The global laundry equipment market is undergoing a significant transformation, driven by increasing demand for automation in both commercial and residential settings. According to Grand View Research, the global laundry care equipment market was valued at USD 17.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. A key driver behind this growth is the rising adoption of smart and automated solutions—such as automatic laundry folders—that enhance efficiency, reduce labor costs, and improve operational throughput in laundromats, hotels, healthcare facilities, and home environments. As labor shortages and operational demands intensify, manufacturers are responding with advanced folding technologies that integrate AI, vision systems, and high-speed robotics. Against this backdrop, we spotlight the top 9 automatic laundry folder manufacturers shaping the future of laundering automation, combining innovation, reliability, and scalability to meet evolving market needs.

Top 9 Automatic Laundry Folder Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JENSEN

Domain Est. 1996

Website: jensen-group.com

Key Highlights: Individual solutions and systems for your laundry technology ✓ Sustainable automation of industrial laundries ✓ Learn more now!…

#2 Partner in laundry technology: Kannegiesser

Domain Est. 1998

Website: kannegiesser.com

Key Highlights: Kannegiesser offers the complete product range of industrial washing technology. With the product areas washing technology, flatwork technology, ……

#3 China Automatic Laundry Folding Machine Manufacturers and …

Domain Est. 2021

Website: ublpacking.com

Key Highlights: Automatic Laundry Folding Machine Manufacturers, Factory, Suppliers From China, We warmly welcome merchants from your home and overseas to contact us and ……

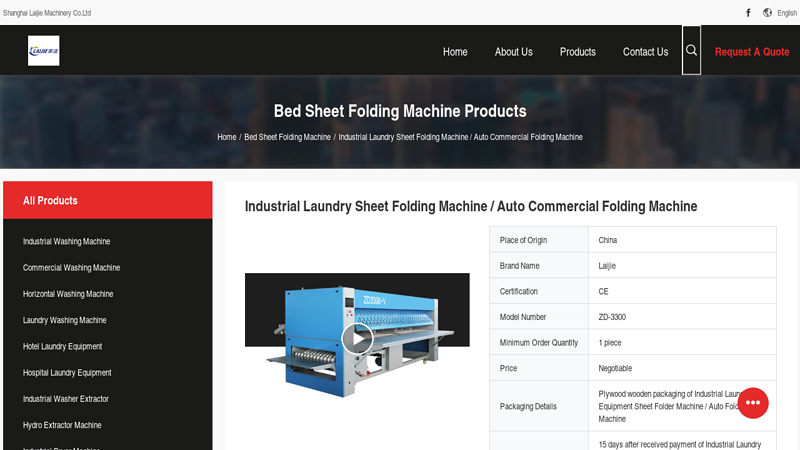

#4 Industrial Laundry Sheet Folding Machine / Auto Commercial …

Domain Est. 2018

Website: autowashingmachine.com

Key Highlights: Good Quality Industrial Laundry Sheet Folding Machine / Auto Commercial Folding Machine From China – Shanghai Laijie Machinery Co.Ltd….

#5 Automatic Laundry Folder Machine

Domain Est. 1997

Website: clmco.com

Key Highlights: Intended for high-speed folding and occupying minimal floor space, Consolidated Laundry Machinery (CLM’s) SPF-1 Towel Folder is ideal for high-output plants….

#6 RoboFold Pro Automatic Garment Folding Robot

Domain Est. 2018

Website: solisdepot.com

Key Highlights: Rating 4.3 (149) Dec 8, 2025 · Automatic garment folding: neat, repeatable folds for everyday items. Smart sizing logic: adapts to shirts, pants, and tees…

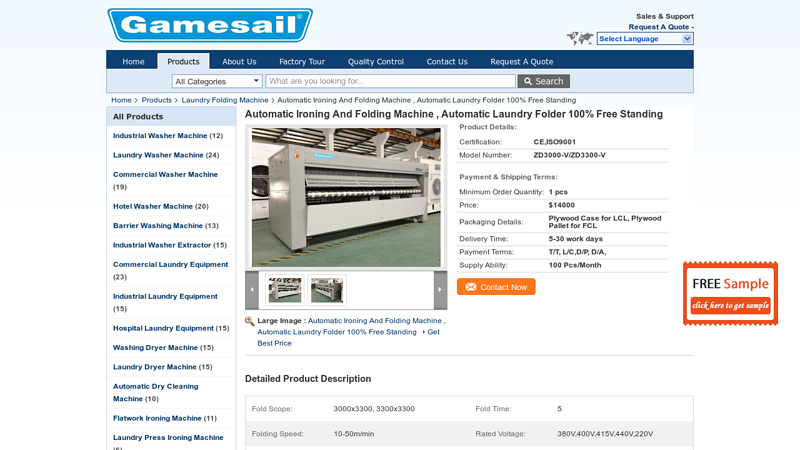

#7 Automatic Ironing And Folding Machine , Automatic Laundry Folder …

Domain Est. 2022

Website: industrialwashermachine.com

Key Highlights: High quality Automatic Ironing And Folding Machine , Automatic Laundry Folder 100% Free Standing from China, China’s leading Laundry Folding Machine product ……

#8 FoldiMate Laundry Folding Machine and Fabric Compatibility

Website: ar.foldimateofficial.com

Key Highlights: Discover how the FoldiMate laundry folding machine handles different fabrics and materials with ease. Smart, efficient, and fabric-friendly….

#9 Top Laundry Folding Machine Manufacturers

Domain Est. 2018

Website: verifiedmarketresearch.com

Key Highlights: Below is a breakdown of the top companies shaping the automatic laundry folding machine industry: FoldiMate (USA). Foldimate-one of the top laundry folding ……

Expert Sourcing Insights for Automatic Laundry Folder

H2: Market Trends for Automatic Laundry Folder in 2026

The automatic laundry folding market is poised for significant growth and transformation by 2026, driven by technological innovation, rising labor costs, and increased demand for convenience in both commercial and residential sectors. Several key trends are expected to shape the industry landscape in the coming years.

1. Expansion in Commercial Applications

By 2026, commercial laundries—including hotels, hospitals, and laundry service providers—are anticipated to be the primary adopters of automatic laundry folders. With a growing emphasis on operational efficiency and cost reduction, businesses are investing in automation to handle high-volume folding tasks. These systems reduce labor dependency, minimize human error, and improve throughput, making them invaluable in time-sensitive environments.

2. Advancements in AI and Machine Learning

Artificial intelligence (AI) and machine learning are revolutionizing automatic laundry folders by enabling smarter fabric recognition, adaptive folding techniques, and self-optimization. By 2026, next-generation models are expected to identify garment types (e.g., shirts, towels, pants) and adjust folding patterns accordingly. This intelligence reduces the need for manual configuration and improves folding accuracy across diverse laundry loads.

3. Integration with Smart Home and IoT Ecosystems

The residential market for automatic laundry folders is set to expand as smart home technology becomes more ubiquitous. By 2026, these devices are likely to integrate seamlessly with home automation platforms such as Google Home, Amazon Alexa, and Apple HomeKit. Consumers will be able to monitor, control, and schedule folding operations remotely via smartphone apps, enhancing convenience and user experience.

4. Focus on Compact and Energy-Efficient Designs

With urban living spaces becoming more compact, manufacturers are expected to prioritize space-saving and energy-efficient designs. By 2026, automatic laundry folders will likely feature modular builds, lower power consumption, and quieter operation—making them suitable for apartment dwellers and eco-conscious consumers.

5. Rising Demand in Emerging Markets

While North America and Europe lead in adoption, emerging economies in Asia-Pacific, Latin America, and the Middle East are expected to experience accelerated demand by 2026. Increasing urbanization, growth in the hospitality sector, and rising disposable incomes are contributing to the adoption of automated laundry solutions in these regions.

6. Sustainability and Circular Economy Initiatives

Sustainability is becoming a key differentiator. By 2026, manufacturers are likely to emphasize recyclable materials, longer product lifecycles, and repairability in their designs. Additionally, automated folding reduces textile wear and improves garment longevity, aligning with broader circular economy goals in the textile industry.

7. Competitive Landscape and Market Consolidation

The market is expected to see increased competition, with established appliance brands and startups vying for market share. Strategic partnerships, mergers, and acquisitions may occur as companies aim to integrate folding technology with full laundry automation systems (e.g., wash-to-fold robots).

In conclusion, the automatic laundry folder market in 2026 will be characterized by intelligent automation, broader accessibility, and integration into both commercial operations and smart homes. As consumer expectations for convenience and efficiency continue to rise, the adoption of these systems is expected to grow steadily across global markets.

Common Pitfalls When Sourcing an Automatic Laundry Folder (Quality, IP)

Sourcing an automatic laundry folder involves more than just comparing prices and delivery times. Two critical areas where buyers often encounter challenges are product quality and intellectual property (IP) risks. Overlooking these aspects can lead to operational inefficiencies, legal disputes, or reputational damage. Below are common pitfalls in these areas to watch out for.

Quality-Related Pitfalls

1. Inconsistent Folding Performance

Not all automatic laundry folders handle various fabric types and garment sizes equally. A major pitfall is assuming that a machine that works well with cotton towels will perform the same with delicate fabrics or bulky items. Poor folding consistency leads to rework, increased labor costs, and customer dissatisfaction.

2. Substandard Build Materials

Some suppliers use lower-grade materials to cut costs, resulting in machines that wear out quickly under continuous commercial use. Look out for flimsy frames, low-quality rollers, or components prone to jamming. These issues increase downtime and maintenance expenses.

3. Lack of Real-World Testing Data

Suppliers may provide ideal lab-condition performance metrics that don’t reflect real-world operations. Without verified throughput rates, error rates, or durability under heavy loads, buyers risk investing in underperforming equipment.

4. Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines need maintenance. A common pitfall is partnering with suppliers who offer little technical support or have long lead times for spare parts—especially critical when sourcing from overseas manufacturers.

Intellectual Property (IP) Pitfalls

1. Risk of Infringing Patented Technology

Automatic laundry folders often incorporate patented mechanisms for folding, feeding, or sensor alignment. Sourcing from manufacturers who replicate these features without licensing can expose your business to IP litigation, especially when importing into regions with strong IP enforcement (e.g., the EU or U.S.).

2. Unclear Ownership of Customized Designs

If you request modifications or custom engineering, ensure contracts clearly define IP ownership. Otherwise, you may not retain rights to the design, preventing future replication or improvement.

3. Counterfeit or Clone Machinery

Some suppliers offer machines that closely resemble well-known brands but are unlicensed replicas. These clones may be cheaper, but they often violate IP laws and lack reliability, safety certifications, or firmware updates.

4. Missing Documentation for IP Compliance

Always request documentation proving the machine does not infringe on existing patents or trademarks. Reputable suppliers should provide IP clearance statements or design registration details—lack of such documents is a red flag.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify quality through on-site demos or third-party inspections, audit the supplier’s manufacturing processes, and consult legal experts to review IP compliance. Investing time upfront can prevent costly issues down the line.

Logistics & Compliance Guide for Automatic Laundry Folder

This guide outlines key logistics and compliance considerations for the transportation, installation, and operation of an Automatic Laundry Folder in commercial or industrial environments.

Product Classification and Documentation

Ensure the Automatic Laundry Folder is correctly classified under the appropriate Harmonized System (HS) code for import/export purposes—typically under heading 8451 (washing, drying, ironing or pressing machinery). Maintain accurate documentation including commercial invoices, packing lists, bill of lading/airway bill, and a Certificate of Conformity (CoC) as required by destination country regulations.

Packaging and Handling Requirements

The machine must be securely packaged in a robust wooden crate or reinforced cardboard with internal bracing to prevent movement during transit. Use moisture-resistant wrapping to protect electrical components. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack,” in compliance with international shipping standards (e.g., ISO 780).

Transportation and Shipping

Use freight carriers experienced in handling heavy industrial equipment. Confirm that the shipping method (road, sea, or air) complies with weight, size, and safety regulations. For sea freight, ensure compliance with the International Maritime Dangerous Goods (IMDG) Code if applicable. Secure the machine with straps or braces inside the container to prevent shifting.

Import/Export Compliance

Verify that the destination country does not restrict or require special permits for importing industrial laundry equipment. Comply with local electrical standards (e.g., CE marking for Europe, UL listing for North America). Provide technical specifications including voltage, frequency, and power consumption to meet customs and regulatory requirements.

Installation and Site Requirements

The installation site must meet electrical, ventilation, and space requirements specified by the manufacturer. Ensure access to proper power supply (e.g., 208–240V, single or three-phase as specified), adequate floor load capacity, and clearances for operation and maintenance. Installation must be performed by certified technicians in accordance with local building and electrical codes.

Safety and Operational Compliance

The Automatic Laundry Folder must comply with relevant safety standards such as IEC 60335-2-4 (safety of electrical household and similar appliances – Part 2-4: Particular requirements for spin extractors and laundry drying machines). Operators must be trained in safe use, emergency shutdown procedures, and routine maintenance. Provide multilingual user manuals and safety signage where applicable.

Environmental and Disposal Regulations

Dispose of packaging materials in accordance with local waste management regulations. At end-of-life, the machine must be recycled or disposed of following Waste Electrical and Electronic Equipment (WEEE) Directive guidelines in applicable regions. Avoid landfill dumping of electronic components and motors.

Recordkeeping and Audits

Maintain all compliance documentation, including test reports, conformity certificates, shipping records, and installation logs. These records may be required for regulatory audits or warranty claims. Update compliance status if the machine is relocated to a different jurisdiction.

Ongoing Maintenance and Regulatory Updates

Schedule regular maintenance per the manufacturer’s guidelines to ensure continued compliance with safety and performance standards. Monitor regulatory changes in target markets (e.g., energy efficiency requirements, RoHS compliance) and update equipment or documentation as needed.

Conclusion for Sourcing an Automatic Laundry Folder:

Sourcing an automatic laundry folder represents a strategic investment in operational efficiency, labor cost reduction, and service consistency—particularly for commercial laundries, hotels, healthcare facilities, and large-scale laundry operations. After evaluating various suppliers, technologies, and models, it is evident that these machines significantly reduce manual labor, minimize human error, and increase throughput, leading to faster turnaround times and improved customer satisfaction.

Key considerations such as machine capacity, folding accuracy, ease of integration, maintenance requirements, and total cost of ownership must align with the specific needs of the operation. While the initial investment may be substantial, the long-term savings in labor and increased productivity often justify the expenditure.

Ultimately, selecting a reliable automatic laundry folder from a reputable supplier ensures durability, technical support, and scalability. As automation continues to transform the laundry industry, adopting this technology positions businesses to remain competitive, efficient, and future-ready in a rapidly evolving market.