The global cable processing equipment market is experiencing steady growth, driven by rising demand in industries such as automotive, construction, and telecommunications. According to Grand View Research, the global wire and cable market size was valued at USD 197.1 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2024 to 2030. This growth directly fuels demand for precision tools like automatic cable strippers, which enhance efficiency, reduce waste, and ensure consistent quality in high-volume production environments. As automation continues to reshape manufacturing workflows, investments in advanced cable preparation technology are becoming a strategic priority. In this evolving landscape, leading manufacturers are innovating with features like programmable logic controls, touchscreen interfaces, and integration with Industry 4.0 systems. Based on market presence, technological capabilities, and product reliability, here are the top 10 automatic cable stripper manufacturers shaping the future of cable processing.

Top 10 Automatic Cable Stripper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to JOKARI Wire Stripping Tools!

Website: jokari.de

Key Highlights: JOKARI GmbH & Co. KG is a specialist in the stripping technology for all types of cables and wires. Find wire stripping tools now!…

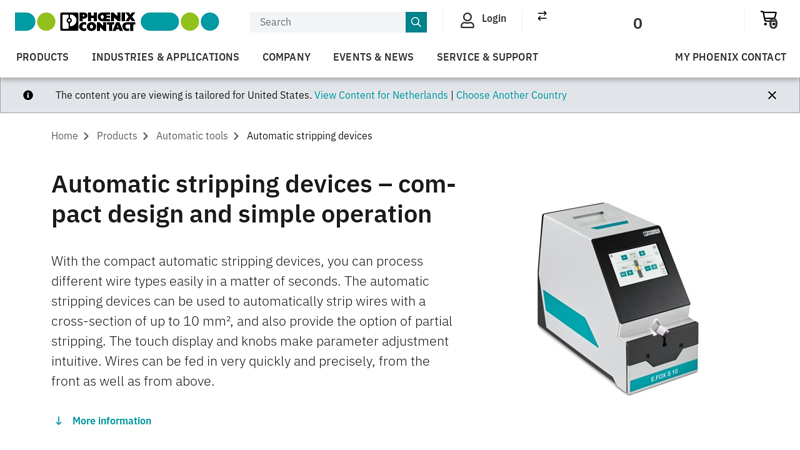

#2 Automatic stripping devices

Domain Est. 1996

Website: phoenixcontact.com

Key Highlights: With the compact automatic stripping devices, you can process wires with standard or special insulation easily in a matter of seconds. Find out more n….

#3 Find stripping and sheathing tools

Domain Est. 1996

Website: weidmuller.com

Key Highlights: Looking for a fast and effortless solution for cutting and stripping cables? With the swifty® CS (Cut & Strip), you always have the perfect tool at hand! This ……

#4 5 in 1 Automatic Wire Stripper and Crimper

Domain Est. 1997

Website: gardnerbender.com

Key Highlights: Use this multi-purpose tool to cut and strip copper and aluminum wire (solid or stranded) or to crimp insulated terminals, non-insulated terminals and More….

#5 KNIPEX ComStrip Automatic insulation stripper

Domain Est. 1997

Website: knipex.com

Key Highlights: Perfect entry-level model: Strips solid, multi-stranded and finely stranded conductors from 0.2 to 6 mm² with standard insulation without any need for ……

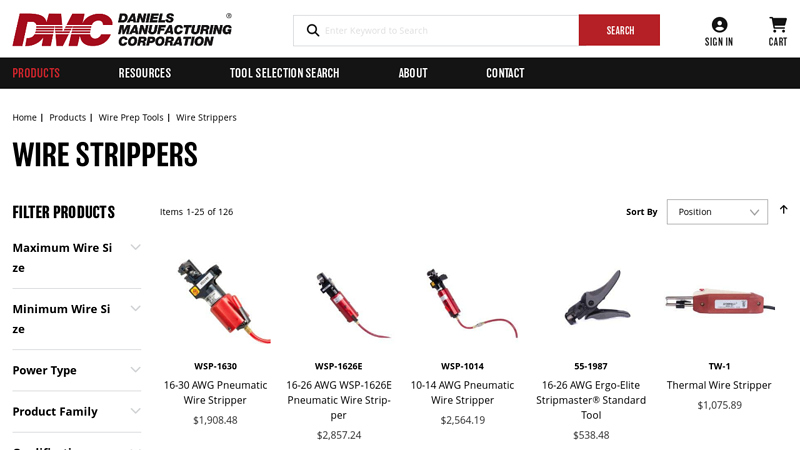

#6 Wire Strippers

Domain Est. 1997

Website: dmctools.com

Key Highlights: Free delivery 30-day returnsOur hand-held pneumatic wire strippers accommodate Stripmaster® blades and cover a range of 10-30 AWG to provide the ultimate combination of ……

#7 Automatic Wire Strippers (14 products)

Domain Est. 2005

Website: knipex-tools.com

Key Highlights: Automatic Wire Stripper 10-24 AWG 12 62 180 Length: 7 1/4″ Grips: Multi-component 1242195-01-3.jpg Automatic Wire Stripper 8-32 AWG…

#8 IDEAL Wire Strippers – Market Leader

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsIDEAL invented the T®-Stripper Wire Stripper in 1956. Compact, lightweight and easy to use. Features built-in looping holes and knife-type ……

#9 STRIPMEISTER

Domain Est. 2013

Website: stripmeister.com

Key Highlights: A premium, electric automatic Wire Stripper with variable-speed control and a stainless-steel rear wire guide for steady alignment and hands-free throughput….

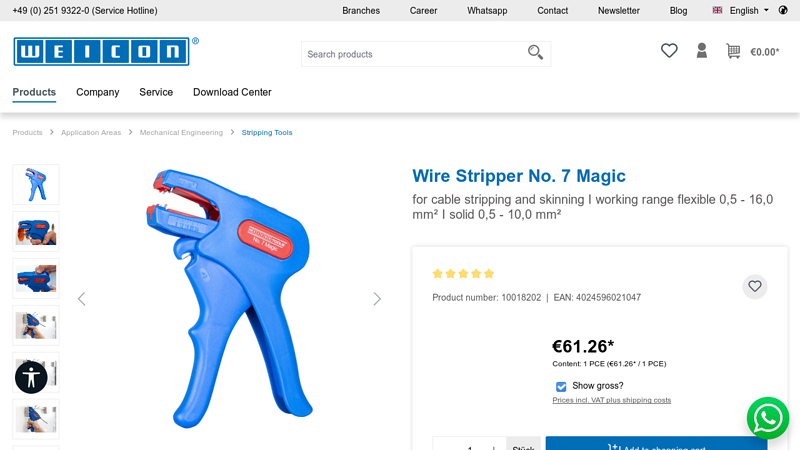

#10 Wire Stripper No. 7 Magic

Website: weicon.de

Key Highlights: Rating 5.0 (3) WEICON Wire Stripper No .7 Magic is a robust, ergonomic automatic wire stripper. The automatic scanning system is adjustable to different cable types and ……

Expert Sourcing Insights for Automatic Cable Stripper

H2: 2026 Market Trends for Automatic Cable Stripper

The global market for automatic cable strippers is poised for significant transformation by 2026, driven by advancements in automation, rising demand for precision in electrical and telecommunications infrastructure, and the expansion of smart manufacturing ecosystems. Key trends shaping the industry include:

-

Increased Adoption in Industrial Automation

As industries embrace Industry 4.0 principles, the integration of automatic cable strippers into robotic assembly lines and automated wire processing systems is accelerating. Manufacturers in automotive, aerospace, and consumer electronics are prioritizing efficiency and repeatability, boosting demand for high-speed, programmable cable-stripping solutions. -

Growth in Renewable Energy and EV Infrastructure

The rapid deployment of electric vehicles (EVs) and renewable energy systems—such as solar and wind farms—requires vast networks of high-voltage and specialized cables. Automatic cable strippers capable of handling diverse cable types (including shielded, coaxial, and high-gauge wires) are becoming essential in these sectors, driving market expansion. -

Technological Advancements and Smart Features

By 2026, automatic cable strippers are expected to incorporate AI-driven diagnostics, IoT connectivity, and real-time monitoring. These smart features enable predictive maintenance, reduce downtime, and ensure consistent stripping accuracy. Touchscreen interfaces, barcode scanning for cable identification, and cloud-based data logging are becoming standard in premium models. -

Demand for Precision and Miniaturization

With the proliferation of compact electronic devices and medical equipment, there is growing demand for automatic strippers that can handle ultra-fine wires (down to 30 AWG or smaller) without damaging conductors. This trend is pushing innovation in blade design, motor control, and micro-servo technologies. -

Regional Market Shifts

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to lead market growth due to booming electronics manufacturing and government-backed infrastructure projects. North America and Europe will maintain strong demand, driven by automation in advanced manufacturing and stringent safety standards requiring consistent wire preparation. -

Sustainability and Energy Efficiency

Equipment manufacturers are focusing on energy-efficient motors and recyclable materials in the construction of automatic cable strippers. Additionally, longer tool life and reduced material waste align with corporate sustainability goals, influencing procurement decisions. -

Competitive Landscape and Consolidation

The market is witnessing increased competition among key players such as Komax, Schleuniger, and Sumitomo, who are investing in R&D and strategic partnerships. Mergers and acquisitions are anticipated as companies seek to broaden their product portfolios and geographic reach.

In conclusion, the 2026 automatic cable stripper market will be defined by智能化 (smart automation), sector-specific customization, and integration with digital manufacturing platforms. Companies that innovate in precision, connectivity, and sustainability are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing an Automatic Cable Stripper (Quality and IP)

Sourcing an automatic cable stripper involves more than just selecting a machine based on price or speed. Overlooking critical quality and intellectual property (IP) factors can lead to long-term operational inefficiencies, legal risks, and increased costs. Below are key pitfalls to avoid:

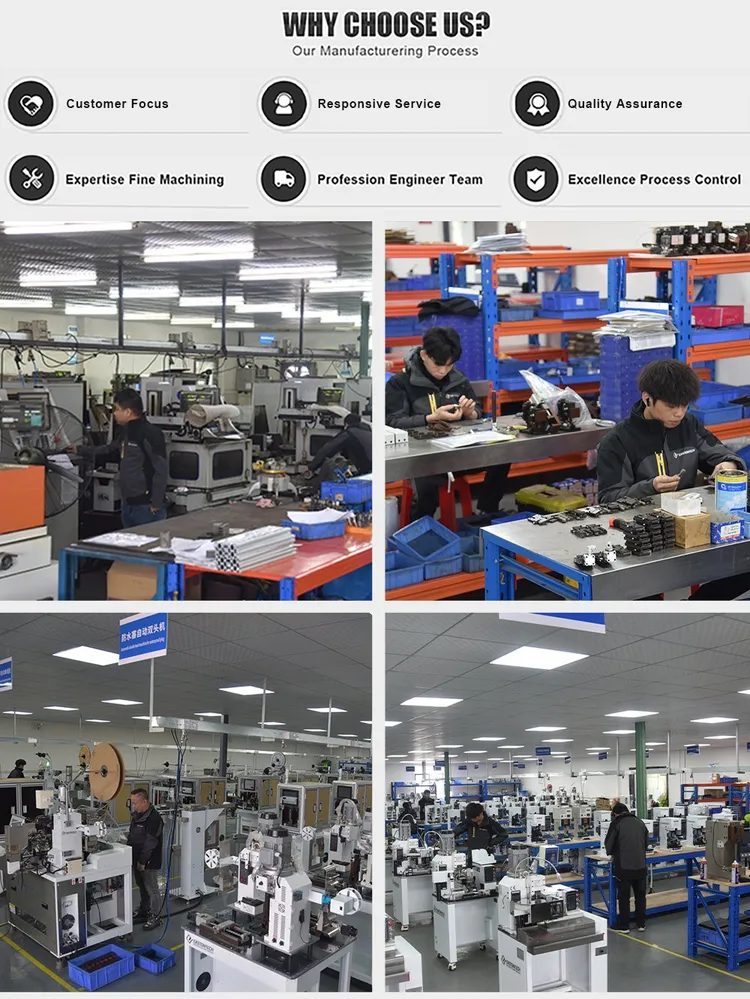

Poor Build Quality and Material Durability

Many low-cost automatic cable strippers use substandard materials and construction methods. This can result in frequent mechanical failures, inconsistent performance, and short service life. Machines made with inferior bearings, motors, or cutting components wear out quickly, especially under high-volume production conditions, leading to unplanned downtime and higher maintenance costs.

Inconsistent Stripping Precision

A common quality issue is poor calibration or lack of repeatability. Inconsistent stripping—such as nicked conductors, incomplete insulation removal, or variable strip lengths—can compromise downstream processes like crimping or termination. This not only affects product reliability but also increases scrap rates and labor for rework.

Lack of Safety and IP Protection (Electrical Enclosures)

When evaluating IP (Ingress Protection) ratings, ensure the machine meets required environmental standards (e.g., IP54 or higher for dust and splash resistance in industrial settings). Machines with inadequate IP ratings may fail prematurely in harsh environments, posing electrical hazards and increasing the risk of costly damage or safety incidents.

Absence of Genuine Components and Counterfeit Risks

Some suppliers use counterfeit or reverse-engineered components, especially in control systems or servo motors. These may appear identical but lack reliability, safety certifications, and technical support. Using such components can void warranties, compromise machine performance, and expose your operations to safety and compliance risks.

Ignoring Intellectual Property Rights

Sourcing machines that infringe on patented technologies—such as unique feeding mechanisms, blade designs, or software algorithms—can expose your company to legal liability. Always verify that the manufacturer holds valid IP rights or proper licensing. Purchasing counterfeit or cloned equipment may lead to lawsuits, import seizures, or forced equipment replacement.

Insufficient Documentation and Software Licensing

Low-quality suppliers often provide incomplete technical documentation, unlicensed software, or non-compliant firmware. This complicates integration, maintenance, and regulatory compliance. Ensure the machine comes with full, legally licensed software and accessible manuals, including safety certifications (e.g., CE, UL) and IP ratings documentation.

Overlooking After-Sales Support and Spare Parts Availability

Even high-quality machines can fail without proper support. Suppliers with weak global service networks may not provide timely technical assistance or genuine spare parts. This leads to extended downtime and forces users to resort to non-OEM (original equipment manufacturer) parts, which can degrade performance and void warranties.

Failure to Validate Real-World Performance

Relying solely on manufacturer claims without testing the machine under actual production conditions is risky. Conduct thorough trials with your specific cable types and volumes to assess true performance, durability, and IP compliance. A machine that works well in a showroom may falter in your facility due to environmental or operational differences.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, request references, inspect machines in person if possible, and confirm quality certifications and IP legitimacy before purchase.

Logistics & Compliance Guide for Automatic Cable Stripper

Product Classification & Documentation

Ensure accurate product classification under the appropriate Harmonized System (HS) code, typically within Chapter 84 (Nuclear reactors, boilers, machinery). Maintain comprehensive technical documentation, including user manuals, specifications, safety certifications, and CE/UL markings, for customs clearance and regulatory compliance.

Import/Export Regulations

Verify import/export requirements based on destination country. Some regions may require electrical equipment to meet specific safety or electromagnetic compatibility (EMC) standards. Confirm if export licenses are needed, especially if the device contains controlled components or dual-use technology.

Packaging & Shipping

Use robust, shock-resistant packaging to protect the cable stripper during transit. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include necessary shipping marks. Comply with international shipping standards such as ISTA for packaged-product testing.

Safety & Environmental Compliance

Ensure the device meets regional safety standards such as CE (Europe), UL (North America), or CCC (China). Adhere to RoHS (Restriction of Hazardous Substances) and REACH regulations regarding prohibited materials. Provide proper disposal guidance in line with WEEE (Waste Electrical and Electronic Equipment) directives.

Customs Clearance & Duties

Prepare commercial invoices, packing lists, and certificates of origin for smooth customs processing. Accurately declare the product’s value, country of origin, and intended use to avoid delays or penalties. Research applicable duty rates and potential trade agreements that may reduce tariffs.

After-Sales & Warranty Logistics

Establish a clear process for handling warranty claims, repairs, and spare parts distribution. Ensure compliance with local consumer protection laws regarding return policies and service support in each target market.

Conclusion for Sourcing an Automatic Cable Stripper:

Sourcing an automatic cable stripper is a strategic investment that enhances efficiency, accuracy, and productivity in wire processing operations. After evaluating various suppliers, models, and technical specifications, it is evident that selecting the right machine depends on specific production needs, cable types, volume requirements, and budget constraints. Automatic cable strippers offer significant advantages over manual methods, including reduced labor costs, minimized material waste, consistent stripping quality, and improved workplace safety.

It is recommended to prioritize machines with versatile adjustment settings, durable construction, user-friendly interfaces, and strong after-sales support. Additionally, choosing a supplier with a proven track record, comprehensive warranty, and readily available spare parts ensures long-term operational reliability. By implementing an appropriate automatic cable stripper, businesses can streamline their wire preparation processes, scale production capabilities, and maintain a competitive edge in the manufacturing or electrical industry.