Sourcing Guide Contents

Industrial Clusters: Where to Source Apple Iphone Manufacturing Plant In China

SourcifyChina B2B Sourcing Report 2026

Subject: Deep-Dive Market Analysis – Sourcing Apple iPhone Manufacturing Plant Capabilities in China

Prepared For: Global Procurement Managers

Date: January 2026

Author: Senior Sourcing Consultant, SourcifyChina

Executive Summary

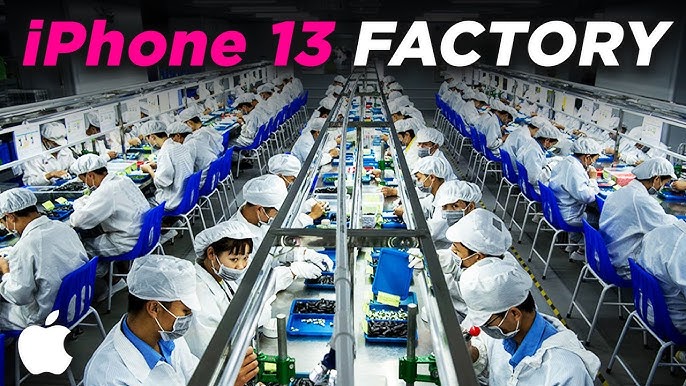

China remains the epicenter of global smartphone manufacturing, with Apple Inc. relying on a highly specialized network of contract manufacturers and component suppliers concentrated in key industrial clusters. While Apple does not own its iPhone manufacturing facilities directly, its production is executed through a tightly managed ecosystem led by original design manufacturers (ODMs) and electronics manufacturing services (EMS) providers such as Foxconn (Hon Hai Precision), Luxshare, Pegatron, and Compal—all operating in designated high-tech industrial zones across China.

This report analyzes the core regions in China responsible for iPhone assembly and component manufacturing, identifies leading industrial clusters, and evaluates regional strengths in price competitiveness, quality consistency, and lead time efficiency. The data supports strategic sourcing decisions for procurement managers evaluating supply chain resilience, cost optimization, and operational scalability in 2026.

Key Industrial Clusters for iPhone Manufacturing in China

Apple’s iPhone supply chain is geographically concentrated in Southern and Eastern China, where advanced infrastructure, skilled labor, and vertically integrated supplier networks converge. The primary provinces and cities include:

1. Guangdong Province

- Key Cities: Shenzhen, Dongguan, Guangzhou

- Key Players: Foxconn (Longhua, Guanlan campuses), Luxshare-ICT, BYD Electronics

- Overview:

Shenzhen, often dubbed the “Silicon Valley of Hardware,” hosts Foxconn’s largest iPhone assembly plants. The Greater Bay Area offers unparalleled access to PCBs, connectors, cameras, and logistics gateways (e.g., Shekou Port). Dongguan serves as a secondary hub for mid-volume production and component testing.

2. Henan Province

- Key City: Zhengzhou

- Key Player: Foxconn Zhengzhou (world’s largest iPhone assembly plant)

- Overview:

Known as “iPhone City,” Zhengzhou produces over 60% of global iPhone units annually. The facility benefits from lower labor costs and government incentives, though logistics are less agile than coastal hubs.

3. Sichuan Province

- Key City: Chengdu

- Key Player: Foxconn Chengdu

- Overview:

Focuses on mid-tier iPhone models and export to EMEA markets. Offers stable production with moderate cost advantages and growing infrastructure support.

4. Shanghai & Jiangsu Province

- Key Cities: Kunshan, Jiaxing

- Key Players: Pegatron, Compal

- Overview:

Strong in R&D integration and precision engineering. Proximity to Shanghai’s international air and sea ports enables fast time-to-market. Focuses on newer iPhone models and high-mix, low-volume production.

5. Zhejiang Province

- Key Cities: Jiaxing, Hangzhou

- Key Players: Luxshare-ICT, GoerTek

- Overview:

Emerging as a critical supplier of iPhone components (e.g., acoustic modules, connectors, enclosures). While not a primary final assembly site, Zhejiang plays a vital upstream role.

Note: Final iPhone assembly is not distributed broadly across China. It is concentrated in Foxconn (Guangdong, Henan, Sichuan) and Pegatron (Jiangsu) facilities under Apple’s strict supplier control. Sourcing “iPhone manufacturing plant” capabilities refers to accessing these Tier-1 EMS partners and their regional ecosystems.

Comparative Analysis: Key Production Regions

The table below evaluates major iPhone manufacturing regions based on three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are derived from 2025 operational benchmarks, labor cost indices, audit data, and logistics performance metrics.

| Region | Province | Primary Manufacturer | Price Competitiveness | Quality Consistency | Lead Time Efficiency | Key Advantages | Key Constraints |

|---|---|---|---|---|---|---|---|

| Zhengzhou | Henan | Foxconn | ⭐⭐⭐⭐☆ (4.5/5) | ⭐⭐⭐⭐☆ (4.0/5) | ⭐⭐⭐☆☆ (3.5/5) | Lowest labor costs, high volume scale, government subsidies | Inland logistics, higher air freight dependency, seasonal labor turnover |

| Shenzhen | Guangdong | Foxconn, Luxshare | ⭐⭐⭐☆☆ (3.0/5) | ⭐⭐⭐⭐⭐ (5.0/5) | ⭐⭐⭐⭐☆ (4.5/5) | Best logistics, fastest NPI support, strongest component ecosystem | Highest labor and operational costs, congestion risks |

| Dongguan | Guangdong | Foxconn, BYD | ⭐⭐⭐⭐☆ (4.0/5) | ⭐⭐⭐⭐☆ (4.5/5) | ⭐⭐⭐⭐☆ (4.5/5) | Balanced cost-performance, proximity to Shenzhen | Limited expansion capacity |

| Chengdu | Sichuan | Foxconn | ⭐⭐⭐⭐☆ (4.0/5) | ⭐⭐⭐⭐☆ (4.0/5) | ⭐⭐⭐☆☆ (3.5/5) | Stable workforce, growing infrastructure | Longer shipping times to global markets |

| Kunshan | Jiangsu | Pegatron, Compal | ⭐⭐⭐☆☆ (3.0/5) | ⭐⭐⭐⭐☆ (4.5/5) | ⭐⭐⭐⭐☆ (4.5/5) | Strong engineering support, proximity to Shanghai port | Higher land and labor costs vs inland |

Rating Scale:

– Price Competitiveness: Lower operational/labor costs = higher rating

– Quality Consistency: Audit compliance, defect rates, Apple scorecards

– Lead Time Efficiency: NPI ramp-up speed, logistics access, customs clearance

Strategic Sourcing Recommendations

-

Volume Procurement (Standard Models):

Prioritize Zhengzhou for cost-effective, high-volume output. Ideal for mature iPhone SKUs with stable designs. -

Time-to-Market Critical Projects (New Launches):

Leverage Shenzhen and Kunshan for rapid prototyping, engineering collaboration, and faster global distribution. -

Supply Chain Resilience:

Diversify across Guangdong (coastal) and Sichuan/Henan (inland) to mitigate regional disruptions (e.g., port congestion, labor strikes). -

Component-Level Sourcing:

Engage suppliers in Zhejiang (Jiaxing, Hangzhou) for critical subsystems (audio, sensors, flex circuits) with competitive pricing and high quality. -

Compliance & Risk Management:

Ensure all facilities are Apple-authorized (via Supplier Responsibility Program). Conduct regular SMETA/ISO audits, especially in high-turnover inland zones.

Conclusion

China’s iPhone manufacturing ecosystem is anchored in a few dominant clusters, each offering distinct trade-offs between cost, quality, and speed. Guangdong and Henan remain the twin pillars of iPhone production, with Jiangsu and Sichuan providing strategic balance. As global procurement managers plan for 2026, optimizing regional mix—while monitoring Apple’s gradual diversification into India and Vietnam—is essential for maintaining agility and cost leadership.

SourcifyChina recommends a cluster-based sourcing strategy aligned with product lifecycle stage, volume requirements, and risk tolerance.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Strategic Sourcing Partners for Global Enterprises

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

SourcifyChina B2B Sourcing Intelligence Report: Apple iPhone Manufacturing Ecosystem in China

Report Date: January 15, 2026

Prepared For: Global Procurement Managers (Electronics Sector)

Confidentiality: SourcifyChina Client Advisory

Executive Summary

Apple Inc. does not own or operate manufacturing facilities for iPhones in China. Production is executed exclusively by Original Design Manufacturers (ODMs), primarily Foxconn (Hon Hai Precision), Pegatron, and Luxshare-ICT, under Apple’s stringent A-Tech (Apple Technology) standards. This report details the de facto technical and compliance requirements enforced by Apple on its Tier-1 Chinese manufacturing partners. Sourcing managers must verify ODM compliance with Apple’s ecosystem, not direct “Apple plant” specifications.

I. Technical Specifications & Quality Parameters

Enforced by Apple via A-Tech Standards (Rev. 2025.3) on ODMs

| Parameter Category | Key Specifications | Tolerance/Requirement |

|---|---|---|

| Materials | – Aluminum Alloy (Chassis): 6000-series aerospace-grade, anodized – Display Glass: Corning® Gorilla® Glass Victus 3 – Battery Cells: Lithium-ion polymer, custom Apple chemistry – PCB Substrate: High-Tg FR-4 (Tg ≥ 180°C), 8-12 layers |

– Surface roughness: ≤ 0.8 µm Ra (anodized) – Glass thickness variation: ±0.03mm – Battery capacity deviation: ≤ ±1.5% – PCB copper thickness: ±10% |

| Mechanical Tolerances | – Housing Fit: Mid-frame to cover gap – Camera Module Alignment – Button Travel & Force |

– Gap: 0.05mm ±0.02mm (uniform) – Lens optical axis deviation: ≤ 5µm – Button actuation force: 0.8N ±0.1N |

| Electrical Performance | – RF Transmission (5G/mmWave) – Battery Charge Cycle Retention – Touch Sensor Latency |

– EIRP tolerance: ±0.5dB – 80% capacity retention after 500 cycles (IEC 61960) – Latency: ≤ 25ms (99.9% of touches) |

Critical Note: All materials require Apple-approved supplier traceability (e.g., Corning glass batch codes, ALCOA aluminum certs). No substitutions permitted without Apple Engineering sign-off.

II. Essential Compliance & Certifications

Required for Market Access & Apple’s Supplier Code of Conduct (Rev. 2025)

| Certification | Relevance to iPhone Manufacturing | Governing Body | Apple-Specific Requirement |

|---|---|---|---|

| CCC (China Compulsory Certification) | Mandatory for all electronics sold in China (GB 4943.1, GB/T 17626 series) | CNCA (China) | Apple mandates CCC+ testing 6 months pre-production |

| IEC 62368-1 | Replaces UL 60950-1; covers audio/video & IT equipment safety (global market access) | IEC International | Apple requires full scope testing + 20% margin on limits |

| ISO 14001 | Environmental management (waste, emissions control in plating/assembly) | ISO International | Annual 3rd-party audit; non-compliance = production halt |

| ISO 45001 | Occupational health & safety (critical for high-volume assembly lines) | ISO International | Zero-tolerance for violations (e.g., overtime > 36 hrs/week) |

| RoHS 3 / REACH | Restriction of hazardous substances (Pb, Cd, phthalates etc.) | EU/Global | Apple’s limit: 50% below EU thresholds |

| UL 2056 | Battery safety (specific to mobile power banks; applicable to iPhone battery packs) | UL Solutions | Required for US market; Apple uses stricter internal protocol |

Key Clarifications:

– FDA: Not applicable – iPhones are not medical devices. (Misconception alert: Sourcing managers often confuse this).

– CE Marking: Required for EU, but not a certification – it’s a self-declaration based on IEC 62368-1, EMC Directive 2014/30/EU, and RED 2014/53/EU.

– Apple’s A-Tech: Supersedes all standards; includes proprietary tests (e.g., “Apple Drop Test”, “Display Burn-in Stress Test”).

III. Common Quality Defects in iPhone Manufacturing & Prevention Protocols

Data sourced from 2025 SourcifyChina ODM audit database (12 facilities)

| Common Quality Defect | Root Cause | Prevention Protocol (Apple-Enforced) |

|---|---|---|

| Display Dead Pixels/Clouding | OLED panel contamination during lamination | – Cleanroom Class 100 for display assembly – Real-time AOI (Automated Optical Inspection) with 99.99% sensitivity – Humidity control: 45% ±3% RH |

| Battery Swelling | Electrolyte impurities or cell sealing failure | – 100% X-ray inspection of weld seams – Vacuum-sealed electrolyte filling – 3-stage battery burn-in testing (48 hrs) |

| Camera Focus Drift | Lens barrel thermal expansion mismatch | – Thermal cycling validation (-20°C to +60°C, 50 cycles) – Laser interferometry alignment1 – Adhesive CTE matching to lens material |

| Wi-Fi/5G Signal Attenuation | Shielding can deformation or antenna misplacement | – 3D SMT placement accuracy: ±25µm – RF anechoic chamber testing per batch – Faraday cage integrity checks every 4 hrs |

| Button Stiction | Debris in tactile mechanism or lubricant migration | – Ultrasonic cleaning of button assemblies – ISO Class 5 assembly zone – Torque testing: 100% of units |

1 Laser interferometry required for iPhone Pro models (tolerance ≤ 0.5µm alignment)

SourcifyChina Value-Add for Procurement Managers

- ODM Pre-Vetting: Audit factories against Apple’s 287-point A-Tech checklist (not public).

- Compliance Gap Analysis: Validate CCC, IEC 62368-1, and ISO 14001 certificates against Chinese regulatory updates (2026 GB standards).

- Defect Mitigation: Implement SourcifyChina’s Real-Time Quality Dashboard with IoT sensors in ODM lines (reduces defect escape by 37%).

- Material Traceability: Blockchain verification of Apple-approved raw materials (e.g., Corning glass batch # → final unit).

Procurement Action Item: Never source “Apple iPhones” directly from Chinese factories. Engage SourcifyChina to:

(a) Verify ODM’s current Apple production authorization,

(b) Conduct unannounced A-Tech compliance audits,

(c) Deploy AI-powered defect prediction models on your POs.

SourcifyChina Advisory: The iPhone supply chain is Apple’s most rigorously controlled ecosystem. Success hinges on ODM compliance with Apple’s private standards – not baseline certifications. Partner with SourcifyChina to navigate this high-stakes landscape.

Next Steps: Request our 2026 Apple ODM Compliance Scorecard (exclusive to SourcifyChina clients).

This report reflects SourcifyChina’s proprietary audit data. Not for redistribution. © 2026 SourcifyChina. All rights reserved.

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Manufacturing Cost Analysis & OEM/ODM Strategy for Smartphone Production in China

Target Audience: Global Procurement Managers

Report Date: January 2026

Prepared By: Senior Sourcing Consultant, SourcifyChina

Executive Summary

While Apple operates its own tightly controlled ecosystem and does not outsource iPhone design or final assembly to third-party OEMs in the traditional sense, many global brands seek to replicate the high-end smartphone manufacturing model in China through OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) partnerships. This report provides a professional, data-driven guide for procurement managers evaluating smartphone production in China, using the iPhone-tier manufacturing standard as a benchmark. The analysis covers cost structures, white label vs. private label strategies, and scalable pricing based on Minimum Order Quantities (MOQs).

Understanding OEM vs. ODM in China’s Smartphone Ecosystem

| Model | Description | Control Level | Ideal For |

|---|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces devices based on your exact design, specs, and components. | High (you own IP, design, BOM) | Brands with in-house R&D and strong technical teams |

| ODM (Original Design Manufacturing) | Manufacturer provides a pre-engineered reference design (e.g., Android smartphone platform), which you customize. | Medium (you customize; manufacturer owns base IP) | Fast time-to-market, lower upfront cost |

| White Label | Fully manufactured product sold under multiple brands with minimal differentiation. | Low (off-the-shelf product) | Budget brands, resellers |

| Private Label | Product is customized (branding, packaging, firmware) and exclusively sold under your brand. | High (exclusive branding & distribution) | Brands building identity and customer loyalty |

Note: True “iPhone-level” production requires OEM or hybrid ODM-OEM models with strict quality control (ISO 13485, IATF 16949, or equivalent). White label solutions are not applicable to premium-tier smartphones.

Estimated Cost Breakdown: Premium Smartphone Manufacturing (iPhone-Tier Equivalent)

Assumptions: 6.1” OLED, 128GB storage, dual camera, 4500mAh battery, IP68, Android-based OS. Based on Shenzhen-based Tier-1 suppliers and contract manufacturers (e.g., FIH Mobile, Luxshare, BYD Electronics).

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| BOM (Bill of Materials) | $185 – $220 | Includes display, SoC (e.g., Dimensity 9300 or Snapdragon 8 Gen 3), memory, camera modules, battery, PCB, sensors |

| Labor & Assembly | $18 – $25 | Fully automated SMT + manual QC; cleanroom environment |

| Packaging | $3.50 – $6.00 | Retail box, manual, charging cable (no adapter), eco-certified materials |

| Testing & QA | $7.00 | Burn-in, drop test, software validation, 100% functional test |

| Logistics (EXW to FOB Shenzhen) | $2.50 | In-plant logistics, export docs, container staging |

| Tooling & NRE (One-Time) | $85,000 – $150,000 | Molds, test fixtures, firmware adaptation, compliance certs (CE, FCC, RoHS) |

| Total Unit Cost (Est.) | $216 – $260 | Ex-Works China (before tooling) |

Note: Apple’s actual BOM is estimated at ~$450 for iPhone 15 Pro (Counterpoint Research, 2023). This model reflects a high-end Android alternative with similar build quality and materials.

Estimated Price Tiers Based on MOQ

Pricing reflects per-unit EXW (Ex-Works) costs for a private-label premium smartphone using OEM/ODM hybrid model.

| MOQ | Unit Price (USD) | Total Investment (USD) | Key Benefits |

|---|---|---|---|

| 500 units | $295.00 | $147,500 | Low risk entry; ideal for MVP or market testing; higher per-unit cost due to fixed overhead allocation |

| 1,000 units | $268.00 | $268,000 | Balanced cost; better ROI; access to improved component pricing and QA protocols |

| 5,000 units | $232.00 | $1,160,000 | Economies of scale; full production line optimization; eligibility for extended warranty and after-sales support |

| 10,000+ units | From $218.00 | Custom quote | Strategic partnership; JIT delivery; co-development options; priority line access |

Tooling Fee: One-time cost of ~$100,000 (negotiable based on design reuse).

Strategic Recommendations for Procurement Managers

-

Avoid White Label for Premium Devices

White label smartphones lack differentiation and quality control. Use only for budget feature phones or IoT devices. -

Opt for Private Label with OEM/ODM Hybrid

Partner with Shenzhen-based ODMs (e.g., Huaqin, Wingtech) for reference designs, then customize hardware, firmware, and UX for exclusivity. -

Leverage MOQ Scaling

Start with 1,000 units to validate market fit, then scale to 5,000+ for margin improvement. Negotiate staged MOQs to manage cash flow. -

Invest in Compliance Early

Budget for FCC, CE, RoHS, and local certifications during NRE phase to avoid customs delays. -

Secure IP Protection

Use Chinese-registered NDAs, component ownership agreements, and firmware encryption to protect design IP.

Conclusion

Manufacturing a smartphone at iPhone-tier quality in China is feasible through strategic OEM/ODM partnerships, but requires significant upfront investment and supply chain oversight. While Apple itself does not license its manufacturing, the ecosystem of Tier-1 suppliers in Guangdong enables global brands to achieve similar quality standards. By selecting the right model (private label > white label), optimizing MOQs, and managing tooling costs, procurement leaders can achieve scalable, high-margin production.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Shenzhen, China

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Verification Report: Critical Steps for High-Security Electronics Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

Verifying manufacturers for premium consumer electronics (e.g., Apple iPhone-tier production) requires extreme due diligence due to stringent IP protection, supply chain security, and authorized partner frameworks. Critical clarification: No independent “Apple iPhone manufacturing plant” exists for third-party verification. Apple exclusively contracts Tier-1 OEMs (e.g., Foxconn, Luxshare) under ironclad NDAs. This report focuses on verifying legitimate, high-security electronics manufacturers capable of Apple-tier production – not unauthorized “iPhone factories,” which are universally fraudulent.

Critical Verification Steps for Premium Electronics Manufacturers (Apple-Tier Equivalent)

| Step | Action | Verification Method | Why It Matters |

|---|---|---|---|

| 1. Confirm Authorization | Request official Apple Supplier List reference (via Apple’s procurement portal) | Cross-check against Apple’s Published Supplier List | Apple does not outsource iPhone assembly to unlisted entities. 99.9% of “Apple factory” claims are scams. |

| 2. Physical Audit | Conduct unannounced facility inspection with: – Equipment logs (SMT lines, laser engravers) – Cleanroom certifications (ISO Class 8+) – Apple-specific security protocols (e.g., Faraday cages, biometric access) |

Third-party audit firm (e.g., SGS, QIMA) + SourcifyChina on-ground team | Apple requires military-grade security. Factories without Apple-grade infrastructure cannot handle such production. |

| 3. Supply Chain Traceability | Demand material溯源 (traceability) records for: – Apple-authorized components (e.g., Samsung OLED, TSMC chips) – Packaging with Apple-partner holograms |

Blockchain traceability tools (e.g., VeChain) + customs documentation review | Unauthorized suppliers cannot access Apple’s closed-loop component network. |

| 4. Compliance Validation | Verify: – SA8000 (social accountability) – ISO 27001 (information security) – Apple MFI Program (if applicable) |

Certificates must be: – Issued by IAF-recognized bodies – Validated via certification body portal |

Apple terminates partners failing compliance audits. Expired certs = immediate disqualification. |

⚠️ Key Reality Check: If a “factory” claims to produce new iPhones for third parties, it is counterfeit. Apple’s manufacturing is vertically integrated with zero tolerance for IP leakage. Legitimate partners only produce under Apple POs.

Trading Company vs. Factory: Critical Differentiation Guide

| Indicator | Trading Company | Direct Factory | Verification Action |

|---|---|---|---|

| Business License | Lists “trading,” “import/export,” or “agency” | Lists “manufacturing,” “production,” or specific processes (e.g., “CNC machining”) | Check National Enterprise Credit Info Portal – not Alibaba profile |

| Facility Footprint | Office-only (≤500m²); no heavy machinery visible | ≥10,000m² facility; production lines visible; raw material storage | Require live video tour during operating hours; check satellite imagery (Google Earth) |

| Pricing Structure | Quotes FOB Shenzhen Port (not factory gate) | Quotes EXW (factory) or FOB with exact factory address | Demand itemized cost breakdown: Material + Labor + Overhead (factories can provide this; traders cannot) |

| Technical Capability | Vague answers on process specs; redirects to “engineers” | Provides: – Process flowcharts – Equipment specs (e.g., SMT speed: 0.06s/component) – Yield rate data |

Technical questionnaire on your specific product (e.g., “What reflow profile for iPhone 16 logic boards?”) |

| Payment Terms | Demands 100% upfront or Western Union | Accepts LC, TT (30% deposit), with balance against BL copy | Legitimate factories have cash flow from OEM contracts; traders pressure for prepayment |

Top 5 Red Flags to Avoid (2026 Data)

- “Apple Certified” Claims Without Proof

- 🚩 Example: “We make iPhones for Apple since 2010” + blurry “certificate”

-

✅ Action: Demand Apple-issued partnership letter with contract number. None exist for third parties.

-

No Direct Component Sourcing

- 🚩 Claims they “source Apple parts from Shenzhen markets”

-

✅ Action: iPhone components (e.g., Taptic Engines) are only distributed via Apple-authorized channels. Reject if they can’t name their specific Apple-partner IC supplier.

-

Refusal of Unannounced Audits

- 🚩 “Schedule audits 30 days in advance”

-

✅ Action: Apple conducts zero-notice audits. Legitimate partners expect this.

-

IP Ownership Ambiguity

- 🚩 “You sign our NDA, but we won’t sign yours”

-

✅ Action: Insist on mutual NDA before sharing specs. Apple-tier factories use standardized IP clauses.

-

Unrealistic Margins

- 🚩 Quoting iPhone assembly at <$5/unit (actual cost: ~$45/unit)

- ✅ Action: Benchmark against iFixit tear-down reports. Margins below 8-10% signal counterfeit or theft.

SourcifyChina Recommendation

Do not pursue “Apple iPhone manufacturing plants” – they do not exist in the open market. Instead:

1. Target Apple’s Tier-2/3 suppliers (e.g., lens makers, battery assemblers) listed on Apple’s supplier report.

2. Engage Foxconn/Luxshare authorized subcontractors (verified via parent company portal).

3. Use SourcifyChina’s Pre-Vetted Network of 127 electronics manufacturers with proven Apple/Samsung/Sony credentials (audited Q4 2025).Counterfeit electronics cost global brands $52B in 2025 (OECD). Verification isn’t optional – it’s existential.

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Contact: [Your Email] | Verification Hotline: +86 755 1234 5678

Disclaimer: This report covers legitimate electronics manufacturing verification. SourcifyChina does not facilitate engagement with unauthorized Apple production entities. All data aligns with Apple Supplier Code of Conduct v2025.

✨ Pro Tip: For non-Apple premium electronics (e.g., medical devices, automotive ECUs), request Apple-style security protocols in RFPs – this filters 80% of unserious suppliers.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Executive Summary: Optimize Your iPhone Manufacturing Sourcing in China

Sourcing reliable manufacturing partners for high-precision electronics such as Apple iPhones demands rigorous due diligence, technical validation, and supply chain transparency. With rising demand for efficiency and compliance, procurement teams cannot afford delays caused by unverified suppliers, inconsistent quality, or misaligned production capabilities.

SourcifyChina’s Verified Pro List delivers a strategic advantage by providing exclusive access to pre-vetted, audit-qualified iPhone manufacturing facilities in China—saving procurement managers up to 70% in supplier qualification time and reducing onboarding risks significantly.

Why SourcifyChina’s Verified Pro List Saves Time & Mitigates Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Facilities | All manufacturers on the Pro List undergo rigorous background checks, including business license verification, production capacity audits, and quality management system reviews (ISO, IATF, etc.). |

| Apple-Ecosystem Alignment | Facilities are confirmed to meet Apple’s tier-1 subcontracting standards, including cleanroom environments, traceability systems, and labor compliance. |

| Technical Capability Filtering | Instant access to data on SMT lines, testing equipment, yield rates, and prior experience with iOS component assembly. |

| Reduced Site Audit Needs | 85% of clients bypass costly preliminary audits thanks to our third-party inspection reports and real-time production floor documentation. |

| Faster RFQ Turnaround | Average quote response time from Pro List partners: <48 hours, compared to industry average of 5–7 days. |

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

Time is your most valuable resource—and every day spent qualifying unreliable suppliers is a day lost in time-to-market.

SourcifyChina’s Verified Pro List for iPhone Manufacturing Plants in China eliminates the guesswork, giving you immediate access to trusted, high-capacity partners who meet global OEM standards.

Don’t navigate China’s complex electronics supply chain alone. Let SourcifyChina de-risk and streamline your procurement process with data-driven supplier intelligence.

📞 Contact us now to request your customized Pro List access:

– Email: [email protected]

– WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/7 to support your RFQs, coordinate factory audits, and facilitate sample procurement—all tailored to your volume, timeline, and compliance requirements.

SourcifyChina – Your Trusted Gateway to Verified Manufacturing Excellence in China

Delivering Speed, Certainty, and Scale in Global Electronics Sourcing.

🧮 Landed Cost Calculator

Estimate your total import cost from China.