The global automotive dolly market is experiencing steady growth, driven by increasing demand for efficient vehicle handling solutions in automotive repair, logistics, and manufacturing sectors. According to Grand View Research, the global automotive aftermarket was valued at USD 496.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 3.7% from 2023 to 2030, with vehicle maintenance and workshop equipment segments contributing significantly to this growth. Additionally, Mordor Intelligence projects that the automotive service equipment market will witness moderate expansion, fueled by rising vehicle ownership and the proliferation of multi-brand repair shops requiring specialized tools like automotive dollies. As workshops and technicians prioritize efficiency and safety, the need for high-quality, durable dollies has become paramount—leading to a competitive landscape among manufacturers innovating in load capacity, mobility, and ergonomic design. Against this backdrop, we take a data-driven look at the top 5 automotive dolly manufacturers leading the charge in performance, reliability, and market presence.

Top 5 Automotive Dolly Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

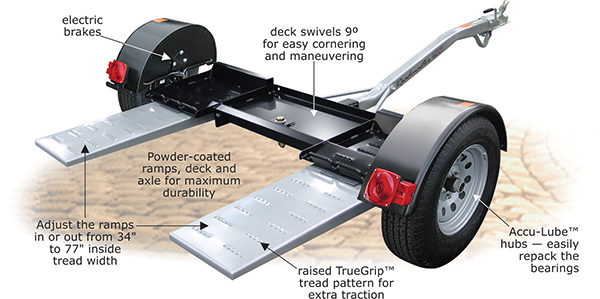

#1 Tow Dolly and Accessories

Domain Est. 1999

Website: roadmasterinc.com

Key Highlights: Find a Factory Rep · Roadmaster. For product-related issues, please call us at 1-800-669-9690. For web-related issues, contact us here. © Copyright 2000-2026 ……

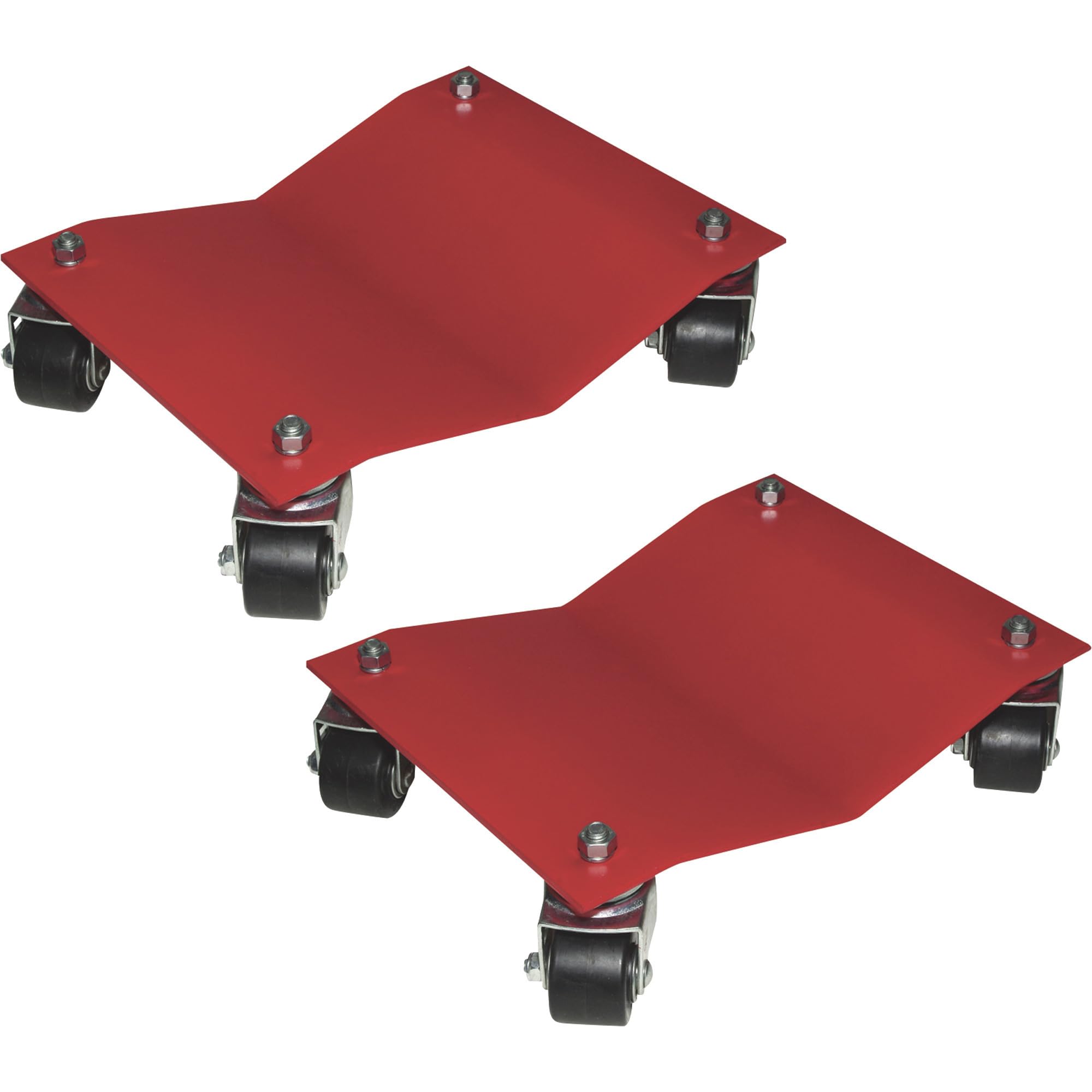

#2 Dolly Products – The Auto Dolly

Domain Est. 2005

Website: theautodolly.com

Key Highlights: The Auto Dolly is placed under each tire of the vehicle, making the vehicle a rolling cart that will now roll in any direction with ease….

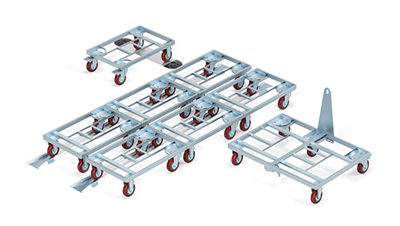

#3 GoJak Wheel Dolly

Domain Est. 2006

#4 Discover the Widest Dolly for Today’s Towing Demands

Domain Est. 2011

Website: collinsdollies.com

Key Highlights: Discover our Hi-Speed® Dolly line of towing equipment–the widest dolly on the market to meet all your tough towing demands….

#5 Garvee Car Dolly [Set of 4 with 8000 lbs Capacity], Manganese …

Domain Est. 2022

Website: garvee.com

Key Highlights: Out of stock Rating 4.7 (32) GARVEE Car Wheel / Dolly Tire. Thicker steel platform for enhanced durability. High weight capacity for heavy vehicles. Anti-skid and recessed design…

Expert Sourcing Insights for Automotive Dolly

H2 2026 Market Trends Analysis: Automotive Dolly

The automotive dolly market is poised for significant transformation and growth in H2 2026, driven by evolving vehicle technologies, shifting logistics demands, and a heightened focus on efficiency and safety. Key trends shaping the market during this period include:

1. Accelerated Adoption of Electric & Heavy-Duty Vehicle (HDV) Dollies:

H2 2026 will see a substantial increase in demand for specialized dollies designed explicitly for electric vehicles (EVs) and heavy-duty trucks. EVs, with their concentrated battery weight and lower centers of gravity, require dollies with enhanced load capacity (often 3-5+ tons) and precise steering control to prevent drivetrain strain. Concurrently, the growth of long-haul electric trucks and hydrogen fuel cell vehicles will drive demand for robust, high-capacity motorized dollies capable of maneuvering multi-axle, heavy trailers in tight depot spaces. Suppliers investing in reinforced frames, advanced electric steering motors, and integrated battery systems will gain a competitive edge.

2. Smart & Connected Dolly Integration:

Connectivity will become a key differentiator. H2 2026 will witness wider deployment of “smart dollies” equipped with IoT sensors, telematics, and fleet management integration. These systems will enable real-time monitoring of dolly location, usage hours, load status, battery health (for powered models), and maintenance alerts. Data analytics will optimize fleet utilization, predict maintenance needs, and enhance security (anti-theft tracking). Integration with warehouse management systems (WMS) and digital yard management platforms will streamline operations in logistics hubs and manufacturing plants.

3. Focus on Ergonomics, Safety, and Operator Assistance:

Regulatory pressure and a focus on workplace safety will drive innovations in H2 2026. Expect increased adoption of features like:

* Advanced Operator Assist: Enhanced power steering, proportional controls, and remote control options (especially for hazardous environments or precision maneuvering).

* Improved Ergonomics: Telescopic handles, better weight distribution, and reduced push/pull forces.

* Integrated Safety Systems: Load stability sensors, anti-tip mechanisms, automatic braking on inclines, and audible/visual proximity warnings to prevent collisions in busy areas.

4. Sustainability and Alternative Power Sources:

Beyond just handling EVs, the dollies themselves are becoming greener. H2 2026 will see:

* Proliferation of Battery-Electric Models: Replacing hydraulic or manual systems, especially in indoor environments (dealerships, service centers, factories) to eliminate emissions and noise.

* Exploration of Sustainable Materials: Increased use of recycled metals and composites in dolly construction.

* Energy Efficiency: Focus on longer battery life, regenerative braking systems (on powered models), and efficient motor designs to reduce operating costs and environmental impact.

5. Market Expansion in Emerging Applications:

While traditional uses (dealerships, workshops, warehouses) remain core, H2 2026 will see growth in niche segments:

* E-Bus & Commercial EV Fleets: Dedicated dollies for maneuvering large electric buses in depots.

* Automated Guided Vehicle (AGV) Integration: Increased use of dollies as modular components in semi-automated or fully automated material handling systems within smart factories.

* Renewable Energy Sector: Specialized dollies for transporting and positioning large components like wind turbine blades or solar panel arrays in remote locations.

Conclusion for H2 2026:

The automotive dolly market in the second half of 2026 will be characterized by technological sophistication, specialization, and digital integration. Success will depend on manufacturers’ ability to innovate beyond basic functionality, offering smart, safe, efficient, and sustainable solutions tailored to the unique demands of electrified, heavier, and increasingly automated vehicles and logistics ecosystems. Companies focusing on connectivity, specialized EV/HDV capabilities, and operator-centric design will capture significant market share.

Common Pitfalls When Sourcing Automotive Dollies (Quality, IP)

Poor Quality Materials and Construction

One of the most frequent issues when sourcing automotive dollies is receiving products made from substandard materials. Low-grade steel or inadequate welding can compromise load-bearing capacity and durability, leading to safety hazards and premature failure. Buyers often encounter dollies that deform under weight or rust quickly due to insufficient coating or poor manufacturing processes.

Lack of Load Capacity Verification

Many suppliers overstate the load capacity of their automotive dollies without providing certified test results. This misrepresentation can result in equipment failure during use, risking damage to vehicles and injury to personnel. It’s essential to verify load ratings through third-party testing documentation or material specifications.

Inadequate Design for Intended Use

Automotive dollies vary widely in design depending on application—e.g., engine removal, chassis work, or vehicle transport. Sourcing a generic dolly without considering specific vehicle weight distribution, clearance, or maneuverability requirements can render the tool ineffective or unsafe.

Intellectual Property (IP) Infringement Risks

Sourcing from overseas manufacturers increases the risk of unintentionally procuring dollies that infringe on patented designs or trademarks. Copycat products may mimic popular branded models, exposing buyers to legal liability, especially in regulated markets like the EU or North America. Always conduct due diligence on supplier IP compliance and request proof of design freedom-to-operate.

Missing Safety Certifications and Compliance

Many low-cost suppliers fail to meet regional safety standards (e.g., CE, ANSI, OSHA). Dollies lacking proper certification may not have undergone required stress testing or safety evaluations, increasing liability and the risk of workplace accidents.

Inconsistent Quality Control Across Batches

Even if initial samples meet expectations, inconsistent quality control in mass production can result in variability in dimensions, weld strength, or component tolerances. Without ongoing inspection protocols or clear quality agreements, buyers may receive non-conforming units in later shipments.

Limited After-Sales Support and Warranty

Low-cost suppliers often provide minimal technical support, spare parts, or warranty coverage. If a dolly fails or requires maintenance, the lack of accessible service can lead to operational downtime and increased total cost of ownership.

Failure to Protect Your Own IP When Customizing

When sourcing custom-designed automotive dollies, companies risk exposing proprietary designs if non-disclosure agreements (NDAs) are not in place or if suppliers reuse designs for other clients. Ensure IP ownership is clearly defined in contracts and consider filing provisional patents for innovative features.

Logistics & Compliance Guide for Automotive Dolly

An automotive dolly is a wheeled device used to move vehicles with inoperable wheels or during transport operations. Proper logistics planning and compliance adherence are essential for safe and legal handling, transport, and storage. This guide outlines key considerations for managing automotive dollies across the supply chain.

Definitions and Types of Automotive Dollies

Automotive dollies can be categorized based on function and design:

– Front/Rear Wheel Dollies: Used to lift either the front or rear axle of a vehicle.

– Full-Frame Dollies: Support the entire vehicle chassis.

– Steerable vs. Fixed-Axis Dollies: Steerable types allow directional control, while fixed-axis require towing.

– Manual vs. Powered Dollies: Manual versions rely on human force; powered versions use hydraulic or electric systems.

Understanding the type is critical for compliance with load limits and transport regulations.

Regulatory Compliance

Compliance with national and international standards ensures safe and legal use of automotive dollies.

DOT and FMCSA Regulations (U.S.)

- Dollies used in commercial transport must comply with Federal Motor Carrier Safety Administration (FMCSA) standards.

- Weight limits must align with axle and gross vehicle weight ratings (GVWR).

- Dollies used in interstate commerce may require proper registration and safety inspections.

OSHA Workplace Safety (U.S.)

- Dollies used in manufacturing or repair facilities must meet OSHA 29 CFR 1910 standards for material handling.

- Workers must be trained in safe lifting and moving techniques.

- Load securement and workplace pathways must prevent tripping or collisions.

International Standards

- ISO 10241: Specifies terminology and safety for vehicle recovery equipment, including dollies.

- ADR/RID/IMDG: For cross-border transport, dollies used in hazardous vehicle movement (e.g., damaged EVs) may need compliance with hazardous materials regulations.

Load Capacity and Weight Distribution

- Always adhere to the manufacturer’s stated load capacity per dolly.

- Combined capacity of multiple dollies must exceed the vehicle’s weight.

- Ensure even weight distribution across all dolly units to prevent tipping or structural failure.

- Account for dynamic loading during movement—sudden stops or turns increase stress.

Transport and Securement

When transporting vehicles on dollies:

– Use appropriate tie-down straps (minimum 4-point securement recommended).

– Straps must meet WLL (Working Load Limit) and be rated for the expected forces.

– Chock non-supported wheels and lock steering if applicable.

– Comply with FMCSA §393.100-106 for cargo securement in the U.S.

Maintenance and Inspection

Regular maintenance ensures reliability and safety:

– Inspect wheels, axles, and frames for cracks, corrosion, or deformation.

– Lubricate moving parts per manufacturer guidelines.

– Check hydraulic systems (if applicable) for leaks or pressure loss.

– Document inspections and retire damaged or worn dollies.

Operational Best Practices

- Only trained personnel should operate dollies, especially powered models.

- Use in dry, level conditions; avoid inclines exceeding manufacturer recommendations.

- Clear pathways of obstacles and personnel before moving.

- For electric vehicles (EVs), ensure dollies do not damage undercarriage battery enclosures.

Storage and Handling

- Store dollies in a dry, secure location to prevent rust and unauthorized use.

- Stack or hang dollies as per design to avoid structural stress.

- Protect wheels and joints from debris and moisture.

Documentation and Recordkeeping

Maintain:

– Manufacturer specifications and user manuals.

– Inspection and maintenance logs.

– Training records for operators.

– Compliance certifications (e.g., DOT, CE marking for EU).

Conclusion

Proper logistics and compliance management of automotive dollies reduce risk, ensure regulatory adherence, and enhance operational efficiency. By following this guide, organizations can safely transport and handle vehicles while meeting legal and safety standards. Always consult local regulations and equipment manuals for specific requirements.

Conclusion for Sourcing an Automotive Dolly:

Sourcing an automotive dolly requires careful consideration of vehicle weight capacity, terrain compatibility, material durability, and ease of use. Whether for personal garage use or commercial applications, selecting the right dolly involves balancing cost, quality, and functionality. Electric or manual models should be chosen based on specific operational needs and frequency of use. It is essential to source from reputable suppliers offering warranties, compliance with safety standards, and reliable after-sales support. By evaluating these factors, businesses and individuals can ensure a safe, efficient, and cost-effective solution for vehicle movement and maintenance.

![Garvee Car Dolly [Set of 4 with 8000 lbs Capacity], Manganese ...](https://www.sohoinchina.com/wp-content/uploads/2026/01/garvee-car-dolly-set-of-4-with-8000-lbs-capacity-manganese-297.jpg)