The automotive lift industry is experiencing robust growth, driven by rising vehicle ownership, increasing after-sales service demand, and the expansion of professional repair facilities globally. According to Mordor Intelligence, the global automotive lift market was valued at approximately USD 1.4 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This growth is further supported by the rising adoption of advanced lifting solutions in EV service centers and automated repair shops. Among the various types of lifts, scissor lifts have gained significant traction due to their low profile, stability, and space efficiency—making them ideal for tire shops, alignment bays, and light to medium-duty maintenance. As demand surges, manufacturers are investing in innovative designs, enhanced load capacities, and smart safety features. In this competitive landscape, identifying the top auto scissor lift manufacturers becomes critical for dealers, service centers, and distributors seeking reliable, high-performance equipment. Based on market presence, technological innovation, global distribution, and customer reviews, here are the top 10 auto scissor lift manufacturers shaping the future of vehicle maintenance.

Top 10 Auto Scissor Lift Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

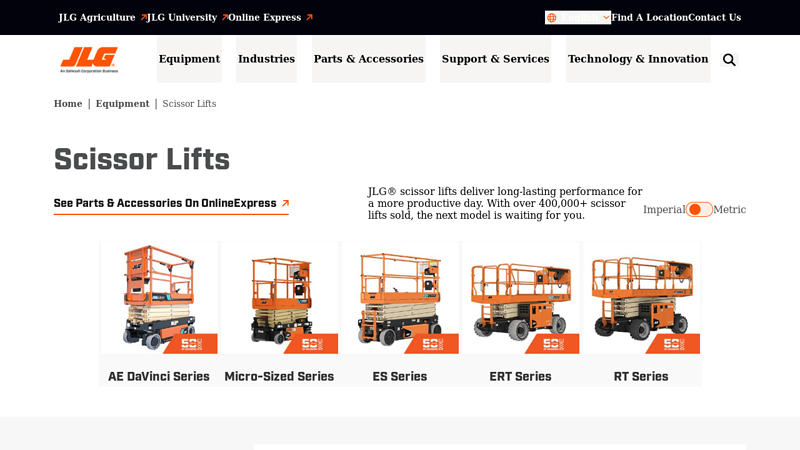

#1 Scissor Lifts

Domain Est. 1995

Website: jlg.com

Key Highlights: JLG® scissor lifts deliver long-lasting performance for a more productive day. With over 400,000+ scissor lifts sold, the next model is waiting for you….

#2 Alignment Scissor Lifts

Domain Est. 1995

Website: hunter.com

Key Highlights: MAXIMUM PRODUCTIVITY, MINIMUM SPACE. Hunter’s automotive scissor lift family offers four capacities and several wheelbase lengths to meet virtually any need….

#3

Domain Est. 1995

Website: genielift.com

Key Highlights: Genie® articulated boom lifts, telescopic boom lifts, scissor lifts and telehandler products are used in a wide range of industries around the world….

#4 BendPak

Domain Est. 1997

Website: bendpak.com

Key Highlights: Mid-Rise Scissor Lifts These portable mid-rise car lift models offer incredible power, versatility and a minimal footprint….

#5 Challenger Lifts

Domain Est. 1997

Website: challengerlifts.com

Key Highlights: Scissor Car Lifts Our scissor lifts are engineered for durability and performance, perfect for quick repair or limited floor plans. Available in 7,700 or 14, ……

#6 Stertil

Domain Est. 1997

Website: stertil-koni.com

Key Highlights: Stertil-Koni is the undisputed #1 leader in advanced, safe and dependable heavy duty vehicle lifting systems. From bus lifts to truck lifts, we do it all….

#7 Skyjack

Domain Est. 2000

Website: skyjack.com

Key Highlights: RT SCISSOR LIFTS · ARTICULATING BOOMS · TELEHANDLERS. en. fr. es. es-lt. pt-br. ELEVATE. en. fr. es. es-lt. pt-br. en-eu. fr-eu. de. en-au. ACCESSORYZERS™. en….

#8 Scissor Lifts For Cars

Domain Est. 2009

Website: rotarysolutions.com

Key Highlights: Rotary scissor car lifts are compact, lightweight and reliable for quick repairs in tight spaces, built with the highest quality materials. Browse models!…

#9 Atlas Automotive Equipment

Domain Est. 2009

Website: atlasautoequipment.com

Key Highlights: … Automotive Equipment 6MR. Atlas Automotive Equipment 6MR Portable Mid-Rise Scissor Lift 6000 lb. Capacity. $2,999.00. Add to Cart. Add to Wish List Add to ……

#10 Stratus Auto Equipment: Car Lifts

Domain Est. 2016

Expert Sourcing Insights for Auto Scissor Lift

2026 Market Trends for Auto Scissor Lifts

The automotive scissor lift market is poised for significant transformation by 2026, driven by evolving industry demands, technological advancements, and shifting regulatory landscapes. Here’s an analysis of key trends expected to shape the market:

Increased Demand from EV Service Infrastructure

As electric vehicle (EV) adoption accelerates globally, specialized service requirements are driving demand for scissor lifts capable of handling heavier EV chassis and battery systems. By 2026, lifts with higher weight capacities (8,000–12,000 lbs), extended height clearances, and integrated safety features for high-voltage components will become standard in EV service centers, creating a major growth vector for manufacturers.

Integration of Smart Technology and IoT

Auto scissor lifts are increasingly incorporating smart features such as remote diagnostics, predictive maintenance alerts, and real-time usage monitoring via IoT connectivity. By 2026, cloud-connected lifts will enable fleet managers and repair shops to optimize equipment utilization, reduce downtime, and improve technician safety—fueling demand for tech-enabled models from both independent garages and large dealership networks.

Emphasis on Workplace Safety and Ergonomics

Regulatory bodies like OSHA and EU directives continue tightening safety standards. In response, manufacturers are focusing on enhanced safety mechanisms—such as dual redundant hydraulic systems, automatic locking at multiple levels, and improved platform non-slip surfaces. By 2026, ergonomic design, including low-rise entry points and intuitive controls, will be a key differentiator in competitive markets.

Growth in Aftermarket and Mobile Service Segments

The rise of mobile mechanics and mobile detailing services is increasing demand for portable and low-profile scissor lifts. Compact, single-post and portable scissor lifts that are easy to transport and install will see robust growth, particularly in urban and emerging markets where space is limited and mobile services are expanding.

Sustainability and Energy Efficiency

With growing environmental regulations, manufacturers are shifting toward energy-efficient hydraulic systems and recyclable materials. By 2026, lifts with reduced hydraulic fluid usage, energy recovery systems, and lower carbon footprints will gain favor among eco-conscious businesses, especially in regions with stringent environmental policies like the EU and parts of North America.

Regional Market Expansion

While North America and Western Europe remain dominant markets, rapid growth in Asia-Pacific—particularly in China, India, and Southeast Asia—will be fueled by expanding automotive ownership and modernization of repair infrastructure. Localized manufacturing and cost-optimized lift models tailored to regional needs will be critical for market penetration by 2026.

In conclusion, the 2026 auto scissor lift market will be characterized by innovation, specialization, and digital integration. Companies that adapt to EV servicing demands, embrace smart technology, and prioritize safety and sustainability will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing Auto Scissor Lifts: Quality and Intellectual Property Concerns

Sourcing auto scissor lifts, especially from international suppliers, can present several challenges, particularly in the areas of quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps businesses make informed decisions and avoid costly mistakes.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

One of the most frequent issues when sourcing auto scissor lifts is encountering inconsistent build quality. Suppliers, especially those from regions with less stringent regulatory oversight, may cut corners on materials or assembly processes. This can result in lifts that fail prematurely or pose safety risks in automotive workshops.

Lack of Certification and Compliance

Many low-cost manufacturers may not adhere to international safety and performance standards such as CE, ISO, or ANSI/ALI ALCTV. Without proper certification, buyers risk purchasing equipment that does not meet local regulatory requirements, which can lead to legal liabilities and operational downtime.

Poor After-Sales Support and Spare Parts Availability

Low-quality suppliers often lack a robust support network. This means limited access to replacement parts, technical documentation, or trained service personnel. The absence of reliable after-sales support can significantly increase long-term maintenance costs and reduce equipment uptime.

Misleading Product Specifications

Some suppliers exaggerate lifting capacity, platform size, or durability in their marketing materials. Buyers may receive a product that does not perform as advertised, leading to inefficiencies or unsafe working conditions.

Intellectual Property (IP) Risks

Counterfeit or Copycat Designs

Auto scissor lifts from certain markets may replicate patented designs from reputable brands without authorization. Purchasing such equipment can inadvertently involve a buyer in IP infringement, especially if the lifts are imported into jurisdictions with strong IP enforcement.

Risk of Legal Liability

If a sourced scissor lift infringes on existing patents or trademarks, the buyer—not just the supplier—can face legal action, product seizures, or customs penalties. This is particularly relevant in regions like the EU or the U.S., where IP laws are strictly enforced.

Lack of Transparency in Supply Chain

Opaque supply chains make it difficult to verify whether a product is original or a clone. Buyers may lack the technical expertise or resources to conduct due diligence on design ownership, increasing exposure to IP-related risks.

No Warranty or Protection Against IP Claims

Many low-cost suppliers do not offer warranties that cover IP infringement. This leaves the buyer fully exposed if third parties assert patent or trademark rights against the equipment.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough due diligence on suppliers, including factory audits and reference checks.

– Request proof of compliance with international standards and certifications.

– Verify the originality of designs and, if possible, consult legal experts on IP clearances.

– Include IP indemnification clauses in procurement contracts.

– Work with reputable distributors or authorized dealers whenever possible.

By addressing quality and IP concerns proactively, businesses can ensure they source reliable, compliant, and legally safe auto scissor lifts.

Logistics & Compliance Guide for Auto Scissor Lift

Product Classification & Documentation

Ensure the auto scissor lift is classified correctly under the Harmonized System (HS) Code for accurate customs clearance. Typically, this falls under HS 8428.90 (other lifting appliances). Maintain complete documentation, including commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and product conformity certificates (e.g., CE, UL).

Regulatory Compliance Standards

Confirm that the auto scissor lift meets international safety and emissions standards. Required certifications may include CE marking (EU), UL/CSA (North America), EAC (Eurasian Union), and PSE (Japan). Verify compliance with ISO 3691-6 (safety requirements for operator-controlled self-propelled industrial trucks) and ANSI/SIA A92.6 (design of vehicle-mounted elevating and rotating work platforms).

Packaging & Handling Requirements

Package the scissor lift securely using weather-resistant materials and sturdy skids or crates. Include protective coverings for hydraulic components, control panels, and lifting surfaces. Clearly label each unit with handling instructions (e.g., “Fragile,” “Do Not Invert,” “Lift Here”) and orientation arrows to prevent damage during transport.

Transportation Mode & Load Securing

Select appropriate transport modes—containerized sea freight, flatbed truck, or air freight—based on size, weight, and delivery urgency. Secure the unit using straps, braces, and anti-slip mats to prevent movement. Follow the International Safe Container (CSC) plate guidelines if shipping in a container and ensure axle weight limits are observed for road transport.

Import/Export Licensing & Duties

Verify the need for export licenses based on destination country regulations. Some regions impose restrictions on dual-use machinery. Calculate and prepare for applicable import duties, VAT, and customs processing fees. Utilize trade agreements where possible to reduce tariff burdens (e.g., USMCA, RCEP).

On-Site Receiving & Inspection

Upon delivery, conduct a joint inspection with the carrier to document any transit damage. Verify the unit against the packing list and inspect for hydraulic leaks, electrical issues, or structural deformities. Retain all shipping documents and damage reports for insurance and warranty claims.

Environmental & Safety Compliance

Dispose of packaging materials in accordance with local environmental regulations. Confirm that the scissor lift meets noise and emission standards for the operating region (e.g., EU Stage V for diesel models). Ensure operator manuals include multilingual safety instructions and maintenance schedules.

After-Sales Support & Warranty Logistics

Establish clear logistics for spare parts distribution and technical service support. Provide customers with warranty registration information and track service history. Maintain a documented chain of custody for returns, repairs, and product recalls to ensure compliance with consumer protection laws.

Conclusion: Sourcing an Auto Scissor Lift

Sourcing an auto scissor lift requires careful consideration of several key factors including load capacity, lifting height, power source, durability, safety features, and compliance with industry standards. Whether for use in automotive repair shops, manufacturing facilities, or maintenance operations, selecting the right scissor lift enhances operational efficiency, improves workplace safety, and contributes to long-term cost savings.

It is essential to evaluate reputable suppliers who offer reliable after-sales support, warranty coverage, and access to spare parts. Additionally, considering both new and certified pre-owned options can provide cost-effective solutions without compromising performance. Customization options should also be explored to ensure the lift meets specific operational needs.

Ultimately, a well-informed sourcing decision—based on thorough research, site requirements, and total cost of ownership—will ensure the acquisition of a high-performing, safe, and durable auto scissor lift that supports productivity and worker safety for years to come.