The automotive lift manufacturing industry in Idaho is gaining momentum within a rapidly expanding national and global market. According to Grand View Research, the global automotive lifts market was valued at USD 2.1 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030, driven by rising demand for vehicle maintenance and repair infrastructure. As regional manufacturing hubs strengthen their presence, Idaho has emerged as a notable contributor, with local manufacturers leveraging advanced fabrication techniques and proximity to Western U.S. distribution networks. This growth is further supported by increasing vehicle ownership and the proliferation of service centers requiring reliable lifting solutions. In this data-driven landscape, nine Idaho-based manufacturers stand out for their innovation, production quality, and market impact—representing a critical segment of a sector poised for sustained expansion.

Top 9 Automotive Lifts In Idaho Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks and technology, with a network of more than 500 forklift ……

#2 Elevators, Escalators, Lifts & Moving Walks

Domain Est. 1994

Website: otis.com

Key Highlights: Otis is a leading manufacturer and maintainer of Elevators, Escalators, Moving Walkways with world class modernization tools & service packages for ……

#3 Maxon Lift

Domain Est. 1996

Website: maxonlift.com

Key Highlights: There’s a Maxon liftgate for every job—find the perfect one for your specific needs right here. If you require further assistance, please contact Customer ……

#4 Rotary Solutions

Domain Est. 2009 | Founded: 1925

Website: rotarysolutions.com

Key Highlights: Trusted source for automotive shop equipment since 1925. Industry-leading vehicle lifts, collision repair tools, and A/C service equipment….

#5 Atlas Automotive Equipment

Domain Est. 2009

Website: atlasautoequipment.com

Key Highlights: Atlas Automotive Equipment has grown to become one of the most well-known and well-respected names in the automotive Industry for Car Lifts and Automotive ……

#6 Professional & Commercial Car Lift Service in Boise

Domain Est. 2016

Website: dsipros.com

Key Highlights: Diversified Systems Idaho sells and services residential and commercial car & vehicle lifts for customers in the Eastern Oregon, Idaho, and Northern Nevada ……

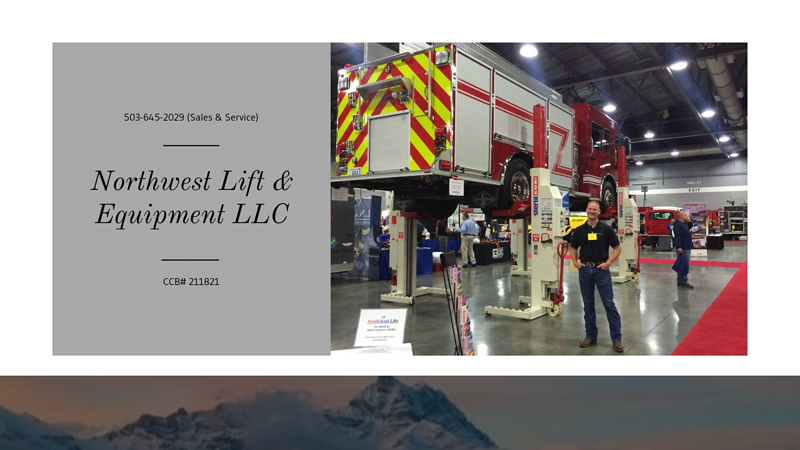

#7 Northwest Lift & Equipment LLC

Domain Est. 2016

Website: nwlift.com

Key Highlights: Heavy Duty Lift, mobile lifts, column lifts, inground lift, truck wash, bus wash, rv wash, trailer wash, shop equipment, agriculture lifts, vehicle lift….

#8 Automotive Lift Solutions

Domain Est. 2023

Website: automotiveliftsolutions.com

Key Highlights: At Automotive Lift Solutions, we have a team of experienced and knowledgeable professionals with over 25 years who are dedicated to providing our customers ……

#9 High

Domain Est. 2024

Website: idahocarlifts.com

Key Highlights: Idaho’s leading lift experts. Best deals on car lifts, installs, repairs, and everything auto shop related. 2 post lifts, 4 post lifts and more….

Expert Sourcing Insights for Automotive Lifts In Idaho

2026 Market Trends for Automotive Lifts in Idaho

Market Overview

The automotive lift market in Idaho is projected to experience steady growth through 2026, driven by increasing demand from auto repair shops, expanding commercial fleets, and rising adoption of advanced vehicle service technologies. As Idaho’s economy continues to diversify and urban centers like Boise, Meridian, and Idaho Falls grow, so does the need for modern vehicle maintenance infrastructure. The state’s growing population and vehicle ownership rates are contributing factors fueling demand for automotive lifts in both independent repair facilities and dealership service centers.

Key Growth Drivers

One of the primary drivers of the automotive lift market in Idaho is the increase in vehicle ownership and usage. According to Idaho Transportation Department data, registered vehicles in the state have risen steadily over the past five years, creating a sustained demand for maintenance and repair services. Additionally, the expansion of light and medium-duty commercial fleets—particularly in logistics, construction, and agriculture sectors—has led to higher requirements for durable and efficient lifting equipment.

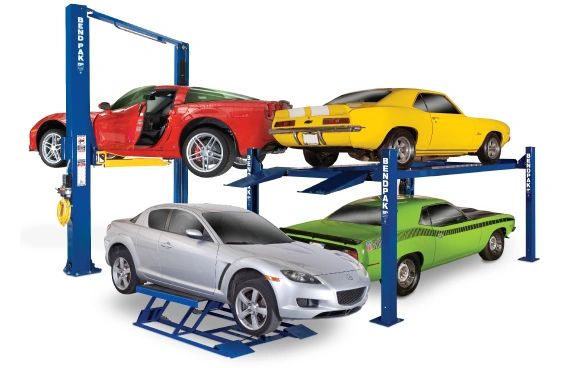

Another key factor is the modernization of repair facilities. Many auto shops across Idaho are upgrading outdated equipment to meet safety standards and improve operational efficiency. This trend is especially prominent in urban counties where competition among service providers is intensifying. As a result, there’s growing interest in hydraulic, two-post, four-post, and alignment lifts with enhanced safety features and digital integration.

Technological Advancements

By 2026, technological innovation will play a significant role in shaping the automotive lift market in Idaho. Smart lifts equipped with IoT sensors, load monitoring systems, and remote diagnostics are gaining traction among forward-thinking repair businesses. These technologies not only improve safety but also reduce downtime and maintenance costs. Additionally, energy-efficient and low-profile lifts are becoming more popular due to space constraints in urban workshops and a broader industry shift toward sustainability.

Manufacturers are also focusing on compliance with updated safety regulations from organizations such as the Automotive Lift Institute (ALI), which influences purchasing decisions in Idaho. Shops are increasingly seeking ALI-certified lifts to ensure adherence to state and federal safety standards, reinforcing the demand for high-quality, compliant equipment.

Regional Demand Patterns

Demand for automotive lifts in Idaho is expected to be strongest in the southwestern region, particularly in Ada, Canyon, and Kootenai counties, where population growth and new business development are most pronounced. These areas are seeing a surge in new auto repair startups and expansions of existing facilities, directly increasing the need for professional-grade lifts.

In contrast, rural areas may adopt lifts at a slower pace due to lower vehicle density and limited capital for investment. However, government-backed small business grants and agricultural vehicle maintenance needs could stimulate modest growth in lift installations across central and northern Idaho.

Competitive Landscape

The Idaho automotive lift market remains competitive, with both national distributors and regional suppliers vying for market share. Companies such as Rotary Lift, BendPak, and Challenger Lifts maintain strong distribution networks in the state. At the same time, local equipment dealers are enhancing their service offerings by providing installation, training, and maintenance support—key differentiators in a market where reliability and after-sales service are highly valued.

Online sales channels are also gaining ground, allowing Idaho-based businesses to compare products and pricing more efficiently. However, many buyers still prefer local suppliers for immediate delivery and personalized technical assistance.

Regulatory and Environmental Influences

Environmental regulations and workplace safety standards will continue to influence purchasing trends through 2026. Idaho’s Occupational Safety and Health Administration (IOSHA) enforces strict guidelines on equipment safety, prompting shops to replace aging or non-compliant lifts. Additionally, environmentally conscious businesses are leaning toward lifts with sealed hydraulic systems and recyclable components to minimize fluid leaks and environmental impact.

Economic and Labor Considerations

Labor availability in Idaho’s automotive service sector is another factor affecting lift adoption. With a tighter labor market, repair shops are investing in lifts that enhance technician productivity and reduce physical strain. Ergonomic designs and faster operation cycles are becoming key selling points. Furthermore, as training programs at technical colleges like the College of Western Idaho expand, a new generation of skilled technicians is entering the workforce, creating demand for up-to-date equipment in training labs and service bays alike.

Outlook for 2026

By 2026, the automotive lift market in Idaho is expected to grow at a compound annual growth rate (CAGR) of approximately 4.5%, driven by infrastructure development, technological adoption, and rising vehicle service demand. The integration of smart technology, emphasis on safety compliance, and regional economic growth will shape purchasing behavior. Stakeholders—including manufacturers, distributors, and service providers—should focus on education, customer support, and innovation to capture emerging opportunities in this evolving market.

Common Pitfalls Sourcing Automotive Lifts in Idaho: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Automotive Lifts in Idaho

Business Registration and Licensing

Before operating in Idaho, businesses involved in the sale, installation, or servicing of automotive lifts must register with the Idaho Secretary of State. This includes choosing a business structure (LLC, corporation, sole proprietorship) and filing the appropriate documentation. Additionally, a General Business License may be required through the local city or county government. Contractors installing lifts may also need a Contractor’s License from the Idaho Division of Building Safety, especially if structural modifications are involved.

Sales and Use Tax Compliance

Automotive lifts sold in Idaho are subject to state sales tax, which has a base rate of 6%. Local jurisdictions may impose additional sales taxes, so total rates can vary. Businesses must collect and remit sales tax through the Idaho State Tax Commission. Exemptions may apply for resellers with valid resale certificates or for certain industrial uses—ensure proper documentation is maintained.

Installation and Building Code Regulations

Installation of automotive lifts must comply with the Idaho Building Code, which adopts the International Building Code (IBC) and International Mechanical Code (IMC). Lift installations often require permits from the local building department, particularly for structural anchoring, electrical connections, and overhead clearance. Compliance with manufacturer specifications and American National Standards Institute (ANSI) standards—such as ANSI/ALI ALOIM for lift installation and maintenance—is essential for safety and code approval.

Electrical and Safety Standards

Electrical work related to lift installation must adhere to the National Electrical Code (NEC) and be performed by a licensed electrician where required. All lifts should be grounded properly and connected to dedicated circuits per manufacturer guidelines. Employers must follow Occupational Safety and Health Administration (OSHA) standards, including providing proper training for lift operation and implementing lockout/tagout (LOTO) procedures for maintenance.

Environmental and Waste Handling Considerations

During installation or servicing, fluids such as hydraulic oil may be handled. Spills must be contained and cleaned in accordance with Idaho Department of Environmental Quality (DEQ) regulations. Used oil and filters are considered hazardous waste and must be stored, labeled, and disposed of through certified recyclers or disposal facilities. Prevent discharge into storm drains or soil to avoid violations.

Transportation and Delivery Logistics

When transporting automotive lifts, businesses must comply with Idaho Transportation Department (ITD) regulations for oversized or heavy loads. Permits may be required for lifts transported on flatbed trailers exceeding standard dimensions or weight limits. Secure loads properly using industry-standard tie-downs and follow federal Motor Carrier Safety Regulations (FMCSA) if operating commercial vehicles.

Product Certification and Manufacturer Requirements

Ensure all automotive lifts meet recognized safety certifications such as ALI (Automotive Lift Institute) certification, indicating compliance with ANSI/ALI standards. Only ALI-certified lifts should be installed or sold to ensure safety and compliance. Maintain documentation from manufacturers, including installation manuals, safety warnings, and load ratings.

Worker Training and OSHA Compliance

Personnel installing or operating lifts must be trained per OSHA 29 CFR 1910.269 and relevant industry practices. Training should cover lift operation, weight limits, inspection routines, and emergency procedures. Employers in Idaho must also comply with OSHA-approved state plan regulations enforced by the Idaho OSHA (IOSHA) program, which includes maintaining injury logs and providing a hazard-free workplace.

Insurance and Liability Protection

Carry adequate liability insurance, including general liability and garagekeepers insurance if lifts are used in repair facilities. Contractors should also have workers’ compensation insurance if they have employees. Proper insurance protects against claims related to lift malfunction, improper installation, or workplace injuries.

Recordkeeping and Documentation

Maintain records of lift inspections, maintenance, installations, and employee training. Keep copies of permits, certifications, sales tax filings, and safety data sheets (SDS) for any hazardous materials used. These documents support compliance during inspections by IOSHA, ITD, or tax auditors.

Conclusion

Operating with automotive lifts in Idaho requires adherence to a range of logistical, safety, and regulatory standards. From proper business licensing and tax collection to safe installation and environmental responsibility, compliance ensures operational legality and protects both workers and customers. Staying informed on state and federal requirements will help businesses avoid penalties and maintain a safe, efficient operation.

In conclusion, sourcing automotive lifts in Idaho requires careful consideration of reputable suppliers, product quality, and local support. With a growing automotive industry and increasing demand for reliable equipment, businesses in Idaho have access to both national distributors and local dealers offering a variety of lift types—including two-post, four-post, alignment, and scissor lifts—suitable for different shop needs. Prioritizing safety certifications (such as ALI accreditation), warranty options, and installation services is essential to ensure long-term performance and compliance. Additionally, leveraging online research, customer reviews, and direct consultations with suppliers can help purchasers make informed decisions. Ultimately, by selecting a trusted vendor and the right lift for their operational requirements, automotive businesses across Idaho can enhance efficiency, safety, and service capability.