The global automotive bolt market is experiencing robust growth, driven by increasing vehicle production, rising demand for lightweight and high-strength fasteners, and stringent safety regulations. According to Mordor Intelligence, the automotive fasteners market was valued at USD 10.4 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2023 to 2028. A key factor fueling this expansion is the automotive industry’s shift toward advanced materials and precision engineering, especially in electric vehicles (EVs), where reliable joining technologies are critical. Bolts and fasteners constitute a small but essential component in vehicle assembly, with over 1,500–2,000 fasteners used per average passenger car, many of which require high durability and corrosion resistance. As automakers prioritize performance and efficiency, the demand for high-quality, engineered bolts from specialized manufacturers has intensified. This growing need has elevated the role of leading automotive bolt producers who combine innovation, scalability, and compliance with global standards. Based on market presence, production capability, innovation, and industry partnerships, the following are the top 10 automotive bolt manufacturers shaping the future of automotive assembly.

Top 10 Automotive Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fastener Supplier for OEM, Distributors, and Industrial Applications

Domain Est. 2021

Website: gobigbolt.com

Key Highlights: Big Bolt is a fastener supplier providing next-day manufacturing, even on custom orders. Learn more about our OEM and distributor fastener products and ……

#2 ARP

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Rod Bolt Extensions … View Catalog. © 2006-2026 AUTOMOTIVE RACING PRODUCTS, INC. Home | Company Information | Contact Us | Trademarks and Legal | Mobile Site…

#3 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#4 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Lightweight, durable, and cost-effective, our plastic fasteners are designed for modern applications across automotive, electronics, and consumer goods….

#5 The Auto Bolt Company

Domain Est. 2019

Website: autoboltusa.com

Key Highlights: The Auto Bolt Company has 70 years of experience manufacturing fasteners and bolts for a variety of industries including the Military, Automotive and OEM….

#6 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#7 NutsandBolts.com

Domain Est. 1996

Website: nutsandbolts.com

Key Highlights: Free delivery over $50 30-day returnsYour One-Stop Shop For Fasteners. Seamless shopping with expert support for your projects. Shop Now. Essential Fastener Kits….

#8 ITW Automotive

Domain Est. 1999

Website: itwautomotive.com

Key Highlights: ITW Automotive partners with customers to solve challenges with fastening, assembly & component solutions that advance performance and sustainability….

#9 rightway fasteners inc

Domain Est. 2001

Website: rfiusa.com

Key Highlights: Righway Fasteners provides a wide variety of quality fasteners to the Automotive Industry. RFI specializes in Cold Forming, Thread Rolling, Heat Treatment, ……

#10 P1 Manufacturing

Domain Est. 2009

Website: p1mfg.com

Key Highlights: P1 specializes in manufacturing superior precision parts for motorsports, aerospace, energy, medical, and other high tech, high-tolerance demand markets….

Expert Sourcing Insights for Automotive Bolt

H2: 2026 Market Trends for Automotive Bolts

As the global automotive industry undergoes significant transformation, the market for automotive bolts is set to evolve in tandem with broader technological, regulatory, and industrial shifts. By 2026, several key trends are expected to shape the demand, production, and innovation landscape for automotive bolts:

-

Growth Driven by Electric Vehicle (EV) Adoption

The accelerating shift toward electric vehicles is a primary driver in the automotive bolt market. EVs require specialized fastening solutions due to differences in vehicle architecture—such as battery pack integration, electric motor assembly, and lightweight components. Bolts used in EVs often demand higher corrosion resistance, thermal stability, and precision engineering. By 2026, an estimated 30–40% of new vehicles produced globally will be electric or hybrid, significantly increasing demand for high-performance automotive bolts tailored to EV applications. -

Lightweighting and Material Innovation

Automakers are increasingly focused on reducing vehicle weight to improve fuel efficiency and extend EV range. This trend is fueling demand for lightweight yet durable fasteners made from advanced materials such as high-strength steel, aluminum alloys, titanium, and composite materials. By 2026, bolts made from such materials are expected to capture a growing share of the market, particularly in premium and performance segments. -

Increased Emphasis on Safety and Reliability

With stricter global safety standards (e.g., Euro NCAP, IIHS), there is rising demand for bolts that ensure structural integrity in critical areas such as chassis, suspension, and powertrain systems. High-tensile bolts with precise torque specifications and anti-loosening features (e.g., serrated flange bolts, patch-coated bolts) are becoming standard. The trend underscores the need for quality control and traceability in bolt manufacturing. -

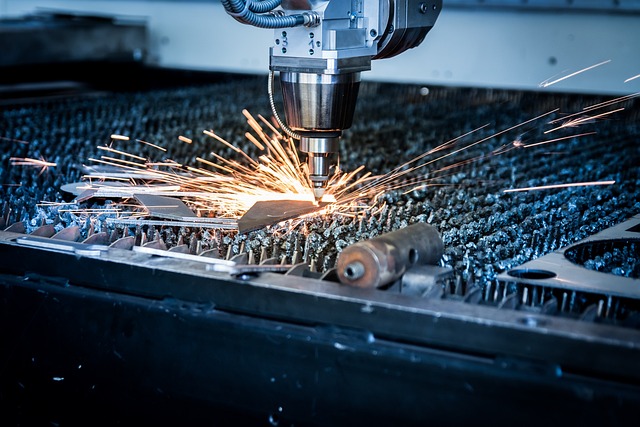

Automation and Smart Manufacturing

The integration of Industry 4.0 technologies in automotive supply chains is influencing bolt production and usage. Automated assembly lines require bolts that are consistent in dimension, strength, and surface treatment. Furthermore, smart bolts with embedded sensors (e.g., load-sensing or torque-monitoring capabilities) may begin to emerge in high-end and commercial vehicles by 2026, enabling predictive maintenance and real-time diagnostics. -

Sustainability and Circular Economy Pressures

Environmental regulations are pushing manufacturers to adopt sustainable practices. This includes using recyclable materials in bolt production, reducing energy consumption during manufacturing, and minimizing waste. By 2026, leading bolt suppliers are expected to offer carbon-neutral or low-impact fasteners, aligning with automakers’ ESG (Environmental, Social, and Governance) goals. -

Regional Market Shifts

Asia-Pacific—particularly China, India, and South Korea—will remain the largest market for automotive bolts due to robust automotive production and EV adoption. Meanwhile, North America and Europe are expected to witness strong demand for high-precision and specialty bolts due to advanced manufacturing ecosystems and strict regulatory environments. -

Supply Chain Resilience and Localization

Ongoing geopolitical tensions and supply chain disruptions have prompted automakers to localize sourcing. By 2026, there will be increased investment in regional bolt manufacturing hubs to reduce dependency on single-source suppliers and ensure continuity, especially for mission-critical fasteners.

Conclusion:

The automotive bolt market in 2026 will be characterized by innovation, specialization, and integration with emerging automotive technologies. Success will depend on manufacturers’ ability to adapt to EV-specific requirements, adopt sustainable practices, leverage smart technologies, and ensure supply chain agility. As vehicles become more complex and performance-driven, the humble bolt will remain a critical enabler of automotive advancement.

Common Pitfalls in Sourcing Automotive Bolts (Quality, IP)

Sourcing automotive bolts may seem straightforward, but it involves significant risks related to quality assurance and intellectual property (IP) protection. Companies that overlook these aspects can face supply chain disruptions, product failures, legal disputes, and reputational damage. Below are common pitfalls to avoid.

Poor Quality Control Standards

One of the most frequent issues in sourcing automotive bolts is inconsistent or inadequate quality control. Automotive applications demand high-strength, precision-engineered fasteners that meet strict performance standards (e.g., ISO, DIN, SAE, or OEM-specific specs). Sourcing from suppliers without certified quality management systems (e.g., IATF 16949) increases the risk of substandard materials, incorrect heat treatment, or dimensional inaccuracies—leading to component failure and safety hazards.

Lack of Material Traceability

Automotive bolts must be traceable to their raw material source, including heat lot numbers and chemical composition. Without proper traceability, it becomes impossible to verify compliance with required metallurgical standards or conduct recalls if defects emerge. Suppliers that fail to provide full material certifications (e.g., Mill Test Certificates) present a major risk.

Inadequate Testing and Certification

Many suppliers claim compliance with industry standards but lack third-party testing or fail to conduct mechanical tests such as tensile strength, hardness, and torque-tension performance. Relying solely on supplier self-certification without independent validation can result in non-compliant parts entering critical systems.

Counterfeit or Non-OEM Compliant Parts

There is a prevalent risk of counterfeit or imitation bolts, especially when sourcing from low-cost regions. These parts may mimic the appearance of certified fasteners but fall short in performance. Using such components can violate OEM specifications and void warranties, creating liability exposure.

Intellectual Property (IP) Infringement

Automotive bolts—especially engineered or patented designs (e.g., torque-to-yield bolts, flange bolts with specific geometries)—may be protected by IP rights. Sourcing reverse-engineered or unlicensed copies can lead to legal action from OEMs or patent holders. This is particularly risky when working with suppliers who do not respect design patents or trademarks.

Insufficient Supplier Vetting

Failing to conduct thorough due diligence on suppliers increases exposure to both quality and IP risks. Without on-site audits, background checks, and review of manufacturing capabilities, companies may unknowingly partner with unreliable or non-compliant vendors.

Inconsistent Coating and Corrosion Protection

Automotive environments expose bolts to moisture, salt, and temperature extremes. Inadequate or inconsistent surface treatments (e.g., zinc plating, Geomet, or Dacromet) can lead to premature corrosion. Suppliers may cut corners on coating thickness or pretreatment, compromising long-term reliability.

Poor Documentation and Compliance Records

Complete and accurate technical documentation—including drawings, specifications, test reports, and IP disclaimers—is essential. Missing or falsified documents can complicate audits, certifications, and liability assessments, especially in regulated markets.

Conclusion

To mitigate these pitfalls, sourcing teams should prioritize suppliers with proven track records, valid certifications, and transparent manufacturing practices. Engaging legal and technical experts early in the procurement process helps ensure both quality integrity and IP compliance in automotive bolt sourcing.

Logistics & Compliance Guide for Automotive Bolts

Overview

This guide outlines the essential logistics and compliance considerations for the manufacturing, transport, storage, and use of automotive bolts. These fasteners are critical safety components in vehicle assembly, requiring strict adherence to industry standards and regulatory requirements throughout the supply chain.

Regulatory Standards and Certifications

Automotive bolts must comply with international and regional standards to ensure safety, reliability, and traceability. Key standards include:

– ISO 898-1: Mechanical properties of bolts, screws, and studs made of carbon steel and alloy steel.

– ISO 4042: Torque/clamp load testing and marking requirements.

– SAE J429: Standard for mechanical and material requirements of steel bolts in the U.S. automotive industry.

– DIN standards (e.g., DIN 933, DIN 931): Widely used in European automotive markets.

– IATF 16949: Quality management system specific to automotive production, required for suppliers.

– REACH and RoHS compliance: Ensures restricted substances (e.g., lead, cadmium) are below allowable limits.

Manufacturers must provide certificates of conformance (CoC), material test reports (MTRs), and maintain full traceability from raw material to final product.

Material and Manufacturing Requirements

- Material Specifications: Typically alloy or carbon steel with precise chemical composition and heat treatment (e.g., quenching and tempering).

- Surface Treatments: Zinc plating, galvanization, or other coatings to resist corrosion; must meet salt spray test requirements (e.g., ISO 9227).

- Dimensional Tolerances: Must adhere to tight tolerances as defined by applicable standards.

- Batch Traceability: Each production batch must be uniquely identifiable for quality control and recalls.

Packaging and Labeling

- Interior Packaging: Use anti-corrosion materials (e.g., VCI paper) and moisture barriers to prevent rust during transit.

- Unit Loads: Packaged in labeled boxes, trays, or reels suitable for automated assembly lines.

- Labeling Requirements:

- Part number, grade (e.g., 8.8, 10.9), standard (e.g., ISO, SAE), manufacturer ID, batch/lot number.

- Hazard symbols if applicable (e.g., for coated bolts with chemical treatments).

- Compliance markings (e.g., CE, IATF 16949).

Storage and Handling

- Environmental Controls: Store in dry, temperature-controlled environments (typically 10–30°C, RH <60%) to prevent corrosion.

- Shelf Life: Monitor coating integrity; typically 12–24 months for plated fasteners if stored properly.

- Handling: Prevent contamination (oil, dust) and mechanical damage (thread wear) using appropriate tools and containers.

- First-Expiry, First-Out (FEFO): Apply to manage coating effectiveness over time.

Transportation and Logistics

- Mode of Transport: Road, sea, or air based on urgency and destination.

- Securement: Use dunnage and load bars to prevent shifting during transit.

- Documentation: Include commercial invoice, packing list, CoC, and safety data sheet (SDS) if coatings involve regulated substances.

- Customs Compliance: HS Code classification (e.g., 7318.15 for threaded steel fasteners) and country-specific import regulations.

- Incoterms: Clearly define responsibilities (e.g., FOB, DDP) in contracts.

Quality Control and Audits

- Incoming Inspection: Verify dimensions, torque performance, coating thickness, and material composition.

- In-Process Checks: Statistical process control (SPC) during manufacturing.

- Final Audit: Full compliance check before shipment, including traceability verification.

- Supplier Audits: Regular assessments of bolt manufacturers to ensure ongoing compliance with IATF 16949 and customer-specific requirements.

Recall and Non-Conformance Management

- Root Cause Analysis: Implement corrective actions (e.g., 8D reports) for defective batches.

- Field Monitoring: Track bolt performance in end-use vehicles.

- Recall Procedures: Maintain a documented process for rapid withdrawal of non-compliant parts, including communication with OEMs and regulators.

Sustainability and Environmental Compliance

- Waste Management: Recycle metal scrap and manage hazardous waste from plating processes.

- Carbon Footprint: Optimize logistics routes and packaging to reduce environmental impact.

- Conflict Minerals: Ensure raw materials (e.g., steel alloys) are sourced responsibly per regulations like Dodd-Frank Act Section 1502.

Conclusion

Effective logistics and compliance for automotive bolts require a holistic approach integrating quality standards, regulatory adherence, secure handling, and traceability. By following this guide, suppliers and distributors can ensure product integrity, minimize risk, and support the safety and reliability of automotive systems.

Conclusion for Sourcing Automotive Bolts

In conclusion, sourcing automotive bolts requires a strategic approach that balances quality, cost, compliance, and supply chain reliability. As critical components in vehicle manufacturing and assembly, bolts must meet stringent industry standards—such as ISO, DIN, or ASTM—to ensure safety, performance, and durability under demanding conditions. A successful sourcing strategy involves thorough supplier evaluation, focusing on certifications, production capabilities, quality control processes, and traceability.

Building strong relationships with reliable suppliers, preferably those with a proven track record in the automotive sector, helps mitigate risks related to delays, defects, and non-compliance. Additionally, considering factors like material selection (e.g., high-tensile steel, corrosion resistance), custom specifications, and logistics efficiency further enhances sourcing effectiveness.

With increasing demands for lightweighting, electrification, and automation in the automotive industry, adaptability and continuous improvement in sourcing practices are essential. Leveraging technology for supply chain visibility and embracing sustainable sourcing principles will further position companies for long-term success. Ultimately, sourcing automotive bolts is not just about procurement—it’s a vital component of ensuring vehicle integrity and overall operational excellence.