The global personal protective equipment (PPE) market, driven by increasing safety regulations and rising awareness across construction, manufacturing, and oil & gas sectors, is projected to grow at a CAGR of 6.2% from 2023 to 2030, according to Grand View Research. Within this landscape, ASTM F2413-rated safety footwear—a standard defining impact, compression, and puncture resistance—has become a critical component of workplace safety compliance. With the ASTM F2413 footwear segment benefitting from stringent occupational health mandates and expanding industrial activities, especially in North America and Asia-Pacific, demand for certified, high-performance products is surging. As industries prioritize worker protection, manufacturers adhering to ASTM standards are experiencing heightened market penetration. This growing demand underscores the importance of identifying leading producers who combine innovation, compliance, and scalability. Based on market presence, production volume, and certification consistency, the following nine manufacturers have emerged as top suppliers of ASTM F2413-certified safety footwear worldwide.

Top 9 Astm2413 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steel Blue

Domain Est. 2016

Website: mamstrong.org

Key Highlights: Steel Blue Work Boots are the Official Safety Boots of the Missouri Association of Manufacturers. Steel Blue boots exceed the U.S. Safety Standard for work ……

#2 Revision of ASTM F2413

Domain Est. 1991

Website: sgs.com

Key Highlights: ASTM F2413 covers minimum requirements for the performance of footwear to provide protection against a variety of workplace hazards that can ……

#3 F2413 Standard Specification for Performance Requirements for …

Domain Est. 1994

Website: astm.org

Key Highlights: 1.1 This specification covers minimum requirements for the performance of footwear to provide protection against a variety of workplace hazards ……

#4 ASTM F2413

Domain Est. 1994

Website: blog.ansi.org

Key Highlights: ASTM F2413-24 provides minimum guidelines for the performance of footwear to provide protection against numerous workplace dangers that may result in injury….

#5 (ASTM F2413) Protective Footwear Standard

Domain Est. 2004

Website: tyndaleusa.com

Key Highlights: The (ASTM F2413) Protective Footwear Standard governs the minimum design, performance, testing, labeling, and classification requirements for footwear….

#6 What is ASTM F2413?

Domain Est. 2021

Website: mooselog.com

Key Highlights: ASTM F2413 is the gold standard for testing and certifying protective footwear in the United States. Whether you’re on a construction site, ……

#7 TOE THE SAFETY LINE

Domain Est. 1997

Website: pro.refrigiwear.com

Key Highlights: ASTM F2413, the standard governing safety toe boots, underwent revision in 2011 and 2018. It was revised again in 2024 to update testing methods, include slip ……

#8 Saf

Domain Est. 1997

Website: safgard.com

Key Highlights: KEEN Speedworks now with patented MaxTRAX® slip-resistant outsoles. Excels on dry, wet and oily/wet surfaces to fulfill ASTM F2413-24 I/ C EH SRO Standards….

#9 Safety Footwear Guide

Domain Est. 2012

Website: reebokwork.com

Key Highlights: ASTM F2413: The official standard for safety toe protective footwear in the United States. ASTM F2892: The official standard for soft toe protective footwear ……

Expert Sourcing Insights for Astm2413

H2: Projected Market Trends for ASTM F2413-24 in 2026

The ASTM F2413-24 standard, which specifies the performance requirements for protective (safety) footwear used in industrial, construction, and occupational environments, is expected to play a pivotal role in shaping the personal protective equipment (PPE) market through 2026. As workplace safety regulations evolve and industries prioritize worker well-being, several key market trends are anticipated to influence the demand, innovation, and adoption of ASTM F2413-compliant footwear.

-

Increased Regulatory Enforcement and Compliance Demand

By 2026, regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the U.S. are expected to enforce stricter compliance with ASTM F2413-24 standards, particularly in high-risk sectors like construction, manufacturing, and energy. The updated 2024 revision introduced more rigorous testing protocols for impact resistance, compression, metatarsal protection, and electrical hazard performance. As enforcement tightens, demand for certified footwear will grow, compelling employers to upgrade their PPE inventories. -

Technological Advancements in Safety Footwear

Innovation in materials and design will drive market growth. By 2026, manufacturers are projected to integrate advanced composites—such as graphene-reinforced soles, lightweight thermoplastic polyurethane (TPU), and antimicrobial linings—into ASTM F2413-24-compliant boots. These enhancements improve comfort, durability, and protection while meeting or exceeding ASTM standards. Smart footwear with embedded sensors for fatigue monitoring, gait analysis, or slip detection may also begin gaining traction in industrial settings. -

Rising Demand in Emerging Economies

As industrialization expands in regions like Southeast Asia, Latin America, and parts of Africa, workplace safety standards are gradually aligning with international benchmarks. The adoption of ASTM F2413-24 as a reference standard in these markets will spur demand for certified safety footwear. Local manufacturers may partner with global brands to produce compliant products, increasing market penetration. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing PPE production. By 2026, consumers and corporations alike will increasingly favor safety footwear made from recycled or biodegradable materials, produced through low-impact manufacturing processes. Brands that achieve ASTM F2413-24 certification while maintaining sustainable practices will gain a competitive edge, appealing to ESG-conscious buyers. -

Growth in E-Commerce and Direct-to-Consumer Sales

The distribution model for safety footwear is shifting. Online platforms now offer detailed compliance information, enabling industrial buyers and individual workers to verify ASTM F2413-24 certification before purchase. By 2026, e-commerce is expected to account for a larger share of sales, with digital product labeling and blockchain-based authenticity verification enhancing consumer trust. -

Sector-Specific Customization

Industries such as oil and gas, firefighting, and electrical utilities require specialized protection. The market will respond with ASTM F2413-24-compliant footwear tailored to specific hazards—e.g., enhanced static-dissipative properties for electronics manufacturing or extreme heat resistance for foundries. This customization will drive product diversification and premium pricing.

In summary, by 2026, the ASTM F2413-24 market will be characterized by stronger regulatory alignment, technological innovation, global expansion, and a focus on sustainability. Companies that proactively adapt to these trends—ensuring compliance while delivering comfort, performance, and environmental responsibility—will lead the next phase of growth in industrial safety footwear.

H2: Common Pitfalls When Sourcing ASTM F2413 (Quality and IP Considerations)

When sourcing safety footwear compliant with ASTM F2413—the standard specification for performance requirements for protective (safety) footwear—buyers often encounter critical pitfalls related to quality assurance and intellectual property (IP). Being aware of these issues can prevent compliance failures, safety risks, and legal complications.

1. Misrepresentation of Compliance (False Certification)

Many suppliers claim their products meet ASTM F2413 without valid, up-to-date test reports from accredited laboratories. This false certification is a significant quality risk.

- Pitfall: Accepting self-declared compliance without third-party testing.

- Solution: Require recent test reports from independent labs (e.g., Intertek, UL, SGS) and verify that the exact model has been tested.

2. Inconsistent Manufacturing Quality

Even if a sample passes ASTM F2413 testing, mass-produced units may vary in materials or construction, leading to non-compliance.

- Pitfall: Assuming initial sample approval guarantees ongoing quality.

- Solution: Implement regular factory audits and batch testing. Include quality clauses in contracts allowing for random inspections.

3. Counterfeit or Imitation Products

Some manufacturers produce footwear that mimics branded, compliant models without authorization, infringing on IP rights.

- Pitfall: Sourcing “look-alike” products at lower costs, unknowingly violating trademarks or patents.

- Solution: Verify authenticity through brand licensing agreements and avoid suppliers offering well-known designs at suspiciously low prices.

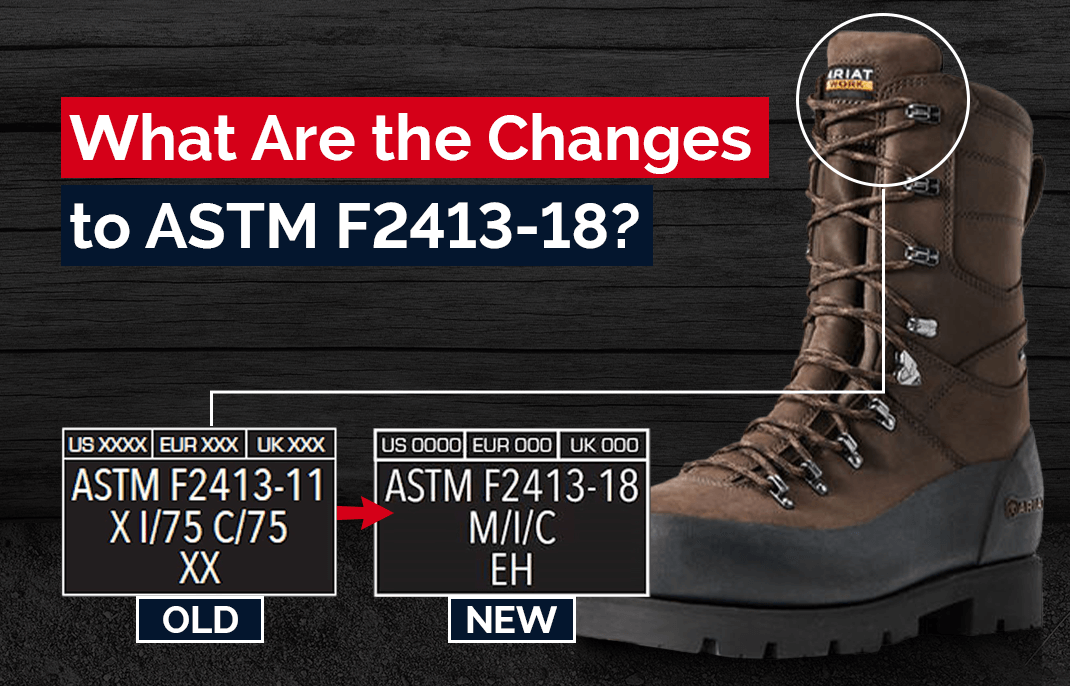

4. Incomplete or Outdated Standard Compliance

ASTM F2413 is periodically updated (e.g., F2413-18, F2413-22). Footwear compliant with older versions may not meet current requirements.

- Pitfall: Sourcing products certified to outdated versions of the standard.

- Solution: Confirm that certification explicitly references the current ASTM F2413 edition required by your organization or jurisdiction.

5. Lack of Intellectual Property Due Diligence

Purchasing counterfeit or unauthorized replicas exposes buyers to legal liability, including IP infringement claims.

- Pitfall: Using footwear with protected designs, logos, or technologies without proper licensing.

- Solution: Conduct IP audits of suppliers and require warranties of non-infringement in procurement contracts.

6. Insufficient Documentation for Traceability

Missing or falsified documentation (e.g., mill certifications, test reports, country of origin) complicates compliance verification and recalls.

- Pitfall: Inability to trace materials or validate claims during audits.

- Solution: Demand complete documentation packages for every shipment and maintain digital records.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure they source ASTM F2413-compliant footwear that is both legally sound and genuinely protective for end users.

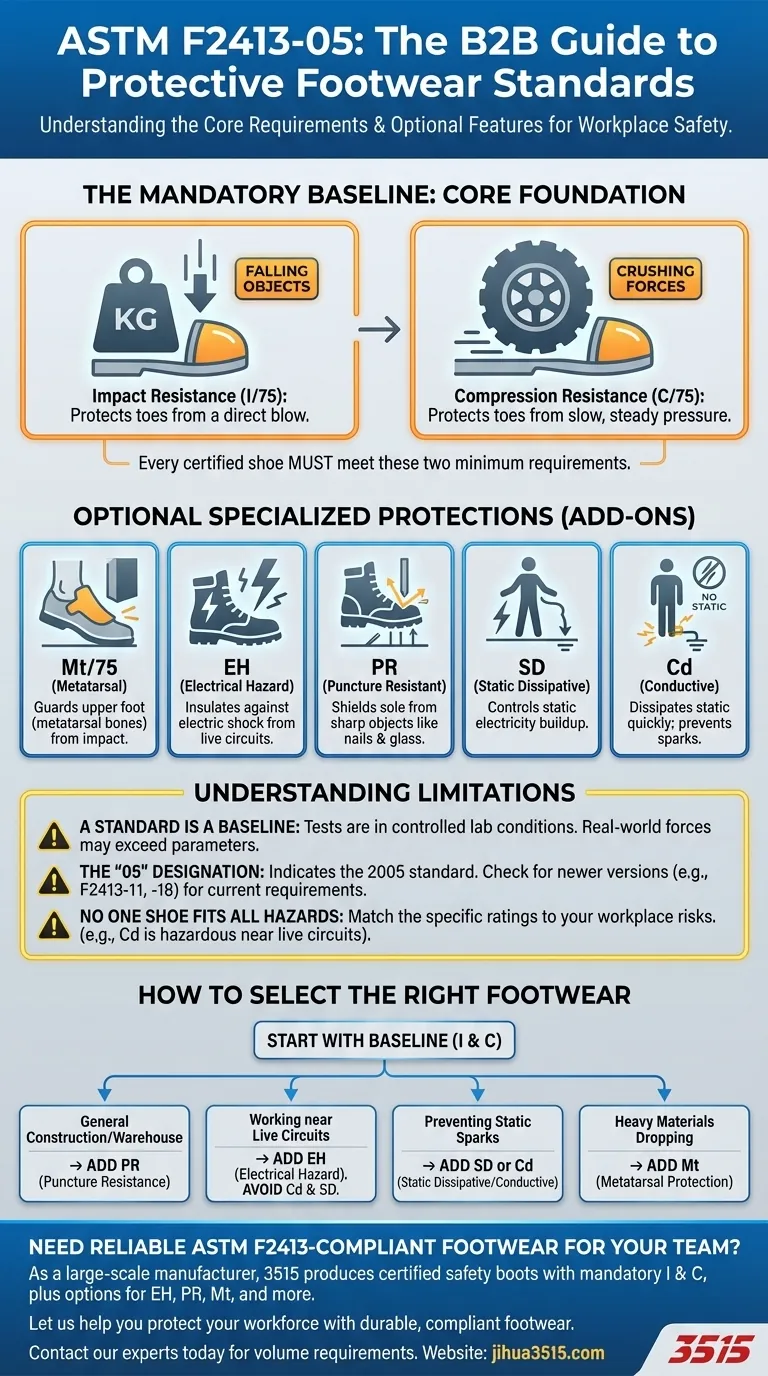

H2: ASTM F2413 – Standard Specification for Performance Requirements for Protective (Safety) Footwear

ASTM F2413 is a widely recognized standard in the United States that establishes minimum performance requirements for protective footwear used in industrial, construction, and other high-risk work environments. Compliance with this standard ensures that safety footwear provides adequate protection against common workplace hazards such as impact, compression, puncture, electrical hazards, and slips.

Below is a logistics and compliance guide to understanding, sourcing, and ensuring adherence to ASTM F2413.

1. Understanding ASTM F2413 Scope and Purpose

- Objective: ASTM F2413 specifies the minimum design, performance, testing, and classification requirements for new performance footwear (e.g., boots, shoes, overshoes) intended to provide protection against workplace injuries.

- Applicability: This standard applies to footwear used in construction, manufacturing, oil and gas, utilities, and other industrial sectors where foot hazards exist.

- Latest Version: Always reference the most current version (e.g., ASTM F2413-20 or ASTM F2413-23) as updates may include revised testing methods or new protective classifications.

2. Key Protective Performance Categories

Footwear must be tested and certified for specific hazard protections. Each category is designated by a performance code:

| Protection Type | Performance Code | Description |

|—————–|——————|———–|

| Impact Resistance | I | Resists impact (e.g., dropped objects); tested at 75 ft-lbf (101 J). |

| Compression Resistance | C | Resists compression (e.g., rolling equipment); tested at 2,500 lbf (11.12 kN). |

| Puncture Resistance | PR | Resists penetration from sharp objects under sole; requires 270 lbf (1,199 N) minimum. |

| Electric Hazard Protection | EH | Reduces risk of electric shock by providing secondary insulation (up to 600V). |

| Static Dissipation | SD | Safely dissipates static electricity to prevent sparks (resistance: 1.0 x 10^5 to 1.0 x 10^8 ohms). |

| Conductive Properties | CD | Quickly disperses static charge (resistance < 1.0 x 10^5 ohms); used in explosive environments. |

| Metatarsal Protection | Mt | Guards the metatarsal bones (top of foot); additional internal or external guard. |

| Slip Resistance | SR | Provides resistance on slippery surfaces (specific test not defined in F2413; may follow other standards). |

| Chain Saw Cut Protection | CS | Only in certain editions; protects against chain saw contact (not standard in all versions). |

| Dielectric Sole | DS | Insulates wearer from electrical circuits (tested at 18,000 V DC). |

Note: Footwear can carry multiple designations (e.g., I/PR/EH means impact, puncture, and electrical hazard protection).

3. Testing and Certification Requirements

- Certification Body: Must be tested and certified by an independent, accredited third-party laboratory.

- Labeling: Each shoe must have a permanent label inside indicating:

- ASTM F2413 compliance

- Year of manufacture

- Size

- Protective features (e.g., I/PR/EH)

- Manufacturer identification

- Quality Assurance: Manufacturers must maintain a quality control program that includes routine production testing.

4. Logistics and Procurement Best Practices

- Supplier Verification:

- Ensure suppliers provide valid test reports and certification documentation.

- Request proof of third-party laboratory testing (e.g., from UL, Intertek, or SGS).

- Procurement Specifications:

- Clearly specify required protection codes in purchase orders (e.g., “Boots compliant with ASTM F2413-20, I/C/PR/EH”).

- Include size ranges, material preferences (leather, synthetic), and additional features (e.g., waterproofing, insulation).

- Inventory Management:

- Track expiration dates; protective components (e.g., puncture plates) degrade over time.

- Rotate stock using FIFO (First In, First Out) to ensure older units are used first.

- Documentation Retention:

- Maintain copies of compliance certificates, test reports, and supplier agreements for audits.

5. Workplace Compliance and Employee Use

- Hazard Assessment:

- Conduct a job hazard analysis (JHA) to determine required protection levels.

- Match footwear specifications to specific worksite risks.

- Training:

- Train employees on the importance of ASTM F2413-rated footwear.

- Educate on proper fit, inspection, and replacement criteria (e.g., worn soles, damaged toe caps).

- Enforcement:

- Enforce footwear policies through safety audits and site inspections.

- Prohibit use of non-compliant or damaged footwear.

6. Common Compliance Pitfalls

- Using outdated standards (e.g., referencing ASTM F2413-11 instead of F2413-20/23).

- Assuming all “steel toe” boots meet ASTM F2413 (must be certified).

- Purchasing counterfeit or uncertified footwear from unverified vendors.

- Ignoring additional OSHA or site-specific requirements (e.g., MSHA for mining).

7. Relationship with Other Standards and Regulations

- OSHA 29 CFR 1910.136: Requires employers to ensure employees use protective footwear where foot hazards exist. ASTM F2413 is the recognized standard to meet this requirement.

- ANSI Z41: Superseded by ASTM F2413; no longer current.

- International Equivalents: ISO 20345 (similar to ASTM F2413 but used globally).

8. Summary: Steps to Ensure ASTM F2413 Compliance

- Identify workplace foot hazards.

- Select footwear with appropriate ASTM F2413 protection codes.

- Procure from certified suppliers with valid documentation.

- Verify labeling on each unit.

- Train employees and enforce usage.

- Maintain records and conduct periodic audits.

By following this guide, organizations can ensure logistical efficiency and full compliance with ASTM F2413, promoting worker safety and regulatory adherence.

Conclusion for Sourcing ASTM F2413-18 Compliant Safety Footwear

Sourcing ASTM F2413-18 compliant safety footwear is a critical step in ensuring workplace safety, regulatory compliance, and employee well-being. This standard sets minimum requirements for protective footwear, including impact and compression resistance, puncture resistance, electrical hazard protection, and slip resistance, among other performance criteria. When sourcing such footwear, it is essential to verify certification through accredited testing laboratories and ensure that each product bears the proper ASTM F2413-18 marking, indicating compliance with specific protective features.

A successful sourcing strategy involves evaluating suppliers based on certification transparency, product quality, durability, comfort, and cost-effectiveness. Prioritizing reputable manufacturers and conducting regular quality audits can mitigate risks associated with counterfeit or substandard products. Furthermore, selecting footwear tailored to the specific hazards of the work environment—such as construction, manufacturing, or electrical utilities—enhances both safety and worker productivity.

In conclusion, sourcing ASTM F2413-18 certified protective footwear is not only a regulatory necessity but also a vital investment in employee safety and operational efficiency. By adhering to this standard and implementing a rigorous procurement process, organizations can ensure reliable protection, reduce workplace injuries, and demonstrate a strong commitment to occupational health and safety.