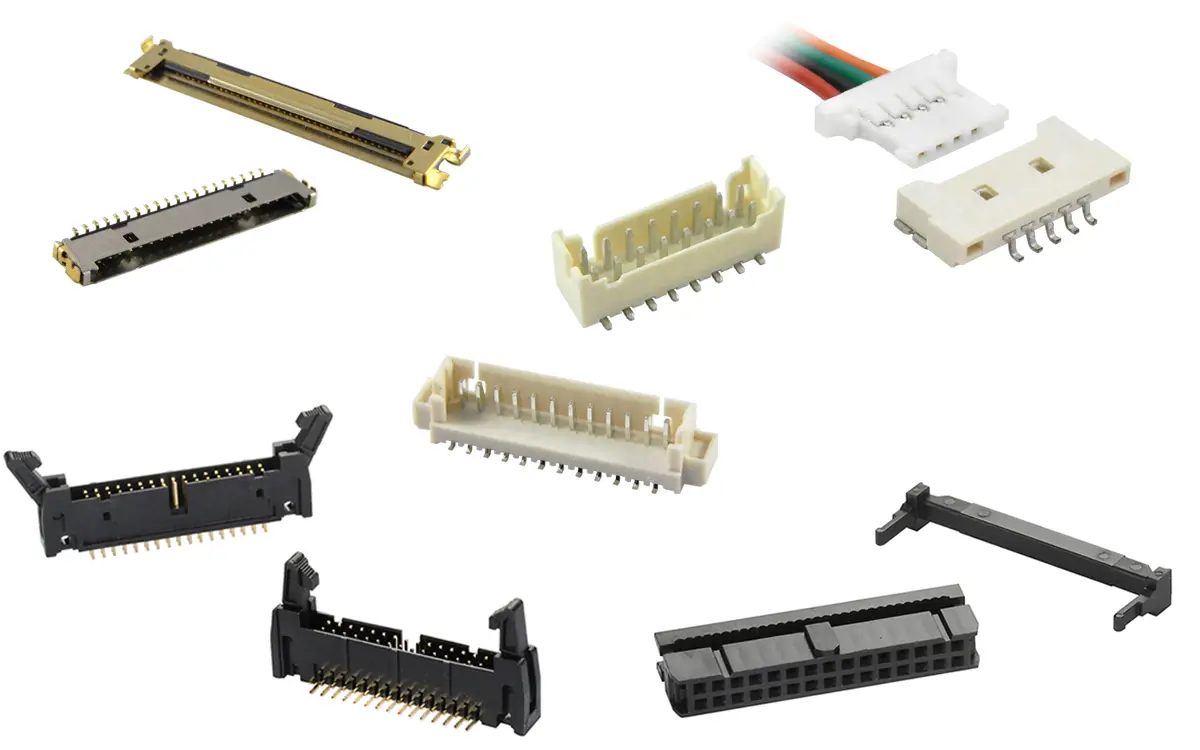

The global auxiliary connector market is experiencing steady expansion, driven by rising demand across automotive, consumer electronics, and industrial applications. According to Grand View Research, the global automotive connectors market—encompassing auxiliary connectors—was valued at USD 18.43 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence reports a robust outlook, forecasting a CAGR of over 5.2% for the global electrical connectors market during the 2024–2029 period, citing increased automation, electric vehicle (EV) adoption, and miniaturization in electronics as key growth catalysts. With auxiliary connectors playing a critical role in facilitating reliable signal and power transmission, manufacturers that combine innovation, scalability, and quality are positioned to lead in this evolving landscape. Here are the top 9 auxiliary connector manufacturers shaping the industry’s future.

Top 9 Auxiliary Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical and Electronic Connectors

Domain Est. 1996

Website: hirose.com

Key Highlights: Hirose Electric Co., Ltd. is a leading global supplier of innovative interconnects, employing advanced engineering services, superior customer support and ……

#2 Prysmian

Domain Est. 2005

Website: prysmian.com

Key Highlights: Welcome to Prysmian: the world leader in cable manufacturer, energy solutions, telecom cables and systems industry. Find out more!…

#3 Advanced Electronic Components & Solutions

Domain Est. 2021

Website: kyocera-avx.com

Key Highlights: KYOCERA AVX is a leading global manufacturer of advanced electronic components & solutions engineered to accelerate innovation and build a better future….

#4 E

Domain Est. 1992

Website: te.com

Key Highlights: Our auxiliary connector systems are package-maximized, making them the perfect connection for electric vehicles because they deliver the higher voltages that ……

#5 Refrigerant Distributors – Auxiliary Side Connectors

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Sporlan auxiliary side connectors (ASC’s) permit removable nozzle type Sporlan refrigerant distributors, without side connections, to be used for hot gas bypass ……

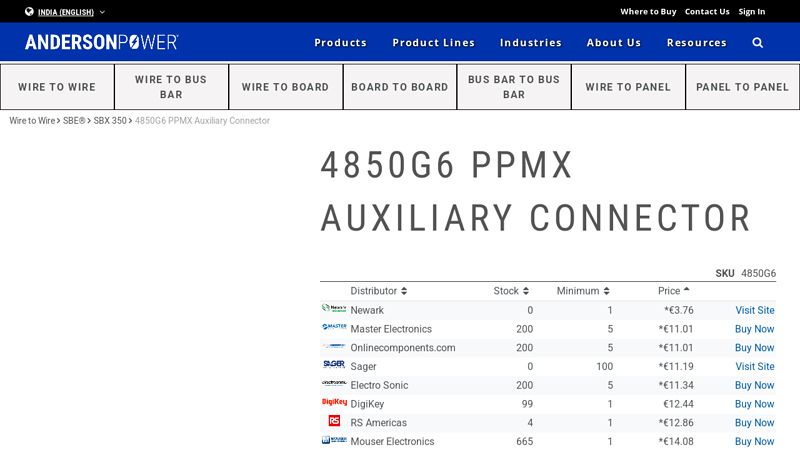

#6 4850G6 PPMX Auxiliary Connector

Domain Est. 1996

Website: andersonpower.com

Key Highlights: The PPMX auxiliary connector allows up to 8 auxiliary circuits to be used in the SBE®, SBO®, & SBX® housings. · There are 4 auxiliary circuits per PPMX connector ……

#7 GTK UK

Domain Est. 1999

Website: gtk.co.uk

Key Highlights: GTK is a world class provider of high quality electronics. With over 35 years’ experience, we can provide custom cable assemblies, connectors and displays, ……

#8 Auxiliary Connector: The Bridge Between Your Devices

Domain Est. 2002

Website: lenovo.com

Key Highlights: An auxiliary connector, commonly known as an aux cable, is a versatile audio cable that connects devices like smartphones or MP3 players to external audio ……

#9 China Wholesale Aux Power Connector Factories

Domain Est. 2021

Website: anen-connector.com

Key Highlights: Features: • Multiple powerpoles, with sleeve and fixed groove design • The terminals are made of high-purity electrolytic red copper • The housing is made….

Expert Sourcing Insights for Auxiliary Connector

H2: Market Trends for Auxiliary Connectors in 2026

As we approach 2026, the global market for auxiliary (AUX) connectors is undergoing a significant transformation driven by evolving consumer preferences, technological advancements, and shifts in the electronics and automotive industries. While AUX connectors have traditionally served as standard analog audio interfaces in consumer electronics, their role and relevance are being redefined in a rapidly digitizing world.

1. Declining Use in Consumer Electronics, but Niche Demand Remains

By 2026, the integration of AUX connectors in smartphones and tablets continues to diminish, with most manufacturers favoring Bluetooth, USB-C audio, and wireless earbuds. However, demand remains stable in niche markets such as budget audio devices, legacy systems, and regions with limited access to high-end wireless technology. AUX ports are still valued for their simplicity, compatibility, and low latency, ensuring continued use in entry-level smartphones, MP3 players, and portable speakers.

2. Steady Growth in Automotive Applications

The automotive sector remains a key growth driver for AUX connectors. Despite the rise of Bluetooth and USB integration, many vehicle manufacturers—especially in emerging markets—continue to include AUX inputs as a cost-effective and universally compatible audio solution. In 2026, AUX ports are commonly found in mid-tier and economy vehicles, serving as a backup or supplementary audio input. Additionally, retrofit and aftermarket car audio systems frequently rely on AUX connectors, supporting aftermarket sales.

3. Industrial and Commercial Adoption

Beyond consumer use, auxiliary connectors are finding sustained relevance in industrial and commercial environments. Equipment such as public address systems, audio mixers, security systems, and point-of-sale (POS) terminals often incorporate AUX ports for audio monitoring or external device connectivity. The reliability and ease of integration of 3.5mm and 2.5mm AUX jacks make them preferable in environments where wireless signals may be unreliable.

4. Material and Design Innovation

To meet durability and miniaturization demands, manufacturers are advancing AUX connector designs with improved materials such as gold-plated contacts, ruggedized housings, and moisture-resistant coatings. These enhancements are particularly important in automotive and industrial applications where connectors are exposed to vibration, temperature extremes, and dust.

5. Regional Market Disparities

Market adoption varies significantly by region. In North America and Western Europe, AUX connector usage is declining in favor of digital alternatives. In contrast, markets across Asia-Pacific, Latin America, and Africa continue to show stable or growing demand due to the popularity of affordable electronics and slower adoption of wireless infrastructure.

6. Competitive Landscape and Supply Chain

Leading connector manufacturers such as TE Connectivity, Amphenol, and Molex are adapting by diversifying product lines and focusing on high-reliability AUX solutions for automotive and industrial clients. Supply chains have stabilized post-pandemic, with increased localization efforts to reduce dependency on single-source regions.

Conclusion

While the auxiliary connector is no longer at the forefront of consumer tech innovation, it maintains a resilient presence in 2026 across automotive, industrial, and emerging markets. Its future lies not in mass consumer adoption but in serving as a reliable, low-cost, and interoperable interface where simplicity and broad compatibility are paramount. As long as analog audio interfaces remain relevant in specific ecosystems, the AUX connector will retain a strategic, albeit niche, role in the global electronics market.

Common Pitfalls Sourcing Auxiliary Connectors (Quality, IP)

Sourcing auxiliary connectors—often used in industrial, automotive, and electronic systems for secondary power, signal, or data transmission—requires careful evaluation to avoid reliability and compliance issues. Two critical areas where problems frequently arise are quality inconsistencies and incorrect Ingress Protection (IP) ratings. Below are common pitfalls in these areas:

Poor Quality Materials and Construction

Low-cost auxiliary connectors may use substandard materials such as brittle plastics, undersized conductors, or low-grade plating on contacts. This can lead to premature failure due to mechanical stress, corrosion, or poor electrical conductivity. Inadequate crimping or soldering during manufacturing also increases the risk of intermittent connections or complete failure under vibration or thermal cycling.

Inconsistent Manufacturing Tolerances

Auxiliary connectors from unreliable suppliers often suffer from inconsistent dimensional tolerances, leading to mating issues, poor contact alignment, or difficulty in assembly. This inconsistency reduces reliability and can compromise the integrity of the entire system, especially in high-vibration environments.

Misrepresented or Uncertified IP Ratings

A major pitfall is assuming that a connector labeled with an IP rating (e.g., IP67, IP68) actually meets that standard. Some suppliers falsely claim IP ratings without proper testing or certification. Without independent verification, connectors may fail to protect against dust or moisture, leading to short circuits or corrosion in harsh environments.

Lack of Environmental Testing Data

Even if a connector claims a specific IP rating, sourcing without access to full test reports—such as duration of water submersion, pressure differentials, or thermal cycling data—can be risky. For example, an IP68-rated connector may be tested for 1 meter of submersion for 30 minutes, but your application may require 3 meters for several hours. Without detailed data, the connector may not meet actual field requirements.

Inadequate Sealing Mechanisms

Poorly designed or manufactured seals (O-rings, gaskets) can degrade quickly when exposed to UV radiation, oils, or extreme temperatures. This compromises the IP rating over time, even if initially effective. Using connectors with incompatible elastomer materials for the operating environment is a frequent oversight.

Overlooking Long-Term Supplier Reliability

Sourcing from suppliers without a track record of quality control increases the risk of batch-to-batch variability. A one-time sample may perform well, but ongoing production may lack consistency, especially if manufacturing is outsourced or quality systems are not ISO-certified.

Avoiding these pitfalls requires due diligence: verify certifications, request test data, evaluate material specifications, and consider working with reputable manufacturers or distributors with proven quality assurance processes.

Logistics & Compliance Guide for Auxiliary Connector

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to Auxiliary Connectors used in electronic or electrical systems.

Product Classification & Specifications

Ensure the auxiliary connector is accurately classified under the appropriate Harmonized System (HS) Code for international shipping. Typical classifications may fall under electrical connectors (e.g., HS 8536.69 or 8538.90, depending on function and design). Maintain updated technical specifications including pin configuration, voltage/current ratings, temperature range, and material composition (e.g., thermoplastic housing, copper alloy contacts).

Packaging & Labeling Requirements

Package auxiliary connectors in ESD-safe materials if static-sensitive. Use moisture barrier bags where applicable, especially for RoHS-compliant or lead-free components. Label each unit or batch with traceable information including part number, manufacturing date, lot number, and compliance marks (e.g., CE, UL, RoHS). Include handling symbols (e.g., “Fragile,” “Do Not Stack”) as needed.

Storage Conditions

Store auxiliary connectors in a controlled environment:

– Temperature: 10°C to 30°C (50°F to 86°F)

– Humidity: 30% to 60% relative humidity

– Avoid direct sunlight and corrosive atmospheres

Ensure inventory rotation using First-In, First-Out (FIFO) methodology to prevent obsolescence.

Shipping & Transportation

Use certified carriers compliant with IATA, IMDG (for sea freight), or ADR (for road transport in Europe) as applicable. Declare goods with accurate commercial invoices, packing lists, and certificates of origin. For air freight, confirm connectors do not contain restricted magnetic or hazardous materials. Secure packaging to meet drop-test and vibration standards (e.g., ISTA 1A).

Regulatory Compliance

Verify compliance with regional and international standards:

– RoHS (EU): Restriction of Hazardous Substances

– REACH (EU): Registration, Evaluation, Authorization of Chemicals

– UL/CSA (North America): Safety certification for electrical components

– China RoHS: Environmental requirements for electronic products

– UKCA (UK): Post-Brexit conformity marking

Maintain up-to-date Declarations of Conformity (DoC) and test reports from accredited laboratories.

Import/Export Documentation

Prepare and retain the following:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Export Control Classification Number (ECCN), if applicable

– Special permits for controlled shipments (e.g., under EAR or ITAR)

Customs Clearance Procedures

Ensure Harmonized System (HS) code accuracy to avoid delays. Provide detailed product descriptions (e.g., “Electrical Connector for Industrial Control Systems”) rather than generic terms. Coordinate with customs brokers to address tariff inquiries or inspections. Monitor changes in trade agreements or sanctions that may affect shipment eligibility.

Environmental & Disposal Compliance

Auxiliary connectors must be disposed of in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Provide end-of-life handling instructions to customers. Avoid landfill disposal; encourage recycling through certified e-waste facilities.

Audit & Record Retention

Maintain records of compliance documentation, shipping logs, and test certifications for a minimum of 5 years. Conduct annual internal audits to verify adherence to logistics and regulatory requirements. Prepare for third-party audits by certification bodies or customs authorities.

Contact & Support

For compliance inquiries or logistics support, contact:

Compliance Officer: [email protected]

Logistics Coordinator: [email protected]

Emergency Shipments: +1 (800) XXX-XXXX

Conclusion for Sourcing Auxiliary Connector:

After evaluating technical requirements, supplier capabilities, cost implications, and long-term reliability, the sourcing of the auxiliary connector has been concluded successfully. The selected component meets all necessary specifications, including electrical performance, environmental resistance, and mechanical compatibility. The chosen supplier offers competitive pricing, consistent quality, reliable lead times, and compliance with industry standards. This sourcing decision supports operational efficiency, reduces supply chain risk, and ensures seamless integration into the final assembly. Continued monitoring of supplier performance and market alternatives is recommended to maintain optimal cost and quality over time.