The global tire changer market is experiencing steady growth, driven by rising vehicle production, increasing demand for automotive maintenance automation, and the expansion of tire service centers worldwide. According to a report by Mordor Intelligence, the global tire changer market was valued at approximately USD 280 million in 2023 and is projected to grow at a CAGR of around 4.5% from 2024 to 2029. This growth is fueled by advancements in technology, including the integration of AI and IoT in automatic tire changing equipment, as well as the growing preference for precision and efficiency in tire servicing operations. As demand rises, especially in emerging economies, leading manufacturers are innovating to offer faster, safer, and more user-friendly automatic tire changers. In this evolving landscape, eight key players have emerged as industry frontrunners, setting benchmarks in performance, reliability, and technological integration.

Top 8 Automatic Tire Changer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tire Changers & Tire Mounters by Ranger Products

Domain Est. 1997

Website: bendpak.com

Key Highlights: Free deliveryOur state-of-the-art tire changer design offers cutting-edge technology and advanced features to make this one of the most profitable pieces of wheel service ……

#2 Corghi Usa Inc.

Domain Est. 2009

Website: corghiusa.us

Key Highlights: All Tire Changers, Balancers, Alignment, and HD equipment are IN STOCK! From entry level, to basic, to fully automatic, to diagnostic! NO NEED TO WAIT 60-120 ……

#3 Robotic Tire Changing

Domain Est. 2022

Website: ati-inc.co

Key Highlights: ATI aims to revolutionize tire changing and balancing with advanced robotic technology, providing a quicker, safer, and more efficient service….

#4 Hunter Tire Changers

Domain Est. 1995

Website: hunter.com

Key Highlights: Whether you’re looking for a table-top, center-clamp, or fully-automatic tire changer, Hunter offers powerful tire changers to meet any need….

#5 Automotive Equipment

Domain Est. 1996

Website: johnbean.com

Key Highlights: John Bean® is an industry leader in automotive equipment. Browse our line of modern Tire Changers, Auto Lifts, Wheel Balancers and more….

#6 Tire Machines

Domain Est. 2016

Website: hofmann-equipment.com

Key Highlights: At Hofmann we offer premiere wheel service equipment including our line of innovative tire machines with tilt tower, leverless, swing arm, or heavy-duty ……

#7 Coats Company

Domain Est. 2022

Website: coatscompany.com

Key Highlights: Coats Company offers premium tire changers, wheel balancers, and auto lifts, all American-made for precision, durability, and efficiency in professional ……

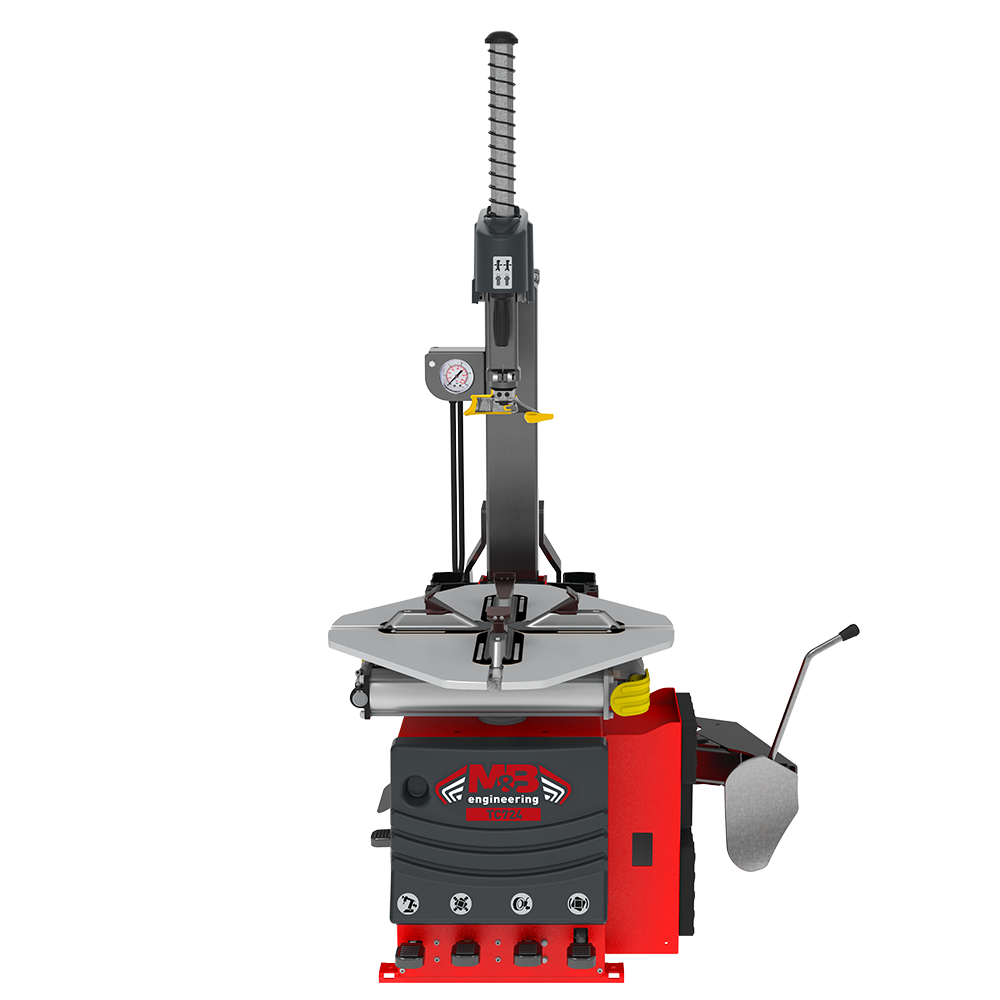

#8 M&B Engineering

Website: mbengineering.info

Key Highlights: DIDO DOUBLE: the new automatic tyre changer with dual-carriage system. DIDO DOUBLE FA is the new super-automatic tire changer for truck, bus, tractor and ……

Expert Sourcing Insights for Automatic Tire Changer

H2: Market Trends for Automatic Tire Changers in 2026

The global market for automatic tire changers is projected to undergo significant transformation by 2026, driven by technological innovation, rising demand for vehicle maintenance efficiency, and the expansion of automotive service infrastructure. Below is an analysis of key market trends expected to shape the automatic tire changer industry in 2026:

1. Increased Adoption in Automotive Service Centers

By 2026, automatic tire changers are anticipated to become standard equipment in both independent repair shops and dealership service centers. The emphasis on reducing labor costs and increasing service throughput is driving widespread adoption. These machines enhance precision and reduce the risk of wheel damage, making them a preferred choice for high-volume operations.

2. Integration of Smart Technology and IoT

A defining trend in 2026 will be the integration of Internet of Things (IoT) and smart diagnostics into automatic tire changers. Next-generation models are expected to feature real-time performance monitoring, predictive maintenance alerts, and cloud-based data reporting. This connectivity allows fleet operators and service centers to optimize equipment utilization and maintenance schedules.

3. Growth in Electric and Autonomous Vehicle Servicing

As electric vehicles (EVs) and autonomous vehicles gain market share, service requirements are evolving. Automatic tire changers are being redesigned to accommodate heavier EV rims and specialized tire types. By 2026, manufacturers will increasingly offer EV-compatible models with enhanced torque control and adaptive clamping systems to meet these new demands.

4. Regional Market Expansion in Asia-Pacific and Latin America

While North America and Europe remain key markets, rapid urbanization and rising vehicle ownership in Asia-Pacific and Latin America are fueling demand. Countries like India, China, Brazil, and Mexico are expected to see robust growth in the automatic tire changer market due to expanding automotive aftermarket networks and government support for modernized repair infrastructure.

5. Focus on Ergonomics and Operator Safety

Safety and ease of use are becoming critical selling points. In 2026, automatic tire changers will increasingly feature user-friendly interfaces, reduced manual intervention, and safety interlocks to minimize workplace injuries. Ergonomic designs will cater to diverse operator skill levels, supporting workforce efficiency and reducing training time.

6. Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop energy-efficient and low-emission models. By 2026, expect to see more automatic tire changers powered by energy-saving motors and constructed with recyclable materials, aligning with global green manufacturing trends.

7. Competitive Landscape and Innovation

The market will see intensified competition among key players such as Hofmann, Hunter Engineering, Corghi, and ChenTai. Innovation will focus on modular designs, AI-assisted tire recognition, and automated rim protection systems. Mergers, acquisitions, and strategic partnerships are likely to accelerate product development and global distribution.

Conclusion

By 2026, the automatic tire changer market will be characterized by smart, connected, and EV-ready solutions tailored to a rapidly evolving automotive landscape. With strong growth drivers across technology, regional demand, and service efficiency, the industry is poised for sustained expansion, offering significant opportunities for manufacturers and service providers alike.

Common Pitfalls When Sourcing an Automatic Tire Changer (Quality and Intellectual Property)

Sourcing an automatic tire changer involves more than just comparing prices and delivery times. Buyers often encounter significant challenges related to quality assurance and intellectual property (IP) risks. Being aware of these pitfalls can prevent costly mistakes and protect your business.

Poor Build Quality and Component Selection

Many low-cost automatic tire changers, especially from less reputable suppliers, use substandard materials and components. Inferior motors, hydraulics, or control systems can lead to frequent breakdowns, reduced lifespan, and increased maintenance costs. Buyers may overlook the importance of durability testing, load capacity, and compliance with safety standards, resulting in unreliable equipment that disrupts workshop operations.

Lack of Safety Certifications and Compliance

A common oversight is failing to verify that the tire changer meets international safety standards such as CE, UL, or ISO. Without proper certification, the equipment may pose safety hazards to operators and fail inspections, leading to legal liabilities. Some suppliers provide fake or self-issued certificates, making due diligence essential.

Inadequate After-Sales Support and Spare Parts Availability

Even with a functional machine, poor post-purchase support can severely impact productivity. Suppliers may not offer technical assistance, training, or timely delivery of spare parts. This is especially problematic with automated systems, where downtime directly affects service throughput. Buyers often underestimate the importance of service network coverage and response times.

Misrepresentation of Automation Capabilities

Some suppliers exaggerate the level of automation or compatibility with various tire types (e.g., run-flat, low-profile, or large-diameter tires). Machines may require more manual intervention than advertised, reducing efficiency gains. It’s crucial to test the equipment with real-world tire models before finalizing a purchase.

Intellectual Property Infringement Risks

Sourcing from manufacturers that copy patented designs or use proprietary software without authorization exposes buyers to legal risks. If the tire changer incorporates stolen technology or reverse-engineered components, your business could face IP litigation, product seizures, or reputational damage. Always verify the manufacturer’s ownership of design rights and software licenses.

Hidden Software Limitations and Licensing Issues

Modern automatic tire changers rely on embedded software for operation and diagnostics. Some suppliers use unlicensed or pirated software, or impose restrictive licensing terms that limit updates and customization. This can hinder integration with existing workshop management systems and create long-term dependency on the supplier.

Insufficient Documentation and Technical Transparency

Lack of comprehensive manuals, circuit diagrams, or programming interfaces can impede maintenance and troubleshooting. This is particularly problematic when dealing with proprietary systems. Buyers should insist on full technical documentation and access to firmware/software specifications.

Conclusion

To avoid these pitfalls, conduct thorough supplier vetting, request third-party quality inspections, verify IP ownership, and prioritize long-term support over initial cost savings. Engaging legal and technical experts during procurement can safeguard both your investment and business integrity.

Logistics & Compliance Guide for Automatic Tire Changer

Product Classification & HS Code

Determine the correct Harmonized System (HS) code for the automatic tire changer to ensure accurate customs classification and applicable duties. Typical classifications fall under HS 8424.90 (machines for cleaning or spraying surfaces, not elsewhere specified), but verify with local customs authorities or a trade compliance expert based on technical specifications.

Import/Export Regulations

Review export control regulations in the country of origin (e.g., U.S. Export Administration Regulations – EAR) and import requirements in the destination country. Confirm whether the tire changer contains any controlled components (e.g., advanced sensors or automation software) that may require export licenses.

Safety & Technical Standards Compliance

Ensure the equipment meets international and local safety standards, such as:

– CE Marking (for European Economic Area): Compliance with Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

– UL/CSA Certification (for North America): Compliance with safety standards like UL 1446 or CSA C22.2 No. 61010.

– EAC Certification (for Eurasian Economic Union): Meets TR CU 010/2011 on machinery safety.

Packaging & Shipping Requirements

Use robust, export-grade packaging to protect the tire changer during transit. Include:

– Wooden or metal pallets compliant with ISPM 15 (for international wood packaging).

– Anti-corrosion protection (VCI paper, desiccants) for electrical and mechanical components.

– Waterproof and shock-resistant wrapping to prevent moisture and impact damage.

Documentation

Prepare all required shipping and compliance documentation:

– Commercial Invoice (with full product description, value, and HS code)

– Packing List (detailing weight, dimensions, and contents per package)

– Bill of Lading or Air Waybill

– Certificate of Conformity (CE, UL, etc., as applicable)

– Export Declaration (if required)

– Warranty and User Manual (in destination country’s official language)

Customs Clearance & Duties

Work with a licensed customs broker in the destination country to ensure smooth clearance. Provide accurate product valuation to avoid delays or penalties. Be prepared to pay applicable import duties, VAT, or GST based on local tariff schedules.

Electrical & Operational Compatibility

Verify that the automatic tire changer’s voltage, frequency, and plug type match the destination country’s electrical standards (e.g., 110V/60Hz in the U.S. vs. 230V/50Hz in Europe). Include power adapters or voltage converters if necessary.

Environmental & Disposal Regulations

Comply with local environmental laws regarding the disposal of packaging materials and end-of-life equipment. Adhere to directives such as WEEE (Waste Electrical and Electronic Equipment) in the EU, which may require registration and recycling plans.

Warranty & After-Sales Support

Ensure compliance with consumer protection laws in the destination market regarding warranty terms, repair services, and spare parts availability. Provide multilingual technical support and service documentation.

Training & Installation Compliance

Offer certified on-site or remote installation and operator training to meet safety and liability requirements. Document all training sessions for compliance and liability protection.

Risk Management & Insurance

Secure comprehensive cargo insurance covering loss, damage, or delay during transit. Include liability coverage for installation and operational use, especially in high-risk industrial environments.

Conclusion for Sourcing an Automatic Tire Changer

In conclusion, sourcing an automatic tire changer is a strategic investment that enhances operational efficiency, improves safety, and ensures consistent service quality in automotive maintenance and tire servicing operations. By automating the tire mounting and demounting process, businesses can reduce labor costs, minimize the risk of wheel and tire damage, and increase throughput—especially in high-volume environments such as service centers, fleet maintenance facilities, and large-scale repair shops.

When selecting an automatic tire changer, key factors such as compatibility with various tire sizes and rim types, build quality, ease of use, safety features, and after-sales support must be carefully evaluated. Additionally, considering total cost of ownership—including maintenance, training, and uptime—ensures long-term value and reliability.

Ultimately, choosing a reputable supplier with proven technology and strong customer service will maximize return on investment and support business growth. With the right automatic tire changer in place, service providers can deliver faster, more professional results, gaining a competitive edge in the evolving automotive industry.