The global automotive clutch market is experiencing steady growth, driven by rising vehicle production, increasing demand for commercial vehicles, and advancements in transmission technologies. According to Grand View Research, the global automotive clutch market was valued at USD 9.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by expanding automotive manufacturing, particularly in Asia-Pacific, as well as the growing adoption of high-performance and durable clutch systems in both passenger and commercial vehicles. With the increasing need for reliable transmission components, the demand for premium auto clutch replacement parts has surged, leading to heightened competition among manufacturers. In this evolving landscape, a select group of companies are emerging as leaders, combining innovation, global reach, and rigorous quality standards to meet the demands of OEMs and aftermarket consumers alike. Here are the top 5 auto clutch replacement manufacturers shaping the industry today.

Top 5 Auto Clutch Replacement Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FCC North America

Domain Est. 2008

Website: fcc-na.com

Key Highlights: FCC is a top clutch manufacturer in North America, delivering innovative automotive and motorcycle transmission components built for performance, ……

#2 Tilton Engineering

Domain Est. 1997

Website: tiltonracing.com

Key Highlights: Tilton’s wide range of products spans across metallic, cerametallic and carbon/carbon racing clutches, hydraulic release bearings, racing clutch disc packs, ……

#3 EXEDY Globalparts Corporation

Domain Est. 2002

Website: exedyusa.com

Key Highlights: EXEDY is not only a leader in providing high-quality clutches but we also manufacture various other vehicle parts….

#4

Domain Est. 2004

Website: setcoauto.com

Key Highlights: At Setco Automotive, we specialize in delivering premium clutches, durable flywheels, and high-performance lubricants designed for commercial vehicles like ……

#5 LuK by Schaeffler

Domain Est. 2006

Website: vehiclelifetimesolutions.schaeffler.us

Key Highlights: We carry a comprehensive product portfolio of complete clutch sets, pressure plates, discs, slave and master cylinders and release bearings….

Expert Sourcing Insights for Auto Clutch Replacement

2026 Market Trends for Auto Clutch Replacement

Market Growth and Demand Drivers

The global auto clutch replacement market is projected to experience steady growth by 2026, driven by several key factors. Increasing vehicle ownership in emerging economies, particularly in Asia-Pacific and Latin America, is expanding the base of vehicles requiring routine maintenance and part replacements. Additionally, the rising average age of vehicles on the road—especially in mature markets like North America and Western Europe—means a higher number of cars are reaching the typical clutch replacement threshold (usually between 50,000 and 100,000 miles). This aging fleet trend supports consistent demand for aftermarket clutch components.

Shift Toward High-Performance and Durable Clutch Systems

By 2026, there is a noticeable shift in consumer preference toward higher-performance and longer-lasting clutch solutions. Advances in materials science have led to the development of organic, ceramic, and dual-mass flywheel (DMF) clutches that offer improved heat resistance, smoother engagement, and extended service life. Aftermarket brands are increasingly offering premium-grade replacement kits that mimic original equipment (OE) performance, appealing to vehicle owners looking to reduce long-term maintenance costs.

Impact of Transmission Technology Evolution

While the rise of electric vehicles (EVs), which do not require traditional clutches, poses a long-term challenge, the majority of the global vehicle fleet in 2026 will still consist of internal combustion engine (ICE) and hybrid vehicles with manual or automated manual transmissions (AMT). In particular, commercial vehicles and performance cars continue to rely heavily on manual transmissions, sustaining demand for clutch replacements. Moreover, the growing popularity of AMTs in budget-friendly and commercial vehicles introduces new replacement dynamics, as these systems often integrate clutch components that wear faster under frequent stop-start conditions.

Aftermarket Expansion and Digital Distribution Channels

The auto clutch replacement market is seeing a surge in e-commerce and digital distribution platforms. By 2026, online marketplaces and specialized automotive parts retailers are playing a dominant role in the aftermarket supply chain. Consumers are increasingly purchasing clutch kits online, supported by detailed compatibility tools, customer reviews, and direct-to-door delivery. This shift is pressuring traditional brick-and-mortar stores to adopt omnichannel strategies while enabling smaller manufacturers to reach broader markets.

Regional Market Dynamics

Regional trends vary significantly. In Asia-Pacific, rapid urbanization and a booming used car market are fueling demand for affordable replacement parts, including clutches. India and Southeast Asia are emerging as key manufacturing and consumption hubs. In contrast, North America and Europe are seeing growth driven by do-it-yourself (DIY) mechanics and certified repair shops that prioritize OE-equivalent quality. Regulatory standards in Europe are also pushing for quieter, more efficient clutch systems, influencing product design and replacement cycles.

Sustainability and Remanufactured Components

Sustainability concerns are beginning to influence the clutch replacement sector. By 2026, remanufactured and recycled clutch assemblies are gaining traction as cost-effective and environmentally friendly alternatives. Companies are investing in reverse logistics and refurbishment technologies to extend the lifecycle of clutch components, reducing waste and appealing to eco-conscious consumers and fleet operators.

Conclusion

The 2026 auto clutch replacement market is characterized by resilient demand driven by an aging vehicle fleet, technological improvements in clutch materials, and the expansion of digital sales channels. While electrification presents a future challenge, the continued prevalence of manual and semi-automatic transmissions ensures that clutch replacement remains a vital segment of the automotive aftermarket. Strategic focus on durability, performance, and sustainability will define market leadership in the coming years.

Common Pitfalls When Sourcing Auto Clutch Replacement (Quality, IP)

Sourcing auto clutch replacements, particularly for original equipment manufacturer (OEM) or high-performance applications, involves navigating several critical challenges. Two of the most significant areas of concern are product quality and intellectual property (IP) risks. Failing to address these can lead to reliability issues, legal exposure, and brand damage. Below are common pitfalls in these areas:

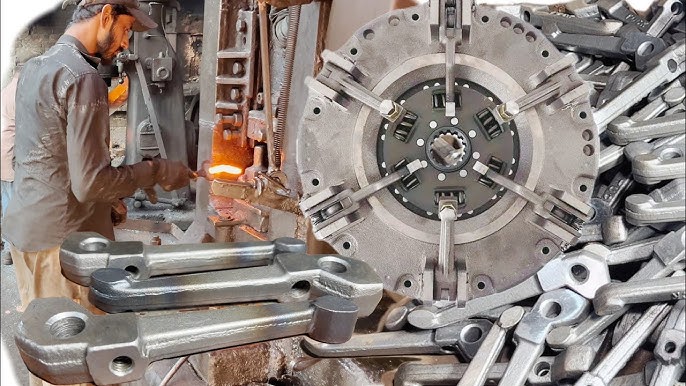

Compromised Product Quality

One of the biggest risks when sourcing auto clutch replacements is receiving substandard components that fail prematurely or under load.

- Inconsistent Material Composition: Many low-cost suppliers use inferior friction materials or heat-treated metals that degrade faster, leading to slippage, overheating, or catastrophic failure.

- Lack of Certification and Testing: Reputable clutches undergo rigorous testing (e.g., SAE J1557), but some suppliers skip these steps. Without proper certifications (ISO/TS 16949, etc.), there’s no assurance of performance or durability.

- Poor Manufacturing Tolerances: Inaccurate machining or assembly leads to imbalance, vibration, and premature wear. This is especially critical in dual-mass flywheels and performance clutches.

- Counterfeit or Refurbished Parts Sold as New: Some suppliers repackage used or salvaged clutches, misrepresenting them as new. These components often fail within months.

Intellectual Property (IP) Infringement

Sourcing clutches from unauthorized or unverified manufacturers can expose buyers to legal risks.

- Copycat Designs: Many aftermarket clutches mimic patented OEM designs (e.g., Sachs, LUK, Exedy). Using such components may infringe on design or utility patents, leading to legal action, especially in regulated markets like the EU or North America.

- Trademark Violations: Unauthorized use of brand names, logos, or part numbers on packaging or documentation can constitute trademark infringement, even if the part is functionally equivalent.

- Lack of Licensing Agreements: Reputable suppliers often license technology from OEMs. Sourcing from unlicensed manufacturers may mean the product violates proprietary engineering, exposing distributors or installers to liability.

- Gray Market Imports: Importing clutches from regions with weak IP enforcement increases the risk of receiving counterfeit or illegally produced parts, potentially leading to customs seizures or litigation.

Mitigation Strategies

To avoid these pitfalls:

– Source from certified suppliers with verifiable quality management systems.

– Request documentation such as test reports, material certifications, and IP compliance statements.

– Conduct audits or third-party inspections of manufacturing facilities.

– Work with legal counsel to ensure compliance with IP laws in your target market.

Proactively addressing quality and IP concerns ensures reliable performance and protects your business from avoidable risks.

Logistics & Compliance Guide for Auto Clutch Replacement

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legally compliant replacement of automotive clutches in workshop or fleet maintenance environments.

Parts Procurement and Inventory Management

Ensure a reliable supply chain for clutch components (clutch disc, pressure plate, release bearing, pilot bearing, alignment tool, and associated hardware). Source parts from reputable suppliers that meet OEM or certified aftermarket specifications. Maintain accurate inventory records to prevent delays and support just-in-time ordering. Verify part numbers match vehicle make, model, year, and engine configuration before procurement.

Tooling and Equipment Requirements

Equip the workshop with necessary tools including torque wrenches, clutch alignment tools, flywheel resurfacing equipment (or outsourcing protocol), engine support fixtures, and appropriate lifting equipment (e.g., transmission jack). Regularly calibrate torque wrenches and inspect tools for wear or damage to ensure precision and safety during installation.

Workshop Safety Protocols

All technicians must adhere to OSHA (or local equivalent) safety standards. Key practices include wearing personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. Ensure vehicles are securely supported on hoists or jack stands before under-vehicle work. Properly disconnect the battery before beginning work to prevent electrical hazards. Follow lockout/tagout (LOTO) procedures when applicable.

Environmental Compliance

Dispose of used clutch components, oils, and cleaning solvents in accordance with EPA (or local environmental agency) regulations. Used friction materials may contain asbestos or other regulated particulates—confirm material safety data sheets (MSDS/SDS) and handle accordingly. Use vacuum systems with HEPA filters when cleaning clutch assemblies to avoid airborne contamination. Recycle metal components and packaging materials where possible.

Technical Compliance and Quality Assurance

All clutch replacements must follow manufacturer service procedures and specifications. Torque fasteners to OEM-specified values using calibrated tools. Use a dial indicator to check flywheel runout; replace or resurface if out of tolerance. Verify proper clutch engagement and release during post-replacement test procedures. Document all work performed, including part numbers, serial numbers (if applicable), and technician details.

Waste Disposal and Recycling

Establish a certified waste management program for used clutch assemblies, oils, and cleaning agents. Partner with licensed disposal vendors to ensure compliance with RCRA (Resource Conservation and Recovery Act) or equivalent regional regulations. Maintain disposal manifests and records for audit readiness.

Training and Certification

Technicians performing clutch replacements must be trained and certified in drivetrain repair procedures. Provide ongoing training on new vehicle technologies, safety updates, and environmental regulations. Maintain training records to demonstrate compliance with industry standards and insurance requirements.

Documentation and Traceability

Keep detailed service records for each clutch replacement, including vehicle identification number (VIN), date of service, components replaced, technician name, and compliance certifications. Digital record-keeping systems should support traceability for warranty claims, recalls, and regulatory audits.

Regulatory and Industry Standards

Adhere to all relevant regulations such as:

– OSHA 29 CFR 1910 (Occupational Safety and Health)

– EPA regulations on hazardous waste (40 CFR)

– ISO 9001 for quality management (if certified)

– Manufacturer service bulletins and technical updates

Regularly review and update procedures to remain compliant with evolving standards.

Conclusion for Sourcing Auto Clutch Replacement:

In conclusion, sourcing an auto clutch replacement requires careful consideration of vehicle compatibility, quality, cost, and supplier reliability. Whether opting for original equipment manufacturer (OEM) parts or high-quality aftermarket alternatives, ensuring proper fitment and durability is essential for optimal performance and longevity. Evaluating suppliers based on reputation, warranty offerings, and customer service helps mitigate risks associated with part failure or delays. Additionally, factoring in installation costs and technical support can further influence decision-making. Ultimately, a well-researched and strategic sourcing approach ensures a reliable, cost-effective clutch replacement that restores vehicle functionality and supports continued safe operation.