The global automotive fasteners market is experiencing robust growth, driven by rising vehicle production, increasing demand for lightweight components, and advancements in manufacturing technologies. According to Grand View Research, the market was valued at USD 86.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. A key contributor to this trend is the rising adoption of plastic rivets in automotive assembly, which offer advantages such as corrosion resistance, vibration dampening, and reduced weight compared to traditional metal fasteners. Mordor Intelligence further projects that innovations in material science and the shift toward electric vehicles—where weight reduction directly impacts efficiency—will accelerate demand for specialized auto plastic rivets. As OEMs and tier suppliers prioritize cost-effective, efficient fastening solutions, a select group of manufacturers has emerged at the forefront of product innovation, quality, and global supply capability. This report identifies the top 8 auto plastic rivets manufacturers shaping the future of automotive assembly through technological leadership and strategic market positioning.

Top 8 Auto Plastic Rivets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Auveco

Domain Est. 1996

Website: auveco.com

Key Highlights: For over 100 years, Auto-Vehicle Parts LLC (Auveco) has been manufacturing and distributing specialty automotive and industrial fasteners. Our company goal ……

#2 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

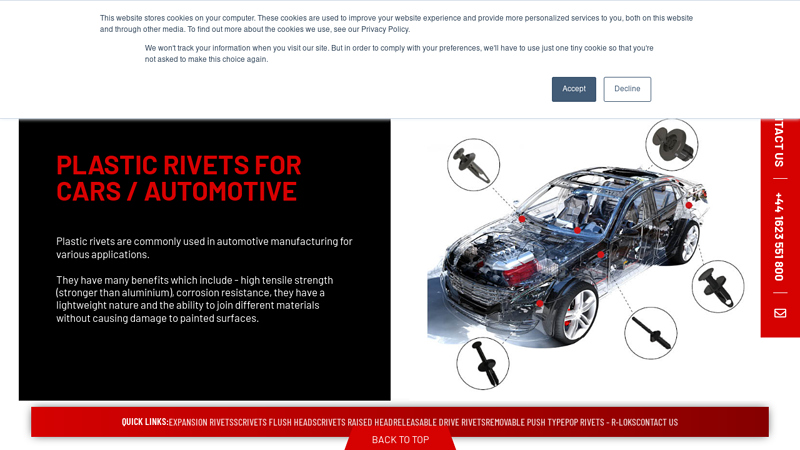

#3 Plastic Rivets for Cars / Automotive

Domain Est. 1996

Website: info.jetpress.com

Key Highlights: Discover durable plastic rivets for automotive use, ensuring secure fastening of trim, panels, and components in cars. Contact JET PRESS now!…

#4 Plastic rivets TY8P1 (241

Domain Est. 1998

Website: hellermanntyton.com

Key Highlights: These simple-to-use plastic rivets are ideal for improving productivity in the working environment, saving time and money over more conventional fixing methods ……

#5 Rivets, Clips, & Pins Archives

Domain Est. 1999

Website: itwautomotive.com

Key Highlights: Our range of rivets, clips, and pins offers flexible assembly solutions for various applications. With options available in both metal and plastic….

#6 Plastic rivets for every need

Domain Est. 2001

Website: emico.com

Key Highlights: Discover our extensive range of snap rivets, push rivets, drive fasteners, PineTreeClips, Snip & Snap and more – emico….

#7 Plastic Rivets

Domain Est. 2012

Website: essentracomponents.com

Key Highlights: The molded plastic material used to manufacture these rivets is highly durable, with wear resistance. These rivets are also resistant to moisture, solvents and ……

#8 W&E NUTS, BOLTS, RIVITS AND PLASTIC CLIPS

Domain Est. 2015

Expert Sourcing Insights for Auto Plastic Rivets

H2: 2026 Market Trends for Auto Plastic Rivets

The global market for auto plastic rivets is poised for significant evolution by 2026, driven by macro-industrial shifts, technological advancements, and changing automotive design philosophies. Key trends shaping this market include:

H2: Accelerated Demand from Lightweighting Initiatives

Automakers are under intense pressure to meet stricter global fuel efficiency and emissions regulations (e.g., Euro 7, CAFE standards). This continues to drive the substitution of metal components with lighter alternatives. Plastic rivets, made from engineering thermoplastics like nylon (PA6, PA66), POM (acetal), and PBT, offer substantial weight savings compared to traditional metal fasteners. Their use in non-structural interior and exterior trim, under-the-hood components, and increasingly in semi-structural body applications is expected to grow significantly by 2026, contributing directly to vehicle lightweighting goals.

H2: Integration with Electric Vehicle (EV) Manufacturing

The rapid proliferation of electric vehicles is a major catalyst. EVs have unique design requirements: higher battery weight necessitates greater overall lightweighting elsewhere, and battery packs, motors, and power electronics often require specialized, non-conductive, and corrosion-resistant fastening solutions. Plastic rivets provide excellent electrical insulation and resistance to battery electrolytes and coolants. Their use in securing battery enclosures, cable harnesses, motor components, and EV-specific interior trims is projected to surge, making EV production a primary growth engine for the auto plastic rivet market by 2026.

H2: Advancements in Material Science and Performance

To meet the demands of more critical applications (higher temperatures, greater loads, chemical exposure), material innovation is accelerating. By 2026, expect wider adoption of:

* High-Performance Polymers: Increased use of PPS, PEEK, and LCP for under-the-hood and near-motor applications requiring superior heat resistance (>200°C).

* Reinforced Plastics: Glass-fiber or mineral-filled grades offering enhanced strength, stiffness, and dimensional stability.

* Self-Lubricating & Wear-Resistant Formulations: Reducing noise, vibration, and harshness (NVH) and extending component life.

* Recycled & Bio-based Content: Growing focus on sustainability will drive R&D and adoption of rivets incorporating recycled plastics or bio-sourced polymers, aligning with OEMs’ circular economy goals.

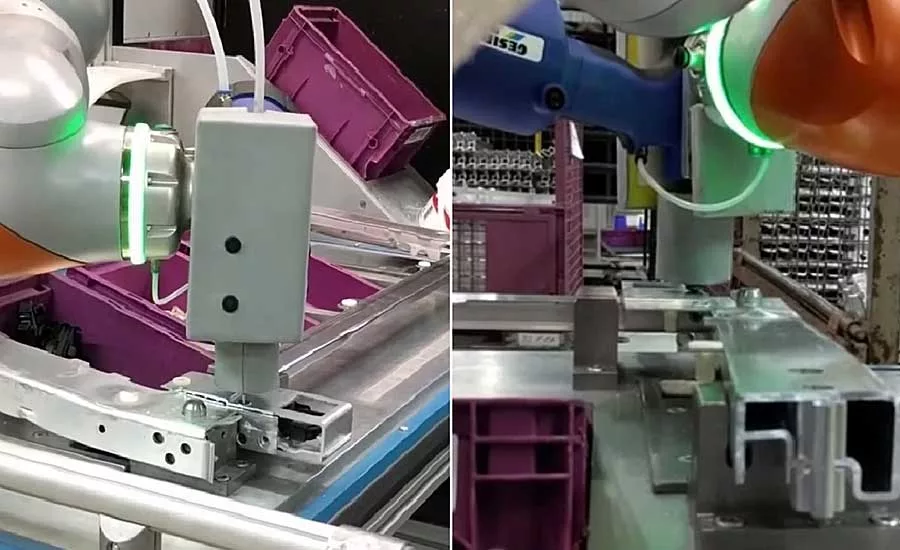

H2: Automation and High-Speed Assembly Demands

Automotive manufacturing lines are becoming faster and more automated. Plastic rivets are inherently well-suited for robotic assembly due to their consistency, ease of feeding, and compatibility with automated insertion tools (pneumatic, electric). The trend towards modular assembly and just-in-time (JIT) manufacturing will further boost demand for reliable, high-speed plastic riveting solutions. Suppliers will focus on developing rivets and installation systems optimized for seamless integration into automated production cells by 2026.

H2: Growing Emphasis on Sustainability and End-of-Life Management

Environmental regulations (e.g., ELV Directive) and consumer pressure are pushing the industry towards more sustainable practices. Key trends include:

* Design for Disassembly: Rivets facilitating easier separation of dissimilar materials (plastic/metal) during vehicle recycling.

* Material Traceability & Recyclability: Increased demand for rivets made from mono-materials or easily separable polymers to enhance recyclability of end-of-life vehicles.

* Reduced Process Waste: Advancements in rivet design and installation minimizing scrap and energy consumption during assembly.

H2: Regional Market Shifts and Supply Chain Resilience

While Asia-Pacific (led by China) remains the largest market due to high vehicle production volumes, growth is expected to be robust in North America and Europe, driven by strong EV adoption and stringent regulations. The push for supply chain resilience (“nearshoring” or “friendshoring”) post-pandemic and geopolitical tensions will likely lead to increased regionalization of plastic rivet manufacturing and supplier partnerships closer to major automotive assembly hubs by 2026.

In conclusion, the 2026 auto plastic rivet market will be characterized by growth fueled by lightweighting and EVs, underpinned by significant advancements in materials and manufacturing processes, and increasingly shaped by sustainability imperatives and evolving global supply chain dynamics.

Common Pitfalls When Sourcing Auto Plastic Rivets: Quality and Intellectual Property Concerns

Sourcing auto plastic rivets for automotive manufacturing or aftermarket applications involves several potential pitfalls, particularly regarding quality consistency and intellectual property (IP) risks. Being aware of these issues can help procurement teams and engineers make informed decisions and avoid costly setbacks.

1. Inconsistent Material Quality

One of the most frequent issues is variability in the quality of raw plastic materials. Low-cost suppliers may use recycled or substandard polymers that compromise the rivet’s durability, heat resistance, and mechanical strength. This can lead to part failure under stress, vibration, or extreme temperatures—critical concerns in automotive environments.

2. Lack of Certification and Compliance

Many suppliers fail to provide proper certifications such as ISO/TS 16949, IATF 16949, or UL approval. Without these, there is no guarantee that the rivets meet automotive industry standards for safety, performance, and traceability. Non-compliance can result in supply chain disruptions or liability in case of product failure.

3. Poor Dimensional Accuracy and Tolerances

Inaccurate dimensions or inconsistent tolerances can prevent proper installation or lead to weak joints. This is often due to outdated tooling or insufficient quality control processes at the supplier’s facility. Even minor deviations can affect assembly line efficiency and final product reliability.

4. Inadequate Testing and Validation Data

Reliable suppliers should provide comprehensive test data (e.g., pull-out strength, shear strength, temperature resistance). However, some vendors offer limited or falsified test results. Relying on unverified data increases the risk of field failures and recalls.

5. Intellectual Property (IP) Infringement

A significant but often overlooked risk is sourcing rivets that mimic patented designs. Some manufacturers replicate original equipment manufacturer (OEM) rivet designs without licensing, exposing buyers to legal liability. Using counterfeit or IP-infringing parts can result in lawsuits, customs seizures, or reputational damage.

6. Limited Traceability and Documentation

Lack of batch traceability and material data sheets (MDS) or certificates of conformance (CoC) complicates quality investigations and compliance audits. This is especially problematic during root cause analysis of field failures or during regulatory inspections.

7. Supplier Transparency and Communication Gaps

Poor communication, unresponsiveness, or reluctance to share technical details often signal unreliable suppliers. Transparent collaboration is essential for resolving quality issues and ensuring long-term supply stability.

Mitigation Strategies

- Conduct thorough supplier audits and request samples for independent testing.

- Verify compliance with automotive standards and request full documentation.

- Work with legal counsel to assess IP risks when sourcing non-OEM parts.

- Prioritize suppliers with robust quality management systems and traceability protocols.

Avoiding these pitfalls ensures the reliability of auto plastic rivets and protects both product integrity and brand reputation.

Logistics & Compliance Guide for Auto Plastic Rivets

Product Overview

Auto plastic rivets are lightweight, corrosion-resistant fasteners used in automotive assembly for securing interior trims, panels, wiring harnesses, and non-structural components. Typically made from polyamide (nylon), polyethylene, or polypropylene, these rivets offer ease of installation, vibration resistance, and electrical insulation.

Packaging & Labeling Requirements

- Packaging: Rivets must be packed in moisture-resistant, anti-static bags or sealed containers to prevent contamination and static damage. Bulk packaging should use sturdy corrugated boxes with internal dividers to avoid part shifting.

- Labeling: Each package must display:

- Part number and description

- Quantity per package

- Batch/lot number

- Date of manufacture

- Manufacturer name and address

- RoHS and REACH compliance symbols (where applicable)

- Handling symbols (e.g., “Fragile,” “Keep Dry”)

Storage Conditions

- Store in a dry, climate-controlled environment with temperatures between 10°C and 30°C.

- Avoid direct sunlight and high humidity to prevent material degradation.

- Keep away from solvents, oils, and strong oxidizing agents.

- Use first-in, first-out (FIFO) inventory rotation to minimize aging risks.

Transportation Guidelines

- Use enclosed, clean vehicles for transport to prevent exposure to dust, moisture, and extreme temperatures.

- Secure packages to prevent movement during transit; stack no higher than recommended.

- For international shipments, comply with IATA/IMDG regulations if classified as non-hazardous general cargo.

- Provide temperature monitoring logs for sensitive consignments.

Regulatory Compliance

- REACH (EU): Confirm absence of Substances of Very High Concern (SVHC) in rivet materials. Supplier declarations must be available.

- RoHS (EU): Ensure compliance with restrictions on lead, cadmium, mercury, and certain phthalates.

- IMDS (International Material Data System): Submit accurate material data sheets for automotive OEM traceability.

- UL/SAE Standards: Meet flammability and mechanical performance standards (e.g., UL 94 V-0/V-2, SAE J844) when required.

- Country-Specific Regulations: Adhere to local chemical and product safety laws (e.g., TSCA in the U.S., K-REACH in South Korea).

Import/Export Documentation

- Commercial Invoice

- Packing List

- Certificate of Origin

- Material Compliance Certificates (RoHS, REACH)

- IMDS Submission Confirmation

- Bill of Lading or Air Waybill

- Export Control Classification Number (ECCN), if applicable (usually EAR99 for plastic rivets)

Quality Assurance & Traceability

- Implement lot traceability from raw material to finished product.

- Conduct periodic audits for dimensional accuracy, insertion/removal force, and environmental resistance.

- Maintain records of compliance testing (e.g., tensile strength, temperature cycling) for minimum 5 years.

Handling & Worker Safety

- Provide gloves and eye protection when handling large volumes to prevent skin irritation or minor injuries.

- Ensure adequate ventilation in storage and processing areas.

- Follow SDS (Safety Data Sheet) guidelines if solvents or adhesives are used during installation.

Sustainability & End-of-Life

- Promote recyclability: Use mono-material designs where possible.

- Provide disposal guidance: Non-hazardous waste streams for non-contaminated plastic rivets.

- Support circular economy initiatives through take-back programs or recycling partnerships.

Supplier & OEM Coordination

- Align logistics schedules with just-in-time (JIT) or sequenced delivery requirements.

- Use EDI (Electronic Data Interchange) for order, shipment, and inventory updates.

- Conduct annual compliance reviews with suppliers to ensure ongoing regulatory adherence.

This guide ensures safe, compliant, and efficient handling of auto plastic rivets across the supply chain, supporting automotive manufacturing standards and environmental responsibility.

In conclusion, sourcing auto plastic rivets requires a strategic approach that balances quality, cost, reliability, and compliance with automotive industry standards. Identifying suppliers with proven expertise in automotive components, consistent manufacturing processes, and certifications such as IATF 16949 ensures the rivets meet required durability and safety specifications. Conducting thorough evaluations—considering material compatibility, resistance to environmental factors, production scalability, and lead times—is essential for seamless integration into assembly processes. Additionally, building strong supplier relationships and considering localization or dual sourcing can mitigate supply chain risks. Ultimately, a well-executed sourcing strategy for auto plastic rivets contributes to improved manufacturing efficiency, reduced maintenance costs, and enhanced vehicle performance and safety.