The global blow molding machine market is experiencing robust growth, driven by rising demand for lightweight, cost-effective packaging across the automotive, consumer goods, and pharmaceutical industries. According to a report by Mordor Intelligence, the blow molding machine market was valued at USD 10.8 billion in 2023 and is projected to reach USD 14.5 billion by 2029, growing at a CAGR of 5.2% during the forecast period. A key contributor to this expansion is the automotive sector’s increasing reliance on plastic components for fuel efficiency and design flexibility—spurring demand for precision auto blow machines. Additionally, Grand View Research highlights that technological advancements in multi-layer and rotary blow molding systems are further accelerating adoption among manufacturers seeking high throughput and reduced material waste. As OEMs prioritize automation and energy-efficient production, leading auto blow machine manufacturers are at the forefront of innovation, delivering scalable solutions tailored to complex automotive applications. In this evolving landscape, the following eight companies stand out for their technological prowess, global footprint, and consistent performance in serving the automotive industry’s specialized packaging and component needs.

Top 8 Auto Blow Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

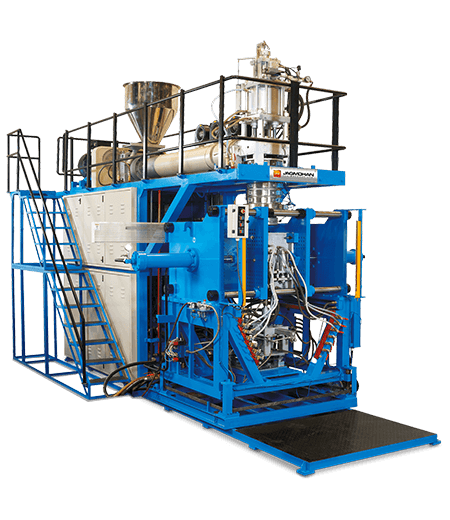

#1 Blow Moulding Machine Manufacturer India

Domain Est. 1999

Website: ranasons.com

Key Highlights: India’s most trusted blow moulding machine manufacturers for HDPE, LDPE, ABS, PET, PVC, PC & PP containers. 55+ years of precision, automation & global ……

#2 Blow Molding Machine Manufacturer in the US: PET

Domain Est. 2008

Website: pet-eu.com

Key Highlights: We develop and manufacture fully automatic and universal semi-automatic blow molding equipment for 0.1-40.0 l bottles with up to 14 000 bph output. Read more h….

#3 Dunamis Machines

Domain Est. 2017

Website: dunamismachines.in

Key Highlights: Dunamis Machines offers high-quality Pet Bottle Blowing Machine, RFC Filling Machine, BOPP Labeling Machine, and Shrink Wrapping Machines in India….

#4 Automatic Blow Moulding Machine manufacturer, Buy good quality …

Domain Est. 2020

Website: autoblowmouldingmachine.com

Key Highlights: China Automatic Blow Moulding Machine · 6 Cavity Two Step Blow Moulding Machine · 6 Cavity 1.5L Plastic Water Bottle Making Machine 3600BPH Easy Installation….

#5 CHUMPOWER

Domain Est. 1998

Website: chumpower.com

Key Highlights: With 40 years of development, CHUMPOWER has becoming the largest leading brand that accounts for 85% of the PET stretch blow molding machine exports in Taiwan….

#6 Parker

Domain Est. 2019

Website: parker-global.com

Key Highlights: We offer a wide range of automatic blow molding machines, injection blow molding machines, extrusion blow molding machines, plastic blow molding machines and ……

#7 China Automatic Blow Moulding Machine(100ML

Domain Est. 2019

Website: m.autoblowmoldingmachine.com

Key Highlights: Good quality Automatic Blow Moulding Machine(100ML-3L) from China, Bottle Blow Molding Machine(3L-5L) factories of Zhangjiagang Apollo Machinery Co.,ltd…..

#8 Plastic Blow Molding Machine

Domain Est. 2024

Website: johsean.com

Key Highlights: The Full Automatic Blow Molding Machine is an advanced, high-efficiency plastic processing equipment designed for the mass production of hollow plastic items….

Expert Sourcing Insights for Auto Blow Machine

2026 Market Trends for Auto Blow Machines: Key Drivers and Forecasts

The global market for automatic blow molding machines (Auto Blow Machines) is poised for significant transformation by 2026, driven by converging technological, economic, environmental, and consumer trends. This analysis examines the key factors shaping the industry landscape over the next few years.

Rising Demand in Packaging and Consumer Goods

The primary driver for Auto Blow Machines remains the robust growth in plastic packaging, particularly for beverages, personal care, and household products. The global shift towards convenience, e-commerce, and on-the-go consumption fuels demand for lightweight, durable, and cost-effective plastic containers. By 2026, emerging markets in Asia-Pacific, Latin America, and Africa are expected to lead volume growth, while North America and Europe maintain strong demand due to product innovation and replacement cycles. The expansion of bottled water, carbonated soft drinks, and personal care products directly correlates with increased investment in high-speed, precision blow molding equipment.

Sustainability and Material Innovation

Environmental regulations and consumer pressure are pushing the industry toward sustainable practices, significantly influencing Auto Blow Machine design and operation. By 2026, machines will increasingly need to handle lightweight, recycled (PCR), and bio-based resins. Key trends include:

* Lightweighting: Machines optimized for thinner wall sections and reduced material usage without compromising strength.

* PCR Integration: Enhanced melting, filtration, and processing capabilities to handle post-consumer recycled PET and HDPE with consistent quality.

* Energy Efficiency: Development of servo-driven systems, improved thermal management, and heat recovery technologies to reduce energy consumption and carbon footprint.

Technological Advancements and Industry 4.0 Integration

Automation and digitalization are transforming blow molding operations. By 2026, Auto Blow Machines will feature deeper integration of Industry 4.0 technologies:

* Smart Machines: Embedded sensors for real-time monitoring of parameters like temperature, pressure, and mold alignment, enabling predictive maintenance and quality control.

* Data Analytics & AI: Machine learning algorithms to optimize settings, reduce scrap rates, and improve overall equipment effectiveness (OEE).

* Remote Monitoring & Support: Cloud-based platforms allowing manufacturers to monitor machine performance, receive alerts, and receive remote diagnostics and support, minimizing downtime.

Growth in Specialty and Customized Applications

Beyond standard bottles, demand is rising for complex, multi-layer, and specialty containers in pharmaceuticals, automotive (fuel tanks, fluid reservoirs), and industrial applications. This trend pushes Auto Blow Machine manufacturers to develop:

* Multi-Layer & Barrier Technology: Machines capable of co-extrusion blow molding with EVOH or other barrier layers to extend shelf life and meet stringent safety standards.

* Large-Part Molding: Increased demand for machines capable of producing large containers, IBCs (Intermediate Bulk Containers), and automotive components with high precision.

* Customization & Flexibility: Machines with quicker changeover times and adaptable configurations to handle diverse product designs and shorter production runs.

Regional Market Dynamics and Competitive Landscape

The Asia-Pacific region, led by China, India, and Southeast Asia, will remain the fastest-growing market due to industrialization, rising disposable incomes, and expanding manufacturing bases. North America and Europe will focus on upgrading existing infrastructure with high-efficiency, sustainable machines. The competitive landscape will see consolidation among key players (e.g., Kautex, Sidel, Bekum, Graham) and increased innovation from regional manufacturers offering cost-effective solutions. Servitization—offering machines as part of integrated service packages—is expected to grow, creating new revenue models.

Conclusion

By 2026, the Auto Blow Machine market will be characterized by a strong emphasis on sustainability, digitalization, and operational efficiency. Success will depend on manufacturers’ ability to deliver machines that are not only faster and more precise but also adaptable to diverse materials and integrated into smart factory ecosystems. Companies investing in R&D for energy efficiency, PCR compatibility, and Industry 4.0 features will be best positioned to capitalize on the evolving market demands.

Common Pitfalls When Sourcing an Auto Blow Machine (Quality and Intellectual Property)

Sourcing an automatic blow molding machine, especially from international or lower-cost suppliers, can present significant risks if due diligence is not thoroughly performed. Two major areas of concern are machine quality and intellectual property (IP) issues. Overlooking these can lead to production delays, increased maintenance costs, legal disputes, and reputational damage.

Poor Machine Quality and Performance

One of the most frequent pitfalls in sourcing auto blow machines is receiving equipment that fails to meet promised performance standards. This often stems from vague or exaggerated supplier claims, lack of standardized testing, or the use of subpar components.

- Inconsistent Output and Cycle Times: Machines may not achieve the advertised output capacity or may suffer from inconsistent cycle times, leading to reduced productivity and unmet production targets.

- Use of Low-Grade Materials and Components: Some suppliers cut costs by using inferior motors, hydraulics, or control systems, resulting in frequent breakdowns, higher downtime, and increased maintenance expenses.

- Poor Build Precision and Alignment: Inaccurate mold alignment or uneven parison control can lead to defective products, high scrap rates, and difficulty in maintaining consistent bottle dimensions.

- Lack of Robust Quality Assurance: Suppliers may not follow rigorous quality control processes during manufacturing, leading to undetected design flaws or assembly errors.

- Inadequate After-Sales Support and Spare Parts Availability: Poor technical support and long lead times for spare parts can severely impact uptime and operational efficiency.

To mitigate these risks, conduct factory audits, request live demonstrations, and insist on performance guarantees and third-party inspection reports before shipment.

Intellectual Property Infringement and Design Copying

Another critical risk when sourcing auto blow machines—particularly from regions with weak IP enforcement—is the potential for purchasing machines that infringe on patented technologies or are outright copies of established designs.

- Use of Counterfeit or Reverse-Engineered Components: Some machines incorporate control systems, mold designs, or mechanical innovations that replicate protected IP without authorization, exposing the buyer to legal liability.

- Supplier Claims of “Original Design” That Are Actually Imitations: Vendors may market machines as proprietary or innovative, when in reality they are clones of well-known models from reputable manufacturers.

- Risk of Legal Action from IP Holders: If the machine uses patented technology without a license, the end user (not just the supplier) may face cease-and-desist orders, fines, or forced equipment seizure.

- Difficulty in Proving IP Ownership: In cross-border transactions, it can be challenging to verify whether the supplier legally owns or has rights to the technology used in the machine.

To protect against IP risks, require suppliers to provide documentation proving the legitimacy of their designs, conduct patent landscape searches, and include indemnification clauses in contracts. Sourcing from reputable manufacturers with established IP portfolios significantly reduces exposure.

Logistics & Compliance Guide for Auto Blow Machine

Product Classification and Documentation

Ensure accurate classification of the Auto Blow Machine under the Harmonized System (HS) Code for smooth customs clearance. Typical classifications may fall under HS 8477 (Machines for working rubber or plastics). Maintain complete documentation, including commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and technical specifications.

Export Controls and Permits

Verify whether the Auto Blow Machine is subject to export control regulations, such as those governed by national trade authorities (e.g., U.S. Department of Commerce for dual-use items). Obtain necessary export licenses or authorizations if required based on destination country and technical capabilities of the machine.

Packaging and Handling Requirements

Package the Auto Blow Machine securely using industrial-grade materials to prevent damage during transit. Include protective measures such as wooden crates, anti-corrosion wraps, and moisture barriers. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include machine model, serial number, and weight for easy identification.

Transportation Mode and Routing

Select the appropriate transportation method—air, sea, or land—based on delivery timeline, machine size, and destination. For oversized or heavy equipment, coordinate with freight forwarders experienced in handling industrial machinery. Plan routing to avoid high-risk regions and comply with international transport regulations (e.g., IMDG for sea freight).

Import Regulations and Duties

Research the import regulations of the destination country, including applicable tariffs, value-added taxes (VAT), and conformity assessment requirements. Some countries may require pre-shipment inspections or local representative registration. Prepare for customs valuation based on transaction value and associated costs (e.g., insurance, freight).

Safety and Technical Compliance

Ensure the Auto Blow Machine meets international safety standards such as CE (European Union), UL (United States), or CCC (China) as applicable. Provide required technical documentation, including Declaration of Conformity, user manuals, and electrical schematics. Machines must comply with local electrical, mechanical, and environmental regulations upon arrival.

Installation and On-Site Support Logistics

Plan for timely delivery of ancillary components (molds, spare parts, tools) and coordinate technician visits if installation or training is required. Confirm site readiness (e.g., power supply, foundation, ventilation) prior to machine arrival to avoid delays. Maintain clear communication with end-users and local agents.

Environmental and Disposal Compliance

Adhere to environmental regulations related to the shipment and operation of industrial equipment. Provide guidance on proper disposal or recycling of packaging materials and machine components at end-of-life in compliance with local laws (e.g., WEEE Directive in EU).

Recordkeeping and Audit Preparedness

Maintain comprehensive records of all logistics and compliance activities for a minimum of five years, including shipping documents, compliance certificates, and correspondence with regulatory bodies. Be prepared for audits by customs or trade authorities.

Conclusion for Sourcing an Auto Blow Machine:

Sourcing an automatic blow molding machine is a strategic decision that significantly impacts production efficiency, product quality, and long-term operational costs. After evaluating various suppliers, machine specifications, and technological capabilities, it is evident that selecting the right auto blow machine requires a balance between upfront investment and long-term value. Key factors such as output capacity, energy efficiency, ease of maintenance, automation level, and after-sales support must be carefully assessed to ensure alignment with production goals.

Opting for a reputable manufacturer with proven experience in the industry, coupled with robust technical support and spare parts availability, minimizes downtime and enhances machine longevity. Additionally, considering future scalability and flexibility to accommodate different product designs will provide a competitive advantage.

In conclusion, a well-researched and informed sourcing decision leads to improved manufacturing performance, reduced waste, and higher return on investment. By prioritizing quality, reliability, and long-term partnership with suppliers, businesses can establish a strong foundation for sustainable growth in the packaging and plastics industry.