The global demand for sealing solutions in plumbing, industrial, and HVAC applications has driven significant growth in the polytetrafluoroethylene (PTFE) tape market. According to a report by Mordor Intelligence, the global PTFE Market was valued at USD 7.2 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, fueled by increasing infrastructure development and expanding industrial manufacturing. Similarly, Grand View Research highlights that the rising need for leak-proof, corrosion-resistant sealing materials in both commercial and residential construction is accelerating the adoption of high-quality Teflon tape. As reliability and performance become critical in fluid system integrity, manufacturers specializing in precision-applied PTFE tape are gaining prominence. The following list highlights the top seven applying Teflon tape manufacturers leading innovation, quality, and market reach in this evolving landscape.

Top 7 Applying Teflon Tape Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 [PDF] 2408.1

Domain Est. 2020

Website: ncosfm.gov

Key Highlights: There are many instructions by equipment manufacturer’s that prohibit the use of PTFE tape, not because of product or code issues, but ……

#2 How to Use Plumber’s Tape: Step-by-Step

Domain Est. 1996

Website: oatey.com

Key Highlights: Thread seal tape, also known as plumber’s tape or Teflon tape, is a simple yet effective way to seal threaded pipe joints and prevent leaks….

#3 Skill

Domain Est. 1996

Website: northerncal.swagelok.com

Key Highlights: To properly apply PTFE tape, you’ll need a couple of tools in addition to the roll of tape: An open-end wrench; A dry, soft-bristled brush; A ……

#4 Plumbing Tape

Domain Est. 1997

Website: teflon.com

Key Highlights: Make an informed purchase and be aware that Chemours has not authorized any plumber tape to be sold as Teflon tape….

#5 How To Use Teflon Tape

Domain Est. 1998

Website: tchindustries.com

Key Highlights: Start the tape on the second thread and apply clockwise. Doing so will help prevent cross threading and ensure tape does not end up inside the pipe….

#6 PTFE Thread Sealant Installation Instructions

Domain Est. 2000

Website: tfcoinc.com

Key Highlights: These instructions are to be used specifically for the application of TFCO’s American made thread sealant tape and are based on TFCO’s product expertise….

#7 How to Properly Apply Teflon Tape

Domain Est. 2010

Website: tapejungle.com

Key Highlights: Properly applied Teflon tape can keep two pieces of piping locked tightly together without letting any water come through, whereas poorly applied tape results ……

Expert Sourcing Insights for Applying Teflon Tape

H2: 2026 Market Trends for Applying Teflon Tape

The global market for Teflon tape—also known as PTFE (polytetrafluoroethylene) thread seal tape—is expected to experience steady growth and transformation by 2026, driven by advancements in industrial applications, sustainability demands, and technological innovation. Below is an analysis of key market trends projected to shape the use and application of Teflon tape in the coming years.

-

Increased Demand in Plumbing and HVAC Industries

The construction and infrastructure sectors are anticipated to remain primary drivers of Teflon tape consumption. With ongoing urbanization and the expansion of residential and commercial building projects—particularly in Asia-Pacific and Africa—the need for reliable pipe sealing solutions will rise. Teflon tape’s resistance to moisture, chemicals, and temperature extremes makes it a preferred choice for sealing threaded pipe connections in plumbing, gas lines, and HVAC systems. By 2026, these sectors are expected to account for over 60% of global Teflon tape demand. -

Growth in Industrial and Manufacturing Applications

Beyond traditional plumbing, Teflon tape is increasingly being adopted in industrial machinery, automotive manufacturing, and chemical processing plants. Its non-stick and low-friction properties make it ideal for protecting threaded components and preventing corrosion in high-stress environments. As industrial automation and precision engineering grow, so will the demand for high-performance sealing materials like PTFE tape, especially in applications requiring leak-proof integrity. -

Shift Toward High-Performance and Specialty Tapes

Market differentiation is emerging through the development of specialized Teflon tapes—such as high-density, pink gas-line, and plumber’s-grade variants. By 2026, manufacturers are expected to focus on value-added products with enhanced durability, temperature resistance, and ease of application. These premium tapes cater to regulated industries like natural gas distribution and pharmaceutical manufacturing, where safety and compliance are critical. -

Sustainability and Environmental Regulations

Environmental concerns are pushing manufacturers to explore recyclable packaging and reduce PTFE waste. While PTFE itself is chemically inert and durable, scrutiny over fluoropolymer production and end-of-life disposal may influence innovation toward more sustainable alternatives or improved lifecycle management. Regulatory frameworks in Europe and North America may encourage the adoption of eco-friendly application methods and reduced material usage through precision tape dispensers. -

Technological Advancements in Application Tools

A notable trend is the integration of smart tools and automated tape applicators in industrial settings. By 2026, robotic systems and AI-assisted tools may streamline the application of Teflon tape in mass production environments, ensuring consistent wrap tension and alignment. This reduces human error and enhances efficiency, particularly in automotive and aerospace assembly lines. -

Regional Market Dynamics

Asia-Pacific is projected to be the fastest-growing market for Teflon tape due to rapid industrialization, infrastructure development, and expanding manufacturing hubs in China, India, and Southeast Asia. North America and Europe will maintain strong demand, driven by building renovations, energy infrastructure upgrades, and stringent safety standards. -

Supply Chain Optimization and Raw Material Costs

Fluctuations in the price of fluorspar and other raw materials used in PTFE production may impact market dynamics. Companies are expected to invest in supply chain resilience, regional production facilities, and long-term supplier contracts to mitigate volatility. Additionally, advancements in PTFE recycling technologies could reduce dependency on virgin materials.

In conclusion, the 2026 market for applying Teflon tape will be characterized by rising demand across diverse sectors, innovation in product formulation and application methods, and increasing emphasis on sustainability. Companies that adapt to these trends through product differentiation, technological integration, and environmental responsibility are likely to gain a competitive edge in the evolving global marketplace.

Common Pitfalls When Sourcing Teflon Tape (Quality and Intellectual Property)

Sourcing Teflon tape—especially under tight budgets or aggressive timelines—can lead to critical oversights regarding both material quality and intellectual property (IP) rights. Avoiding these pitfalls ensures performance, compliance, and brand protection.

Poor Material Quality and Performance Issues

One of the most frequent issues when sourcing Teflon tape is receiving substandard products that fail to perform under real-world conditions. Generic or low-cost alternatives often use inferior polytetrafluoroethylene (PTFE) or blend PTFE with lower-grade polymers to cut costs. This compromises key properties such as chemical resistance, temperature tolerance, and tensile strength. Poorly manufactured tape may tear during application, lack uniform thickness, or fail to seal properly, leading to leaks and system failures. Additionally, inconsistent die-cutting or adhesive backing (in coated variants) can reduce usability and reliability, particularly in industrial or high-pressure applications.

Misuse of Brand Names and Trademark Infringement

“Teflon” is a registered trademark of The Chemours Company (formerly DuPont) and applies specifically to genuine PTFE products manufactured under their standards. A common IP pitfall arises when suppliers misleadingly market generic PTFE tape as “Teflon tape” to imply equivalence or quality. This not only misleads buyers but also exposes the purchaser to potential trademark infringement liabilities, especially if the product is resold or used in branded systems. Relying on trademarked names in procurement specifications without authorization can lead to legal challenges or supply chain disruptions during audits.

Lack of Certification and Compliance Documentation

Sourcing decisions often overlook the need for proper certifications, such as FDA compliance for food-grade applications, NSF approval for plumbing, or UL ratings for electrical use. Without verified documentation, there’s no assurance the tape meets industry-specific safety and performance standards. Suppliers may provide falsified or generic certificates, putting end-users at risk of non-compliance with regulatory requirements. This is particularly critical in regulated industries like pharmaceuticals, aerospace, and potable water systems.

Supply Chain Transparency and Counterfeit Risk

Many low-cost suppliers, especially those located offshore, operate with limited traceability. This opacity increases the risk of receiving counterfeit or diverted genuine products. Counterfeit tapes may resemble authentic ones in packaging but contain non-PTFE materials entirely. Without chain-of-custody verification or direct supplier audits, organizations cannot ensure authenticity or consistency across batches, undermining quality control and safety protocols.

Inadequate Technical Support and Specification Mismatch

Procurement teams may prioritize price over technical compatibility, resulting in tapes that don’t meet specific requirements—such as tape thickness, density, or elongation properties. Generic suppliers often lack the technical expertise to advise on optimal product selection, increasing the risk of application failure. Without access to material data sheets or engineering support, buyers cannot validate suitability for critical sealing tasks.

To mitigate these risks, buyers should source from reputable, certified suppliers, clearly specify material requirements using technical terminology (e.g., “virgin PTFE tape, 0.1mm thick, ASTM D4894 compliant”), avoid trademarked brand references unless licensing agreements exist, and conduct periodic quality audits. Proper due diligence protects both operational integrity and intellectual property compliance.

Logistics & Compliance Guide for Applying Teflon Tape

Purpose

This guide outlines the proper logistical handling, application procedures, and regulatory compliance requirements for using Teflon tape (also known as PTFE tape or thread seal tape) in industrial, commercial, and plumbing applications. Correct usage ensures system integrity, prevents leaks, and maintains compliance with safety and environmental standards.

Scope

This document applies to all personnel involved in the storage, handling, application, and inspection of Teflon tape across piping, plumbing, and fluid conveyance systems. It covers standard white PTFE tape for general-purpose sealing, as well as specialty tapes (e.g., pink for gas lines, yellow for high-pressure water, gray for oxygen lines).

Storage and Handling Logistics

Temperature and Environment

Store Teflon tape in a cool, dry place away from direct sunlight and heat sources. Ideal storage conditions are between 50°F and 77°F (10°C to 25°C). Exposure to UV light or extreme temperatures may degrade tape quality and reduce effectiveness.

Shelf Life and Inventory Management

- Standard PTFE tape has a shelf life of approximately 5 years when stored properly.

- Implement FIFO (First In, First Out) inventory rotation to prevent use of expired materials.

- Inspect rolls before use for brittleness, discoloration, or delamination.

Packaging and Transportation

- Keep tape in original sealed packaging until use to prevent contamination or moisture absorption.

- During transport, protect rolls from crushing, punctures, and exposure to solvents or oils.

Application Procedures

Surface Preparation

- Clean male threads thoroughly using a wire brush or cloth to remove dirt, grease, rust, or old sealant residue.

- Ensure threads are dry before applying tape.

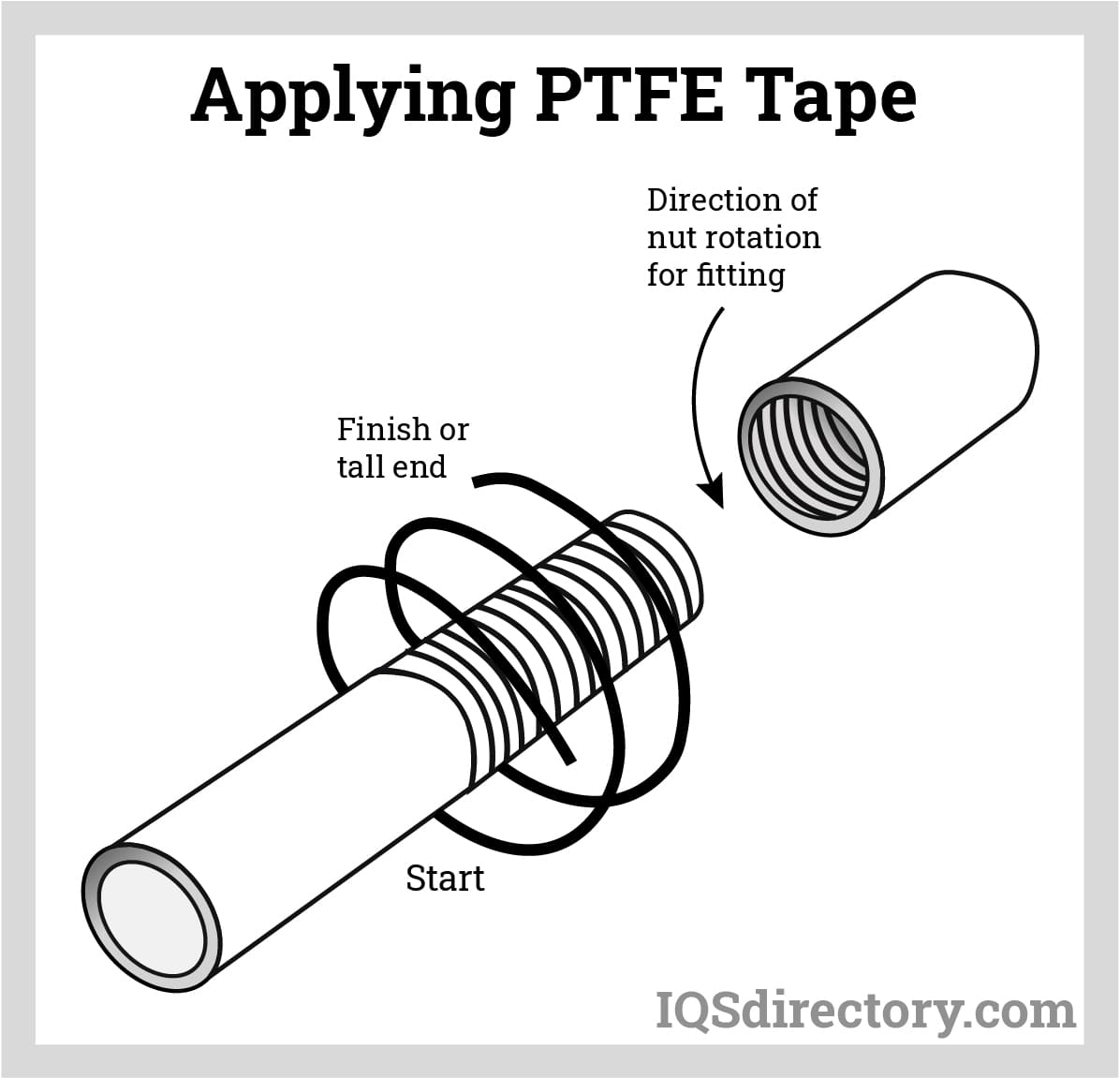

Direction of Wrap

- Wrap the tape clockwise (as viewed from the end of the male thread) to ensure it does not unravel during fitting engagement.

- Start wrapping 1–2 threads back from the end of the male thread to prevent tape from entering the pipe system.

Number of Wraps

- General use (water lines): 2–3 wraps.

- High-pressure systems (hydraulics, gas): 4–6 wraps (using appropriate color-coded tape).

- Avoid over-wrapping, which can cause thread damage or fitting cracks.

Tension and Overlap

- Apply tape with light to moderate tension.

- Overlap each wrap by 50% to ensure full thread coverage.

- Smooth the tape with fingers after application to ensure adhesion.

Compliance Requirements

Regulatory Standards

- OSHA (Occupational Safety and Health Administration): Ensure safe handling practices to prevent slips, trips, or injuries during application. Use appropriate PPE (gloves, eye protection) when necessary.

- EPA (Environmental Protection Agency): Dispose of used or expired tape in accordance with local waste regulations. PTFE is non-toxic but should not be incinerated without proper emission controls.

- CGA (Compressed Gas Association): For oxygen systems (gray tape), follow CGA G-4.1 standards to prevent contamination and combustion risks. Use only oxygen-compatible tape and ensure no oil or hydrocarbon contamination.

Industry-Specific Codes

- Plumbing Codes (IPC/UPC): Teflon tape is an accepted method for sealing threaded joints in water, gas, and drain-waste-vent (DWV) systems when used appropriately.

- ASME B1.20.1: Standard for pipe threads; confirms compatibility of PTFE tape with NPT (National Pipe Taper) threads.

- NFPA 55 & 99: For fuel gas and healthcare applications, use only approved tapes and follow installation guidelines.

Material Safety Data (MSDS/SDS)

- Maintain Safety Data Sheets (SDS) for all PTFE tape products on-site.

- PTFE is chemically inert and non-reactive at room temperature but can release toxic fumes when heated above 500°F (260°C). Avoid open flames during installation.

Inspection and Quality Control

Post-Application Checks

- Visually inspect tape for gaps, wrinkles, or loose ends before assembly.

- After joint assembly, check for leaks under operating pressure.

- Re-tape and reassemble if leaks are detected.

Documentation

- Record tape application in work logs, especially for critical systems (gas, medical gas, high-pressure).

- Use traceable lot numbers for quality tracking in regulated environments.

Disposal and Environmental Compliance

- Discarded tape is typically non-hazardous and may be disposed of in regular waste streams, depending on local regulations.

- Do not incinerate PTFE tape without proper air filtration systems due to potential release of perfluoroisobutylene (PFIB) and other hazardous decomposition products at high temperatures.

Training and Competency

- All personnel applying Teflon tape must complete documented training on proper techniques and compliance requirements.

- Retraining is required annually or after incidents involving sealant failure.

Revision History

| Version | Date | Changes Made |

|———|————|———————————-|

| 1.0 | 2023-04-01 | Initial release |

| 1.1 | 2024-06-15 | Added oxygen system compliance |

This document is controlled. Unauthorized copying is prohibited.

Conclusion on Sourcing and Applying Teflon Tape

In conclusion, sourcing and applying Teflon tape (also known as PTFE tape) is a simple yet critical step in ensuring leak-free threaded pipe connections in plumbing, HVAC, and various industrial applications. When sourcing Teflon tape, it is essential to select the correct type—such as standard white tape for water lines, yellow tape for gas lines, or pink tape for water supplies—based on the specific application to ensure safety, compatibility, and optimal performance. High-quality tape from reputable suppliers ensures adequate thickness, durability, and adhesion.

Proper application techniques—such as wrapping the tape clockwise around the male threads, applying 2–3 even layers without overhang, and avoiding excessive tension—are equally important to maintain seal integrity and prevent tape shredding or particle contamination in the system.

By combining reliable sourcing practices with correct application methods, Teflon tape remains a cost-effective, efficient solution for sealing threaded joints, minimizing maintenance issues, and enhancing the longevity and safety of piping systems.

![[PDF] 2408.1](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-24081-151.png)