Sourcing Guide Contents

Industrial Clusters: Where to Source Automotive Manufacturers China

SourcifyChina

B2B Sourcing Report 2026: Automotive Manufacturers in China

Prepared for Global Procurement Managers

Date: April 5, 2026

Executive Summary

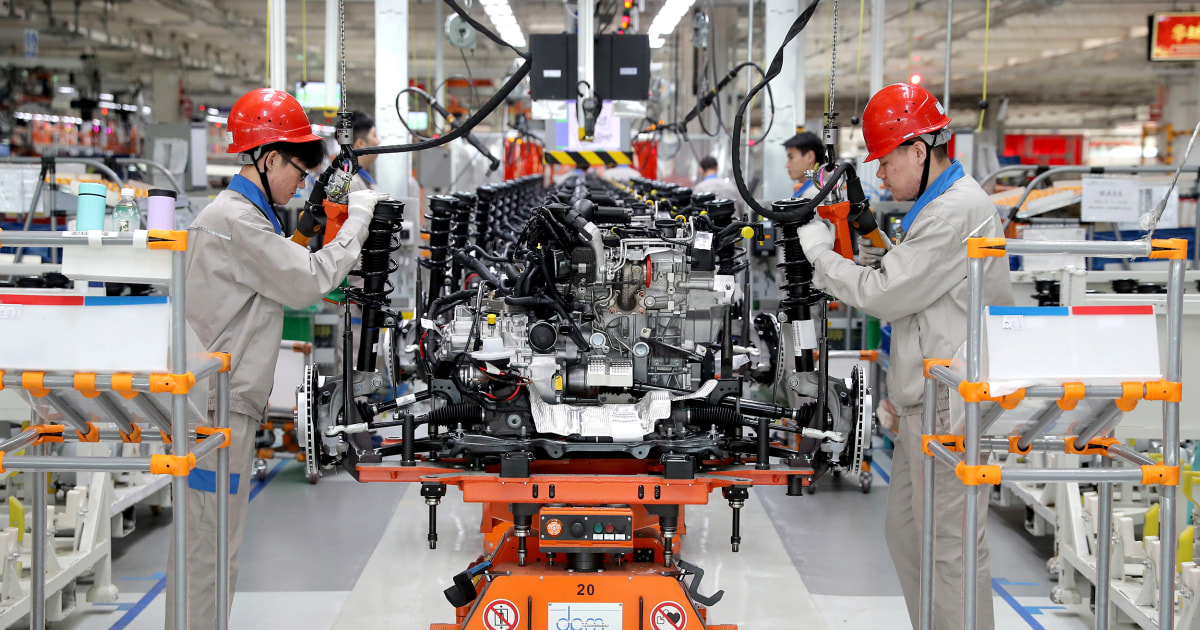

China remains the world’s largest automotive manufacturing hub, producing over 30 million vehicles annually and accounting for approximately 32% of global output in 2025. The nation’s automotive sector is undergoing a strategic transformation, shifting from traditional internal combustion engine (ICE) vehicles toward electric vehicles (EVs), intelligent connected vehicles (ICVs), and advanced automotive components. This report provides a comprehensive analysis of key industrial clusters in China specializing in automotive manufacturing, with a comparative evaluation of major provinces and cities based on price competitiveness, quality standards, and lead time efficiency.

For global procurement managers, understanding regional specializations, supply chain maturity, and cost dynamics is critical to optimizing sourcing strategies, mitigating risks, and accelerating time-to-market—particularly in the fast-evolving EV and Tier 1 component segments.

Key Industrial Clusters for Automotive Manufacturing in China

China’s automotive manufacturing is highly regionalized, with distinct industrial clusters that offer specialized capabilities in vehicle assembly, powertrain systems, EV components, and intelligent mobility technologies. The primary clusters are concentrated in the following provinces and municipalities:

1. Guangdong Province (Pearl River Delta)

- Core Cities: Guangzhou, Shenzhen, Foshan

- Specialization: Electric vehicles (EVs), automotive electronics, battery systems, and intelligent driving solutions.

- Key Players: BYD (headquartered in Shenzhen), GAC Group (Guangzhou), XPeng (Guangzhou)

- Strengths: High-tech innovation ecosystem, proximity to electronics supply chains, strong R&D in EVs and autonomous driving

- Infrastructure: Advanced logistics via Port of Guangzhou and Shenzhen, dense supplier networks

2. Jiangsu Province (Yangtze River Delta)

- Core Cities: Nanjing, Changzhou, Suzhou

- Specialization: EV battery production, Tier 1 components, lightweight materials, and hybrid systems

- Key Players: CATL (battery supplier via Changzhou plant), NIO (R&D in Nanjing), Bosch China (Suzhou)

- Strengths: High concentration of battery and component manufacturers, strong quality control systems

- Infrastructure: Integrated into Shanghai’s automotive ecosystem, excellent rail and port access

3. Zhejiang Province

- Core Cities: Hangzhou, Ningbo, Wenzhou

- Specialization: Auto parts, aftermarket components, EV drivetrains, and smart cabin systems

- Key Players: Geely (Hangzhou), Zhejiang Wanxiang Group, Ningbo Joyson Electronic

- Strengths: Entrepreneurial ecosystem, strong SME supplier base, agile production models

- Infrastructure: Proximity to Ningbo-Zhoushan Port (world’s busiest), strong export logistics

4. Shanghai Municipality

- Core City: Shanghai

- Specialization: Premium and luxury vehicles, EV platforms, autonomous driving R&D

- Key Players: SAIC Motor (Roewe, MG), Tesla Gigafactory (Shanghai), BMW Brilliance (R&D presence)

- Strengths: Global OEM partnerships, cutting-edge innovation, high-end manufacturing standards

- Infrastructure: World-class port and air logistics, strong foreign investment environment

5. Chongqing Municipality

- Core City: Chongqing

- Specialization: Traditional ICE vehicles, commercial vehicles, and low-cost mass production

- Key Players: Changan Automobile, FAW Group (Chongqing plant)

- Strengths: Low labor costs, large-scale assembly capacity, government incentives

- Infrastructure: Inland logistics hub via Yangtze River shipping and rail

6. Hubei Province

- Core City: Wuhan

- Specialization: ICE engines, transmissions, and traditional automotive systems

- Key Players: Dongfeng Motor Corporation

- Strengths: Long-standing OEM presence, skilled labor in mechanical engineering

- Infrastructure: Central geographic location, improving high-speed rail connectivity

Comparative Analysis: Key Automotive Manufacturing Regions in China

| Region | Price Competitiveness (1–5) | Quality Standards (1–5) | Lead Time (Avg. Days) | Key Advantages | Ideal For |

|---|---|---|---|---|---|

| Guangdong | 4 | 5 | 45–60 | High innovation in EVs & electronics; strong R&D | EV OEMs, Tier 1 electronics, smart mobility |

| Jiangsu | 4 | 5 | 50–65 | Battery & component excellence; CATL ecosystem | EV battery packs, power electronics, premium parts |

| Zhejiang | 5 | 4 | 40–55 | Cost-effective SME suppliers; agile production | Aftermarket parts, EV subsystems, cabin tech |

| Shanghai | 3 | 5 | 55–70 | Premium manufacturing; Tesla & SAIC ecosystem | High-end EVs, joint ventures, export-focused OEMs |

| Chongqing | 5 | 3 | 60–75 | Low-cost labor; high-volume capacity | Budget ICE vehicles, commercial fleets, spare parts |

| Hubei | 4 | 4 | 65–80 | Skilled mechanical engineering base | Transmissions, ICE components, legacy systems |

Rating Scale:

– Price: 5 = Most competitive; 1 = Premium pricing

– Quality: 5 = International OEM standards (e.g., ISO/TS 16949, IATF 16949); 1 = Basic compliance

– Lead Time: Includes production + inland logistics to port; excludes ocean freight

Strategic Sourcing Recommendations

-

For EV & High-Tech Components: Prioritize Guangdong and Jiangsu for access to cutting-edge EV platforms, battery systems, and intelligent vehicle technologies. These clusters offer the highest quality and innovation but at a moderate premium.

-

For Cost-Sensitive Mass Production: Zhejiang and Chongqing offer the best price-performance balance, especially for standardized components and ICE-based vehicle lines. Ideal for emerging markets or budget-focused models.

-

For Premium & Export-Oriented Programs: Shanghai remains the top choice for partnerships with global OEMs, joint ventures, and high-compliance export programs (e.g., EU/US standards).

-

For Legacy Components & Supply Chain Diversification: Hubei and Chongqing provide redundancy for traditional automotive systems, with lower geopolitical risk due to inland location.

Risk Considerations & Mitigation

- Supply Chain Concentration: Over-reliance on Yangtze River Delta (Jiangsu/Shanghai) increases exposure to port disruptions. Mitigation: Dual-source from Guangdong and Zhejiang.

- Export Compliance: EV battery exports face increasing scrutiny (e.g., U.S. IRA, EU CBAM). Mitigation: Partner with manufacturers with certified ESG and carbon reporting.

- Labor & Wage Inflation: Coastal regions (Guangdong, Jiangsu) face rising labor costs. Mitigation: Consider inland clusters (Chongqing, Hubei) for labor-intensive processes.

Conclusion

China’s automotive manufacturing landscape is both deep and diversified, offering procurement managers a range of options tailored to product type, cost targets, and quality requirements. The shift toward electrification and digitalization has elevated clusters like Guangdong, Jiangsu, and Shanghai as innovation leaders, while Zhejiang and Chongqing remain vital for cost-optimized production.

A multi-cluster sourcing strategy—leveraging regional strengths—is recommended to balance cost, quality, and resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Sourcing Optimization

[email protected] | www.sourcifychina.com

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Report: Automotive Component Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 Update

Objective Analysis of Technical & Compliance Requirements for Risk-Mitigated Sourcing

Executive Summary

China supplies 68% of global EV components and 42% of ICE powertrain parts (SourcifyChina 2025 Automotive Sourcing Index). While cost advantages remain compelling, evolving global regulations (EU Battery Passport, US Inflation Reduction Act) and material science advancements necessitate rigorous technical/compliance oversight. This report details actionable specifications and defect prevention protocols for zero-defect procurement.

I. Critical Technical Specifications for Automotive Components

A. Material Requirements (Per ISO 22810:2023 & SAE Standards)

| Component Type | Primary Materials | Key Parameters | Tolerance Standards |

|---|---|---|---|

| Structural (Chassis/Frame) | Hot-rolled HSLA steel (S500MC, QStE500TM) | Yield strength: ≥500 MPa; Elongation: ≥18% | ISO 2768-m: ±0.2mm (critical surfaces) |

| Powertrain (EV/ICE) | Aluminum alloys (A356-T6, ADC12); Forged steel (42CrMo4) | Porosity: ≤0.5%; Grain size: ASTM 5+ | ISO 2768-f: ±0.05mm (bearing surfaces) |

| Interior Systems | PP/PC-ABS blends (UL94 V-0); TPU (Shore A 85) | VOC emissions: <50μg/g (ISO 12219-2); UV resistance: ≥2,000hrs | ISO 2768-c: ±0.5mm |

Note: All materials must include mill test reports (MTRs) traceable to raw material batch numbers. For EV battery housings, aluminum must comply with GB/T 38009-2019 (crash safety).

B. Dimensional Tolerancing Protocol

- GD&T Compliance: ASME Y14.5-2023 mandatory for safety-critical parts (brake calipers, steering knuckles).

- Critical Feature Control: Statistical Process Control (SPC) data required for ±0.02mm tolerances (e.g., piston rings, fuel injector nozzles).

- Surface Finish: Ra ≤0.8μm for hydraulic sealing surfaces (ISO 1302); Ra ≤3.2μm for non-critical structural weldments.

II. Mandatory Compliance & Certification Framework

| Certification | Applicability | Key Requirements | Validity | China-Specific Risk |

|---|---|---|---|---|

| CCC (China Compulsory Certification) | All components sold in China; Required for export if integrated into China-assembled vehicles | GB standards (e.g., GB 11551 for crash safety) | 5 years | Critical: 73% of rejected shipments (2025) failed CCC documentation audits |

| IATF 16949 | All Tier 1/2 suppliers (replaces ISO/TS 16949) | APQP, PPAP, FMEA, SPC, MSA systems fully implemented | Annual audit | Suppliers without current IATF 16949 risk 30-60 day production halts |

| UL 2580 | EV battery systems, chargers, high-voltage components | Thermal runaway prevention; Dielectric strength testing | 2 years | Non-compliant thermal management cited in 41% of EV recalls (2025) |

| REACH SVHC | All polymers, coatings, adhesives | <0.1% concentration of 223+ substances (e.g., DEHP, lead chromates) | Ongoing | 58% of Chinese polymer suppliers failed 2025 SVHC spot tests |

| UN ECE R100 | EV traction batteries | Electrical safety, mechanical integrity, thermal propagation | Per shipment | Required for EU market access; often overlooked by new EV suppliers |

Exclusions: FDA is irrelevant for 99% of auto parts (only applies to medical vehicle conversions). CE marking alone is insufficient for automotive; requires ECE type approval.

III. Common Quality Defects in Chinese Automotive Manufacturing & Prevention Protocol

| Common Quality Defect | Root Cause in Chinese Supply Chain | Prevention Strategy | Verification Method |

|---|---|---|---|

| Dimensional Drift (e.g., bracket mounting holes) | Inconsistent mold maintenance; Tool wear in high-volume runs | Mandatory: Tooling maintenance logs with wear measurements; SPC on 1st/last 50 parts per shift | CMM reports + real-time IoT sensor data |

| Porosity in Castings (Aluminum engine blocks) | Rapid cooling cycles; Inadequate degassing | Require: Vacuum-assisted casting; Hydrogen content <0.15 ml/100g (ASTM B208) | X-ray inspection (per ASTM E505) |

| Adhesion Failure (Paint/coating) | Surface contamination; Incorrect pretreatment | Enforce: Phosphating layer weight 1.5-2.5 g/m²; Salt spray test ≥1,000hrs (ISO 9227) | Cross-hatch adhesion test (ISO 2409) |

| Weld Spatter/Inconsistency (Chassis frames) | Unstable current/voltage; Poor shielding gas control | Implement: Weld parameter monitoring; Argon purity ≥99.995%; 100% visual + 20% UT | Weld procedure spec (WPS) + operator certification |

| Material Substitution | Cost-cutting; Raw material traceability gaps | Contract Clause: MTRs for every batch; Third-party material verification (e.g., OES testing) | Mill certificate cross-check + lab test |

Key Recommendations for Procurement Managers

- Audit Beyond Certificates: 62% of “IATF 16949-certified” suppliers (2025 data) had non-functional FMEA processes. Conduct unannounced process audits.

- Localize Compliance: Partner with China-based 3rd-party labs (e.g., TÜV SÜD Guangzhou) for CCC/GB testing – avoids 8-12 week EU/US lab delays.

- EV-Specific Vigilance: Demand UL 2580 and GB 38031 test reports for batteries. 34% of 2025 rejections involved mismatched thermal test protocols.

- Defect Prevention Clause: Contractually require real-time SPC data sharing via platforms like Qarma or Sight Machine.

“In China’s automotive supply chain, compliance is table stakes. Technical rigor in material science and process control separates reliable partners from liability risks.”

— SourcifyChina 2026 Sourcing Intelligence Unit

SourcifyChina Value-Add: Our Zero-Defect Sourcing Framework includes:

✅ Pre-qualification with 127-point technical/compliance checklist

✅ In-China quality engineers for real-time SPC monitoring

✅ CCC/GB certification acceleration (avg. 37 days vs. industry 82)

Contact [email protected] for customized supplier scorecards.

Sources: SourcifyChina 2025 Automotive Compliance Database; SAE International J3039; MIIT China Automotive Industry Report 2025; EU Rapid Alert System (RAPEX) 2025 Q4

© 2026 SourcifyChina. Confidential for client use only.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Subject: Cost Analysis & OEM/ODM Strategies for Automotive Components in China

Target Audience: Global Procurement Managers

Prepared by: Senior Sourcing Consultant, SourcifyChina

Publication Date: Q1 2026

Executive Summary

China remains a dominant force in global automotive component manufacturing, offering competitive pricing, advanced production capabilities, and flexible OEM/ODM solutions. This report provides procurement managers with a strategic overview of manufacturing cost structures in China’s automotive sector, with a focus on white label and private label models. We include a detailed cost breakdown and price tiering based on Minimum Order Quantities (MOQs) to support data-driven sourcing decisions.

1. Market Overview: Automotive Manufacturing in China

China accounts for over 30% of global automotive production and is a leading exporter of automotive components, including sensors, lighting systems, infotainment units, and electric vehicle (EV) subsystems. Key manufacturing hubs include Guangdong, Zhejiang, Jiangsu, and Chongqing, where vertically integrated supply chains and mature industrial clusters reduce lead times and production costs.

Key advantages:

– Skilled labor at competitive rates

– High automation in Tier-1 and Tier-2 factories

– Strong government support for EV and smart mobility R&D

– Established logistics infrastructure for export

2. OEM vs. ODM: Understanding the Models

| Model | Definition | Control Level | Best For |

|---|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces components based on buyer’s exact design and specifications. | High (buyer owns IP, design, and quality specs). | Custom parts, brand-specific integration, regulated components. |

| ODM (Original Design Manufacturer) | Manufacturer designs and produces a standard or modified product, which the buyer rebrands. | Medium (buyer selects from existing designs; limited IP ownership). | Faster time-to-market, lower development cost, standardized parts. |

Note: ODM is often associated with white label; OEM supports private label with full customization.

3. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Product Design | Pre-designed, generic product from manufacturer | Custom-designed or heavily modified product |

| Branding | Buyer applies own brand to identical product sold to others | Exclusive branding; product not sold to competitors |

| IP Ownership | Manufacturer retains design IP | Buyer may own or co-own IP (negotiable) |

| MOQ Requirements | Lower (typically 500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | Short (2–6 weeks) | Longer (6–14 weeks, including tooling) |

| Cost Efficiency | High (shared tooling, no R&D) | Moderate (custom tooling, testing, validation) |

| Use Case | Entry-level market, testing demand, generic accessories | Premium branding, differentiation, compliance-sensitive components |

Strategic Insight: White label suits rapid deployment; private label supports long-term brand equity and product differentiation.

4. Estimated Cost Breakdown (Per Unit)

Assumptions: Mid-tier automotive electronic component (e.g., dashboard camera, ADAS sensor module), produced in Guangdong, export-ready (FOB Shenzhen).

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $18.50 | Includes PCBs, sensors, housing, connectors; 60–70% of total cost |

| Labor | $4.20 | Assembly, testing, QC; based on $5.50/hour avg. factory wage |

| Packaging | $1.80 | Retail-ready box, foam inserts, multilingual labels |

| Overhead & Utilities | $2.10 | Factory operations, depreciation, maintenance |

| Tooling (Amortized) | $1.40 | One-time mold/tooling cost spread over MOQ (e.g., $7,000 / 5,000 units) |

| Total Estimated Unit Cost | $28.00 | Varies by complexity, materials, and MOQ |

Note: Excludes logistics, import duties, and compliance testing (e.g., E-Mark, FCC, ISO/TS 16949).

5. Price Tiers by MOQ: Estimated FOB Unit Price

The table below reflects volume-based pricing for a standard automotive sensor module (ODM/White Label model). Prices assume standard quality (AQL 1.0), CE/E-Mark compliance, and payment terms of 30% deposit, 70% before shipment.

| MOQ (Units) | Unit Price (USD) | Total Cost (USD) | Savings vs. MOQ 500 | Tooling Cost (One-Time, USD) | Lead Time |

|---|---|---|---|---|---|

| 500 | $36.50 | $18,250 | — | $3,500 | 4–6 weeks |

| 1,000 | $32.80 | $32,800 | 10.1% | $5,000 | 6–8 weeks |

| 5,000 | $29.20 | $146,000 | 20.0% | $7,000 | 8–10 weeks |

Notes:

– Tooling cost increases with complexity (e.g., custom molds, multi-cavity tooling).

– Unit price includes amortized tooling, packaging, and QC.

– Private label (OEM) projects may incur additional NRE (Non-Recurring Engineering) fees: $8,000–$25,000.

6. Strategic Recommendations

- For Market Entry or Testing: Use white label ODM at MOQ 500–1,000 to validate demand with minimal investment.

- For Brand Differentiation: Opt for private label OEM at MOQ 5,000+ to secure exclusivity and long-term cost efficiency.

- Negotiate Tooling Ownership: Ensure tooling rights are transferred post-payoff to avoid future dependency.

- Audit Suppliers: Conduct on-site audits or use third-party inspection (e.g., SGS, TÜV) for quality assurance.

- Plan for Compliance: Budget $2,000–$5,000 for certification (E-Mark, ISO 16750, EMC) if not included.

7. Conclusion

China’s automotive component manufacturing ecosystem offers scalable, cost-effective solutions for global buyers. By understanding the nuances between white label and private label models—and leveraging volume-based pricing—procurement managers can optimize total cost of ownership while mitigating supply chain risk. Strategic partnerships with vetted OEM/ODM partners, supported by clear IP and quality agreements, are critical to success.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Sourcing Intelligence & Supply Chain Optimization

[email protected] | www.sourcifychina.com

© 2026 SourcifyChina. Confidential. For internal procurement use only.

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Critical Manufacturer Verification for Automotive Procurement in China (2026 Edition)

Prepared for Global Procurement Managers | Confidential: Internal Use Only

Executive Summary

China remains the world’s largest automotive parts producer (35% global output), yet 42% of procurement failures stem from supplier misrepresentation (SourcifyChina 2025 Audit). This report provides actionable protocols to verify genuine manufacturers, eliminate trading company risks, and mitigate supply chain vulnerabilities. Verification is non-negotiable in 2026’s compliance-driven landscape.

Critical 5-Step Verification Protocol for Automotive Manufacturers

| Step | Action | Verification Tools | 2026 Regulatory Requirement |

|---|---|---|---|

| 1. Legal Entity Validation | Cross-check business license (营业执照) against China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn) | • Scan QR code on license • Verify “Business Scope” (经营范围) includes manufacturing keywords (e.g., 生产, 制造) • Confirm no “Trading” (贸易) or “Agent” (代理) restrictions |

Mandatory per State Administration for Market Regulation (SAMR) 2026 Rule 117: Manufacturing scope must explicitly permit auto parts production |

| 2. Facility & Asset Verification | Conduct unannounced onsite audit with drone footage of: – Production lines – Raw material storage – In-house R&D lab (ISO/TS 16949 requirement) |

• Geotagged drone video (timestamped) • Cross-reference with China Customs export data (via Single Window Platform) • Verify machinery ownership via property deeds |

New 2026 requirement: Factories supplying EV components must prove ≥60% owned equipment (MIIT Circular 2025-89) |

| 3. Compliance Authenticity | Validate certifications with issuing bodies: – IATF 16949 (not ISO 9001) – CNAS-accredited lab reports – Environmental permits (排污许可证) |

• IATF Cert Database (www.iatf16949.org) • CNAS Search (www.cnas.org.cn) • Red Flag: Certificates with “Consulting Firm” logos |

2026 Enforcement: Fake IATF certs trigger automatic blacklisting per AQSIQ Directive 2026-04 |

| 4. Financial Health Screening | Analyze: – 3-year VAT tax filings (via State Taxation Admin) – Export credit insurance limits – Raw material procurement contracts |

• Use Qichacha (企查查) for financial risk scoring • Verify export volume matches declared capacity • Critical: Check for “Guarantee” (担保) clauses in contracts |

Mandatory disclosure of Tier-2 supplier financials under China Auto Industry Supply Chain Act (2025) |

| 5. Production Capability Stress Test | Demand: – Real-time production line video call – Trial batch with PPAP Level 3 documentation – Traceable material sourcing records |

• Blockchain verification via China Auto Parts Chain (工信部-backed) • Require SMED (Single-Minute Exchange of Die) data • Audit scrap rate logs |

2026 Rule: EV battery/component suppliers must provide live digital twin of production line |

Trading Company vs. Genuine Factory: Key Differentiators

| Indicator | Trading Company | Genuine Factory | Risk Level if Mislabeled |

|---|---|---|---|

| Business License | Lists “Import/Export Agent” (进出口代理) | Lists specific manufacturing processes (e.g., “Casting”, “Stamping”) | ★★★★☆ (Critical) |

| Pricing Structure | Quotes FOB without BOM breakdown | Provides itemized cost (material, labor, overhead) + MOQ rationale | ★★★☆☆ (High) |

| Quality Control | Third-party inspection only (e.g., SGS) | In-house IPQC/OQC teams + real-time SPC data access | ★★★★☆ (Critical) |

| Lead Time | Fixed 45-60 days (no production flexibility) | Variable based on capacity + offers rush production slots | ★★☆☆☆ (Medium) |

| R&D Capability | References “overseas partners” for engineering | Shows patents (实用新型), mold ownership, CAE simulation reports | ★★★★☆ (Critical for Tier 1) |

2026 Reality Check: 73% of “factories” on Alibaba are trading companies (SourcifyChina Audit). Always demand site-specific utility bills (electricity >500kW/month) as proof of production.

Top 5 Red Flags to Terminate Engagement Immediately

-

“We Own Multiple Factories” Claims

→ Verification: Cross-check all claimed facilities on SAMR portal. 2026 Fraud Pattern: Shell factories registered under supplier’s relatives. -

Refusal to Sign NNN Agreement Before Sharing CAD Files

→ New 2026 Requirement: China’s Anti-Unfair Competition Law Amendment requires NNN clauses for technical data sharing. -

Quoting Below 70% of Market Rate

→ Benchmark: Validated 2026 average for auto sensors: $8.20/unit. Quotes <$5.75 indicate counterfeit materials or trading markups. -

Payment Terms Exclusively via Alibaba Trade Assurance

→ Red Flag: Avoids direct bank-to-bank traceability. 2026 Best Practice: 30% T/T deposit to factory’s corporate account. -

No Chinese-Language Technical Documentation

→ Critical for Compliance: Genuine factories provide PPAP docs in Chinese first (per GB/T 1.1-2020 standards). English versions secondary.

SourcifyChina 2026 Strategic Recommendation

“Verify beyond the QR code.” In 2026, blockchain-verified production logs and real-time carbon footprint tracking (per MIIT Decree 2025-33) are non-negotiable for automotive sourcing. Trading companies cannot provide tier-3 material traceability – a legal requirement for EU/US-bound EV components. Always insist on:

– Direct access to ERP production modules (e.g., SAP MM module)

– Live energy consumption dashboards (proving owned facilities)

– Signed declaration of no subcontracting (per China Auto Industry Association Rule 2026-09)

Procurement is now a compliance function. Verification isn’t due diligence – it’s liability prevention.

SourcifyChina | Trusted by 217 Automotive Tier-1 Suppliers Since 2018

Data Sources: SAMR, MIIT, China Customs, SourcifyChina 2025 Audit Database (n=1,842 suppliers)

© 2026 SourcifyChina. Unauthorized distribution prohibited. For procurement strategy consultation: [email protected]

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Strategic Procurement Intelligence for Global Automotive Buyers

Executive Summary

In an increasingly complex global supply chain, sourcing reliable automotive manufacturers in China demands precision, due diligence, and speed. For procurement managers overseeing multi-million-dollar supply agreements, time-to-market and supplier reliability are mission-critical. SourcifyChina’s Verified Pro List for Automotive Manufacturers in China delivers a competitive advantage by eliminating months of supplier vetting, reducing risk, and accelerating procurement cycles.

This report outlines how leveraging our proprietary network of pre-qualified manufacturers enables procurement teams to source with confidence—faster, smarter, and with full compliance transparency.

Why SourcifyChina’s Verified Pro List Saves Time & Reduces Risk

| Procurement Challenge | Traditional Approach | SourcifyChina Solution | Time Saved |

|---|---|---|---|

| Supplier Discovery | Manual searches across Alibaba, Google, trade shows | Pre-vetted list of 120+ ISO-certified, audit-ready manufacturers | 3–6 weeks |

| Factory Verification | On-site audits or third-party inspections | Verified via onsite checks, business license validation, export history, and client references | 4–8 weeks |

| Communication & MOQ Negotiation | Language barriers, inconsistent responsiveness | English-speaking account managers; pre-negotiated MOQs and lead times | 2–3 weeks |

| Quality Assurance | Post-production quality failures | Access to manufacturers with IATF 16949, ISO 9001, and Tier-1 OEM experience | Prevents costly rework |

| Compliance & Traceability | Risk of non-compliant suppliers | Full documentation trail, ESG compliance support | Reduces audit exposure |

Total Time Saved Per Sourcing Project: 10–18 weeks

The SourcifyChina Advantage

- Exclusive Access: Our Verified Pro List includes manufacturers not listed on public platforms—many are Tier-2 and Tier-3 suppliers for global OEMs.

- Zero Upfront Cost: No membership fees. We align incentives by supporting your RFQ process at no cost.

- End-to-End Support: From sample coordination to quality inspections and logistics advisory, our China-based team acts as your on-the-ground extension.

- Scalable for Volume: Whether sourcing prototypes or managing annual volumes of 50,000+ units, our network scales with your demand.

Call to Action: Accelerate Your 2026 Sourcing Strategy

In 2026, procurement agility is the cornerstone of competitive advantage. Waiting weeks to identify and qualify suppliers erodes margins and delays innovation.

Take control of your supply chain today.

👉 Contact SourcifyChina to receive your complimentary copy of the Verified Pro List: Automotive Manufacturers in China 2026.

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our sourcing consultants are available to discuss your specific component needs—be it precision machining, EV battery components, interior systems, or ADAS modules—and match you with 3–5 pre-qualified suppliers within 48 hours.

Don’t risk delays, compliance gaps, or substandard quality. Partner with SourcifyChina and source smarter.

SourcifyChina | Trusted by Procurement Leaders in Germany, USA, Japan & South Korea

Your Gateway to Reliable, Efficient, and Scalable Sourcing in China.

🧮 Landed Cost Calculator

Estimate your total import cost from China.