The global artificial marble market is experiencing robust growth, driven by rising demand for sustainable, low-maintenance, and aesthetically versatile surfacing solutions in residential and commercial construction. According to Grand View Research, the global solid surface materials market—where artificial marble is a key segment—was valued at USD 4.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030. This growth is fueled by advancements in manufacturing technologies, increasing urbanization, and a shift toward eco-friendly building materials. As design flexibility and durability become critical purchasing factors, both established and emerging manufacturers are investing heavily in R&D to enhance product performance and expand their global footprint. In this evolving landscape, identifying the top artificial marble manufacturers offers valuable insight into innovation leaders shaping the future of architectural and interior design surfaces.

Top 10 Artificial Marble Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Artificial

Domain Est. 2018

Website: srsstone.com

Key Highlights: SRS is one of the most professional artificial-marble manufacturers and suppliers in China. Our factory offers the best quality artificial-marble made in ……

#2 BMC Artificial Marble

Website: yoshimoto-sangyo.co.jp

Key Highlights: Yoshimoto was the world’s first manufacturer who researched, developed and scaled up to large-scale the production of BMC Artificial Marble….

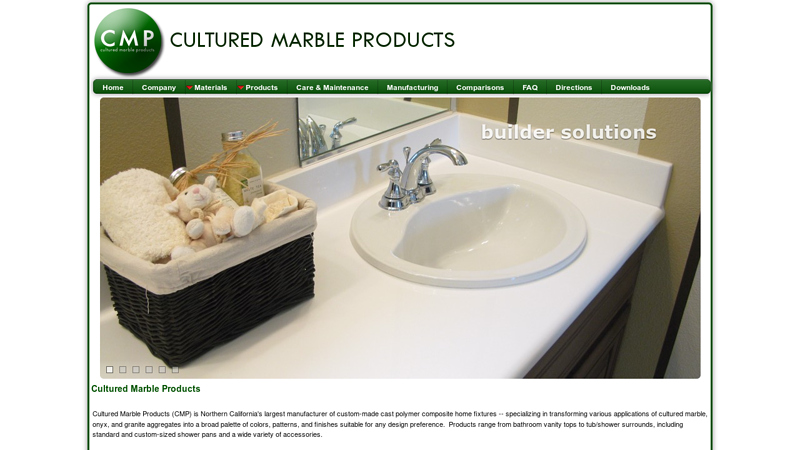

#3 Cultured Marble Products

Domain Est. 1998

Website: marbleproducts.com

Key Highlights: Cultured Marble Products (CMP) is Northern California’s largest manufacturer of custom-made cast polymer composite home fixtures — specializing in ……

#4 to Marblecraft Company, Inc.

Domain Est. 2009

Website: marblecraftcompany.com

Key Highlights: We manufacture our own cultured marble and create our own unique colors, every order is made to its own unique specifications….

#5 High Quality Basin and Artificial Marble suppliers and manufacturers

Domain Est. 2022

Website: matex-frp.com

Key Highlights: Mix with gravel, stone, for casting process, to make artificial marble, sink, artificial agate, bathtubs, basins(lavabo), spas, kitchen countertops….

#6 Artificial marble

Domain Est. 1995

Website: ipco.com

Key Highlights: This makes IPCO produced artificial stone suitable for uses such as solid surface flooring, synthetic marble sinks or engineered stone composite countertops….

#7 Stone floor and wall tiles: our company

Domain Est. 1997

Website: quarella.com

Key Highlights: WE PRODUCE ENGINEERED MARBLE AND QUARTZ SURFACES FOR DESIGN CLADDINGS AND FLOORS. Quarella is the Italian leading brand of engineered marble and quartz surfaces ……

#8 StoneContact.com: Stone, Marble, Granite

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Stone portal website(StoneContact.com) is the world leading B2B stone website.We offer abundant stone products, prices, pictures, suppliers, such as marble, ……

#9 NEOLITH – Kitchens

Domain Est. 2010

Website: neolith.com

Key Highlights: Neolith is a global leader in sintered stone surfaces—ultra-resistant, sustainable, and beautifully designed. It’s the perfect choice for modern architecture ……

#10 Artificial Marble

Domain Est. 2014

Website: chinaartificialstone.com

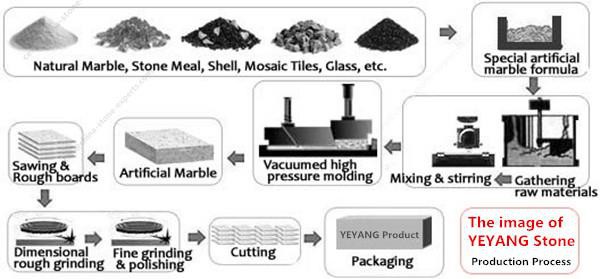

Key Highlights: We supply China Composite Marble Slabs and Tiles. Composite marble is made of natural marble scraps aggregate, calcium powder, resin and pigment by vacuum ……

Expert Sourcing Insights for Artificial Marble

H2: 2026 Market Trends for Artificial Marble

The artificial marble market is poised for significant evolution by 2026, driven by shifting consumer preferences, technological advancements, and growing sustainability concerns. Here are the key trends expected to shape the industry:

1. Heightened Focus on Sustainability and Circularity:

* Bio-Based & Recycled Content: Demand will surge for artificial marble incorporating significant percentages of recycled materials (post-consumer plastics, glass, stone waste) and bio-based resins derived from renewable sources (e.g., plant oils). This directly addresses environmental concerns about virgin plastic use.

* Low-VOC & Non-Toxic Formulations: Stricter regulations and consumer health awareness will push manufacturers towards formulations with minimal volatile organic compounds (VOCs) and hazardous additives, making products safer for indoor environments.

* Improved End-of-Life Management: Developments in recyclability and the emergence of take-back programs or closed-loop systems will become competitive differentiators, moving beyond mere “durability” to true circularity.

2. Advancements in Aesthetics and Material Science:

* Hyper-Realistic Mimicry: AI-driven design and advanced manufacturing (like high-definition 3D printing within the slab process) will enable artificial marble to replicate the intricate veining, depth, and tactile feel of rare natural stones with unprecedented accuracy, blurring the lines.

* Expanded Design Palette: Beyond traditional marbles, expect a wider variety of finishes (ultra-matte, textured, metallic inlays), colors (bold hues, custom colors), and patterns (abstract, terrazzo-inspired) to cater to diverse design trends.

* Enhanced Performance: Formulations will focus on improved UV resistance (for outdoor use), better heat resistance (around cooktops), and increased scratch/impact resistance, closing the performance gap with natural stone.

3. Market Expansion and Diversification:

* Beyond Countertops: While kitchen and bathroom countertops remain core, growth will accelerate in new applications: wall cladding, flooring, furniture (tables, vanities), facades, and even retail/hospitality interiors, driven by design flexibility and cost-effectiveness.

* Emerging Market Growth: Rapid urbanization and rising disposable incomes in Asia-Pacific (especially India, Southeast Asia) and Latin America will be significant growth drivers, where artificial marble offers a premium look at a more accessible price point than imported natural stone.

* Integration with Smart Materials: Early exploration of embedding functionalities like self-cleaning surfaces (photocatalytic coatings), antimicrobial properties, or even integrated lighting/sensors into artificial marble slabs may emerge for high-end applications.

4. Digitalization and Customization:

* E-commerce & AR/VR Tools: Online platforms will offer sophisticated visualization tools (Augmented Reality apps) allowing consumers and designers to preview artificial marble in their specific spaces virtually, boosting confidence in online purchases.

* Mass Customization: Digital manufacturing will enable easier production of custom shapes, edges, and integrated features (sink cutouts, drain boards) with shorter lead times, moving towards a “design-on-demand” model.

* Digital Product Passports: Adoption of digital records detailing material composition, origin, and environmental impact will become crucial for transparency and meeting future regulatory requirements (like EU Ecodesign).

5. Competitive Landscape and Consolidation:

* Innovation Arms Race: Established players and new entrants will fiercely compete on sustainability credentials, aesthetic innovation, and performance, leading to rapid product iteration.

* Consolidation: The market may see mergers and acquisitions as larger companies seek to acquire innovative technologies (especially in bio-resins or recycling) or expand their geographic reach to gain economies of scale.

* Premiumization vs. Value Segments: A clear bifurcation will emerge: high-end segments focusing on ultra-sustainable, hyper-realistic, and customizable products, and value segments offering durable, design-led options for cost-conscious consumers.

Conclusion:

By 2026, the artificial marble market will be defined by a powerful convergence of sustainability, hyper-realistic aesthetics, and digital enablement. Success will depend on manufacturers’ ability to innovate beyond just mimicking stone, focusing instead on creating truly sustainable, high-performance, and customizable materials that meet the evolving demands of consumers, designers, and regulators, particularly in rapidly growing emerging economies.

Common Pitfalls When Sourcing Artificial Marble (Quality, IP)

Sourcing artificial marble—whether for construction, furniture, or design applications—can present several challenges, especially concerning material quality and intellectual property (IP) risks. Being aware of these pitfalls can help buyers mitigate risks and ensure a reliable, legal supply chain.

Inconsistent Material Quality

One of the most frequent issues when sourcing artificial marble is encountering inconsistent product quality. Artificial marble (often made from polyester resin mixed with marble powder or other fillers) can vary significantly in composition, finish, and durability depending on the manufacturer. Low-cost suppliers may cut corners by using inferior resins or insufficient filler ratios, leading to products that are prone to cracking, yellowing under UV exposure, or poor stain resistance. Buyers may receive samples that look premium but differ drastically from bulk shipments.

Lack of Standardized Testing and Certifications

Many suppliers, especially in less-regulated markets, do not adhere to international quality standards such as ISO 9001 or ASTM C503. Without third-party certifications or proper test reports for physical properties (e.g., flexural strength, water absorption, impact resistance), it’s difficult to verify product performance. This lack of documentation increases the risk of receiving subpar materials unsuitable for intended applications.

Hidden Intellectual Property Infringements

Artificial marble often involves proprietary formulations, surface textures, or color patterns protected by patents or design rights. When sourcing from manufacturers—particularly in regions with weak IP enforcement—there’s a risk of inadvertently purchasing counterfeit or cloned products. For example, a supplier may replicate a high-end brand’s veining pattern or patented solid surface technology without authorization. Buyers risk legal liability, shipment seizures, or reputational damage if such IP violations are discovered.

Misrepresentation of Material Composition

Suppliers may mislabel or exaggerate the composition of artificial marble. For instance, a product marketed as “90% natural marble” might contain significantly less marble powder than claimed, with higher resin or filler content. This misrepresentation affects both the material’s aesthetic quality and long-term performance. Independent material analysis may be required to verify claims, especially when large volumes are involved.

Inadequate IP Due Diligence from Suppliers

Many manufacturers, particularly smaller or OEM-focused ones, cannot or will not provide proof of IP ownership or licensing for their designs and technologies. They may assert that “the design is generic” when, in fact, it closely mimics a protected product. Without proper contractual assurances or warranties, buyers assume full responsibility for any IP disputes.

Supply Chain Opacity and Subcontracting Risks

Some suppliers outsource production to third-party factories without the buyer’s knowledge. This lack of transparency makes it difficult to audit manufacturing processes, verify quality control, or ensure IP compliance. Subcontracting increases the risk of unauthorized design replication and inconsistent production standards.

Conclusion

To avoid these pitfalls, buyers should conduct thorough due diligence: request material test reports, verify IP rights, audit manufacturing facilities, and include quality and IP indemnity clauses in procurement contracts. Partnering with reputable suppliers and using legal safeguards can significantly reduce risks associated with sourcing artificial marble.

Logistics & Compliance Guide for Artificial Marble

Artificial marble, a composite material typically made from polyester resin, natural stone powders (like marble dust), and pigments, offers design versatility and durability. However, its transportation and regulatory compliance require careful planning due to its weight, fragility, chemical composition, and potential environmental impact. This guide outlines key logistics and compliance considerations for handling artificial marble effectively and legally.

Product Classification and Identification

Proper identification is essential for regulatory compliance and safe handling. Artificial marble is generally classified as follows:

– HS Code (Harmonized System): Typically 3926.10 (Articles of plastics used as tableware, kitchenware, or other household articles) or 6802.91 (Other artificially agglomerated stone, in slabs). Final classification should be confirmed with customs authorities based on composition and form (slabs, tiles, finished products).

– UN Number: Usually not classified as dangerous goods when fully cured. However, uncured resins may fall under UN 1866 (Resin Solution, flammable) or similar codes.

– Material Safety Data Sheet (MSDS/SDS): Required for any resins, adhesives, or finishing chemicals used in manufacturing or installation. The finished artificial marble product may not require an SDS unless it emits hazardous substances under normal conditions.

Packaging and Handling Requirements

Protecting artificial marble during transit is critical to prevent damage and ensure customer satisfaction:

– Edge Protection: Use rigid corner guards or foam protectors on all edges to prevent chipping.

– Surface Protection: Apply protective film or paper to both faces to avoid scratches, staining, or adhesive residue.

– Palletization: Secure slabs or tiles on wooden pallets using non-abrasive straps. Avoid overhanging edges. Use dunnage between layers to prevent scratching.

– Cradle Storage: For curved or complex shapes, custom cradles or foam molds may be necessary.

– Labeling: Clearly label packages with “Fragile,” “This Side Up,” weight, handling instructions, and product details (e.g., batch number, dimensions).

Transportation and Storage

Transport considerations depend on mode and environmental exposure:

– Mode of Transport: Suitable for road, sea, and air freight. For air transport, confirm weight and size restrictions with carriers.

– Temperature Control: Avoid extreme temperatures during transit. High heat may soften resin; freezing can cause cracking.

– Humidity: Store in dry conditions to prevent moisture absorption, which may affect dimensional stability.

– Stacking Limits: Observe manufacturer-recommended stacking heights to prevent deformation or breakage.

– Ventilation: If transporting uncured materials or resins, ensure adequate ventilation to avoid fume accumulation.

Customs and Import/Export Compliance

International shipments require adherence to trade regulations:

– Documentation: Prepare commercial invoices, packing lists, certificates of origin, and bill of lading/airway bill.

– Duties and Tariffs: Verify applicable import duties based on destination country and HS code.

– Import Restrictions: Some countries may impose restrictions on composite materials containing certain resins or fillers. Check local environmental or building material regulations (e.g., REACH in the EU, TSCA in the U.S.).

– Labeling Requirements: Products sold in certain markets may require labeling in local languages and compliance with labeling standards (e.g., CE marking in Europe).

Environmental and Safety Regulations

Artificial marble production and disposal are subject to environmental regulations:

– VOC Emissions: During manufacturing, resin curing may release volatile organic compounds (VOCs). Ensure compliance with local air quality regulations (e.g., EPA, EU VOC Directive).

– Waste Disposal: Scrap material and production waste may be classified as non-hazardous solid waste when cured. Uncured resin or solvent waste may be hazardous and require special handling.

– Recyclability: While not easily recyclable like natural stone, some manufacturers offer take-back programs or grinding for reuse in new composites.

– REACH (EU): Confirm that all chemical components (e.g., styrene in polyester resin) comply with registration, evaluation, and restriction requirements.

– Proposition 65 (California, USA): Disclose if the product contains chemicals known to the state of California to cause cancer or reproductive harm (e.g., crystalline silica dust during cutting).

Worker Safety and Installation Compliance

End-use safety is critical during fabrication and installation:

– Cutting and Fabrication: Use wet-cutting methods and local exhaust ventilation to minimize respirable dust. Provide appropriate PPE (respirators, gloves, eye protection).

– Chemical Handling: Workers using resins, adhesives, or polishing compounds must follow SDS guidelines for safe handling and spill response.

– Building Codes: Ensure artificial marble installations meet local building codes for countertops, flooring, or cladding, particularly regarding load-bearing capacity and fire resistance.

Certification and Quality Standards

Voluntary certifications can enhance market access and consumer trust:

– NSF/ANSI 51 (U.S.): For food-contact surfaces like countertops.

– ISO 9001: Quality management systems in manufacturing.

– GREENGUARD or LEED: For low-emitting materials in sustainable building projects.

– CE Marking: Required for sales in the European Economic Area, indicating conformity with health, safety, and environmental standards.

Conclusion

Successfully managing the logistics and compliance of artificial marble requires attention to material properties, regulatory frameworks, and safe handling practices. By implementing proper packaging, adhering to international trade rules, ensuring environmental compliance, and prioritizing worker safety, companies can minimize risks and enhance the reliability of their supply chain. Always consult local regulators and industry standards to stay up to date with evolving requirements.

In conclusion, sourcing artificial marble requires a strategic approach that balances quality, cost, durability, and aesthetic appeal. As a versatile and cost-effective alternative to natural stone, artificial marble offers numerous advantages, including customizable designs, consistent appearance, and improved resistance to stains and moisture. However, successful sourcing depends on selecting reputable suppliers who adhere to industry standards and provide transparent information about material composition and manufacturing processes.

Key considerations include evaluating the intended application—whether for residential, commercial, or high-traffic environments—assessing the product’s physical properties such as heat and scratch resistance, and ensuring compliance with environmental and safety regulations. Additionally, comparing pricing, lead times, and after-sales support can significantly impact long-term satisfaction and project success.

Ultimately, thorough research, sample testing, and building strong relationships with trusted manufacturers or distributors will help ensure the reliable and efficient sourcing of high-quality artificial marble that meets both performance requirements and design expectations.