The global automation manufacturing market is undergoing rapid transformation, driven by increasing demand for smart manufacturing, industrial IoT integration, and labor efficiency. According to Grand View Research, the industrial automation market was valued at USD 187.7 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 9.3% from 2024 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of 9.5% over the next five years, citing advancements in robotics, AI-driven process optimization, and rising adoption across sectors like automotive, pharmaceuticals, and consumer goods. As industries prioritize resilience and scalability, automation manufacturers are at the forefront of enabling digital transformation. This list highlights the top 10 companies leading innovation, market share, and technological advancement in the space.

Top 10 Automation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Factory Automation Solutions

Domain Est. 1996

Website: us.mitsubishielectric.com

Key Highlights: Factory automation solutions from Mitsubishi Electric Automation deliver on quality, performance, and compatibility with technology empowering companies to ……

#2 Trusted Partner in Helping to Solve the Biggest Challenges of …

Domain Est. 1995

Website: emerson.com

Key Highlights: As a global automation leader, Emerson is poised to transform industrial manufacturing. Explore the next-generation automation architecture designed to ……

#3 Allied Automation

Domain Est. 1996

Website: allied-automation.com

Key Highlights: Allied Automation has the Industrial Manufacturing Automation engineering expertise and partnerships with industry leading brands to craft your solutions….

#4 Omron Automation

Domain Est. 1997

Website: automation.omron.com

Key Highlights: Your trusted partner in industrial automation and safety. Omron Automation works with customers to develop solutions for their manufacturing challenges….

#5 Industrial Automation Software Solutions by Inductive Automation

Domain Est. 2005

Website: inductiveautomation.com

Key Highlights: Inductive Automation provides SCADA software and industrial automation solutions. Ignition software is the universal platform for automation industry needs….

#6 NEFF Automation

Domain Est. 2014

Website: neffautomation.com

Key Highlights: NEFF is a leading industrial automation solutions provider. We create custom automated solutions for manufacturing process optimization….

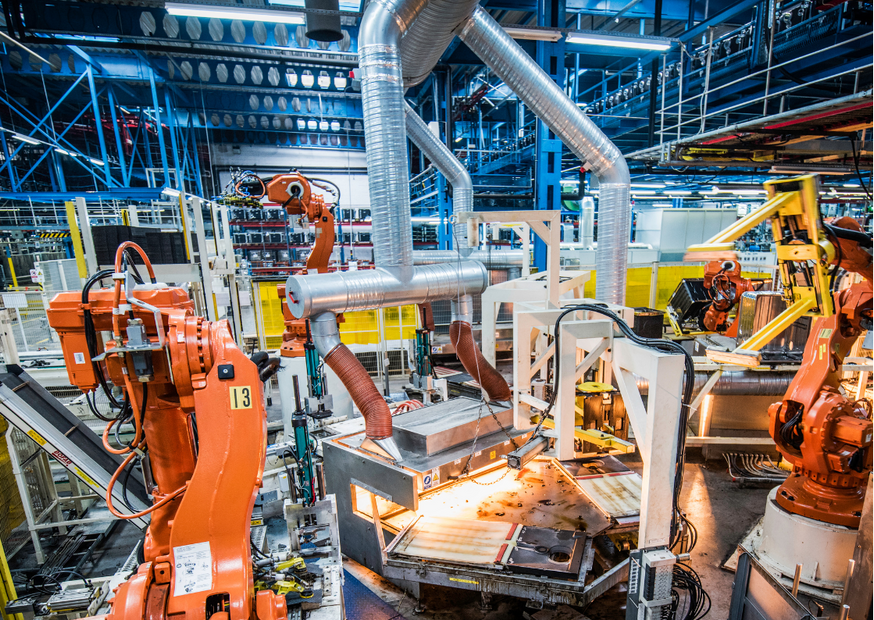

#7 ABB Robotics

Domain Est. 1990

Website: abb.com

Key Highlights: ABB Robotics leads in robotics and automation with integrated robots, AMRs, and software, helping industries boost resilience and efficiency….

#8 Brooks Automation

Domain Est. 1995

Website: brooks.com

Key Highlights: At Brooks, innovative ideas, cutting-edge technologies, and passionate teams are transforming our future….

#9 ATC Automation

Domain Est. 2013

Website: atcautomation.com

Key Highlights: ATC’s assembly lines use all types and brands of robots for assembling transportation, medical devices, consumer products, and energy storage (batteries)….

#10 HAHN Automation Group

Website: hahnautomation.group

Key Highlights: As a custom equipment provider, we develop, design, build, and integrate high-performance automation and robotics solutions for manufacturing companies….

Expert Sourcing Insights for Automation

2026 Market Trends for Automation

By 2026, the global automation market is poised for transformative growth, driven by technological convergence, economic pressures, and evolving workforce dynamics. Key trends shaping the landscape include:

Accelerated Adoption of AI-Driven Automation

Artificial intelligence, particularly machine learning and generative AI, will be deeply embedded in automation solutions. Intelligent process automation (IPA) will move beyond rule-based tasks to handle complex decision-making, predictive maintenance, and real-time optimization. Expect widespread use of AI-powered digital workers in customer service, supply chain forecasting, and financial operations.

Expansion of Hyperautomation Strategies

Organizations will increasingly adopt hyperautomation—a holistic approach combining RPA, AI, process mining, and low-code platforms—to automate end-to-end business processes. By 2026, over 70% of large enterprises are projected to have implemented hyperautomation initiatives, aiming for operational resilience and agility in volatile markets.

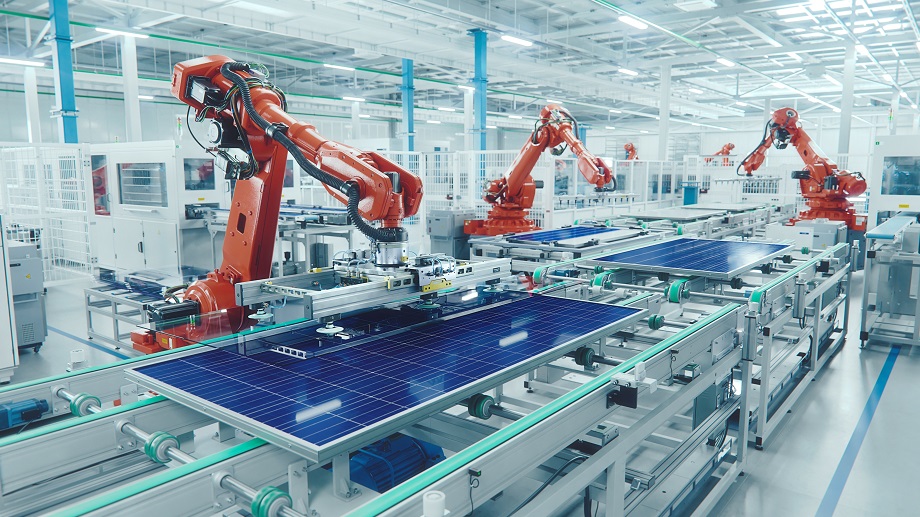

Rise of Autonomous Systems in Physical Environments

Automation in manufacturing, logistics, and warehousing will evolve with advanced robotics, computer vision, and edge computing. Autonomous mobile robots (AMRs), collaborative robots (cobots), and smart sensors will enable flexible, lights-out factories and self-optimizing supply chains, reducing dependency on manual labor.

Integration of Digital Twins and Simulation

Digital twin technology will become mainstream for modeling and optimizing automated systems before deployment. In industries like energy, automotive, and aerospace, digital twins will enable predictive analytics, scenario testing, and continuous improvement of automated operations.

Increased Focus on Sustainability and Energy Efficiency

Automation will play a critical role in helping organizations meet ESG goals. Smart building systems, energy-optimized manufacturing lines, and automated environmental monitoring will grow in demand as companies seek to reduce carbon footprints and comply with stricter regulations.

Skills Shift and Workforce Transformation

As automation handles routine tasks, the workforce will pivot toward oversight, maintenance, and innovation roles. Upskilling programs in data analytics, AI management, and automation design will be essential. Human-machine collaboration will define the future of work, emphasizing augmented intelligence over full replacement.

Regulatory and Ethical Considerations Gain Prominence

With automation influencing critical sectors, governments will introduce frameworks governing AI ethics, data privacy, and algorithmic transparency. Compliance with regulations like the EU AI Act will shape automation design, requiring explainability, accountability, and bias mitigation.

In summary, the 2026 automation landscape will be characterized by smarter, more integrated, and sustainable systems. Success will depend on strategic investment in adaptive technologies, workforce development, and ethical governance.

Common Pitfalls in Sourcing Automation: Quality and Intellectual Property Risks

When sourcing automation solutions—whether software, robotics, or integrated systems—organizations often focus heavily on cost and speed, overlooking critical risks related to quality and intellectual property (IP). Failing to address these pitfalls can lead to project failures, legal disputes, security vulnerabilities, and long-term operational inefficiencies. Below are key challenges to watch for:

Poor Quality Assurance and Inadequate Testing

Many vendors deliver automation solutions that appear functional on the surface but fail under real-world conditions. Lack of robust testing, insufficient error handling, or poorly documented code can result in system instability, downtime, and integration issues. Organizations may inherit solutions that are brittle, difficult to maintain, or incompatible with existing infrastructure.

Mitigation: Enforce strict quality standards in contracts, require third-party code reviews, demand comprehensive testing reports (including edge cases), and include performance benchmarks and SLAs.

Hidden Technical Debt

Sourced automation solutions may rely on outdated libraries, undocumented workarounds, or custom code that introduces technical debt. This debt becomes the client’s responsibility post-delivery, making future upgrades costly and risky.

Mitigation: Conduct thorough technical due diligence, require access to source code and architecture documentation, and assess maintainability before finalizing agreements.

Unclear or Incomplete Intellectual Property Rights

One of the most significant risks in sourcing automation is ambiguity around IP ownership. Vendors may retain rights to core components, algorithms, or custom-developed code, limiting your ability to modify, scale, or transfer the solution. In some cases, the vendor may use open-source components with restrictive licenses (e.g., GPL), creating compliance risks.

Mitigation: Clearly define IP ownership in contracts—ensure full transfer of custom-developed IP to your organization. Require disclosure of all third-party and open-source components and validate license compliance.

Use of Proprietary Black-Box Systems

Some vendors deliver automation tools as closed systems with limited visibility into how they operate. This lack of transparency makes it difficult to audit, troubleshoot, or ensure alignment with regulatory or security standards.

Mitigation: Insist on transparency and right-to-audit clauses. Prefer solutions with open APIs, modular design, and documented logic, especially in regulated industries.

Vendor Lock-In Through IP and Integration

Vendors may design automation solutions that tightly couple functionality with their proprietary platforms, making it difficult or expensive to switch providers. This dependency can be enforced through IP restrictions, exclusive APIs, or data format limitations.

Mitigation: Negotiate for open standards, data portability, and modular architecture. Ensure contracts allow for third-party support and future migration.

Inadequate Protection of Your Own IP

During the development process, your organization may share sensitive business logic, data, or trade secrets with the vendor. Without proper safeguards, this information could be reused across clients or exposed through weak security practices.

Mitigation: Implement strong NDAs, limit data sharing to what’s necessary, and require compliance with data protection standards (e.g., GDPR, SOC 2). Audit vendor security protocols.

By proactively addressing quality and IP concerns during the sourcing process, organizations can reduce risk, ensure long-term control over their automation investments, and avoid costly disputes or system failures down the line.

Logistics & Compliance Guide for Automation

This guide outlines key considerations for integrating automation into logistics operations while ensuring adherence to regulatory and compliance standards.

Strategic Planning and Risk Assessment

Before implementing automation, conduct a comprehensive assessment of current logistics processes, identify pain points, and define clear objectives. Evaluate potential risks related to data security, operational disruptions, and workforce transitions. Develop a risk mitigation plan that includes contingency measures for system failures and supply chain interruptions.

Regulatory Compliance Framework

Ensure all automated systems comply with relevant international, national, and industry-specific regulations. This includes adherence to data protection laws (e.g., GDPR, CCPA), customs regulations (e.g., CBP, EU Customs Code), and transportation safety standards (e.g., FMCSA, EUMTS). Maintain up-to-date documentation and audit trails for all automated processes.

Data Integrity and Cybersecurity

Protect sensitive logistics data through robust cybersecurity protocols. Implement encryption, access controls, and regular security audits for automated platforms such as warehouse management systems (WMS), transportation management systems (TMS), and robotic process automation (RPA) tools. Ensure data accuracy and consistency across automated workflows to prevent compliance violations.

Integration with Supply Chain Partners

Coordinate automation initiatives with suppliers, carriers, and third-party logistics providers (3PLs). Standardize data formats and communication protocols (e.g., EDI, API integrations) to enable seamless information exchange. Verify that partner systems meet required compliance standards, especially regarding data privacy and traceability.

Workforce Training and Change Management

Prepare employees for the transition to automated systems through targeted training programs. Address concerns about job displacement and emphasize upskilling opportunities. Establish clear roles for human oversight in automated processes, particularly in exception handling and compliance monitoring.

Environmental and Sustainability Compliance

Leverage automation to enhance sustainability by optimizing routing, reducing fuel consumption, and minimizing waste. Ensure compliance with environmental regulations such as emissions standards and waste disposal laws. Use automated reporting tools to track and disclose sustainability metrics.

Audit Readiness and Documentation

Maintain comprehensive records of all automated processes, including system configurations, change logs, and compliance certifications. Conduct regular internal audits to verify adherence to policies and regulations. Prepare for external audits by ensuring automated systems can generate required reports on demand.

Continuous Monitoring and Improvement

Implement real-time monitoring tools to track the performance and compliance status of automated systems. Use analytics to identify inefficiencies and emerging risks. Regularly update software, compliance protocols, and operational procedures to adapt to evolving regulations and technological advancements.

In conclusion, sourcing automation manufacturers requires a strategic approach that balances quality, cost, scalability, and technological expertise. Conducting thorough due diligence—evaluating manufacturing capabilities, certifications, production capacity, supply chain reliability, and after-sales support—is essential to ensure long-term success. Leveraging digital sourcing platforms, attending industry trade shows, and building strong relationships with pre-vetted suppliers can streamline the selection process. Additionally, prioritizing manufacturers that embrace innovation, sustainability, and compliance with international standards enhances competitiveness and reduces operational risks. Ultimately, a well-executed sourcing strategy for automation manufacturers not only supports efficient production but also drives business growth and resilience in an increasingly automated global market.