The global automotive battery quick disconnect switch market is experiencing steady growth, driven by increasing demand for vehicle safety, rising adoption of aftermarket modifications, and growing concerns around battery conservation and theft prevention. According to a 2023 report by Mordor Intelligence, the global automotive battery market is projected to grow at a CAGR of over 7.2% from 2023 to 2028, with auxiliary components such as quick disconnects gaining traction due to their role in enhancing electrical system safety and maintenance efficiency. Similarly, Grand View Research highlights the expansion of the automotive electrical and electronics market—valued at USD 333.6 billion in 2022 and expected to grow at a CAGR of 7.8% through 2030—as a key enabler for ancillary components like battery disconnect switches. As vehicles become more electronically complex and off-road and fleet applications rise, manufacturers of reliable, high-performance quick disconnects are poised to benefit from this upward trend. In this landscape, the top nine auto battery quick disconnect manufacturers distinguish themselves through innovation, durability, and compliance with evolving industry standards.

Top 9 Auto Battery Quick Disconnect Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 KISSLING Battery Disconnect Switches for Reliable Power Control

Domain Est. 1992

Website: te.com

Key Highlights: Our battery disconnect switches are designed not just to function but to excel in high-voltage systems, commercial vehicles, and industrial applications….

#2 Battery Quick Disconnect Kit – Safe, Fast Power Connection

Domain Est. 2009

Website: newportvessels.com

Key Highlights: In stock Rating 4.9 (49) Easily connect and disconnect your battery with Newport’s Quick Battery Disconnect – safe, efficient, and perfect for trolling motors and marine batterie…

#3 Quick Disconnects Archives

Domain Est. 1996

Website: quickcable.com

Key Highlights: Quick Disconnects. Our Quick® Disconnects enable quick disconnection of power from the battery. Categories. Categories. Battery Terminals & Lugs (4)….

#4 Battery Doctor® Battery Disconnect Switches

Domain Est. 1996

Website: wirthco.com

Key Highlights: We provide battery disconnect switches to cut off electrical power, preserving battery life and preventing theft, with a variety of benefits for ……

#5 Anderson Power

Domain Est. 1996

Website: andersonpower.com

Key Highlights: An Innovative Connector for the Future of Battery Charging. Our new IBC DIN-style connector is designed to take your battery charging to the next level….

#6 Premium Quick Connectors & Couplings

Domain Est. 1998

Website: fastestinc.com

Key Highlights: Explore FasTest’s top-quality quick connectors and couplings, engineered for reliability….

#7 Automotive battery protection & disconnection

Domain Est. 1999

Website: infineon.com

Key Highlights: Fast and accurate disconnection of the battery from the charger when triggered by failure events; Safe disconnection of the battery when the vehicle is off…

#8 Wiring and Electrical

Domain Est. 2000

Website: quickcar.com

Key Highlights: Allows for quick power disconnection.Easy installation, connects to negative post.Loosen knob to disconnect power; tighten to reconnect.Rated for 125 amps ……

#9 Automotive Quick Connectors

Domain Est. 2012

Website: cpcworldwide.com

Key Highlights: CPC quick connectors are useful for automotive applications like low-pressure fuel delivery systems, inflation devices for tires and seats, washer fluid ……

Expert Sourcing Insights for Auto Battery Quick Disconnect

2026 Market Trends for Auto Battery Quick Disconnect

The auto battery quick disconnect (ABQD) market is poised for significant evolution by 2026, driven by advancements in automotive technology, increasing focus on vehicle safety, and growing demand for energy efficiency. As the automotive industry shifts toward electrification and enhanced vehicle security, the role of battery disconnect devices is expanding beyond traditional applications. This analysis explores key trends shaping the ABQD market in 2026.

Rising Demand for Vehicle Security and Anti-Theft Solutions

One of the primary drivers of the ABQD market by 2026 is the heightened concern over vehicle theft, particularly in commercial fleets and high-value automobiles. Quick disconnect switches provide a simple yet effective method to disable a vehicle by cutting off the power supply, making them an attractive anti-theft solution. With increasing incidents of relay attacks and keyless entry thefts, especially in luxury and electric vehicles, OEMs and aftermarket providers are integrating ABQDs into vehicle security systems. The trend is especially strong in regions like North America and Western Europe, where vehicle crime rates have prompted both consumers and fleet operators to adopt preventative technologies.

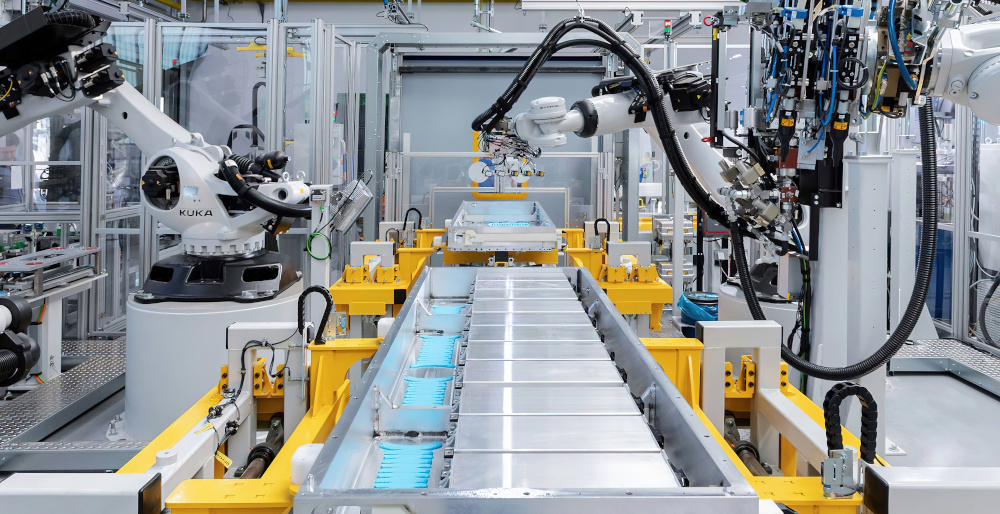

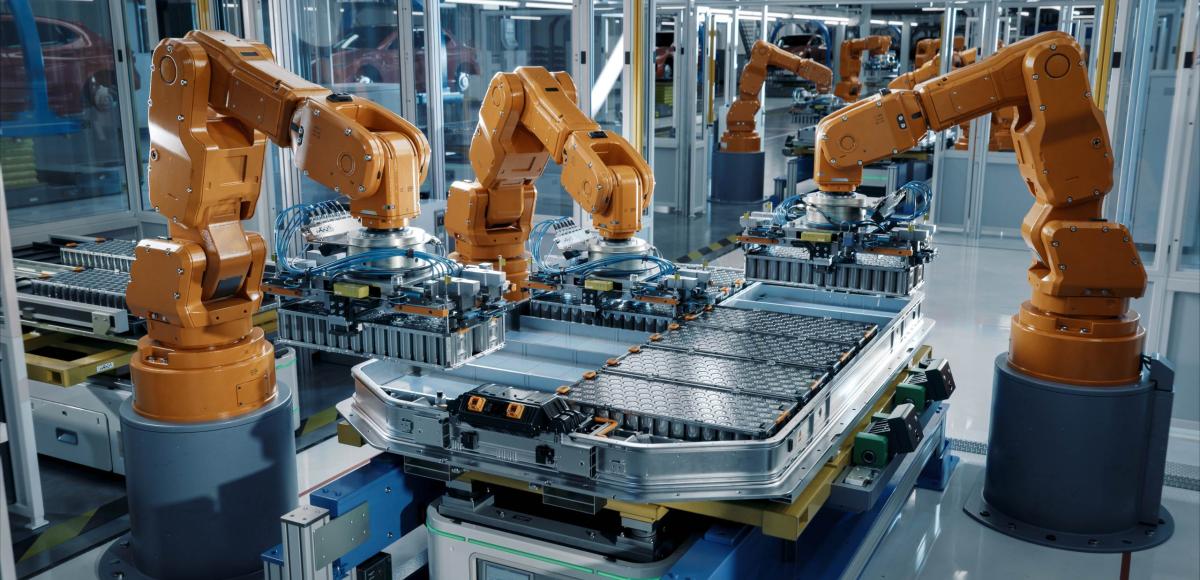

Integration with Electric and Hybrid Vehicles

As electric vehicles (EVs) and hybrid electric vehicles (HEVs) gain market share, the application of battery disconnect mechanisms is evolving. While traditional ABQDs were used primarily in internal combustion engine (ICE) vehicles to prevent battery drain or theft, modern disconnect systems in EVs are engineered for high-voltage safety. By 2026, the ABQD market is expected to see increased demand for high-voltage disconnect switches that comply with EV safety standards such as ISO 6469 and UN GTR 20. These systems are critical during collisions or maintenance to isolate the high-voltage battery, enhancing technician and passenger safety. Automakers are partnering with component suppliers to develop compact, automated disconnect solutions that integrate seamlessly with battery management systems (BMS).

Growth in Aftermarket and DIY Installations

The aftermarket segment is anticipated to dominate the ABQD market in 2026, fueled by do-it-yourself (DIY) automotive culture and the availability of user-friendly disconnect kits. Consumers are increasingly aware of battery drain issues—especially in vehicles used seasonally or infrequently—and are turning to quick disconnects to preserve battery life. Online retail platforms and social media tutorials have simplified access and installation, contributing to market expansion. Additionally, RVs, off-road vehicles, and classic car owners represent niche but growing user bases for ABQDs, seeking both protection and convenience.

Technological Advancements and Smart Features

By 2026, smart battery disconnect devices are expected to gain traction, incorporating Bluetooth connectivity, remote control via smartphone apps, and integration with vehicle telematics. These intelligent systems allow users to monitor battery health, receive low-voltage alerts, and remotely disconnect the battery—enhancing both security and maintenance efficiency. Some advanced models feature automatic disconnection when the vehicle is inactive for a set period, preventing parasitic drain. These innovations are particularly appealing to fleet managers and owners of high-end vehicles, driving up average selling prices and encouraging product differentiation among manufacturers.

Regulatory and Safety Standards Influence

Government regulations and safety standards will play a pivotal role in shaping the ABQD market. In response to rising EV adoption, regulatory bodies are likely to mandate fail-safe battery isolation systems in new vehicles. For instance, the European Union’s General Safety Regulation and similar frameworks in the U.S. and China may require automatic high-voltage disconnects in crash scenarios. These mandates will create new opportunities for ABQD manufacturers to supply safety-compliant components to OEMs, boosting market growth and encouraging innovation in reliability and response time.

Regional Market Dynamics

Regionally, North America and Europe are expected to lead the ABQD market in 2026 due to high vehicle ownership rates, strict safety regulations, and strong aftermarket demand. Asia-Pacific, particularly China and India, will see accelerated growth driven by expanding EV production and urbanization. Local manufacturers are beginning to produce cost-effective ABQD solutions tailored to regional vehicle types, supporting broader adoption across price-sensitive markets.

Conclusion

By 2026, the auto battery quick disconnect market will be shaped by converging trends in vehicle electrification, security, and digital integration. While traditional applications remain relevant, the shift toward smarter, safer, and more automated disconnect systems is transforming the landscape. Manufacturers that innovate in high-voltage compatibility, user convenience, and regulatory compliance will be well-positioned to capture growing demand across both OEM and aftermarket channels.

Common Pitfalls When Sourcing Auto Battery Quick Disconnects (Quality & IP)

Sourcing Auto Battery Quick Disconnects (ABQDs) requires careful attention to quality and Ingress Protection (IP) ratings to ensure reliability, safety, and longevity. Overlooking key factors can lead to performance issues, safety hazards, and costly failures. Below are common pitfalls to avoid:

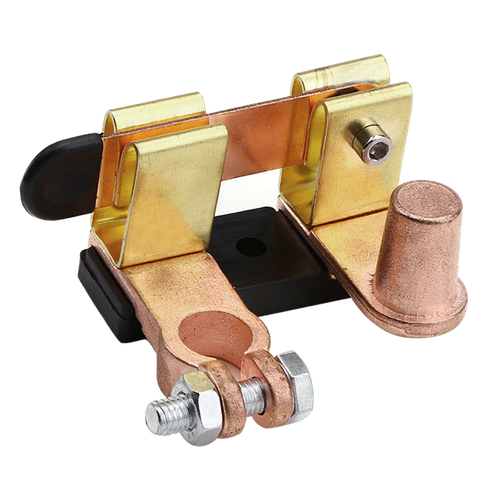

1. Compromising on Build Quality for Lower Cost

One of the most frequent mistakes is selecting low-cost ABQDs made from substandard materials. Cheap connectors often use:

– Inferior plastics that become brittle in extreme temperatures

– Corroding metal contacts (e.g., non-tinned or low-grade copper)

– Weak mechanical latches that fail under vibration

These issues lead to increased resistance, overheating, and potential disconnection during operation—posing serious safety risks, especially in emergency or high-vibration environments.

2. Ignoring Ingress Protection (IP) Ratings

The IP rating indicates protection against dust and moisture. A common oversight is selecting connectors without adequate IP protection for the intended environment:

– Using IP44-rated connectors outdoors or in high-dust areas, where IP67 or IP68 is required

– Failing to verify that the IP rating applies to the mated connection (some ratings only cover the unmated state)

Without proper sealing, moisture ingress can cause short circuits, corrosion, and permanent damage—especially in off-road vehicles, marine applications, or regions with heavy rain or snow.

3. Assuming All “Waterproof” Claims Are Equal

Marketing terms like “waterproof” or “sealed” are not standardized. Many low-quality ABQDs make bold claims without independent IP certification. Always verify:

– The exact IP rating (e.g., IP67 vs. IP65)

– Certification from recognized testing bodies

– Performance data under real-world conditions (temperature cycling, salt spray, etc.)

Relying on unverified claims may result in premature failure when exposed to harsh environments.

4. Overlooking Vibration and Mechanical Durability

Automotive environments are subject to constant vibration and shock. Poorly designed disconnects may:

– Loosen over time, leading to intermittent power loss

– Crack or break under stress

– Fail to maintain low contact resistance after repeated use

Ensure the ABQD is specifically tested and rated for automotive or off-road use, with robust locking mechanisms and strain relief.

5. Mismatched Current and Voltage Ratings

Selecting a disconnect with insufficient current capacity is a critical error. Overloading causes:

– Excessive heat buildup

– Melting of housing or contacts

– Fire hazard

Always match or exceed the system’s maximum current draw, especially for high-power applications like winches, inverters, or electric vehicle auxiliary systems. Also, verify voltage compatibility (12V vs. 24V systems).

6. Neglecting Ease of Use and Accessibility

A poorly designed ABQD may be difficult to operate with gloves or in tight engine bays. Pitfalls include:

– Excessive force required for disconnection

– Small or awkward handles

– Lack of clear visual or tactile feedback when fully engaged

This reduces usability in emergencies and increases the risk of improper connection.

7. Failing to Verify Compliance and Certifications

Reputable ABQDs should comply with relevant automotive or safety standards (e.g., SAE, UL, RoHS). Avoid products without:

– Clear documentation of compliance

– Traceable manufacturer information

– Warranty or technical support

Non-compliant products may not meet safety or performance benchmarks and could void vehicle or equipment warranties.

8. Not Considering Long-Term Maintenance and Corrosion Resistance

Even with good initial quality, connectors in humid or salty environments can corrode over time. Pitfalls include:

– Lack of corrosion-resistant plating (e.g., gold or tin over copper)

– Poor dielectric grease compatibility

– No maintenance guidelines from the supplier

Choose connectors designed for longevity, with features like sealed contact chambers and recommended maintenance intervals.

By avoiding these common pitfalls—focusing on verified quality, appropriate IP ratings, and application-specific performance—you can ensure reliable and safe battery disconnection in any automotive or mobile power system.

Logistics & Compliance Guide for Auto Battery Quick Disconnect

Overview

An Auto Battery Quick Disconnect (ABQD) is a safety device used in vehicles to rapidly disconnect the battery in emergencies or during maintenance. Proper logistics and compliance with regulatory standards are essential to ensure safe handling, transportation, storage, and use of these devices. This guide outlines key considerations for manufacturers, distributors, installers, and end-users.

Regulatory Compliance

ABQDs must meet various national and international standards to ensure safety, reliability, and compatibility. Key compliance areas include:

- FMVSS (Federal Motor Vehicle Safety Standards) – USA: While not directly regulating ABQDs, FMVSS 305 addresses electrical safety in electric and hybrid vehicles, influencing disconnect design.

- UL 2594 – Standard for Safety for Battery Disconnection Devices: Applies to battery disconnect switches used in automotive applications, covering construction, performance, and fire resistance.

- ISO 6469 (Electrically Propelled Road Vehicles – Safety Specifications): Relevant for electric vehicles, particularly Parts 1 (On-board electrical energy storage) and 3 (Protection of persons against electric shock).

- ECE R100 – United Nations Economic Commission for Europe: Covers safety provisions for electric power trains, including isolation and emergency disconnects.

- RoHS & REACH (EU): Ensure restricted hazardous substances (e.g., lead, cadmium) are not used in manufacturing.

- IP (Ingress Protection) Ratings: Devices should meet at least IP65 for dust and water resistance in automotive environments.

Compliance documentation (e.g., test reports, certifications, Declaration of Conformity) must be maintained and available upon request.

Transportation & Shipping

Proper logistics are critical due to the electrical and mechanical nature of ABQDs:

- Packaging: Devices must be packaged in anti-static, shock-resistant materials to prevent damage during transit. Individual units should be sealed in moisture-barrier bags if applicable.

- Labeling: Include:

- Product name and model number

- Manufacturer/brand information

- Compliance markings (e.g., UL, CE)

- Handling symbols (e.g., “Fragile,” “Do Not Stack”)

- Hazard Classification: ABQDs are generally non-hazardous for transport (not classified as dangerous goods under IATA, IMDG, or ADR) unless integrated with battery components.

- Storage Conditions: Store in a dry, temperature-controlled environment (typically 0°C to 40°C) away from direct sunlight and corrosive substances.

Import & Export Considerations

International shipments require adherence to customs and trade regulations:

- HS Code Classification: Use appropriate Harmonized System codes (e.g., 8536.50 for electrical switches) to ensure correct duty assessment.

- Country-Specific Approvals: Some markets (e.g., China CCC, South Korea KC) may require local certification before sale.

- Documentation: Include commercial invoice, packing list, bill of lading/airway bill, and certificates of compliance.

- Tariff and Duty Management: Leverage free trade agreements (e.g., USMCA, CETA) where applicable to reduce costs.

Installation & Use Compliance

End-users and installers must follow safety and operational guidelines:

- Installation Standards: Follow manufacturer instructions and applicable electrical codes (e.g., NEC Article 690 for solar applications, NFPA 70).

- Vehicle Compatibility: Verify compatibility with vehicle make, model, and battery specifications (voltage, amperage).

- Emergency Access: Ensure the disconnect is easily accessible and clearly labeled for emergency responders.

- Lockout/Tagout (LOTO): In commercial or fleet applications, integrate ABQDs into LOTO procedures for worker safety.

Environmental & End-of-Life Management

Sustainable logistics include responsible disposal and recycling:

- WEEE Compliance (EU): ABQDs fall under Waste Electrical and Electronic Equipment directives. Producers may be required to finance take-back programs.

- Battery Integration: If the disconnect is sold with a battery, follow local battery recycling laws (e.g., California’s Battery Recycling Law).

- Recycling Instructions: Provide end-users with disposal guidance and locate certified e-waste recyclers.

Recordkeeping & Audits

Maintain detailed records to support compliance and traceability:

- Batch/lot numbers and manufacturing dates

- Certifications and test reports

- Shipping and receiving logs

- Customer complaints and corrective actions

Regular internal audits help ensure continued compliance with evolving regulations.

Conclusion

Proper logistics and compliance for Auto Battery Quick Disconnects protect users, ensure product reliability, and support market access. Stakeholders should stay informed about regulatory updates and engage certified testing laboratories for product validation. Adherence to this guide minimizes risk and promotes safe, sustainable deployment of ABQDs worldwide.

Conclusion:

The sourcing of an auto battery quick disconnect should prioritize safety, reliability, and compatibility with the vehicle’s electrical system. After evaluating various suppliers, product types (such as manual switch disconnects or remote-controlled models), and key factors like current rating, ease of installation, and durability, it is clear that selecting a high-quality disconnect from a reputable manufacturer is crucial. Sourcing from certified suppliers or OEM-recommended brands ensures compliance with industry standards and enhances long-term performance. Additionally, considering cost-effectiveness without compromising on safety features will provide optimal value. Ultimately, a well-sourced battery quick disconnect not only protects the vehicle’s electrical components but also offers convenience and peace of mind for the user, especially in scenarios involving maintenance, security, or emergency shutdowns.