non-OEM Components

Some sellers offer “B16-spec” heads that are not genuine Honda parts. These may be replicas or modified heads from other engines, falsely marketed as authentic. Performance and durability often fall short of OEM standards.

Intellectual Property (IP) Concerns

Unauthorized Replicas and Knock-offs

Several aftermarket manufacturers produce cylinder heads that mimic the B16 design but do not hold licensing rights from Honda. These replicas may infringe on Honda’s intellectual property and lack official engineering validation, resulting in reliability and fitment issues.

Misrepresentation of Authenticity

Sellers may falsely claim that a head is a genuine OEM part when it is a replica or from a different engine variant (e.g., B18 or D-series modified to resemble a B16). This misrepresentation can lead to legal exposure for commercial resellers and performance issues for end users.

Lack of Compliance with Trademark Laws

Marketing a product as a “Honda B16 Head” without authorization can violate trademark laws, especially if the product is not genuine. Distributors and importers may face legal action if they profit from mislabeled or counterfeit parts.

Conclusion

To avoid these pitfalls, buyers should source B16 heads from reputable suppliers, verify authenticity through part numbers and casting marks, and request documentation of rebuild history when applicable. Additionally, ensuring compliance with IP regulations protects both consumers and businesses from legal and performance risks.

Logistics & Compliance Guide for B16 Head

Overview

This guide outlines the essential logistics and compliance considerations for handling, transporting, and managing the B16 Head, a key component typically associated with industrial engines or machinery. Adherence to regulatory standards, safe handling practices, and efficient logistical planning ensures operational integrity and legal compliance.

Regulatory Compliance

International Standards

The B16 Head must comply with relevant international standards such as ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) where applicable. Ensure documentation reflects conformity with mechanical and material specifications.

Export Controls

Verify if the B16 Head falls under export control regulations such as:

– EAR (Export Administration Regulations) – U.S. Department of Commerce

– ITAR (International Traffic in Arms Regulations) – if applicable due to dual-use or military applications

Obtain proper export licenses when shipping to restricted destinations.

Environmental Regulations

Comply with environmental directives such as:

– REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – EU regulation for material safety

– RoHS (Restriction of Hazardous Substances) – applicable if electronic components are integrated

Ensure material declarations are available and up to date.

Transportation & Handling

Packaging Requirements

Use custom-fitted, shock-absorbent packaging to prevent damage during transit. Include:

– Anti-corrosion coating or VCI (Vapor Corrosion Inhibitor) packaging

– Secure crating for international shipments

– Clearly labeled handling instructions (e.g., “Fragile,” “This Side Up”)

Shipping Documentation

Maintain accurate shipping documentation, including:

– Commercial invoice with HS code (e.g., 8409.91 for engine parts)

– Packing list detailing weight, dimensions, and quantity

– Certificate of Origin (required for customs clearance)

– Bill of Lading or Air Waybill (AWB)

Mode of Transport

Choose the appropriate transport method based on urgency, cost, and destination:

– Air Freight – for time-sensitive or high-value shipments

– Sea Freight – for bulk or non-urgent deliveries

– Land Transport – for regional distribution; ensure vehicle suspension and securing systems prevent vibration damage

Customs Clearance

HS Code Classification

Classify the B16 Head under the correct Harmonized System (HS) code. Typical classification may fall under:

– 8409.91 – Parts suitable for use solely or principally with internal combustion piston engines

Confirm with local customs authorities to avoid misclassification penalties.

Duties & Tariffs

Research import duties, VAT, and any trade agreement benefits (e.g., USMCA, EU free trade agreements) applicable to the destination country. Factor these into cost projections.

Import Licenses

Determine whether special import permits or technical certifications are required in the destination country, especially for industrial engine components.

Storage & Inventory Management

Warehouse Conditions

Store B16 Heads in a dry, temperature-controlled environment to prevent:

– Corrosion

– Contamination

– Deformation from stacking or pressure

Use pallet racking systems to avoid direct floor contact.

Inventory Tracking

Implement a barcode or RFID-based tracking system to monitor:

– Batch numbers

– Manufacturing and expiry dates (if applicable)

– Location within warehouse

Ensure traceability for compliance audits.

Quality Assurance & Documentation

Inspection Protocols

Conduct pre-shipment inspections to verify:

– Conformance to technical drawings and tolerances

– Absence of surface defects or machining errors

– Proper labeling and packaging

Certifications

Maintain and provide upon request:

– Certificate of Conformity (CoC)

– Material Test Reports (MTR)

– Calibration certificates for measurement tools used in production

Safety & Risk Management

Handling Safety

Train personnel on proper lifting techniques and use of material handling equipment (e.g., forklifts, hoists) to prevent injury and component damage.

Risk Mitigation

- Purchase freight insurance covering loss, theft, and damage

- Establish contingency plans for supply chain disruptions

- Perform regular audits of logistics providers for compliance and performance

Conclusion

Effective logistics and compliance management for the B16 Head ensures timely delivery, regulatory adherence, and customer satisfaction. Regular review of international regulations, carrier performance, and internal procedures is essential for continuous improvement.

In conclusion, sourcing a B16 head requires careful consideration of compatibility, authenticity, condition, and cost. Whether for a performance build, engine swap, or restoration project, ensuring that the B16 cylinder head matches your specific engine variant (such as B16A, B16B, or B16A1) is crucial for optimal performance and fitment. Purchasing from reputable suppliers, verifying part numbers, and inspecting for damage like cracks or worn valve guides will help secure a reliable component. Additionally, consider rebuilding or reconditioning the head to OEM specifications to maximize efficiency and longevity. Overall, a well-sourced and properly maintained B16 head can significantly enhance engine performance, making it a worthwhile investment for Honda enthusiasts and performance builders alike.