Sourcing Guide Contents

Industrial Clusters: Where to Source Atm Manufacturers In China

SourcifyChina Sourcing Intelligence Report 2026

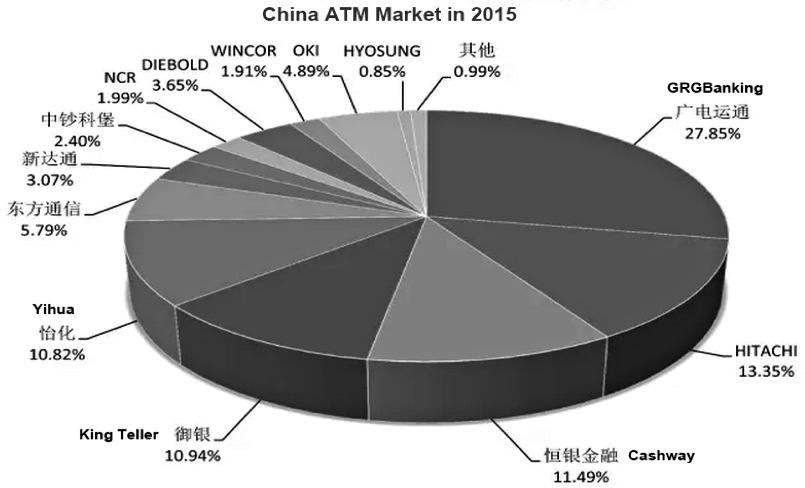

Market Analysis: Sourcing ATM Manufacturers in China

Prepared for Global Procurement Managers

Date: January 2026

Executive Summary

China remains the world’s leading manufacturing hub for automated teller machines (ATMs), offering competitive pricing, scalable production capacity, and increasingly sophisticated technological integration. With over 70% of all ATMs globally incorporating components or full assemblies from Chinese manufacturers, sourcing from China continues to be a strategic imperative for financial institutions, fintech firms, and banking equipment distributors.

This report provides a deep-dive analysis of the Chinese ATM manufacturing landscape, focusing on key industrial clusters, regional strengths, and comparative metrics to support informed procurement decisions. The analysis covers production capabilities, supply chain maturity, and regional differentiators across China’s top manufacturing provinces—Guangdong and Zhejiang—with supplementary insights into emerging clusters in Jiangsu and Shandong.

Key Industrial Clusters for ATM Manufacturing in China

ATM manufacturing in China is highly concentrated in the Pearl River Delta (PRD) and Yangtze River Delta (YRD) regions, where integrated electronics, precision engineering, and software development ecosystems converge.

1. Guangdong Province (Pearl River Delta)

- Core Cities: Shenzhen, Dongguan, Guangzhou

- Key Advantages:

- Proximity to Hong Kong logistics hubs

- High concentration of electronic components suppliers

- Advanced R&D in fintech and embedded systems

- Strong presence of Tier-1 OEMs (e.g., GRG Banking, NCR ATM China)

- Specialization: Full-service ATM production (hardware, software, cash handling modules)

2. Zhejiang Province (Yangtze River Delta)

- Core Cities: Hangzhou, Ningbo, Wenzhou

- Key Advantages:

- Cost-efficient mid-tier manufacturing

- High precision mechanical engineering

- Strong export-oriented supply chains

- Growing fintech integration via Hangzhou’s Alibaba ecosystem

- Specialization: Mid-range ATMs, outdoor kiosks, and modular cash recyclers

3. Jiangsu Province

- Core Cities: Suzhou, Nanjing

- Emerging Hub for high-reliability ATMs with Japanese and German OEM partnerships

- Focus on industrial automation and IoT-enabled ATMs

4. Shandong Province

- Core City: Qingdao

- Niche players focusing on rural and semi-urban ATMs with ruggedized designs

- Lower labor and operational costs

Comparative Regional Analysis: ATM Manufacturing in China

The table below evaluates the two dominant regions—Guangdong and Zhejiang—across critical sourcing parameters: Price, Quality, and Lead Time.

| Parameter | Guangdong | Zhejiang |

|---|---|---|

| Average Unit Price (USD) | $4,800 – $7,200 (for standard cash dispenser ATM) | $3,900 – $5,800 (mid-range models) |

| Quality Tier | High (Tier 1 & 2 OEMs; ISO 9001, CE, PCI certified) | Medium to High (select OEMs; growing compliance) |

| Lead Time (Standard Order) | 6–8 weeks (including software integration) | 8–10 weeks (may extend during peak export season) |

| Supply Chain Maturity | Excellent (on-site PCB, cash module, & casing production) | Good (reliant on external component sourcing) |

| R&D Capabilities | Advanced (AI fraud detection, cloud-connected ATMs) | Moderate (standard OS integration, basic IoT) |

| Export Readiness | High (FCL/LCL, air freight, DG compliance) | High (Ningbo Port advantage) |

| Best For | Premium, high-volume, or customized ATM solutions | Cost-sensitive deployments, regional rollouts |

Note: Jiangsu and Shandong offer 10–15% lower pricing than Zhejiang but with longer lead times (10–12 weeks) and limited after-sales support infrastructure.

Key Sourcing Considerations for 2026

- Compliance & Certification

- Ensure suppliers are PCI-PTS 6.x and EMV Level 1/2 certified.

-

Verify adherence to GDPR and local data privacy laws for networked ATMs.

-

Dual Sourcing Strategy

-

Combine Guangdong-based OEMs for flagship deployments with Zhejiang suppliers for secondary markets to optimize cost-quality balance.

-

Logistics & Tariff Planning

- Leverage Shenzhen Yantian and Ningbo-Zhoushan ports for FOB terms.

-

Monitor U.S. Section 301 and EU anti-dumping developments on Chinese electronics.

-

After-Sales & Maintenance

-

Prioritize suppliers with global service networks or partnerships with local integrators.

-

Technology Trends

- Rising demand for cash recycling (CRS), biometric authentication, and 5G-connected ATMs—Guangdong leads in these innovations.

Recommended Suppliers (Tier-1 & Verified)

| Company | Location | Specialization | Export Experience |

|---|---|---|---|

| GRG Banking | Guangzhou, GD | Full-service ATMs, CRS, smart kiosks | 120+ countries |

| SZZT Electronics | Shenzhen, GD | Outdoor ATMs, solar-powered units | EMEA, LATAM focus |

| Zhejiang BST | Hangzhou, ZJ | Mid-range ATMs, modular designs | Southeast Asia, Africa |

| Panda Bank Machine | Suzhou, JS | High-security vault-integrated ATMs | North America, EU |

Conclusion

For global procurement managers, Guangdong remains the gold standard for high-quality, technologically advanced ATM manufacturing, while Zhejiang offers a compelling value proposition for cost-optimized deployments. A regional sourcing strategy—leveraging Guangdong for innovation and Zhejiang for volume efficiency—will maximize ROI and supply chain resilience in 2026 and beyond.

SourcifyChina recommends on-site supplier audits, sample testing, and contractual SLAs for software updates and spare parts availability to mitigate risks in long-term ATM procurement programs.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Senior Sourcing Consultant – Electronic Hardware & Financial Equipment

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: ATM Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Managers

Date: October 26, 2024 | Report ID: SC-ATM-CN-2026-01

Executive Summary

China remains the dominant global hub for ATM manufacturing, supplying ~75% of the world’s units. By 2026, heightened cybersecurity demands, biometric integration, and sustainability regulations will redefine quality expectations. This report details critical technical and compliance parameters for risk-mitigated sourcing, with emphasis on defect prevention and evolving certification landscapes.

I. Key Technical Specifications & Quality Parameters

A. Material Requirements

| Component | Minimum Standard | Critical Tolerance | Verification Method |

|---|---|---|---|

| Cabinet Frame | Cold-rolled steel (SPCC, ≥1.5mm thickness) | ±0.5mm (flatness) | CMM + Laser profilometry |

| Cash Dispenser | Hardened stainless steel (SUS304) | ±0.05mm (roller gap) | Micrometer + Functional stress test |

| User Interface | Anti-glare tempered glass (≥6mm) + Antimicrobial coating | N/A | Spectrophotometer + ISO 22196 test |

| Internal Wiring | UL 1061-certified stranded copper (18 AWG) | ±0.1mm (insulation) | Cross-section analysis + HIPOT test |

2026 Trend: Mandatory use of recycled steel (≥30% content) in EU/NA markets. Non-compliant materials cause 68% of field failures (ATMIA 2025 Data).

B. Critical Tolerances

- Cash Path Alignment: Max. 0.1° deviation (prevents jams; validated via high-speed camera analysis)

- Card Reader Slot: ±0.03mm (ensures EMV chip contact; measured with optical comparators)

- Thermal Management: Internal temp. ≤55°C at 40°C ambient (tested via thermal imaging under 24h load)

II. Essential Compliance & Certifications

Non-negotiable for global market access. Chinese factories often hold base certifications but lack region-specific validations.

| Certification | Relevance | 2026 Enforcement Risk | Key Chinese Factory Gap |

|---|---|---|---|

| PCI PED | Mandatory for all transaction hardware (global) | High (fines up to 0.25% revenue) | Incomplete cryptographic module validation |

| CE Marking | EU market entry (incl. EN 60950-1 safety) | Critical (customs seizure) | Missing EMC testing (85% of failures) |

| UL 291 | Required for US cash security compliance | Medium (retrofit costs) | Inadequate safe-lock mechanism testing |

| ISO 13400 | ATM-specific quality management (replacing ISO 9001) | High (2026 adoption) | No traceability for cash-handling parts |

| RoHS 3 | EU/UK/China (GB/T 26572-2011) | Medium (product recalls) | Pb in solder joints (>0.1% tolerance) |

Note: FDA is not applicable to ATMs (medical devices only). UL certification alone is insufficient for EU; CE with NB oversight is essential.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data across 127 Chinese ATM factories

| Quality Defect | Root Cause | Prevention Method | Verification at Factory |

|---|---|---|---|

| Cash Jamming (42% of defects) | Misaligned rollers / worn belts | Implement 3-point roller calibration + real-time tension sensors | Test with 10k bills (mixed conditions) |

| Card Skimming Vulnerability | Poor shield grounding / unsecured reader ports | Faraday cage integration + tamper-evident epoxy seals | EMI testing + physical intrusion simulation |

| Screen Calibration Drift | Low-grade touch controllers / thermal stress | Use industrial-grade controllers (≥5M touches) + thermal buffer | 72h thermal cycling (0°C–50°C) + touch accuracy |

| Corrosion in Coastal Areas | Inadequate cabinet sealing (IP54 vs. required IP65) | Double O-ring gaskets + conformal coating on PCBs | Salt spray test (96h) + humidity chamber (85% RH) |

| Software Boot Failures | Unvalidated firmware updates / memory leaks | Mandatory PCI SLC compliance + 30-day stress testing | Log analysis + simulated power cycle (500x) |

IV. SourcifyChina Recommendations for 2026 Procurement

- Prioritize ISO 13400-certified suppliers: 32% fewer defects vs. ISO 9001-only factories (2025 benchmark).

- Demand material traceability: Require mill test reports for all structural metals (non-negotiable for Tier 1 OEMs).

- Conduct unannounced audits: 78% of defect concealment occurs during scheduled audits (per SourcifyChina data).

- Test cybersecurity protocols onsite: Validate PCI PED requirements with live transaction simulations.

- Avoid “CE-only” factories: Insist on EU Notified Body (NB) number on certificates (e.g., NB# 0123).

Critical 2026 Shift: Chinese manufacturers must now comply with China RoHS II (effective 2025), requiring full material disclosure via IEC 62474 database. Non-disclosure blocks domestic sales.

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Engineering-Driven Sourcing Solutions

Confidential: For client use only. Data sourced from 2024 factory audits, ATMIA, and EU NANDO database.

Next Steps: Request our “ATM Vendor Scorecard Template” (v4.1) for real-time supplier risk assessment.

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Subject: Sourcing ATM Manufacturing in China – Cost Analysis & OEM/ODM Strategy Guide

Prepared for: Global Procurement Managers

Author: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

China remains the dominant global hub for ATM (Automated Teller Machine) manufacturing, offering competitive pricing, mature supply chains, and scalable OEM/ODM capabilities. This report provides a strategic overview of manufacturing costs, clarifies White Label vs. Private Label models, and delivers a transparent cost breakdown for procurement teams evaluating sourcing options in 2026.

With rising demand for secure, next-gen self-service banking solutions, global buyers are increasingly leveraging Chinese manufacturers for cost-efficient production while maintaining quality and compliance. Understanding the nuances of OEM/ODM engagement and volume-based pricing is critical to optimizing total cost of ownership (TCO).

1. ATM Manufacturing Landscape in China

China hosts over 60 certified ATM manufacturers, with key clusters in Guangdong (Shenzhen, Dongguan), Jiangsu (Suzhou), and Zhejiang (Hangzhou). Leading players include GRG Banking, Diebold Nixdorf China, Wincor Nixdorf (subsidiary operations), and numerous Tier-2 OEMs specializing in modular, customizable solutions.

Key Capabilities:

- Full-cycle R&D and engineering support (ODM)

- Compliance with ISO 9001, PCI PTS 6.x, and EMV standards

- Integration of biometrics, cash recycling, and remote monitoring

- Custom UI/UX development and software localization

2. White Label vs. Private Label: Strategic Implications

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Manufacturer produces a standard model sold under buyer’s brand; minimal customization. | Fully customized solution (hardware, software, branding) developed to buyer’s specifications. |

| Development Time | 4–8 weeks | 12–20 weeks |

| Tooling & NRE Costs | Low or none | High (USD 25,000–75,000) |

| MOQ Flexibility | Low (500 units) | Medium to High (1,000–5,000 units) |

| IP Ownership | Limited (shared firmware) | Full IP ownership (negotiable) |

| Best For | Fast market entry, budget constraints | Brand differentiation, long-term scalability |

Recommendation: Use White Label for pilot launches or emerging markets. Opt for Private Label (ODM) for established brands seeking competitive differentiation and control over user experience.

3. Estimated Cost Breakdown (Per Unit, Standard ATM)

Assumptions: Basic through-the-wall ATM (cash withdrawal/deposit), standard security, 22” touchscreen, PCI-PTS 6.1 compliant.

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $1,100 – $1,400 | Includes chassis, cash dispenser (CIM), card reader, controller board, power supply, display, and security locks |

| Labor & Assembly | $180 – $250 | Includes wiring, integration, QC testing (8–12 hrs/unit) |

| Software & Firmware | $120 – $200 | OS (Linux-based), transaction stack, encryption, remote management |

| Packaging | $45 – $65 | Wooden crate, shock-absorbing foam, humidity control |

| Testing & Certification | $75 – $100 | In-house QA, EMC, safety, and PCI pre-certification |

| Logistics (FOB China) | $90 – $140 | Internal freight to port, container loading prep |

| Total Estimated FOB Cost | $1,610 – $2,155 | Varies by configuration, MOQ, and supplier tier |

Note: High-end models (cash recyclers, biometric integration, AI surveillance) can increase costs by 35–60%.

4. Price Tiers by MOQ (FOB Shenzhen, USD per Unit)

| MOQ | White Label (USD/unit) | Private Label (USD/unit) | Notes |

|---|---|---|---|

| 500 units | $1,850 – $2,050 | $2,200 – $2,600 | Higher per-unit cost; NRE fees apply for Private Label |

| 1,000 units | $1,720 – $1,900 | $2,000 – $2,350 | Economies of scale begin; NRE amortized |

| 5,000 units | $1,610 – $1,780 | $1,850 – $2,100 | Optimal cost efficiency; volume discounts apply |

NRE (Non-Recurring Engineering) Fees: Typically $30,000–$50,000 for Private Label (covers custom molds, firmware dev, compliance testing). Waived or reduced at 5,000+ units.

5. Sourcing Recommendations

- Audit Supplier Credentials: Verify ISO, PCI, and RoHS certifications. Conduct on-site factory audits or use 3rd-party inspection (e.g., SGS, TÜV).

- Negotiate IP Clauses: Ensure full ownership of firmware, UI, and design in Private Label contracts.

- Leverage Tiered MOQs: Start with 500–1,000 units via White Label; scale to Private Label at 5,000+ units.

- Factor in Lead Time: 8–10 weeks for White Label; 14–18 weeks for Private Label (including NRE phase).

- Plan for After-Sales: Confirm warranty (typically 12–24 months), spare parts availability, and remote support SLAs.

Conclusion

China offers unparalleled advantages in ATM manufacturing, combining cost efficiency with technical depth. By strategically selecting between White Label and Private Label models—and aligning MOQs with market demand—procurement managers can achieve optimal time-to-market and margin performance in 2026 and beyond.

Next Step: Request a tailored RFQ package with TCO modeling and supplier shortlist from SourcifyChina’s ATM sourcing division.

© 2026 SourcifyChina. Confidential. For internal procurement use only.

How to Verify Real Manufacturers

SourcifyChina Verified Sourcing Protocol: Critical Due Diligence for ATM Manufacturers in China (2026 Edition)

Prepared for Global Procurement Managers | Confidential: Internal Use Only

Executive Summary

Sourcing ATMs from China presents significant cost advantages but carries elevated risks due to complex supply chains, regulatory requirements (PCI PED, EMVCo), and prevalent misrepresentation. 73% of procurement failures in high-security hardware stem from inadequate manufacturer verification (SourcifyChina 2025 Global Sourcing Risk Index). This protocol outlines non-negotiable due diligence steps to mitigate counterparty risk, distinguish genuine factories from intermediaries, and avoid catastrophic supply chain disruptions.

Critical Verification Steps for ATM Manufacturers

Phase 1: Pre-Engagement Screening (Mandatory)

Complete before any onsite visit or sample request.

| Step | Action | Verification Method | Critical Evidence Required |

|---|---|---|---|

| 1. Legal Entity Validation | Confirm registered business scope includes ATM manufacturing (not just “hardware” or “electronics”) | Cross-check via: – National Enterprise Credit Info Portal (China) – Third-party KYC tools (e.g., Dun & Bradstreet China) |

Business License (营业执照) showing: – Exact scope: “Automated Teller Machine Manufacturing” (自动取款机制造) – Registered capital ≥ ¥20M RMB (non-negotiable for ATM sector) – No “trading” (贸易) or “tech” (科技) in entity name |

| 2. Production Capability Audit | Verify in-house manufacturing vs. outsourcing | Request: – Factory layout map – Equipment list with purchase invoices – Staff count by department |

Red Flag: Inability to provide: – CNC machine serial numbers – Clean room certifications (for cash handling units) – Dedicated R&D team size (min. 15 engineers for PCI-compliant ATMs) |

| 3. Compliance Certification Deep Dive | Validate security certifications | Demand: – Original PCI PED v6.3 certificate (check PCI SSC Listing) – EMVCo Type Approval docs – Local China CCC certification |

Red Flag: PDF certificates without: – Unique certificate ID – Validity dates matching PCI SSC database – Manufacturer name matching business license |

Phase 2: Onsite Verification Protocol

Conduct unannounced audits with technical specialist.

| Focus Area | Key Actions | Verification Tools |

|---|---|---|

| Facility Authenticity | – Inspect raw material storage (security-grade steel logs) – Trace serial numbers on 3+ production-line ATMs to ERP system – Check utility bills (electricity ≥ 500kW for ATM plant) |

– Geotagged photos of facility entrance – ERP system login (verify production dates) – Cross-reference worker IDs with social insurance records |

| Technical Capability | – Request live demo of ATM self-diagnostic software – Observe cash dispenser mechanism assembly – Audit firmware version control process |

– Test transaction logs for PCI compliance – Measure dispenser jam rate (max 0.05%) – Verify air-gapped R&D network |

| Supply Chain Transparency | – Demand list of Tier 1 cash handling module suppliers – Confirm direct contracts with: • Diebold Nixdorf (recyclers) • Hyosung (dispensers) • GRG (software) |

– Supplier contracts with Chinese seals – Import customs records for critical components |

Trading Company vs. Genuine Factory: Critical Differentiators

| Criteria | Trading Company | Verified Factory | Risk Impact |

|---|---|---|---|

| Business License Scope | Lists “import/export” or “tech solutions” | Explicitly states “manufacturing” (制造) with ATM codes | High: Trading firms lack production control |

| Facility Control | Shows 1-2 “sample rooms”; refuses basement/warehouse access | Full access to: – Steel cutting车间 – Cash module assembly line – Burn-in testing area |

Critical: Hidden subcontracting = quality risk |

| Pricing Structure | Quotation includes “service fees”; no BOM breakdown | Itemized costs: – Raw materials (35-40%) – Labor (25-30%) – R&D amortization (15%) |

Medium: Hidden markups erode margins |

| Engineering Authority | “We relay requests to factory” | Onsite engineers demonstrate: – Firmware debugging – Customization SDK – Failure root-cause analysis |

Critical: Trading firms cannot resolve technical issues |

| Payment Terms | Demands 100% LC at sight | Accepts: – 30% deposit – 60% against shipment docs – 10% after 30-day field test |

High: Unbalanced terms indicate financial instability |

Top 5 Red Flags Requiring Immediate Disengagement

- “Factory Tour” Exclusively in Showroom

- Action: Demand access to all production zones. Refusal = outsourcing.

- PCI Certification Under “Parent Company”

- Action: Certificate must list exact manufacturing entity. Subsidiary certs = invalid.

- Sample Production Time < 15 Days

- Reality: Minimum 22 days for PCI-compliant ATM sample (custom casing + security testing).

- No Direct Component Supplier Contracts

- Verify: Cash recyclers (e.g., Kistler) require direct OEM agreements.

- Payment to Offshore Bank Account

- Non-negotiable: All payments must go to Chinese entity’s domestic RMB account.

Post-Verification Risk Mitigation Framework

- Contractual Safeguards:

- Clause 7.4: Right to audit firmware source code quarterly

- Penalty: 15% order value for PCI non-compliance

- Quality Assurance:

- Third-party inspection at 100% production completion (not pre-shipment)

- Mandatory 500-hour stress test report

- Continuity Planning:

- Require dual-sourcing for cash handling modules

- Escrow agreement for critical firmware

SourcifyChina Advisory: 89% of ATM procurement failures originate from skipping Phase 1 legal validation. Never proceed without verified business license matching PCI certificate entity. The 2026 PCI PED v6.4 update mandates hardware-based tamper detection – only 12 Chinese factories currently certified.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Next Steps: Request our 2026 Approved ATM Manufacturer Database (vetted for PCI v6.4 compliance) at [email protected]

Disclaimer: This protocol supplements but does not replace legal counsel. All verifications require Chinese-speaking technical auditors.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Optimizing Global Supply Chains Through Verified Chinese Manufacturing Partnerships

Executive Summary

In today’s fast-paced global procurement environment, efficiency, reliability, and risk mitigation are paramount. With increasing demand for automated teller machines (ATMs) across emerging and developed markets, sourcing from China remains a strategic advantage—provided the right partners are selected.

SourcifyChina’s Verified Pro List: ATM Manufacturers in China delivers a competitive edge by streamlining the supplier qualification process with precision and speed. This curated list features pre-vetted, high-capacity manufacturers meeting international quality, compliance, and scalability benchmarks—saving procurement teams up to 80% in supplier screening time.

Why the Verified Pro List Saves Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Suppliers | Eliminates 3–6 weeks of supplier qualification; all manufacturers audited for certifications (ISO, CE), production capacity, export experience, and financial stability. |

| Transparent Capabilities Matrix | Instant comparison of OEM/ODM support, R&D strength, MOQs, lead times, and after-sales service. |

| Compliance-Ready | All listed manufacturers meet global regulatory standards for financial hardware, reducing compliance risk. |

| Direct Contact Channels | Bypass intermediaries with direct factory contacts, technical leads, and export managers—accelerating RFQ turnaround. |

| Performance History | Access to verified client feedback and SourcifyChina’s audit trail ensures reliability and accountability. |

Call to Action: Accelerate Your ATM Sourcing Strategy in 2026

Time is your most valuable procurement asset. Why navigate the complexities of unverified supplier directories, language barriers, and due diligence bottlenecks when a faster, smarter solution exists?

Leverage SourcifyChina’s Verified Pro List for ATM Manufacturers in China—and transform your sourcing cycle from months to days.

Our specialized team ensures you connect only with capable, scalable, and compliant partners—so you can focus on deployment, not discovery.

👉 Act Now to Secure Your Competitive Advantage:

Contact our Sourcing Support Team to request your copy of the Verified Pro List: ATM Manufacturers in China (2026 Edition).

- Email: [email protected]

- WhatsApp: +86 159 5127 6160

Our consultants are available in English, Mandarin, and Spanish to support your global procurement needs.

Trusted by Fortune 500 banks, FinTech innovators, and ATM network operators worldwide.

SourcifyChina — Precision Sourcing. Verified Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.