The global automotive refinish coatings market, which directly drives demand for high-quality auto paint booth equipment, was valued at USD 11.6 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2030, according to Grand View Research. This expansion is fueled by rising vehicle production, increasing demand for refurbished vehicles, and stricter environmental regulations spurring innovation in paint application systems. As a critical component in achieving precise, contaminant-free finishes, auto paint booths have become essential infrastructure in OEM and aftermarket body shops worldwide. With North America and Europe leading in adoption due to stringent VOC emission standards, and Asia-Pacific witnessing rapid growth driven by industrialization and expanding automotive sectors, the market for reliable paint booth manufacturers is more competitive than ever. Based on production capacity, technological innovation, global footprint, and compliance with safety and environmental standards, the following ten manufacturers have emerged as leaders shaping the future of automotive painting environments.

Top 10 Auto Paint Stand Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About GSB Industries, Automotive & Industrial Spray Booth Supplier

Domain Est. 2012

Website: gsbindustries.com

Key Highlights: A paint booth distribution company that installs, maintains and refurbishes paint booths and other products in the automotive and industrial equipment space.Missing: stand manufac…

#2 Industrial Painting Equipment

Domain Est. 2013

Website: bzbspraybooth.com

Key Highlights: 25+ Years Spray Painting Paint Booth & Finishing System. Specialize in the Engineering, Manufacture of Various Car Spray Booth, Bus Spray Bus, etc….

#3 Graco Inc.

Domain Est. 1994

Website: graco.com

Key Highlights: Graco is one of the world’s leading suppliers of fluid management products and packages. We manufacture equipment to move, measure, mix, control, ……

#4 Paint Booth, Industrial Spray Booths Installation

Domain Est. 2000

Website: paintbooth.com

Key Highlights: High-quality paint booth for auto, booths for truck & industrial finishing or powder coating – System Design sales service & installation….

#5 Paint Booths & Industrial Spray Application Systems

Domain Est. 2002

#6 Accudraft Paint Booths

Domain Est. 2003

Website: accudraftpaintbooths.com

Key Highlights: Accudraft Paint Booths is a leading paint booth manufacturer of paint booths, spray booths, prep stations, and finishing systems. Outfit your shop today!…

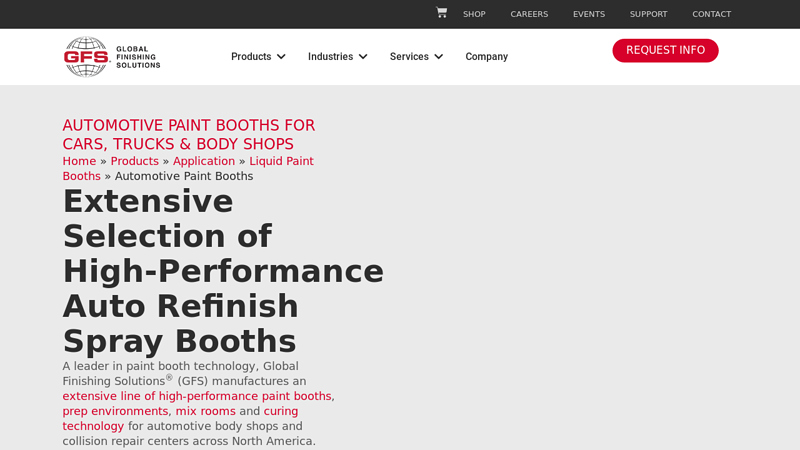

#7 Automotive Paint Booths

Domain Est. 2003

Website: globalfinishing.com

Key Highlights: A leader in paint booth technology, Global Finishing Solutions® (GFS) manufactures an extensive line of high-performance paint booths, prep environments, ……

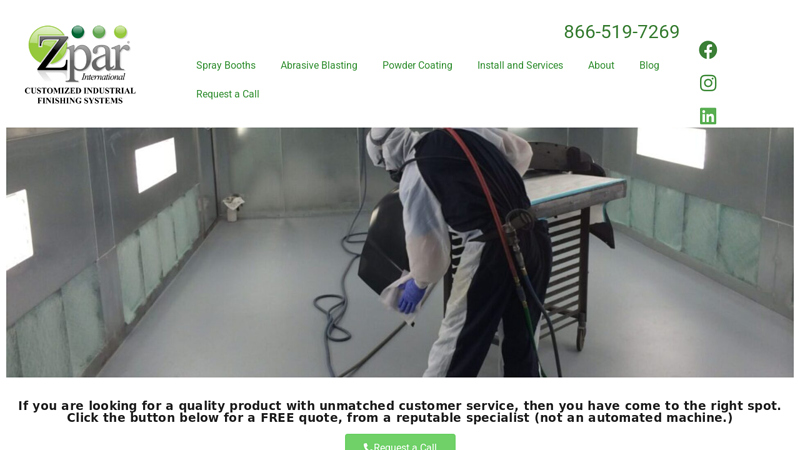

#8 Paint Booths, Spray Booths, Finishing Systems

Domain Est. 2011

Website: zparint.com

Key Highlights: We are an automated paint booth supplier located in the USA. We design and manufacture sturdy and durable work booths for various industrial-based businesses….

#9 Spray Booths And Finishing Solutions

Domain Est. 2016

Website: rttsolutions.com

Key Highlights: RTT Finishing Solutions provides the highest quality industrial and automotive paint booths in the industry. Our finishing equipment and systems include paint ……

#10 Mobile Environmental Solutions

Domain Est. 2013

Website: mobileenvironmentalsolutions.com

Key Highlights: Mobile Environmental Solutions is the leading provider of Mobile Paint booths manufactured in the US. Our design is now patented across the World….

Expert Sourcing Insights for Auto Paint Stand

2026 Market Trends for Auto Paint Stand

The global auto paint stand market is poised for significant transformation by 2026, driven by advancements in automotive manufacturing, increased demand for aftermarket customization, and a shift toward sustainable and efficient painting solutions. This analysis explores key trends expected to shape the industry in the coming years.

Rising Demand in Automotive Aftermarket

The automotive aftermarket sector is experiencing robust growth, particularly in regions such as North America, Europe, and Asia-Pacific. Car owners are increasingly investing in aesthetic enhancements, including custom paint jobs, which drives demand for high-quality, adjustable, and durable auto paint stands. These stands are essential for achieving even, professional-grade finishes during vehicle refinishing, especially in collision repair shops and detailing centers.

Technological Advancements and Automation

By 2026, manufacturers are expected to integrate smart technologies into auto paint stands, including motorized height adjustment, load sensors, and compatibility with digital workshop management systems. These innovations improve precision, worker safety, and operational efficiency. Additionally, modular designs that support quick assembly and disassembly will appeal to small and mid-sized repair shops seeking space-saving solutions.

Growth in Electric Vehicle (EV) Production

The surge in electric vehicle manufacturing is influencing repair and maintenance infrastructure. EVs often require specialized handling due to their battery placement and lightweight materials. Auto paint stands designed to accommodate the unique chassis and weight distribution of EVs will see growing demand. Manufacturers are likely to develop EV-specific models with enhanced stability and non-conductive components to ensure safety during painting.

Emphasis on Ergonomics and Worker Safety

Workplace safety regulations are becoming stricter globally, prompting shops to adopt ergonomic equipment. Auto paint stands with adjustable height, anti-slip platforms, and weight-distribution features will be in higher demand to reduce strain on technicians and minimize injury risks. By 2026, compliance with OSHA (U.S.) and similar international standards will be a key selling point for premium paint stand models.

Sustainability and Eco-Friendly Materials

Environmental concerns are pushing manufacturers to use recyclable and non-toxic materials in the construction of paint stands. Powder-coated steel and aluminum frames resistant to paint solvents and corrosion are becoming standard. Furthermore, companies promoting sustainable manufacturing practices and low-carbon supply chains will gain a competitive edge in environmentally conscious markets.

Expansion in Emerging Markets

Countries in Southeast Asia, Latin America, and Africa are witnessing increased vehicle ownership and growth in automotive service infrastructure. This expansion creates new opportunities for auto paint stand suppliers. Localized manufacturing and distribution partnerships will be critical for companies aiming to capture market share in these regions by offering cost-effective and region-specific designs.

E-Commerce and Direct-to-Consumer Sales

The digitalization of B2B and B2C markets is enabling easier access to auto paint stands through e-commerce platforms. By 2026, online marketplaces such as Amazon, Alibaba, and specialized automotive equipment sites will dominate distribution channels. Enhanced product visualization, customer reviews, and fast shipping options will influence purchasing decisions, especially among independent mechanics and hobbyists.

Consolidation and Brand Differentiation

The market is expected to see consolidation as larger industrial equipment companies acquire niche paint stand manufacturers. However, innovation and brand reputation will remain vital for differentiation. Brands that offer warranties, technical support, and modular accessories (e.g., wheel cradles, turntables) will strengthen customer loyalty and market positioning.

In conclusion, the 2026 auto paint stand market will be shaped by technological innovation, sustainability, and evolving automotive industry needs. Companies that anticipate these trends and adapt their product offerings accordingly will be well-positioned for growth in a competitive and dynamic landscape.

Common Pitfalls When Sourcing Auto Paint Stands (Quality and Intellectual Property)

Sourcing auto paint stands—especially from overseas suppliers—can present significant challenges related to both product quality and intellectual property (IP) risks. Being aware of these common pitfalls helps mitigate potential issues that could affect performance, safety, and legal compliance.

Poor Build Quality and Material Standards

One of the most frequent issues is receiving auto paint stands made with substandard materials or poor craftsmanship. Low-cost suppliers may use thin-gauge steel, inadequate welding, or inferior finishes that compromise structural integrity. This can lead to instability during vehicle lifting, posing serious safety hazards in body shops. Additionally, rust-prone materials or lack of proper corrosion protection reduce the lifespan of the equipment.

Lack of Load Capacity Verification

Many sourced paint stands advertise high load ratings without third-party testing or certifications. Buyers may assume the stands can safely support heavy vehicle components, only to discover later that the actual capacity falls short. This discrepancy increases liability risks and can result in equipment failure during use.

Inconsistent Dimensional Accuracy

Auto paint stands must fit precisely with vehicle chassis and lifting equipment. Sourced products often suffer from inconsistent fabrication, leading to misaligned mounting points or incorrect height/width dimensions. This forces body shops to modify stands or face inefficiencies during vehicle setup, increasing labor costs and downtime.

Missing Safety Features

Reputable auto paint stands include safety mechanisms such as locking pins, non-slip pads, and secure connection points. However, low-cost alternatives may omit these features to cut production costs. The absence of such safeguards increases the risk of vehicle slippage or collapse, endangering personnel and property.

Non-Compliance with Regional Safety Standards

Auto repair equipment must often comply with regional regulations (e.g., OSHA in the U.S., CE in Europe). Sourced paint stands may not meet these requirements, particularly if manufactured without oversight. Importing non-compliant equipment can result in fines, work stoppages, or voided insurance coverage.

Intellectual Property Infringement

Some suppliers replicate patented designs from well-known manufacturers without authorization. Purchasing such counterfeit or imitation products exposes buyers to legal risk, including potential liability for IP infringement. Customs authorities may seize shipments, and using infringing equipment can damage a shop’s reputation.

Limited or No Technical Support and Documentation

Many low-cost suppliers fail to provide comprehensive assembly instructions, load charts, or maintenance guidelines. This lack of documentation complicates installation and safe usage. Furthermore, limited after-sales support makes it difficult to resolve issues or obtain replacement parts.

Hidden Costs from Re-Work and Returns

Initially low purchase prices can be misleading. Hidden costs arise when stands require modification, fail prematurely, or must be replaced due to safety concerns. Shipping, customs, and handling expenses for returns or replacements further erode cost savings.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Request samples and conduct on-site or third-party quality inspections.

– Verify material specifications and load testing certifications.

– Confirm compliance with relevant safety standards (e.g., ANSI, CE).

– Conduct IP due diligence by checking patent databases and supplier reputations.

– Work with reputable suppliers who provide full documentation and support.

By proactively addressing quality and IP concerns, businesses can source reliable, safe, and legally compliant auto paint stands that deliver long-term value.

Logistics & Compliance Guide for Auto Paint Booths

Overview

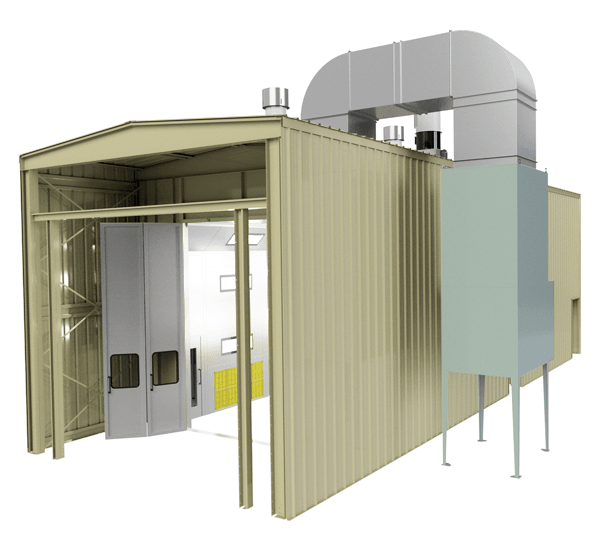

Auto paint booths are specialized enclosures used in automotive refinishing to control environmental conditions during painting operations. Proper logistics planning and regulatory compliance are essential for safe installation, operation, and maintenance. This guide outlines key considerations for transporting, installing, and legally operating an auto paint booth.

Transportation & Handling

- Pre-Shipment Preparation: Ensure the paint booth is disassembled (if modular) or secured (if pre-assembled) according to manufacturer specifications. Protect sensitive components such as filters, ductwork, and control panels.

- Vehicle Requirements: Use flatbed trucks or enclosed trailers capable of handling the booth’s dimensions and weight. Confirm local road regulations for oversized loads if applicable.

- Handling Equipment: Utilize forklifts, cranes, or telehandlers with proper lifting points to avoid structural damage during offloading.

- Site Access: Verify clear pathways, door clearances, and floor load capacity at the destination facility before delivery.

Installation & Site Requirements

- Foundation & Flooring: Install on a level, non-combustible surface (e.g., concrete) with adequate drainage for solvent runoff. Confirm structural integrity for booth weight and equipment.

- Ventilation & Exhaust: Connect to properly sized ducting that routes emissions outdoors in compliance with local air quality regulations. Include fire dampers and spark arrestors where required.

- Electrical Connections: Use licensed electricians to connect to a dedicated power supply meeting booth specifications (voltage, phase, amperage). Ground all components to prevent static discharge.

- Fire Suppression: Install approved fire suppression systems (e.g., automatic sprinklers or chemical suppression) integrated with smoke/heat detectors.

Environmental Compliance

- Air Quality Regulations: Adhere to EPA and state/local air pollution control rules (e.g., NESHAP, RACT). Use high-efficiency particulate air (HEPA) and carbon filtration to capture VOCs and overspray.

- Permitting: Obtain necessary permits for air emissions, hazardous materials usage, and fire safety. Submit engineering plans if required.

- Emissions Monitoring: Maintain records of filter changes, airflow testing, and emission reports. Conduct regular stack testing if mandated.

Safety & Operational Compliance

- OSHA Standards: Comply with OSHA 29 CFR 1910.94 (Ventilation) and 1910.107 (Spray Finishing). Provide explosion-proof lighting and electrical fixtures in classified areas.

- Hazard Communication: Maintain Safety Data Sheets (SDS) for all paints and solvents. Label containers and train staff on chemical handling.

- Personal Protective Equipment (PPE): Require respirators, fire-resistant clothing, gloves, and eye protection for personnel.

Maintenance & Inspections

- Scheduled Maintenance: Follow manufacturer guidelines for cleaning filters, inspecting fans, and checking ignition sources. Document all service activities.

- Compliance Audits: Conduct internal or third-party audits annually to ensure adherence to fire codes, environmental rules, and workplace safety standards.

- Filter Disposal: Dispose of spent filters and contaminated materials as hazardous waste through licensed vendors. Keep disposal manifests for recordkeeping.

Documentation & Recordkeeping

- Retain copies of permits, installation certifications, training logs, maintenance records, and emission test results for a minimum of 5 years (or as required by jurisdiction).

- Update compliance documentation promptly following equipment modifications or regulatory changes.

Conclusion

Successfully managing the logistics and compliance of an auto paint booth requires coordination across transportation, installation, environmental, and safety domains. Proactive planning, adherence to regulations, and diligent documentation ensure safe, legal, and efficient operations in any automotive refinishing environment.

Conclusion: Sourcing an Auto Paint Stand

Sourcing the right auto paint stand is a critical decision that directly impacts the efficiency, safety, and quality of automotive painting operations. After evaluating various suppliers, materials, designs, and pricing models, it is evident that selecting a durable, adjustable, and ergonomically designed stand enhances workplace productivity and ensures a consistent, high-quality finish. Key factors such as load capacity, compatibility with different vehicle types, corrosion resistance, and ease of assembly should guide the procurement process. Additionally, choosing a supplier that offers reliability, warranty support, and strong customer service adds long-term value. By investing in a high-quality auto paint stand from a reputable source, businesses can improve workflow, reduce downtime, and maintain professional standards in refinishing operations. Ultimately, the right sourcing decision supports both operational excellence and cost-effectiveness in the automotive repair and customization industry.