The global Archimedes water screw market is experiencing steady growth, driven by increasing demand for energy-efficient water lifting solutions in irrigation, municipal wastewater management, and hydropower applications. According to Mordor Intelligence, the screw pump market is projected to grow at a CAGR of approximately 4.2% during the forecast period of 2024–2029, fueled by infrastructure development and sustainable water management initiatives. Similarly, Grand View Research highlights rising adoption of mechanical dewatering systems in industrial and agricultural sectors as a key growth driver. Amid this expanding demand, manufacturers of Archimedes water screws are innovating to enhance efficiency, durability, and scalability. Below is a data-backed overview of the top 8 manufacturers leading technological advancements and market share in the Archimedes water screw industry.

Top 8 Archimedes Water Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Archimedes Screw Hydro Power Technology Explained

Domain Est. 2008

Website: neppump.com

Key Highlights: It features a durable screw-shaped mechanism that efficiently captures the kinetic energy of the water and converts it into electricity, making it an ideal ……

#2 Archimedes Screw Pump Redesignated as an ASME Landmark

Domain Est. 1994

Website: asme.org

Key Highlights: The device, which moves water from low to higher ground, was originally designed and built by Andrew Oliver in the 1870s. It was used for more ……

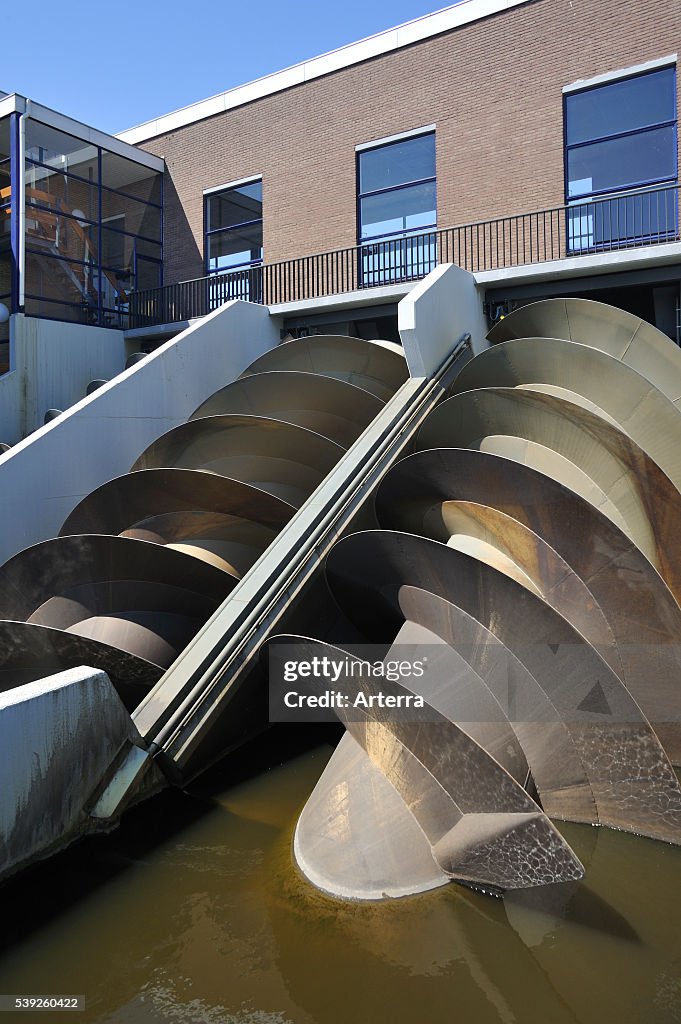

#3 Archimedean screw pump

Domain Est. 1995

Website: ksb.com

Key Highlights: The Archimedean screw pump is used for constant-pressure lifting of a fluid to a given geodetic height with the aid of a rotating screw….

#4 Screw Pump

Domain Est. 1995

Website: pumps-systems.netzsch.com

Key Highlights: An Archimedean screw represents a conveyor arrangement consisting of a helix in an inclined pipe and a trough at both ends. A common name for this is a screw ……

#5 Archimedean Screw Pumps

Domain Est. 1997

Website: epicintl.com

Key Highlights: Archimedean screw pumps are ideal for pumping unscreened liquids due to their capability to carry large solids and manage high-flow applications….

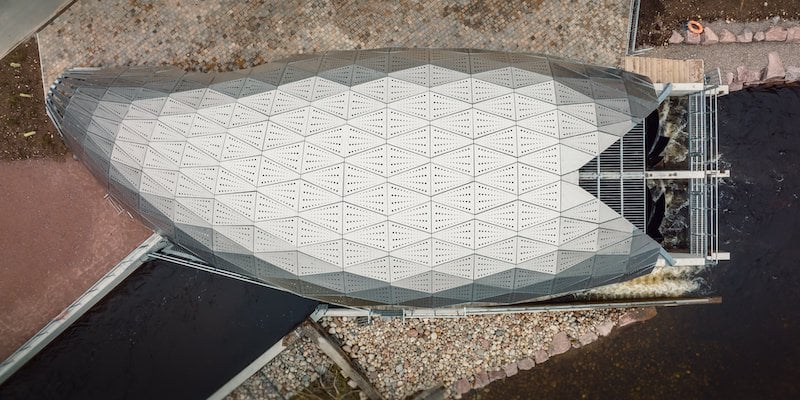

#6 The 21st Century Archimedes Screw

Domain Est. 1999

Website: energy.gov

Key Highlights: A next-generation Archimedes hydrodynamic screw turbine constructed from composite materials and leveraging advanced manufacturing methods….

#7 How the Archimedes Screw of 234 BC Relates to Backflow

Domain Est. 2014

Website: hydrocorpinc.com

Key Highlights: The Archimedes Screw was capable of lifting water from a lower to a higher elevation with remarkable efficiency….

#8 Archimedean Screw Pump

Domain Est. 2019

Website: lantec-environmental.com

Key Highlights: Spaans is specialized in the design and manufacture of water treatment equipment such as screw pumps and screw generators. archimedean screw pump. Types ……

Expert Sourcing Insights for Archimedes Water Screw

H2: Market Trends for Archimedes Water Screw in 2026

By 2026, the market for Archimedes Water Screw (AWS) technology is projected to experience steady growth, driven by increasing global demand for sustainable water management and renewable energy solutions. Key trends shaping this market include advancements in low-head hydropower generation, rising adoption in irrigation and wastewater applications, and supportive environmental regulations.

-

Expansion in Renewable Energy Applications

The growing emphasis on decentralized and low-impact hydropower is fueling interest in Archimedes Water Screws for electricity generation. With efficiencies now exceeding 80% in optimal conditions and the ability to operate effectively at low hydraulic heads (as low as 1 meter), AWS systems are becoming a preferred choice for micro-hydropower installations in rural and off-grid areas. By 2026, integration with smart grid systems and hybrid renewable setups (e.g., combining solar and hydro) is expected to broaden their deployment across Europe, Southeast Asia, and parts of Africa. -

Agricultural and Irrigation Demand

In response to climate change and water scarcity, agricultural sectors in developing economies are turning to energy-efficient pumping solutions. The mechanical simplicity, low maintenance, and ability to handle debris-laden water make Archimedes screws ideal for irrigation in regions with limited infrastructure. Countries such as India, Bangladesh, and Nigeria are anticipated to increase investment in AWS-based pumping systems, supported by government subsidies and international development programs. -

Wastewater and Urban Water Management

Municipalities are increasingly adopting Archimedes screws in wastewater treatment plants and urban flood control systems due to their reliability and fish-friendly operation. By 2026, urban resilience projects in flood-prone cities are expected to incorporate AWS technology for dewatering and water level regulation. The EU’s Green Deal and similar sustainability mandates are accelerating this trend, particularly in coastal and delta regions. -

Technological Innovation and Material Advancements

Ongoing R&D is focused on lightweight composite materials and modular designs to reduce manufacturing and installation costs. IoT-enabled monitoring systems are being integrated for real-time performance tracking and predictive maintenance. These innovations are expected to enhance scalability and attract private investment into the AWS sector. -

Regulatory and Environmental Support

Stringent environmental regulations, particularly in Europe and North America, favor fish-safe and low-carbon technologies. Archimedes screws meet ecological standards better than traditional turbines, giving them a competitive advantage in environmentally sensitive areas. Incentives such as feed-in tariffs and green certifications are expected to further stimulate market growth through 2026.

In conclusion, the Archimedes Water Screw market in 2026 will be characterized by diversification across energy, agriculture, and urban infrastructure, underpinned by sustainability goals and technological innovation. With favorable policy landscapes and rising awareness of decentralized water-energy solutions, the AWS market is poised for moderate but meaningful expansion globally.

Common Pitfalls When Sourcing an Archimedes Water Screw (Quality, IP)

Sourcing an Archimedes water screw—whether for irrigation, drainage, or renewable energy applications—requires careful consideration to avoid costly mistakes. Two critical areas where challenges frequently arise are product quality and intellectual property (IP) rights. Overlooking these factors can lead to performance issues, safety hazards, legal disputes, or project delays.

Quality-Related Pitfalls

1. Substandard Materials and Construction

A common issue is selecting a screw made from low-grade materials that corrode or degrade quickly, especially in wet or saline environments. Suppliers may use thin-gauge steel without proper coatings or non-marine-grade plastics, leading to premature failure. Always verify material specifications (e.g., stainless steel grade, UV resistance for polymers) and request corrosion test reports.

2. Poor Manufacturing Tolerances

The efficiency of an Archimedes screw depends heavily on precise helical geometry and alignment. Inconsistent pitch, uneven flights, or misaligned shafts reduce pumping efficiency and increase wear. Confirm that the manufacturer uses CNC-forming or precision tooling and request dimensional drawings or quality control documentation.

3. Inadequate Bearing and Sealing Systems

Water ingress into bearings is a leading cause of failure. Low-quality seals or improperly rated bearings degrade rapidly. Ensure the design includes maintenance-friendly, high-performance seals (e.g., lip seals or mechanical seals) and bearings rated for continuous wet operation.

4. Lack of Independent Testing or Certification

Some suppliers may provide inflated performance claims without third-party validation. Always request test data from accredited labs showing flow rate, efficiency, and head performance under real-world conditions. Certification to relevant standards (e.g., ISO, CE) adds credibility.

Intellectual Property (IP)-Related Pitfalls

1. Infringement of Patented Designs

Several modern Archimedes screw designs—especially those optimized for hydropower generation—remain under patent protection. Sourcing a screw that copies patented features (e.g., specific blade profiles, modular assembly methods) can expose you to legal action. Conduct a patent landscape search and require suppliers to confirm freedom-to-operate.

2. Unclear or Missing IP Ownership in Contracts

When customizing a screw design, ensure contracts clearly define who owns any new IP developed during the process. Ambiguity can lead to disputes over usage rights, resale, or future modifications. Specify in writing whether the design remains proprietary to the supplier or transfers to the buyer.

3. Use of Counterfeit or Reverse-Engineered Products

Some low-cost suppliers offer screws that closely resemble patented models without authorization. These may mimic appearance but lack performance and safety standards. Avoid suppliers unwilling to disclose design origins or provide engineering documentation.

4. Inadequate Protection of Custom Designs

If you’ve developed a proprietary screw configuration, ensure NDA (Non-Disclosure Agreement) coverage before sharing details with potential suppliers. Without proper IP safeguards, your design could be replicated or shared with competitors.

By proactively addressing quality standards and IP considerations, you can mitigate risks and ensure a reliable, legally compliant Archimedes water screw solution.

Logistics & Compliance Guide for Archimedes Water Screw

Overview

The Archimedes Water Screw, a historic yet still-relevant technology for lifting water, requires careful planning for modern logistics and compliance. This guide outlines key considerations for the safe, legal, and efficient transport, installation, and operation of Archimedes Water Screws, whether used in agriculture, wastewater management, or renewable energy applications.

Transportation and Handling

Ensure proper planning for the movement of the water screw from manufacturing site to installation location. Due to their length and weight (especially for large-scale models), coordination with transport providers is critical. Use cranes or forklifts with appropriate lifting points; never lift by the screw blade or shaft alone. Secure the unit during transit using straps and protective padding to prevent deformation. For long-distance shipping, comply with international transport regulations (e.g., IMDG for sea freight if applicable, ADR for road in Europe).

Packaging and Storage

Store units in a dry, covered environment away from direct sunlight and corrosive elements. If stored outdoors, use waterproof covers and elevate off the ground to prevent moisture contact. Rotate stored units periodically if applicable to avoid deformation. Protect bearing housings and drive components with anti-corrosion coatings or VCI (Vapor Corrosion Inhibitor) wraps.

Import and Export Compliance

Verify all export controls and import regulations in both origin and destination countries. Archimedes Water Screws may be classified under HS Code 8479.89 (machines for specific purposes, not elsewhere specified). Check for:

– Import duties and tariffs

– Customs documentation (commercial invoice, packing list, bill of lading/airway bill)

– Certificates of origin, if required

– Sanitary or phytosanitary regulations (especially if used in agricultural water systems)

Ensure compliance with relevant trade sanctions and export control regimes (e.g., EAR in the U.S.).

Environmental and Safety Regulations

Comply with local and international environmental standards:

– Water Use Permits: Obtain necessary permits for water abstraction, especially in regulated watersheds.

– Discharge Compliance: If used in wastewater or irrigation return flow, ensure effluent meets local water quality standards.

– Noise and Wildlife Impact: Assess noise emissions and potential effects on aquatic life; install screens or bypass systems where required.

– REACH & RoHS (EU): Confirm that materials (e.g., coatings, lubricants, drive components) comply with chemical safety regulations.

Installation and Site Compliance

Installation must adhere to local building codes and engineering standards. Anchor foundations securely to prevent movement. Electrical components (e.g., motors, control panels) must meet regional electrical safety codes (e.g., NEC in the U.S., IEC in Europe). Follow OSHA or equivalent workplace safety regulations during installation. Ensure site access allows for maintenance and emergency shutdown.

Operational Compliance and Maintenance

Establish a routine maintenance schedule to ensure long-term efficiency and compliance:

– Monitor for leaks, corrosion, or wear on the screw and seals

– Lubricate bearings according to manufacturer specifications

– Keep records of inspections and repairs

– Train operators on emergency procedures and environmental best practices

Adhere to any reporting requirements related to water usage, energy consumption, or environmental impact.

Documentation and Record Keeping

Maintain comprehensive records including:

– Transport and customs documentation

– Installation certificates and engineering approvals

– Maintenance logs and inspection reports

– Environmental permits and compliance certifications

These records support audits, warranty claims, and regulatory inspections.

Conclusion

Successful deployment of an Archimedes Water Screw requires attention to logistics planning and strict adherence to compliance standards. By following this guide, stakeholders ensure safe handling, legal operation, and sustainable performance of this efficient water-moving technology. Always consult local authorities and regulatory bodies for region-specific requirements.

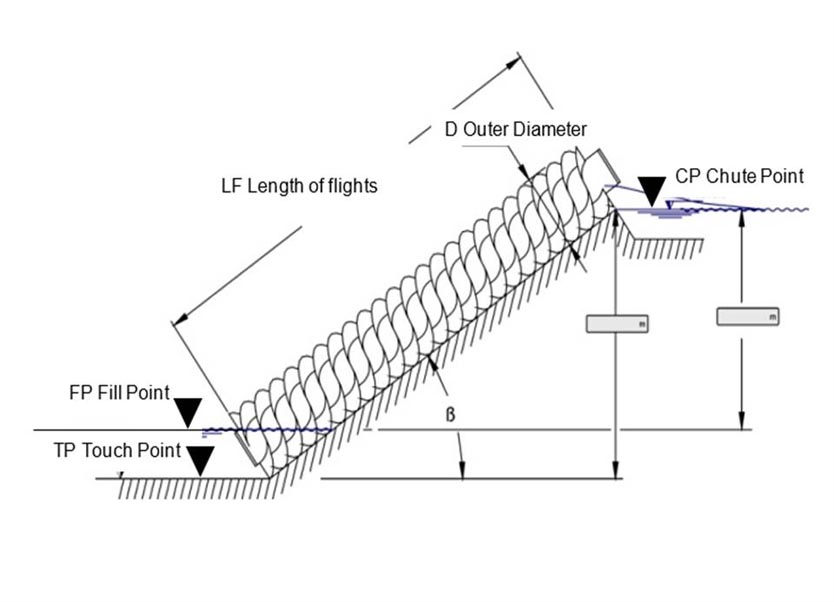

Conclusion on Sourcing an Archimedes Water Screw

In conclusion, sourcing an Archimedes water screw presents a sustainable and efficient solution for low-head water lifting applications, particularly in agriculture, wastewater treatment, and small-scale hydropower generation. Its simple, robust design offers reliable performance with minimal maintenance, making it well-suited for both off-grid and environmentally sensitive settings. When sourcing, it is essential to consider factors such as material quality, screw diameter and length, incline angle, and drive mechanism to ensure optimal performance for the intended application. Additionally, evaluating suppliers based on engineering expertise, customization capabilities, and after-sales support will help secure a durable and efficient system. With growing emphasis on renewable technologies and energy-efficient water management, the Archimedes water screw stands out as a proven, eco-friendly option worth investing in. Proper sourcing and installation can deliver long-term operational benefits, contributing to sustainable water and energy solutions.