The global automotive upholstery market is experiencing steady growth, driven by rising vehicle production, increasing consumer demand for premium interiors, and advancements in sustainable and durable materials. According to Grand View Research, the global automotive interior components market size was valued at USD 84.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A critical enabler of this expansion is the specialized equipment used in manufacturing high-quality upholstery—including industrial sewing machines designed for automotive applications. As automakers emphasize comfort, aesthetics, and customization, the demand for precision sewing technology has surged. This has elevated the role of leading automotive upholstery sewing machine manufacturers, who provide advanced, automated, and robust solutions tailored to the rigorous standards of modern automotive textile production. In this evolving landscape, nine manufacturers stand out for innovation, reliability, and market reach.

Top 9 Automotive Upholstery Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Artisan Sewing Supplies

Domain Est. 1999

Website: artisansew.com

Key Highlights: Artisan Sewing Machines – a quality manufacturer of industrial sewing machines, Leather Sewing Machine, Heavy Duty Sewing Machine, and cutters….

#2 Industrial sewing machines for automotive upholstery USA

Domain Est. 2006

Website: cowboysew.com

Key Highlights: Hightex 205-370BF is sophisticated upholstery sewing machine has been improved by the leading leather sofas and furniture manufacturers (La-Z-Boy, Ethan Allen ……

#3 Automotive Upholstery Sewing Machine Manufacturers and Suppliers

Domain Est. 2016

Website: topeaglesewing.com

Key Highlights: Shop online for the efficient automotive upholstery sewing machine for sale at topeaglesewing.com. Assisted by the advanced equipment and technology, ……

#4 Sewing machines — English

Domain Est. 2000

Website: pfaff-industrial.com

Key Highlights: Sewing of medium-heavy materials, e.g. furniture and car upholstery, leather clothing, leather goods, etc. PFAFF 1246. Double-needle flatbed sewing machines ……

#5 Industrial Sewing Machines

Domain Est. 2000

Website: brother-usa.com

Key Highlights: Free delivery over $50 · 30-day returnsIndustrial Sewing Machines. Whether straight stitch, buttonholer or bar tack, Brother has the right sewing machine for your production line….

#6 Global Industrial Sewing Machines!

Domain Est. 2010

Website: globalsew.com

Key Highlights: Welcome at Global Industrial Sewing Machines! As one of the largest distributors in industrial sewing, IMCA/Global has a lot to offer….

#7 FOXSEW Sewing Machine, Cutting Machine manufacturer, Garment …

Domain Est. 2011

Website: foxsew.com

Key Highlights: FOXSEW specialized in manufacturing all kinds of sewing machines series, Like Heavy Duty Sewing Machines, Programmable Pattern Sewing Machines, Special Sewing ……

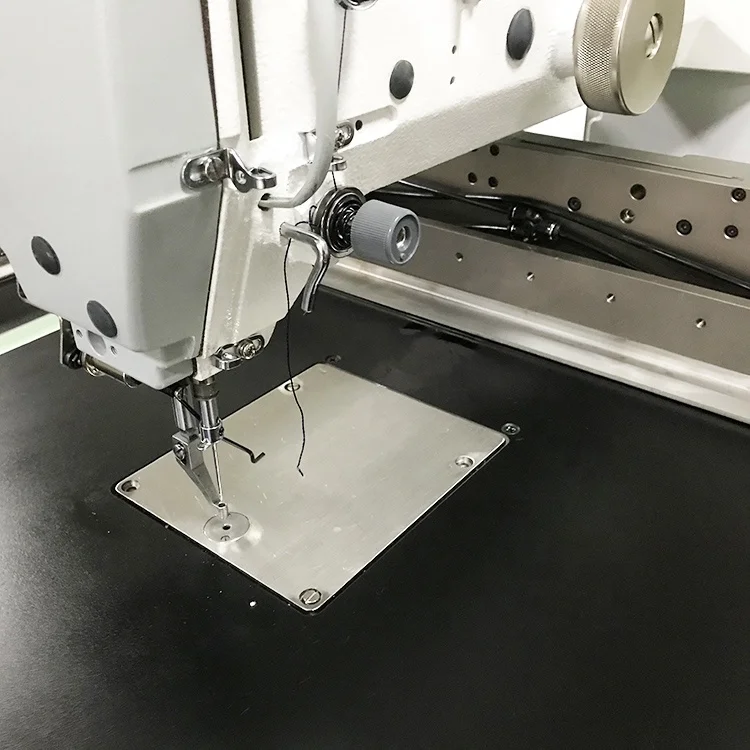

#8 Industrial Sewing Machines in Furniture and Automotive Upholstery

Domain Est. 2012

Website: zjkwonglam.com

Key Highlights: This article explores the applications of heavy-duty sewing machines in furniture and automotive industries, focusing on material requirements, machine ……

#9 Jacksew

Domain Est. 2021

Website: jacksew.com

Key Highlights: Free delivery 30-day returnsJacksew: Top US distributor of industrial sewing machines, offering new machines, spare parts, and custom sewing solutions. Contact us for expert ……

Expert Sourcing Insights for Automotive Upholstery Sewing Machine

2026 Market Trends for Automotive Upholstery Sewing Machines

The global market for automotive upholstery sewing machines is poised for significant transformation by 2026, driven by advancements in automotive manufacturing, rising demand for premium interiors, and the integration of automation and smart technologies. This analysis explores key trends shaping the industry landscape in the coming years.

Rising Demand for Premium and Customized Vehicle Interiors

Consumers are increasingly prioritizing comfort, aesthetics, and personalization in vehicle interiors. As automakers respond with higher-end materials such as leather, Alcantara, and sustainable textiles, the need for precision sewing equipment rises. This trend is particularly evident in the luxury and electric vehicle (EV) segments, where interior design plays a crucial role in brand differentiation. By 2026, manufacturers of upholstery sewing machines will need to offer models capable of handling diverse materials with high stitch quality and design flexibility.

Growth of Electric and Autonomous Vehicles

The rapid expansion of the electric vehicle market is reshaping production requirements. EV interiors often feature innovative layouts and advanced materials to enhance user experience, demanding more sophisticated sewing solutions. Additionally, as semi-autonomous and autonomous vehicles evolve, interior spaces are being reimagined—incorporating lounge-like seating and modular designs. These changes require adaptable sewing machines that support complex 3D patterns and seamless joins, accelerating demand for programmable and multi-axis sewing systems.

Automation and Smart Manufacturing Integration

By 2026, automation will be a dominant force in automotive upholstery production. Sewing machines equipped with robotics, computer vision, and IoT connectivity are expected to become standard in Tier-1 supplier facilities. These smart machines enable real-time monitoring, predictive maintenance, and integration with digital production lines, improving efficiency and reducing downtime. The adoption of Industry 4.0 principles will drive demand for sewing systems compatible with centralized manufacturing execution systems (MES).

Sustainability and Eco-Friendly Materials

Sustainability is becoming a core focus across the automotive supply chain. The use of recycled fabrics, bio-based leathers, and low-impact dyes is on the rise. Sewing machines will need to adapt to the unique handling characteristics of these materials, which may be more delicate or irregular than traditional textiles. Machine manufacturers are expected to develop specialized attachments and tension controls to ensure consistent performance with eco-friendly substrates.

Regional Manufacturing Shifts and Supply Chain Localization

Geopolitical factors and supply chain resilience concerns are prompting automakers to localize production. This shift is increasing demand for sewing machines in emerging markets such as India, Southeast Asia, and Eastern Europe. Equipment suppliers will need to offer cost-effective, durable models tailored to regional production scales and infrastructure. Additionally, modular and easy-to-maintain machines will gain favor in areas with limited technical support.

Advancements in Sewing Machine Technology

Innovation in sewing machine design will continue through 2026, with trends including:

– Servo-driven systems for energy efficiency and precise control.

– Laser-guided stitching to improve accuracy on curved surfaces.

– AI-powered defect detection integrated directly into sewing stations.

– Collaborative robots (cobots) paired with sewing machines to assist human operators.

These advancements will enhance productivity while reducing waste and labor costs, making high-end upholstery more accessible across vehicle segments.

Conclusion

By 2026, the automotive upholstery sewing machine market will be defined by technological sophistication, sustainability, and alignment with next-generation vehicle design. Manufacturers that invest in automation, adaptability, and smart integration will be best positioned to meet evolving industry demands and capitalize on growth opportunities in both traditional and emerging automotive markets.

Common Pitfalls When Sourcing Automotive Upholstery Sewing Machines (Quality and Intellectual Property)

Sourcing automotive upholstery sewing machines involves several critical considerations, especially regarding product quality and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, legal disputes, and reputational damage. Below are key pitfalls to avoid:

1. Prioritizing Low Cost Over Quality

One of the most common mistakes is selecting machines based solely on price. Low-cost machines often use inferior materials and components, leading to frequent breakdowns, inconsistent stitch quality, and higher long-term maintenance costs. Automotive upholstery requires high-tension, heavy-duty stitching for materials like leather, vinyl, and reinforced fabrics—machines not built for such demands will underperform.

Solution: Evaluate total cost of ownership, including durability, service life, and maintenance. Opt for reputable suppliers with proven track records in industrial sewing applications.

2. Inadequate Verification of Technical Specifications

Buyers may assume that generic industrial sewing machines are suitable for automotive use. However, automotive upholstery often requires specialized features such as programmable stitch patterns, automatic thread trimmers, high-speed operation, and compatibility with thick layered materials.

Solution: Clearly define technical requirements and validate machine capabilities through testing or third-party certifications. Request performance data and case studies from existing clients.

3. Overlooking After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and occasional repairs. Sourcing from suppliers without a local service network or reliable spare parts supply can result in extended downtime.

Solution: Confirm the availability of technical support, training, and spare parts before purchase. Prefer suppliers with established service centers or partnerships in your region.

4. Ignoring Intellectual Property Rights

When sourcing from overseas manufacturers—particularly in regions with lax IP enforcement—there’s a risk of inadvertently purchasing machines that infringe on patented technologies. Some suppliers may clone popular models from well-known brands (e.g., Juki, Brother, or Bartlett) without licensing.

Solution: Conduct due diligence on the supplier’s IP compliance. Request documentation proving original design or licensing agreements. Avoid deals that seem too good to be true, as they may involve counterfeit or pirated technology.

5. Lack of Compliance with Industry Standards

Automotive manufacturing often requires adherence to strict quality and safety standards (e.g., ISO, IATF 16949). Non-compliant machines may not integrate well into certified production lines or could compromise product quality.

Solution: Ensure machines meet relevant industry standards and request compliance documentation. Verify certifications with independent bodies if necessary.

6. Insufficient Supplier Vetting

Relying on online marketplaces or brokers without verifying a supplier’s legitimacy increases the risk of fraud, substandard products, or IP violations.

Solution: Perform on-site audits or use third-party inspection services. Check business licenses, customer references, and past export history. Use secure payment terms (e.g., letters of credit) to mitigate financial risk.

By addressing these pitfalls proactively, buyers can ensure they source reliable, high-performance automotive upholstery sewing machines that meet both quality expectations and legal requirements.

Logistics & Compliance Guide for Automotive Upholstery Sewing Machines

Overview

Automotive upholstery sewing machines are specialized industrial equipment used in the manufacturing and repair of vehicle interiors. Transporting and deploying these machines internationally requires careful attention to logistics, regulatory compliance, and technical specifications. This guide outlines key considerations to ensure smooth shipment, customs clearance, and operational compliance.

Classification & HS Code

Identify the correct Harmonized System (HS) code to ensure accurate customs classification and tariff assessment. For automotive upholstery sewing machines, the typical HS code falls under:

8452.21 – Sewing machines, for making up or repairing garments, including those for sewing or stitching leather or textiles.

Note: Confirm with local customs authorities, as sub-classifications may vary by country and machine function (e.g., industrial vs. specialized automotive use).

Packaging & Handling Requirements

Proper packaging is essential to prevent damage during transit:

– Secure the machine on a wooden pallet using stretch wrap or straps.

– Use anti-vibration mounts or foam padding to protect sensitive components.

– Enclose electrical parts in moisture-resistant materials to prevent corrosion.

– Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up,” “Do Not Stack”).

– Include a detailed packing list inside and outside the shipment.

Transportation Modes

Choose the appropriate transportation method based on urgency, cost, and destination:

– Air Freight: Best for urgent deliveries; suitable for single or small-batch machines.

– Ocean Freight: Cost-effective for bulk shipments; use FCL (Full Container Load) or LCL (Less than Container Load).

– Ground Transport: Used for regional or domestic delivery; ensure vehicles are equipped with lifting capabilities.

Import & Export Documentation

Ensure all required documentation is prepared and accurate:

– Commercial Invoice (detailing value, description, and parties)

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (may be required for preferential tariffs)

– Import/Export License (if applicable by country)

– Technical Specifications Sheet (for customs and compliance review)

– Insurance Certificate

Regulatory & Safety Compliance

Adhere to safety and electrical standards in both origin and destination countries:

– CE Marking (EU): Required for machines sold in the European Economic Area; ensures compliance with health, safety, and environmental standards.

– UL/CSA Certification (USA/Canada): Ensures electrical safety compliance.

– RoHS/REACH Compliance: Restricts hazardous substances; particularly relevant for electrical components.

– EMC Directive: Ensures electromagnetic compatibility.

– Local certifications may also apply (e.g., CCC in China, PSE in Japan).

Customs Clearance Process

Facilitate smooth customs clearance by:

– Providing complete and consistent documentation.

– Declaring accurate Harmonized System (HS) codes and product value.

– Paying applicable duties, taxes, and fees promptly.

– Engaging a licensed customs broker in the destination country if necessary.

– Preparing for potential inspections or technical audits.

Installation & Operational Compliance

Ensure the machine meets workplace safety and operational standards:

– Verify compatibility with local power supply (voltage, frequency, plug type).

– Conduct on-site safety checks, including grounding and emergency stop functionality.

– Provide operator training and safety manuals in the local language.

– Comply with occupational health and safety regulations (e.g., OSHA in the U.S., HSE in the UK).

After-Sales Service & Spare Parts Logistics

Plan for ongoing support:

– Maintain a supply of critical spare parts in the destination region.

– Establish service agreements with local technicians or distributors.

– Ensure software/firmware updates comply with local cybersecurity regulations.

– Document warranty terms and service response times.

Environmental & Disposal Compliance

Follow environmental regulations for end-of-life management:

– Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

– Provide guidelines for proper recycling or disposal of the machine and packaging.

– Minimize hazardous materials in design and components.

Conclusion

Successfully managing the logistics and compliance of automotive upholstery sewing machines requires meticulous planning across documentation, transportation, regulatory standards, and after-sales support. By following this guide, manufacturers, distributors, and importers can minimize delays, avoid penalties, and ensure safe, compliant operation in global markets. Always consult with local regulatory bodies and logistics experts to address region-specific requirements.

In conclusion, sourcing an automotive upholstery sewing machine requires a careful evaluation of durability, stitching precision, power, and compatibility with heavy-duty materials such as leather, vinyl, and synthetic fabrics commonly used in vehicle interiors. Key considerations include machine type (e.g., walking foot, cylinder arm, or orbital head), stitch consistency, maintenance requirements, and supplier reliability. Opting for industrial-grade machines from reputable manufacturers ensures longevity, operational efficiency, and reduced downtime in high-demand production environments. Additionally, evaluating after-sales support, warranty, and availability of spare parts contributes to a successful long-term investment. By aligning machine specifications with production needs and quality standards, businesses can enhance productivity, maintain superior craftsmanship, and remain competitive in the automotive upholstery industry.