The global automotive air conditioning (A/C) market is experiencing steady growth, driven by increasing vehicle production, rising consumer demand for in-cabin comfort, and stricter regulations around system efficiency and refrigerant use. According to Mordor Intelligence, the automotive HVAC market was valued at USD 26.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. A critical component of A/C performance is the condenser, which requires regular maintenance to maintain thermal efficiency and system longevity—fueling demand for high-performance A/C condenser cleaners. As vehicles adopt more compact and complex condenser designs, especially in electric and hybrid models, the need for specialized cleaning solutions has surged. This growing maintenance imperative has led to increased innovation and competition among chemical manufacturers. Based on market presence, product efficacy, and technological advancement, the following six companies have emerged as leading manufacturers of automotive A/C condenser cleaners.

Top 6 Automotive A/C Condenser Cleaner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

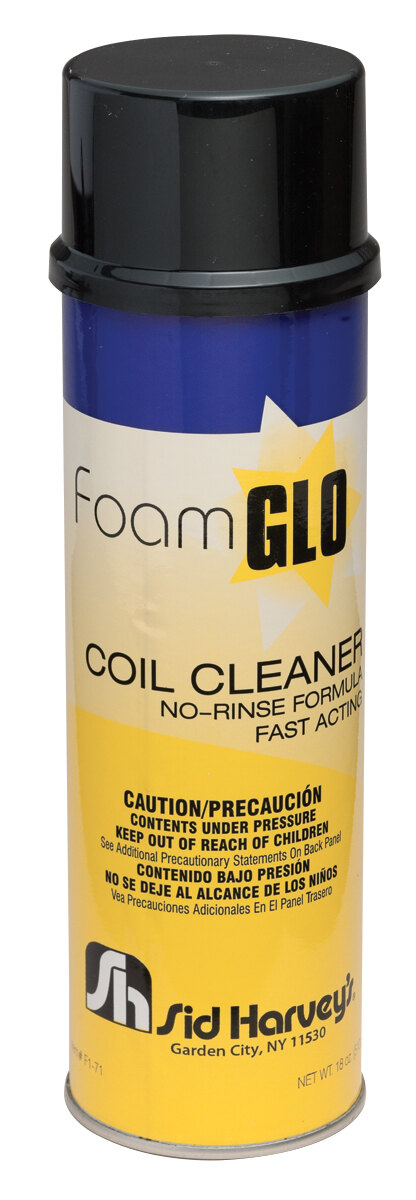

#1 Sid Harvey Chemicals and Solder Cleaner, Coil, A/C &

Domain Est. 1997

Website: sidharvey.com

Key Highlights: Container Size. All. -Manufacturers. DIVERSITECH CORP. (7); HOSHIZAKI NORTHEASTERN DC INC. (1); ICOR INTERNATIONAL INC (1); MISC ONE TIME VENDOR (1) ……

#2 Supercool

Domain Est. 2000

Website: supercool.ac

Key Highlights: TSI Supercool is a quality and solution driven ISO 9001 certified manufacturer of specialty lubricants for industrial and automotive markets worldwide….

#3 BG Frigi

Domain Est. 1997

Website: bgprod.com

Key Highlights: Restores A/C system efficiency, removes foul odors and obstructions, and freshens interior air. BG Frigi-Clean is biodegradable, nontoxic, and noncorrosive….

#4 The Original Automotive A/C Evaporator Cleaner

Domain Est. 1998

#5 A/C system cleaning

Domain Est. 2001

Website: liqui-moly.com

Key Highlights: Practical instructions and information on cleaning the air conditioning system for various vehicle models….

#6 Nu

Domain Est. 2001

Website: qualitychemical.com

Key Highlights: A high quality alkaline detergent system designed to easily and safely clean grease sludge, muck and grime on external coils….

Expert Sourcing Insights for Automotive A/C Condenser Cleaner

H2: 2026 Market Trends for Automotive A/C Condenser Cleaner

The global market for automotive A/C condenser cleaners is poised for steady growth through 2026, driven by rising vehicle ownership, increasing awareness of vehicle maintenance, and a growing emphasis on cabin air quality and energy efficiency. As automotive air conditioning systems become more complex and integral to passenger comfort, the demand for effective maintenance products like condenser cleaners is expected to rise significantly.

One of the dominant trends shaping the 2026 market is the increasing adoption of proactive vehicle maintenance practices, especially in emerging economies. With the surge in both passenger and commercial vehicle fleets across regions like Asia-Pacific, Latin America, and Africa, vehicle owners and service centers are prioritizing preventive maintenance to extend component lifespan and improve fuel efficiency. A clean A/C condenser ensures optimal heat exchange, directly impacting cooling performance and reducing strain on the compressor—key factors driving cleaner usage.

Another significant trend is the shift toward eco-friendly and non-corrosive formulations. Regulatory bodies such as the EPA in the U.S. and REACH in Europe are tightening restrictions on volatile organic compounds (VOCs) and ozone-depleting substances. As a result, manufacturers are reformulating A/C condenser cleaners to be biodegradable, non-toxic, and safe for use on aluminum and plastic components. By 2026, demand for environmentally responsible cleaners is expected to grow at a faster rate than conventional chemical-based products.

The rise of electric vehicles (EVs) also plays a role in shaping market dynamics. While EVs do not have traditional engine-driven A/C compressors, their thermal management systems still rely heavily on efficient heat exchange. Clean condensers are essential for maintaining battery and cabin temperature control, making condenser maintenance relevant even in electric platforms. This convergence is prompting cleaner manufacturers to develop EV-compatible formulations, opening new market avenues.

Moreover, the aftermarket segment remains a key growth driver. Independent auto repair shops and DIY consumers are increasingly investing in easy-to-use, aerosol-based condenser cleaning solutions. Enhanced product accessibility through e-commerce platforms and bundled service packages is further accelerating adoption. By 2026, digital sales channels are projected to account for over 30% of total automotive chemical sales, including A/C condenser cleaners.

Finally, technological advancements such as smart diagnostics and connected vehicles are enabling predictive maintenance alerts. These systems can detect reduced A/C efficiency due to dirty condensers and recommend cleaning services, creating a data-driven demand for maintenance products.

In conclusion, the 2026 automotive A/C condenser cleaner market will be characterized by innovation in product formulation, expansion in emerging markets, integration with EV maintenance protocols, and growth in digital distribution. Companies that align with sustainability goals and leverage smart vehicle data will be best positioned to capture market share.

Common Pitfalls When Sourcing Automotive A/C Condenser Cleaner (Quality & IP)

Sourcing Automotive A/C Condenser Cleaner involves navigating critical quality and intellectual property (IP) challenges. Overlooking these can lead to product failure, customer dissatisfaction, and legal exposure. Here are the key pitfalls to avoid:

1. Inadequate Performance Validation & Quality Control

- Overreliance on Supplier Claims: Accepting performance data (cleaning efficacy, biodegradability, material compatibility) without independent verification through third-party testing or in-house validation.

- Poor Raw Material Sourcing & Consistency: Suppliers may use inconsistent or substandard raw materials (solvents, surfactants, corrosion inhibitors), leading to batch-to-batch variability in cleaning power and potential damage to A/C components (O-rings, aluminum, plastics).

- Insufficient Corrosion Inhibition: Failure to verify that the cleaner effectively protects condenser fins, tubing, and other system metals (aluminum, copper, steel) from corrosion, especially in humid environments.

- Material Compatibility Risks: Not rigorously testing the cleaner against all common A/C system materials (specific elastomers, plastics, solders) can result in swelling, cracking, or degradation, causing leaks and system failure.

- Lack of Standardized Testing Protocols: Using non-industry-standard or poorly defined test methods to assess cleaning performance or safety, making results unreliable or non-comparable.

2. Intellectual Property (IP) Infringement and Lack of Transparency

- Sourcing “White Label” or Generic Formulas with Unverified IP Status: Procuring cleaners labeled generically or as “equivalent” without confirming the supplier owns the formulation rights or has proper licensing. This risks infringing on patented chemistries.

- Unclear or Absent IP Ownership Agreements: Failing to establish in contracts who owns the rights to the specific formulation developed or modified for your brand, especially in private-label or co-development scenarios. This can lead to disputes and loss of control.

- Reverse Engineering Without Due Diligence: Attempting to replicate a competitor’s successful product without thorough freedom-to-operate (FTO) analysis, potentially violating patents on specific ingredient combinations or processes.

- Supplier Secrecy and Lack of Documentation: Reputable suppliers should provide Safety Data Sheets (SDS), Certificates of Analysis (CoA), and technical data. Excessive secrecy without justification can be a red flag for potential IP issues or quality concerns.

- Ignoring Trademark Risk: Using product names, logos, or packaging that are confusingly similar to established brands, risking trademark infringement lawsuits and brand damage.

3. Regulatory and Safety Non-Compliance

- Misleading Environmental Claims: Making unsubstantiated claims about biodegradability, being “eco-friendly,” or “non-toxic” without proper certification or testing, leading to regulatory fines (e.g., FTC, EPA) and reputational harm.

- Inadequate Hazard Communication: Failing to ensure the SDS is accurate, complete, and compliant with GHS (Globally Harmonized System) or local regulations, posing safety risks and legal liability.

- Volatile Organic Compounds (VOC) Violations: Sourcing cleaners with VOC levels exceeding regional environmental regulations (e.g., SCAQMD, EU VOC Directive), resulting in sales bans or penalties.

- Improper Labeling: Labels missing critical safety warnings, usage instructions, first-aid measures, or regulatory information required by law.

4. Supply Chain and Supplier Reliability Issues

- Single-Source Dependency: Relying on one supplier without a qualified backup increases risk of disruption due to their production issues, financial instability, or quality problems.

- Unverified Manufacturing Capabilities: Not auditing the supplier’s manufacturing facility for GMP (Good Manufacturing Practice), quality control processes, and scale-up capability, risking inconsistent quality or supply shortages.

- Poor Change Control Management: Suppliers making undocumented changes to the formula or raw material sources without notification, potentially altering performance, safety, or IP status.

- Inadequate Packaging Integrity: Using packaging that degrades, leaks, or allows evaporation (e.g., poor-quality plastic bottles, seals), compromising product quality and safety.

Mitigation Strategy: Conduct thorough due diligence on potential suppliers, including audits, independent testing of samples, rigorous IP FTO analysis, clear contractual agreements on IP ownership and quality standards, and establishing a robust quality assurance program with ongoing monitoring.

H2: Logistics and Compliance Guide for Automotive A/C Condenser Cleaner

-

Product Overview

Automotive A/C Condenser Cleaner is a specialized chemical formulation designed to remove dirt, debris, oil, and contaminants from air conditioning condensers in vehicles. The product typically contains solvents, degreasers, and surfactants to ensure efficient cleaning without damaging aluminum fins or other sensitive components. -

Regulatory Classification

Prior to shipping or handling, confirm the regulatory classification of the product based on its chemical composition: -

GHS Classification (Globally Harmonized System):

- Flammability: If the product contains flammable solvents (e.g., hydrocarbons), classify as Flammable Liquid Category 2 or 3.

- Health Hazards: May include Skin Irritation (Category 2), Eye Irritation (Category 2), or Specific Target Organ Toxicity (Single Exposure – Category 3).

-

Environmental Hazards: Assess potential aquatic toxicity.

-

UN Number and Proper Shipping Name:

- Example: UN1993, FLAMMABLE LIQUID, N.O.S. (if applicable)

-

Packaging Group: II or III, depending on flash point and boiling point.

-

OSHA Hazard Communication Standard (HCS 2012):

- Ensure Safety Data Sheet (SDS) is compliant, with all 16 sections completed.

-

Label containers with GHS-compliant pictograms, signal words, hazard statements, and precautionary statements.

-

Safety Data Sheet (SDS) Requirements

- Maintain an up-to-date SDS in compliance with local regulations (e.g., OSHA in the U.S., CLP in the EU).

- SDS must include:

- Chemical composition and concentration

- First-aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage guidance

- Exposure controls and PPE recommendations

- Physical and chemical properties

- Stability and reactivity

-

Regulatory information

-

Packaging and Labeling

- Use UN-certified packaging appropriate for the hazard class and volume.

- Label each container with:

- Product identifier

- GHS pictograms

- Signal word (e.g., “Danger” or “Warning”)

- Hazard and precautionary statements

- Supplier information

-

Include secondary packaging for added protection during transport.

-

Transportation Regulations

- Domestic (U.S.):

- Comply with Department of Transportation (DOT) regulations under 49 CFR.

- Shipper must provide proper shipping papers, labels, and placards if required.

-

Training for personnel handling hazardous materials is mandatory (49 CFR Part 172, Subpart H).

-

International (IMDG, IATA, ADR):

- For air transport: Follow IATA Dangerous Goods Regulations (e.g., Packing Instruction 355 for limited quantities).

- For sea transport: Comply with IMDG Code.

- For European road transport: Follow ADR regulations.

-

Ensure proper declaration, documentation, and segregation from incompatible materials.

-

Storage Guidelines

- Store in a well-ventilated, cool, dry area away from direct sunlight and heat sources.

- Keep away from ignition sources (open flames, sparks, electrical equipment).

- Use compatible secondary containment (e.g., spill pallets) to prevent environmental contamination.

-

Segregate from strong oxidizers, bases, and foodstuffs.

-

Handling Procedures

- Use personal protective equipment (PPE): chemical-resistant gloves, safety goggles, and protective clothing.

- Avoid inhalation of vapors—use in well-ventilated areas or with local exhaust ventilation.

-

Prohibit eating, drinking, or smoking in handling areas.

-

Environmental and Disposal Compliance

- Do not release into sewers or waterways.

- Follow RCRA (Resource Conservation and Recovery Act) guidelines for hazardous waste disposal if applicable.

-

Use licensed waste disposal contractors for spent product or contaminated materials.

-

Import/Export Considerations

- Verify destination country regulations (e.g., REACH in the EU, K-REACH in Korea).

- Obtain necessary permits or notifications for chemical import.

-

Ensure product labeling and SDS are in the local language(s) of the destination country.

-

Emergency Response

- Provide spill kits and fire extinguishers (Class B for flammable liquids) in storage/handling areas.

- Train personnel in emergency procedures.

-

Include emergency contact information on SDS and shipping documents (e.g., 24-hour chemical emergency hotline).

-

Recordkeeping

- Maintain records of:

- SDS versions and revision dates

- Employee training certifications

- Shipping manifests and hazardous waste disposal receipts

-

Incident reports and spill documentation

-

Compliance Audits and Updates

- Conduct annual audits of safety, storage, and transportation procedures.

- Review and update SDS and compliance documentation whenever formulation changes occur or new regulations are enacted.

By adhering to this H2-compliant logistics and compliance guide, businesses can ensure safe, legal, and efficient handling, storage, and transportation of Automotive A/C Condenser Cleaner across domestic and international supply chains.

In conclusion, sourcing an automotive A/C condenser cleaner requires careful consideration of several key factors, including product effectiveness, compatibility with vehicle systems, ease of application, environmental impact, and cost-efficiency. Whether opting for chemical-based sprays, foaming cleaners, or eco-friendly alternatives, it is essential to select a reliable and reputable supplier that offers high-quality, tested products. Additionally, prioritizing brands with positive industry reviews and compliance with safety and environmental standards ensures both optimal performance and regulatory adherence. Proper sourcing not only enhances the efficiency and longevity of vehicle air conditioning systems but also contributes to improved cooling performance and customer satisfaction. By evaluating suppliers based on product quality, availability, technical support, and value for money, automotive service providers and parts distributors can make informed decisions that support operational excellence and long-term success.