The global demand for automatic spikes—mechanical fasteners widely used in agriculture, construction, and sports—has seen steady growth, driven by increasing automation in manufacturing and rising infrastructure development. According to a 2023 report by Mordor Intelligence, the global fasteners market is projected to grow at a CAGR of 6.3% from 2023 to 2028, with automated production systems playing a pivotal role in meeting precision and scalability requirements. A significant portion of this expansion is attributed to advancements in automatic spike manufacturing, particularly in regions like Asia-Pacific and North America, where industrial automation and construction activities are accelerating. With manufacturers increasingly adopting CNC-based systems and robotic integration to enhance output efficiency and product consistency, the competitive landscape is shifting toward innovation and operational excellence. This shift has propelled several key players to the forefront of the automatic spike manufacturing sector.

Top 8 Automatic Spike Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

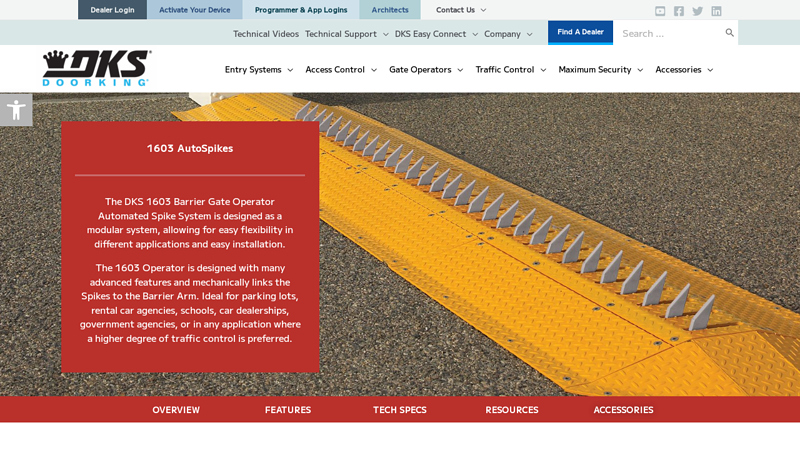

#1 1603 AutoSpikes

Domain Est. 1996

Website: doorking.com

Key Highlights: The DKS 1603 Barrier Gate Operator / Automated Spike System is designed as a modular system allowing for easy flexibility in different applications and easy ……

#2 Motorized Traffic Control Spikes

Domain Est. 1998

Website: deltascientific.com

Key Highlights: Motorized Traffic Teeth Control Spikes are designed to provide top protection against unauthorized traffic moving through a protected gate….

#3 Spike Systems

Domain Est. 2006

Website: spikesystems.com

Key Highlights: We have pioneered the development of automatic and motorized vehicle control devices. Our commitment to superior engineering and exceptional service has made ……

#4 Traffic Spikes

Domain Est. 2012

Website: secure-lane.com

Key Highlights: Traffic control spikes are ideal for controlling traffic direction and speed through a controlled entry location or parking lot….

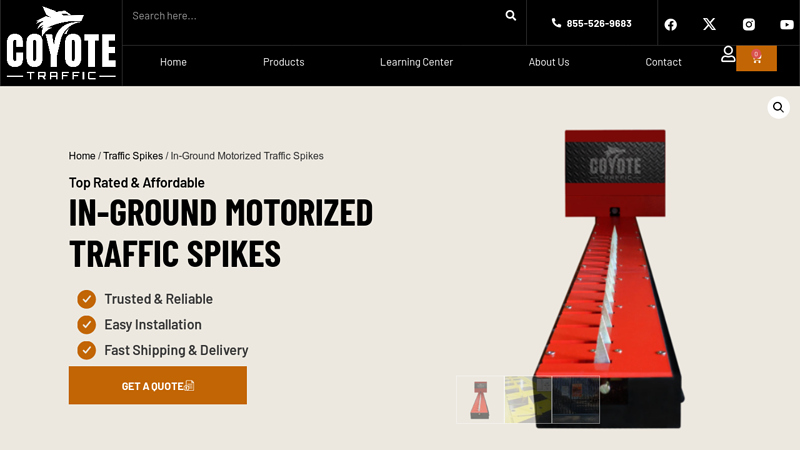

#5 In

Domain Est. 2015

Website: coyotetraffic.com

Key Highlights: Our Flush Motorized Traffic Spikes offer a sophisticated solution for secure and efficient vehicle management. Ideal for a variety of environments….

#6 Tire Spike Barriers And Vehicle Barricades

Domain Est. 2020

Website: protogetic.com

Key Highlights: Does your access control entrance or parking lot need a tire spike barriers? Protogetic carries portable and in-ground tire spike systems….

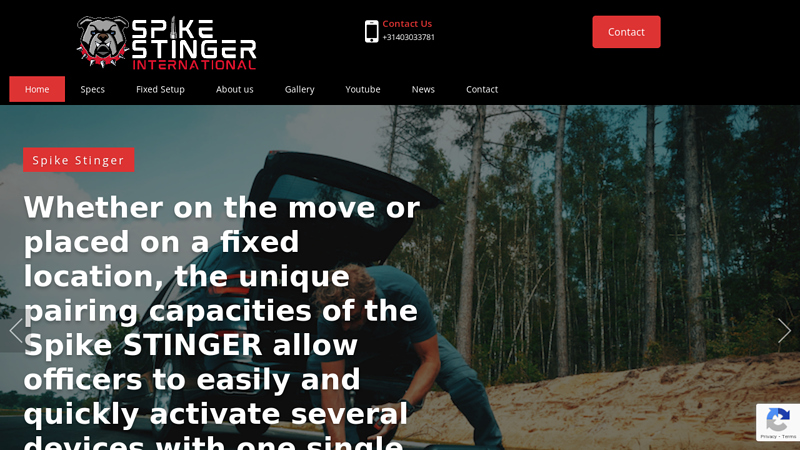

#7 The no 1 Vehicle Stopping System around the world

Domain Est. 2021

Website: spikestingerinternational.com

Key Highlights: The Spike STINGER is the only autonomous device able to stop any vehicle from motorcycles to trailer trucks in seconds….

#8 Autospike.net

Domain Est. 2023

Website: autospike.net

Key Highlights: Autospike.net is the official website for the AUTO-SPIKE Tire Deflation system by Spike Devil. The Auto-Spike has an accordion frame, which folds up into a ……

Expert Sourcing Insights for Automatic Spike

H2 2026 Market Trends for Automatic Spikes

As we look toward the second half of 2026, the market for automatic spikes—primarily referring to automated, retractable traction devices used in athletic footwear (especially track and field, football, and soccer)—is poised for significant evolution driven by technological innovation, sustainability demands, and shifting consumer expectations. Here’s a breakdown of key trends expected to shape the industry:

1. Advanced Material Integration and Lightweight Engineering

Manufacturers will increasingly adopt next-generation materials such as graphene-enhanced composites, ultra-lightweight thermoplastics, and carbon-fiber-reinforced polymers. These materials will reduce overall shoe weight while improving durability and energy return. The focus will be on optimizing spike plate stiffness and responsiveness, with H2 2026 likely seeing commercial releases of shoes that dynamically adapt spike deployment based on terrain and gait.

2. Smart Spike Systems with Embedded Sensors

By H2 2026, smart automatic spike technology will move beyond prototypes into mainstream elite and mid-tier athletic footwear. Shoes will feature integrated micro-sensors (pressure, motion, and terrain detection) that adjust spike length and retraction in real time. Data from these systems will sync with athlete performance apps, offering real-time feedback on traction efficiency, stride optimization, and injury risk—positioning automatic spikes as performance analytics tools, not just mechanical aids.

3. Sustainability and Circular Design

Environmental concerns will drive innovation in recyclable spike mechanisms and biodegradable spike pins. Major brands will launch take-back programs for worn spike units, with H2 2026 marking the debut of fully recyclable automatic spike systems. Water-based adhesives, reduced plastic use, and modular designs (allowing spike mechanism replacement without discarding the entire shoe) will become standard compliance with tightening global sustainability regulations.

4. Expansion into Consumer and Lifestyle Markets

While currently dominant in performance sports, automatic spike technology will begin appearing in premium outdoor and lifestyle footwear by H2 2026. Brands will target urban adventurers and all-weather commuters with hybrid shoes featuring retractable micro-spikes for icy sidewalks or wet trails. This crossover appeal will open new revenue streams and increase market penetration beyond elite athletes.

5. Customization and 3D-Printed Solutions

Advances in on-demand manufacturing will enable personalized automatic spike configurations. Athletes will use AI-powered platforms to customize spike pattern, length, and deployment timing based on biomechanical scans. By late 2026, leading brands may offer 3D-printed spike mechanisms tailored to individual foot shape and running style, enhancing performance and comfort.

6. Regulatory and Competitive Standardization

As automatic spikes become more prevalent, governing bodies like World Athletics may introduce clearer regulations on spike deployment mechanisms, maximum length, and material composition. H2 2026 could see proposed standards to ensure fair competition, particularly as self-adjusting systems raise questions about performance enhancement boundaries.

Conclusion

H2 2026 will mark a turning point for automatic spike technology—transitioning from niche innovation to mainstream adoption in performance and lifestyle markets. The convergence of smart materials, data-driven personalization, and sustainability will define competitive advantage. Brands that integrate AI-responsive systems with eco-conscious design will lead the market, while compliance with emerging regulations will be critical for global scalability.

Common Pitfalls Sourcing Automatic Spike (Quality, IP)

When sourcing an Automatic Spike system—commonly used in industrial automation, robotics, or precision manufacturing—organizations face several critical challenges related to quality assurance and intellectual property (IP) protection. Overlooking these pitfalls can result in operational inefficiencies, legal risks, and compromised product integrity.

Poor Quality Control and Inconsistent Performance

One of the most frequent issues is sourcing from suppliers with inadequate quality management systems. Low-quality Automatic Spike units may suffer from mechanical wear, inconsistent actuation, or premature failure. Without proper certifications (e.g., ISO 9001) or verifiable testing protocols, buyers risk integrating unreliable components into their systems, leading to downtime and increased maintenance costs.

Lack of Transparency in Manufacturing Standards

Suppliers may not disclose detailed manufacturing processes, materials used, or tolerances. This opacity makes it difficult to assess long-term durability or compatibility with existing systems. Components produced with substandard materials or imprecise machining can negatively impact the overall performance of automated assemblies.

Intellectual Property Infringement Risks

Sourcing Automatic Spike mechanisms from unverified vendors increases the risk of IP violations. Some suppliers may replicate patented designs or use proprietary technology without authorization. Purchasing such components can expose the buyer to legal liability, especially in regulated industries or international markets where IP enforcement is stringent.

Insufficient Documentation and Traceability

Many suppliers fail to provide comprehensive technical documentation, including CAD models, compliance certificates, or revision histories. This lack of traceability complicates integration, maintenance, and future sourcing efforts. It also raises concerns about whether the components meet industry-specific standards or safety regulations.

Inadequate Support for Customization and Integration

Off-the-shelf Automatic Spike units may not meet specific application requirements. Vendors who lack engineering support or are unwilling to collaborate on customization can hinder system optimization. Without proper integration guidance, performance issues may arise during deployment.

Hidden Costs from Short-Term Sourcing Decisions

Opting for lower-cost suppliers may seem economical initially but often leads to higher total cost of ownership due to frequent replacements, warranty claims, or operational disruptions. A holistic evaluation of lifecycle costs is essential to avoid long-term financial and technical setbacks.

Failure to Secure Licensing or Usage Rights

Even if the physical component is legally sourced, usage rights for embedded software or firmware may be restricted. Failing to verify licensing terms can result in unauthorized use of protected algorithms or control logic, creating exposure to IP litigation.

To mitigate these risks, buyers should conduct thorough supplier audits, require IP indemnification clauses in contracts, and prioritize vendors with strong quality certifications and transparent development practices.

Logistics & Compliance Guide for Automatic Spike

This guide outlines the essential logistics and compliance considerations for the deployment, operation, and maintenance of Automatic Spike systems. These systems, typically used in traffic management, security perimeters, or access control, must adhere to strict regulatory, safety, and logistical standards to ensure effectiveness and legal compliance.

Regulatory Compliance

Ensure all Automatic Spike installations comply with local, state, and national regulations. This includes traffic control laws, building codes, and public safety standards. In many jurisdictions, automated barriers and road spikes fall under transportation or public safety authority oversight. Obtain necessary permits before installation and maintain documentation for inspections.

Safety Standards and Certifications

Automatic Spike systems must meet recognized safety certifications such as ISO 3834 (welding safety), CE marking (for EU compliance), or ANSI/UL standards (in the U.S.). Systems should include fail-safe mechanisms, emergency stop functions, and clear warning signage. Regular third-party audits and certification renewals are required to maintain compliance.

Installation and Site Preparation

Proper site evaluation is critical before installation. Assess ground composition, drainage, proximity to utilities, and traffic patterns. Coordinate with municipal engineers and utility providers to avoid underground line damage. Install with embedded sensors and communication links to central monitoring systems. Ensure all electrical and hydraulic components are protected from environmental exposure.

Operational Protocols

Define clear operational procedures, including activation protocols, response times, and integration with access control or surveillance systems. Only authorized personnel should have control access. Systems must include manual override capabilities for emergencies. Log all activations and maintenance actions for audit purposes.

Maintenance and Inspection

Implement a scheduled maintenance program aligned with manufacturer guidelines. Conduct monthly functional tests, quarterly mechanical inspections, and annual full-system diagnostics. Keep detailed records of all maintenance, repairs, and component replacements. Replace worn spikes or actuators promptly to prevent failure.

Data Privacy and Cybersecurity

If the Automatic Spike system connects to a network or stores operational data, ensure compliance with data protection regulations (e.g., GDPR, CCPA). Secure communication channels with encryption, enforce strong authentication, and conduct regular vulnerability assessments. Limit data access to authorized users only.

Environmental and Accessibility Considerations

Ensure installations do not impede emergency vehicle access or violate ADA (Americans with Disabilities Act) requirements for pedestrian pathways. Evaluate environmental impact, especially in ecologically sensitive areas. Use corrosion-resistant materials and environmentally safe hydraulic fluids where applicable.

Training and Documentation

Provide comprehensive training for operators, security staff, and maintenance personnel. Training should cover safe operation, emergency procedures, and compliance requirements. Maintain up-to-date system manuals, as-built drawings, and compliance certificates on file.

Incident Reporting and Liability Management

Establish a protocol for reporting and investigating malfunctions, accidents, or unauthorized activations. Document all incidents thoroughly and report to relevant authorities if required. Maintain liability insurance that covers automated barrier systems and review coverage annually.

By adhering to this guide, organizations can ensure that Automatic Spike systems are deployed safely, operate efficiently, and remain in full compliance with all applicable laws and standards.

Conclusion for Sourcing Automatic Spike:

In conclusion, the sourcing of an automatic spike system represents a strategic investment in efficiency, consistency, and scalability within construction, agriculture, or industrial operations. By automating the process of spike placement or installation, organizations can significantly reduce manual labor, minimize human error, and enhance overall productivity. Careful evaluation of technical specifications, durability, compatibility with existing equipment, and total cost of ownership is essential when selecting a supplier or system. Additionally, partnering with reputable manufacturers who offer strong after-sales support, warranty coverage, and innovation-driven designs ensures long-term reliability and operational success. As automation continues to reshape various industries, adopting an automatic spike solution not only streamlines processes but also positions businesses at the forefront of technological advancement and operational excellence.