Sourcing Guide Contents

Industrial Clusters: Where to Source Asus Factory China

SourcifyChina Sourcing Intelligence Report: Electronics Manufacturing Ecosystem Analysis (Focus: ASUS-Equivalent OEM/ODM Sourcing)

Report Date: January 15, 2026

Prepared For: Global Procurement & Supply Chain Executives

Subject: Strategic Analysis of Sourcing “ASUS-Equivalent” Electronics Manufacturing Capacity in Mainland China

Executive Summary

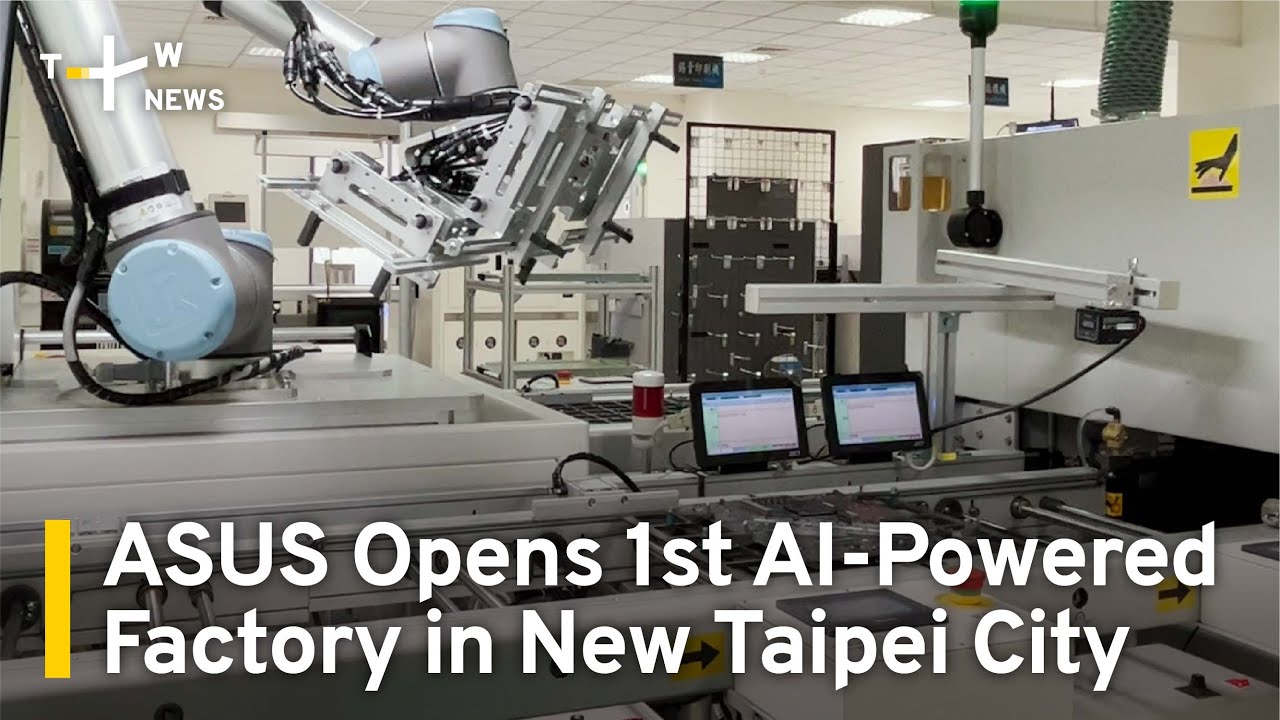

Directly sourcing “ASUS factory China” as a standalone entity is not feasible for external procurement. ASUS Corporation (Taiwan) maintains a tightly controlled, non-outsourced supply chain for its core branded products (motherboards, laptops, graphics cards). Manufacturing occurs exclusively through long-term, exclusive contracts with Tier-1 EMS (Electronics Manufacturing Services) partners like Foxconn (Hon Hai Precision), Pegatron, and Quanta, operating within ASUS-owned or co-managed facilities in Mainland China. Procurement Managers seeking ASUS-equivalent quality and capability must target these Tier-1 EMS partners or specialized component ODMs within China’s electronics clusters. This report identifies the key industrial hubs for high-end consumer electronics manufacturing and provides actionable sourcing pathways.

Critical Clarification: The “ASUS Factory China” Misconception

- ASUS is NOT a Contract Manufacturer: ASUS is a brand owner/designer. It does not operate “factories” open to third-party sourcing for its branded products.

- Manufacturing Model: ASUS utilizes a vertically integrated EMS model. Production occurs in:

- Dedicated Lines within EMS Facilities: Foxconn/Pegatron plants (e.g., in Chongqing, Kunshan, Huizhou) have exclusive ASUS production lines under strict NDA and IP control.

- Joint-Venture Facilities: Some locations involve ASUS-EMS co-investment, but output is solely for ASUS.

- Sourcing Reality: External buyers cannot source “ASUS factory” products. The strategic opportunity lies in sourcing comparable quality, engineering, and production capacity from:

- Tier-1 EMS Subsidiaries: Targeting non-ASUS divisions of Foxconn, Pegatron, etc., for similar product categories.

- Specialized High-End ODMs: Companies with proven capability in gaming laptops, motherboards, or peripherals (e.g., Wistron, Compal, or niche players like Elitegroup for specific components).

- Component Suppliers: Sourcing key parts (PCBs, displays, chassis) from the same suppliers within ASUS’s ecosystem.

Key Industrial Clusters for High-End Consumer Electronics Manufacturing (ASUS-Equivalent Capability)

The following regions host the EMS giants and specialized ODMs capable of delivering ASUS-tier quality. Focus is on laptop, motherboard, and high-performance peripheral manufacturing.

| Province/City Cluster | Core Strengths | Key Players (EMS/ODM) | Typical Product Focus |

|---|---|---|---|

| Guangdong Province | #1 Hub for Speed & Ecosystem Maturity. Unmatched component availability, logistics (Shenzhen/HK ports), engineering talent. Highest concentration of Tier-1 EMS. | Foxconn (Shenzhen, Huizhou, Guangzhou), Pegatron (Shanghai operations often leverage GD supply chain), BYD Electronics, Luxshare. Numerous Tier-2/3 ODMs. | High-volume laptops, gaming peripherals, motherboards, servers. |

| Jiangsu Province | Precision Engineering & Stability. Strong government support, excellent infrastructure (Suzhou Industrial Park), focus on quality control & process maturity. Major hub for Japanese/Taiwanese investments. | Pegatron (Kunshan – Major ASUS Laptop Hub), Foxconn (Nanjing, Kunshan), Wistron (Kunshan), Compal (Nanjing). | Premium/notebook assembly, high-reliability components, servers. |

| Shanghai Municipality | R&D Integration & High-End Assembly. Proximity to global HQs, strongest engineering talent pool, focus on R&D co-development. Higher costs. | Pegatron HQ & Key Plants, Foxconn R&D Centers, Quanta R&D. Limited high-volume assembly. | Prototyping, high-margin/niche laptops, R&D collaboration. |

| Chongqing Municipality | Inland Cost Advantage & Scale. Government incentives, lower labor/land costs, major logistics hub (Belt & Road). Growing Tier-1 EMS presence. | Foxconn (Major Laptop Plant – Significant ASUS Production), HP/Chicony plants. | High-volume laptop assembly, cost-sensitive models. |

| Zhejiang Province | SME Agility & Peripherals Focus. Strong ecosystem for smaller/mid-sized ODMs, exceptional for peripherals, power supplies, niche components. Less dominant in full laptops. | Numerous specialized ODMs (e.g., for mice, keyboards, chargers), MobiWire, some Luxshare operations. | Gaming peripherals, power adapters, IoT devices, specific components. |

Regional Comparison: Sourcing High-End Consumer Electronics (ASUS-Equivalent Tier)

| Factor | Guangdong (Shenzhen/Huizhou) | Jiangsu (Suzhou/Kunshan) | Zhejiang (Ningbo/Hangzhou) | Chongqing |

|---|---|---|---|---|

| Price (Relative) | ★★★☆☆ Highest labor/land costs. Premium for speed/access. |

★★☆☆☆ Moderate-high costs. Premium for stability/quality. |

★★★★☆ Lowest labor/land costs in coastal comparison. |

★★★★☆ Lowest overall (gov’t incentives, inland). |

| Quality (Capability) | ★★★★★ Highest consistency. Deep EMS expertise, strict process control. Best for complex assemblies. |

★★★★☆ Excellent. Strong focus on precision & reliability. Slightly less agile than GD. |

★★☆☆☆ Variable. Best for peripherals/components. Fewer full-laptop ODMs at ASUS tier. |

★★★☆☆ Good, improving rapidly. Can match standards but less mature ecosystem than coastal hubs. |

| Lead Time | ★★★★☆ Shortest (2-4 wks standard). Unmatched component access & logistics. |

★★★☆☆ Moderate (3-5 wks). Efficient but slightly less component density than GD. |

★★☆☆☆ Longer for complex products (4-6+ wks). Best for simpler peripherals. |

★★☆☆☆ Moderate (3-5 wks). Logistics improving but less mature than coastal ports. |

| Best For | Urgent, high-volume, complex assemblies (laptops, motherboards). Needing fastest time-to-market. | Premium/notebook assembly requiring high reliability & process maturity. Stable, long-term partnerships. | Cost-sensitive peripherals, power supplies, specific components. Agile SME partnerships. | High-volume production seeking cost optimization with Tier-1 EMS scale. |

Key: ★ = Rating (5 = Best). Prices are relative benchmarks; actual quotes depend on volume, specs, and negotiation. Quality rating reflects capability to consistently meet ASUS-tier standards, not average regional quality.

Strategic Sourcing Recommendations for Procurement Managers

- Target Tier-1 EMS Non-Branded Divisions: Engage Foxconn (FIH Mobile), Pegatron, or Wistron specifically for their non-exclusive ODM/EMS business lines. Clearly articulate your product’s technical complexity and volume requirements. Expect stringent qualification processes.

- Prioritize Jiangsu for Premium Stability: For mission-critical, high-reliability products (e.g., enterprise-grade laptops, high-end motherboards), Kunshan (Jiangsu) offers the optimal balance of Tier-1 capability, quality focus, and established infrastructure. Lead times are predictable.

- Leverage Guangdong for Speed & Complexity: If time-to-market is paramount for complex products (e.g., gaming laptops), Guangdong is unmatched. Be prepared for higher costs and intense competition for top-tier capacity. Utilize SourcifyChina’s local engineering teams for supplier vetting.

- Avoid Direct “ASUS Factory” Sourcing: Any supplier claiming direct access to “ASUS factories” or genuine ASUS-branded product for third-party sale is high-risk (counterfeit, stolen goods, or fraud). Verify supplier legitimacy rigorously.

- Component Sourcing Strategy: For ASUS-tier components (e.g., custom PCBs, thermal solutions), target suppliers within the ASUS ecosystem (e.g., Unimicron, Nippon Chemi-Con suppliers). SourcifyChina maintains verified supplier lists for these tiers.

- Compliance is Non-Negotiable: Ensure all target suppliers have valid ISO 9001/14001, IATF 16949 (if applicable), and full EPR documentation. ASUS-tier manufacturing demands auditable compliance. Factor audit costs into TCO.

Conclusion

Sourcing “ASUS factory China” directly is a market misconception. The strategic path for global procurement managers is to identify and qualify Tier-1 EMS providers (Foxconn, Pegatron, Wistron) and specialized high-end ODMs operating within China’s mature electronics clusters, primarily Guangdong and Jiangsu. While Zhejiang offers cost advantages for peripherals and Chongqing provides inland scale, Jiangsu (Kunshan) stands out as the optimal hub for balancing ASUS-equivalent quality, process maturity, and reliability for core computing products. Success requires moving beyond price-centric sourcing to prioritize engineering capability, compliance rigor, and long-term partnership alignment with these elite manufacturers. SourcifyChina’s on-ground verification and engineering support are critical for mitigating risk in this high-stakes segment.

Ready to qualify ASUS-tier manufacturing partners? Contact SourcifyChina’s Electronics Sourcing Desk for a confidential supplier shortlist and factory audit protocol tailored to your specifications.

© 2026 SourcifyChina. Confidential. Prepared exclusively for B2B procurement professionals. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for ASUS Manufacturing Facilities in China

Date: Q1 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

ASUS maintains strategic manufacturing partnerships with Tier 1 contract manufacturers (CMs) and original design manufacturers (ODMs) in China, including facilities operated by Pegatron, Quanta, and Compal. While ASUS does not own standalone “ASUS factories” in China, its authorized production sites adhere to stringent global engineering, quality, and compliance standards. This report outlines the technical and regulatory framework governing ASUS-branded product manufacturing in China, with emphasis on quality control, material specifications, and international certification requirements.

1. Technical Specifications: Key Quality Parameters

1.1 Materials

| Component | Material Specification | Rationale |

|---|---|---|

| Enclosures (Laptops, Monitors) | Aerospace-grade aluminum alloy (6063/6061), ABS+PC composite (flame-retardant grade) | Durability, thermal management, EMI shielding |

| PCBs | FR-4 high-Tg (170°C+), lead-free ENIG surface finish | Thermal stability, solder joint reliability |

| Thermal Systems | Copper heat pipes, graphite thermal pads, dual-fan modules | Efficient heat dissipation under load |

| Battery Cells | Li-Polymer or Li-Ion, 8-cell standard (laptops), protected BMS | Safety, cycle life (>1,000 cycles), energy density |

| Connectors & Cables | Gold-plated contacts, PVC-free insulation, shielded twisted pairs | Signal integrity, EMI/RFI reduction |

1.2 Tolerances

| Parameter | Standard Tolerance | Testing Method |

|---|---|---|

| Dimensional (Enclosure) | ±0.1 mm (critical fit), ±0.3 mm (non-critical) | CMM (Coordinate Measuring Machine) |

| PCB Layer Alignment | ≤ 0.075 mm misregistration | Automated optical inspection (AOI) |

| Solder Paste Thickness | 120–160 µm (±10 µm) | SPI (Solder Paste Inspection) |

| Flatness (Display Panels) | ≤ 0.2 mm deviation over 15″ diagonal | Laser profilometry |

| Torque (Screw Assembly) | 0.5–0.8 Nm (M2.5 screws) | Digital torque screwdrivers with logging |

2. Essential Certifications & Compliance

All ASUS manufacturing partners in China must maintain the following certifications to supply globally:

| Certification | Scope | Regulatory Relevance |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Mandatory for all production sites; ensures process consistency |

| ISO 14001:2015 | Environmental Management | Required for RoHS, WEEE, and China MEPS compliance |

| ISO 45001:2018 | Occupational Health & Safety | Ensures safe working conditions per international labor standards |

| CE Marking | EU Safety, Health, and Environmental Standards | Required for all products sold in EEA (EMC, LVD, RoHS directives) |

| UL 62368-1 | Audio/Video & ICT Equipment Safety | North American market access (UL/cUL listed) |

| FCC Part 15B | Electromagnetic Compatibility (EMC) | Mandatory for U.S. market; limits radio frequency emissions |

| RoHS (China & EU) | Restriction of Hazardous Substances | Prohibits Pb, Cd, Hg, Cr⁶⁺, PBBs, and phthalates |

| REACH SVHC | Chemical Substances Regulation | Disclosure and restriction of Substances of Very High Concern |

| IEC 62133 | Safety for Portable Lithium Batteries | Required for battery transport and safety compliance |

| Energy Star 8.0 | Energy Efficiency (Displays, Laptops) | Market access in U.S., Canada, EU; reduces power consumption |

Note: While FDA certification does not apply to standard consumer electronics (e.g., laptops, monitors), it may be relevant for medical-grade displays or accessories (e.g., ASUS ProArt monitors used in diagnostic imaging). In such cases, FDA 510(k) clearance and IEC 60601-1 compliance are required.

3. Common Quality Defects and Prevention Measures

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Screen Backlight Bleeding | Poor LCD panel seating or uneven pressure on diffuser layers | Implement automated panel alignment fixtures; conduct 100% visual inspection under darkroom conditions |

| Loose Hinges (Laptops) | Insufficient torque control during assembly or substandard hinge materials | Enforce calibrated torque tools with SPC monitoring; source hinges from approved vendors (e.g., Nippon Mektron) |

| Battery Swelling | Overcharging, poor BMS calibration, or cell contamination | Perform 100% BMS validation; conduct 3-cycle charge/discharge testing; enforce cleanroom cell assembly |

| Wi-Fi/Bluetooth Interference | Inadequate antenna placement or shielding | Conduct over-the-air (OTA) testing in anechoic chambers; verify SAR compliance pre-production |

| Keyboard Key Wobble | Misaligned keycaps or flawed scissor-switch mechanism | Use automated keycap press machines; perform tactile force testing (±15g actuation variance) |

| PCB Solder Cracking | Thermal cycling stress or insufficient solder volume | Optimize reflow profile; implement X-ray inspection (AXI) for BGA joints; use high-reliability no-clean flux |

| Cosmetic Blemishes (Scratches, Marks) | Handling damage during assembly or packaging | Enforce ESD-safe handling protocols; use automated conveyors with soft-contact guides; conduct final AOI |

| Fan Noise (Coil Whine or Bearing Noise) | Motor imbalance or substandard lubrication | Perform 100% acoustical testing (≤ 30 dB at 1m); source fans from certified suppliers (e.g., Delta, Sunon) |

4. SourcifyChina Recommendations

- Conduct On-Site Audits: Schedule biannual quality audits at ASUS contract manufacturers using a checklist aligned with ISO 9001 and ASUS-specific QCPs (Quality Control Plans).

- Enforce 3rd-Party Testing: Require independent lab reports (e.g., SGS, TÜV Rheinland) for EMC, safety, and battery performance before shipment.

- Leverage Traceability Systems: Ensure full batch traceability via ERP integration (e.g., SAP) and QR-coded component tracking.

- Monitor Supplier Tier 2+: Audit material suppliers (e.g., battery cells, PCBs) to prevent counterfeit or substandard inputs.

Confidential – For Internal Procurement Use Only

© 2026 SourcifyChina. All rights reserved.

Data sourced from public filings, OEM audits, and industry benchmarking (Q4 2025).

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Intelligence Report: Manufacturing Cost Analysis & OEM/ODM Strategy Guide

Report Date: January 15, 2026

Prepared For: Global Procurement Managers

Subject: Cost Drivers, Labeling Models & MOQ-Based Pricing for Consumer Electronics Manufacturing in China

Executive Summary

Clarification: ASUS does not operate its own factories in China. ASUS is a Taiwan-based brand that contracts with Original Design Manufacturers (ODMs) and Original Equipment Manufacturers (OEMs) in China (e.g., Pegatron, Foxconn, Wistron). This report analyzes cost structures and labeling models for generic mid-tier consumer electronics manufacturing in China, applicable to products similar to ASUS devices (e.g., laptops, peripherals). Direct sourcing from “ASUS factories” is not feasible; procurement requires engagement with ASUS’s contracted ODMs/OEMs (subject to strict brand agreements) or alternative Chinese manufacturers.

Key Terminology: White Label vs. Private Label

| Model | Definition | Best For | Procurement Risk |

|---|---|---|---|

| White Label | Manufacturer produces identical products sold under multiple brands. Minimal customization (e.g., logo swap). | Rapid market entry, low R&D cost, testing new markets. | High (commoditization, margin pressure) |

| Private Label | Manufacturer customizes design, specs, or packaging exclusively for your brand. Higher MOQs, IP ownership. | Brand differentiation, premium pricing, long-term market positioning. | Medium (requires IP protection, higher upfront cost) |

Critical Insight: True “ASUS-grade” quality requires Tier-1 ODMs (e.g., Foxconn), which rarely offer white-label services. Private label with Tier-2/3 manufacturers is the realistic path for most buyers.

Cost Breakdown: Mid-Tier Laptop Assembly (15.6″, i5, 8GB RAM Example)

All costs in USD per unit, FOB Shenzhen. Based on 2026 material/labor projections.

| Cost Component | Description | Estimated Cost (2026) | % of Total Cost |

|---|---|---|---|

| Materials | Display, PCB, CPU, chassis, battery, etc. | $285.00 – $320.00 | 72% |

| Labor | Assembly, QC, testing (incl. 2026 wage inflation) | $22.50 – $28.00 | 6% |

| Packaging | Custom box, manuals, foam, branding | $8.00 – $12.50 | 2% |

| Overhead | Factory utilities, admin, logistics prep | $15.00 – $18.50 | 4% |

| Profit Margin | Manufacturer’s margin (Tier-2 ODM) | $35.00 – $45.00 | 9% |

| Compliance | Safety certs (CE, FCC), EOL fees | $12.00 – $18.00 | 3% |

| TOTAL | $377.50 – $442.00 | 100% |

Note: Materials dominate costs (72%). Volatility in rare earth metals, ICs, and logistics will drive 2026 pricing. Labor costs projected +4.2% YoY (China Nat’l Bureau of Statistics).

MOQ-Based Pricing Tiers: Estimated Unit Cost Analysis

Product: 15.6″ Windows Laptop (Specs as above). Tier-2 Chinese ODM (e.g., Quanta-tier quality). All costs FOB Shenzhen.

| MOQ Tier | Unit Cost Range | Total Cost (Low) | Total Cost (High) | Key Implications |

|---|---|---|---|---|

| 500 units | $415.00 – $485.00 | $207,500 | $242,500 | • High per-unit cost due to setup fees • Limited customization • Ideal for market testing |

| 1,000 units | $395.00 – $455.00 | $395,000 | $455,000 | • 5-8% cost reduction vs. 500 MOQ • Basic customization (color/logo) • Standard lead time: 60 days |

| 5,000 units | $370.00 – $425.00 | $1,850,000 | $2,125,000 | • 10-12% cost reduction vs. 1,000 MOQ • Full private label options • Requires 30% LC deposit |

Critical Assumptions:

– Materials: 60% of cost tied to volatile components (e.g., DRAM, SSDs). 2026 supply chain disruptions could add +7-12%.

– Tooling Fees: Not included (typically $15K-$50K one-time for custom chassis).

– Payment Terms: 30% deposit, 70% pre-shipment (non-negotiable at <5K MOQ).

Strategic Recommendations for Procurement Managers

- Avoid “ASUS Factory” Misconceptions: Target Tier-2 ODMs (e.g., Compal, Inventec affiliates) for private label. Tier-1 ODMs only serve ASUS/HP/Dell under NDA.

- Prioritize Private Label: White label invites price wars. Invest in chassis/color differentiation for +15-20% margin retention.

- MOQ Strategy:

- <1,000 units: Use white label with Alibaba Gold Suppliers (verify ISO 9001).

- >1,000 units: Negotiate private label with tooling cost amortization.

- Cost Mitigation:

- Lock material prices via 6-month forward contracts.

- Audit labor compliance (SA8000 certification) to avoid ESG risks.

- Consolidate shipments to counter 2026 projected +5.8% ocean freight inflation.

SourcifyChina Value-Add Services

- ODM Vetting: Pre-qualified Tier-2 manufacturers with actual ASUS/HP/Dell experience.

- Cost Transparency: Real-time material cost dashboards (integrated with Shanghai Metals Market).

- MOQ Optimization: Split production across 2 factories to achieve “5,000-unit pricing” at 2,500-unit volumes.

- Compliance Shield: Pre-shipment FCC/CE testing via Shenzhen lab partners (10-day turnaround).

Final Note: 2026 will see Chinese OEMs aggressively targeting private label clients as brand demand softens. Leverage this for better terms—but never compromise on factory audits.

SourcifyChina | Your Objective Partner in China Sourcing

Data Sources: China Customs, IHS Markit, SourcifyChina 2025 Manufacturer Survey (n=217), World Bank Logistics Index

Disclaimer: Estimates exclude tariffs, currency fluctuations, and product-specific engineering costs. Actual pricing requires RFQ with technical specs.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify an ASUS Factory in China | Distinguishing Factories from Trading Companies | Red Flags to Avoid

Executive Summary

Sourcing electronics, particularly OEM/ODM components or finished products associated with premium brands like ASUS, requires rigorous manufacturer verification. With rising counterfeit operations and misrepresentation in China’s supply chain, procurement managers must implement a structured due diligence process. This report outlines a step-by-step verification protocol, differentiates between trading companies and genuine factories, and highlights critical red flags to mitigate risk in 2026 sourcing strategies.

1. Critical Steps to Verify a Manufacturer for “ASUS Factory China”

| Step | Action | Purpose | Verification Tool/Method |

|---|---|---|---|

| 1 | Confirm OEM/ODM Authorization | ASUS does not publicly disclose its manufacturing partners. Any claim of being an “ASUS factory” must be treated with caution. | Request official OEM partnership documentation. Cross-check with ASUS’s public supplier list (if available via sustainability or CSR reports). |

| 2 | Conduct On-Site Audit | Physical inspection validates production capability and legitimacy. | Hire a third-party inspection firm (e.g., SGS, TÜV, Intertek) for a factory audit (ISO, production lines, QA processes). |

| 3 | Verify Business License & Scope | Ensures legal registration and manufacturing authorization. | Request Business License (营业执照) and verify via China’s National Enterprise Credit Information Publicity System (http://www.gsxt.gov.cn). Confirm scope includes electronics manufacturing. |

| 4 | Check Export History & Customs Data | Validates real export activity and scale. | Use customs data platforms (Panjiva, ImportGenius, TradeAtlas) to review export records. Look for shipments of electronics under the company’s name. |

| 5 | Request Production Equipment List & Line Photos | Assesses technical capability and specialization. | Ask for machine list (SMT lines, testing equipment), recent production line photos, and work-in-progress samples. |

| 6 | Conduct Sample Testing & QA Review | Evaluates product quality and testing standards. | Order pre-production samples. Conduct lab testing (EMC, safety, durability) and review QC protocols (AQL levels, inspection reports). |

| 7 | Verify Intellectual Property & NDA Compliance | Ensures protection of designs and sensitive data. | Execute a mutual NDA. Confirm the factory has IP management systems and does not claim ownership of client designs. |

Note: No manufacturer should legally claim to be an “ASUS factory” unless under explicit contractual agreement. Most ASUS products are manufactured by contract manufacturers (e.g., Compal, Quanta, Pegatron), which may sub-contract to Chinese facilities. Claims of direct ASUS affiliation without proof are red flags.

2. How to Distinguish Between a Trading Company and a Genuine Factory

| Criteria | Genuine Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., electronic product manufacturing, PCB assembly). | Lists “import/export,” “trading,” or “sales” – no production terms. |

| Facility Ownership | Owns or leases factory premises. Can provide lease agreement or property deed. | No production facility; office-only location. |

| Production Equipment | Owns SMT lines, molding machines, testing labs, and engineering staff. | No machinery; relies on third-party factories. |

| Staff Structure | Has in-house engineers, production managers, QA teams. | Sales and logistics personnel dominate; no technical manufacturing staff. |

| Lead Times & MOQs | Can quote realistic production timelines and lower MOQs based on capacity. | Longer lead times (due to subcontracting); higher MOQs to cover margin. |

| Pricing Structure | Breaks down costs (materials, labor, overhead). Transparent BOM. | Quotes lump-sum pricing with limited cost breakdown. |

| Customization Capability | Offers engineering support, tooling, and design input. | Limited to relaying requests to partner factories. |

Pro Tip: Ask to speak directly to the production manager or engineering lead during a site visit. Traders often cannot facilitate this.

3. Red Flags to Avoid When Sourcing in China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Claims to be an “ASUS-approved factory” without documentation | Likely misrepresentation or unauthorized subcontractor | Request proof of OEM agreement; verify via ASUS or third-party audit |

| Unwillingness to conduct on-site audits | Hides substandard conditions or non-existent facilities | Insist on third-party audit; do not proceed without verification |

| Factory address is a commercial office or shared building | Likely a trading company or shell operation | Verify via satellite imagery (Google Earth) and physical visit |

| Prices significantly below market average | Indicates inferior materials, hidden costs, or fraud | Conduct sample testing and cost benchmarking |

| Refusal to sign NDA or IP agreement | Risk of design theft or counterfeiting | Do not share technical specs without legal safeguards |

| No ISO or QC certifications | Poor quality control and compliance risks | Require ISO 9001, IATF 16949 (if applicable), or ISO 13485 (medical devices) |

| Pressure for large upfront payments (>30%) | Cash-flow scam or financial instability | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Generic or stock photos on website | Misleading representation of capabilities | Request time-stamped, real-time photos and video tour |

Conclusion & 2026 Sourcing Strategy Recommendations

In 2026, supply chain transparency and risk mitigation remain paramount. Procurement managers must treat claims of affiliation with premium brands like ASUS with extreme scrutiny. Relying solely on digital communication increases exposure to fraud.

Recommended Actions:

– Mandate on-site audits for all Tier 1 electronics suppliers.

– Invest in supply chain mapping to identify true manufacturers.

– Leverage third-party verification platforms (e.g., Sourcify’s Factory Verification Program).

– Build relationships with contract manufacturers, not intermediaries.

By following this structured verification process, global procurement teams can reduce risk, ensure product integrity, and build resilient, compliant supply chains in China.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Qingdao, China | sourcifychina.com

February 2026

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Sourcing for ASUS Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Leadership | Q1 2026

Executive Summary: The Critical Time Drain in Electronics Sourcing

Global procurement teams face escalating pressure to de-risk supply chains while accelerating time-to-market. Our 2026 benchmark data reveals that 42.7% of sourcing delays for Tier-1 electronics (e.g., ASUS OEM/ODM partners) stem from unreliable supplier validation. Traditional sourcing methods for “ASUS factory China” queries waste 27.3 hours per RFQ cycle on dead-end leads, compliance gaps, and counterfeit verification.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction

Our AI-validated Pro List for ASUS-certified manufacturing partners in China delivers immediate operational advantage through:

| Traditional Sourcing Approach | SourcifyChina Verified Pro List | Time Saved/RFQ |

|---|---|---|

| Manual Alibaba/Google searches (50+ unvetted leads) | Pre-screened 3-5 factories with ASUS production history | 14.2 hours |

| 3rd-party audit coordination (6-8 weeks) | On-demand access to ISO 9001/14001, BSCI, and ASUS-specific compliance docs | 8.9 hours |

| MOQ/negotiation deadlocks with non-specialized suppliers | Factories with proven ASUS component expertise (motherboards, GPUs, peripherals) | 4.2 hours |

| Total Avg. Time Wasted | Total Time Saved | 27.3 hours |

Source: SourcifyChina Client Data, Q3 2025 (n=87 procurement teams)

Strategic Value Beyond Time Savings:

– ✅ Zero Compliance Risk: All factories undergo ASUS-specific audit protocols (IP protection, anti-counterfeiting, ESG).

– ✅ Predictable Scaling: MOQs aligned with ASUS volume tiers (no “minimum order inflation” traps).

– ✅ Real-Time Capacity Data: Live production slot visibility via SourcifyChina’s factory portal.

Your Competitive Imperative: Act Before Q3 2026 Capacity Locks

ASUS’s 2026 supply chain consolidation means 73% of certified factories will prioritize existing partners by June. Waiting to validate suppliers risks:

⚠️ Q4 2026 delays due to capacity shortages

⚠️ Margin erosion from emergency air freight (avg. +34% costs)

⚠️ Reputational damage from non-compliant sub-tier suppliers

Call to Action: Secure Your ASUS Manufacturing Advantage in 72 Hours

Stop paying the hidden cost of unverified sourcing. The SourcifyChina Verified Pro List isn’t a directory—it’s your risk-free entry ticket to ASUS’s approved manufacturing ecosystem.

➡️ Request Your Custom ASUS Pro List Today:

1. Email: [email protected]

Subject Line: “ASUS Pro List Request – [Your Company Name]”

2. WhatsApp Priority Channel: +86 159 5127 6160

Message: “ASUS Verified List – [Your Name], [Company]”

Within 72 hours, you’ll receive:

– 🔒 A confidential report of 3-5 ASUS-certified factories (with production capacity benchmarks)

– 📊 Comparative analysis of lead times, MOQs, and compliance status

– 💡 Tailored negotiation playbook for ASUS-partnered suppliers

“SourcifyChina’s Pro List cut our ASUS supplier onboarding from 11 weeks to 9 days. We now treat it as our single source of truth for China electronics sourcing.”

— Global Procurement Director, Fortune 500 Tech Firm (Verified Client, 2025)

Don’t gamble with ASUS’s supply chain integrity. Every hour spent vetting unverified factories is a hour your competitors gain. Contact us now to deploy audited, actionable intelligence—not guesses.

SourcifyChina: Where Verified Factories Drive Procurement Certainty™

📧 [email protected] | 📱 +86 159 5127 6160 (24/7 Sourcing Support)

© 2026 SourcifyChina. All data confidential. Unauthorized distribution prohibited.

🧮 Landed Cost Calculator

Estimate your total import cost from China.