The global ball valve market is experiencing robust growth, driven by rising demand in oil & gas, water treatment, and power generation industries. According to Mordor Intelligence, the ball valve market was valued at USD 8.2 billion in 2023 and is projected to reach USD 11.3 billion by 2029, growing at a CAGR of 5.6% during the forecast period. This expansion is fueled by increasing infrastructure investments, stringent regulatory standards for fluid control systems, and the growing adoption of automated valve solutions. Within this evolving landscape, manufacturers leveraging advanced materials, smart actuation technologies, and digital sales platforms—such as Apollo, a leading distributor of industrial valves—are gaining competitive advantage. As demand for reliable, high-performance ball valves rises, particularly in North America and Asia-Pacific, a select group of manufacturers has emerged as key suppliers on Apollo’s network, combining quality, scalability, and technical innovation to meet global industry needs.

Top 9 Apollo Ball Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Apollo Valves

Domain Est. 1997

Website: aivinc.com

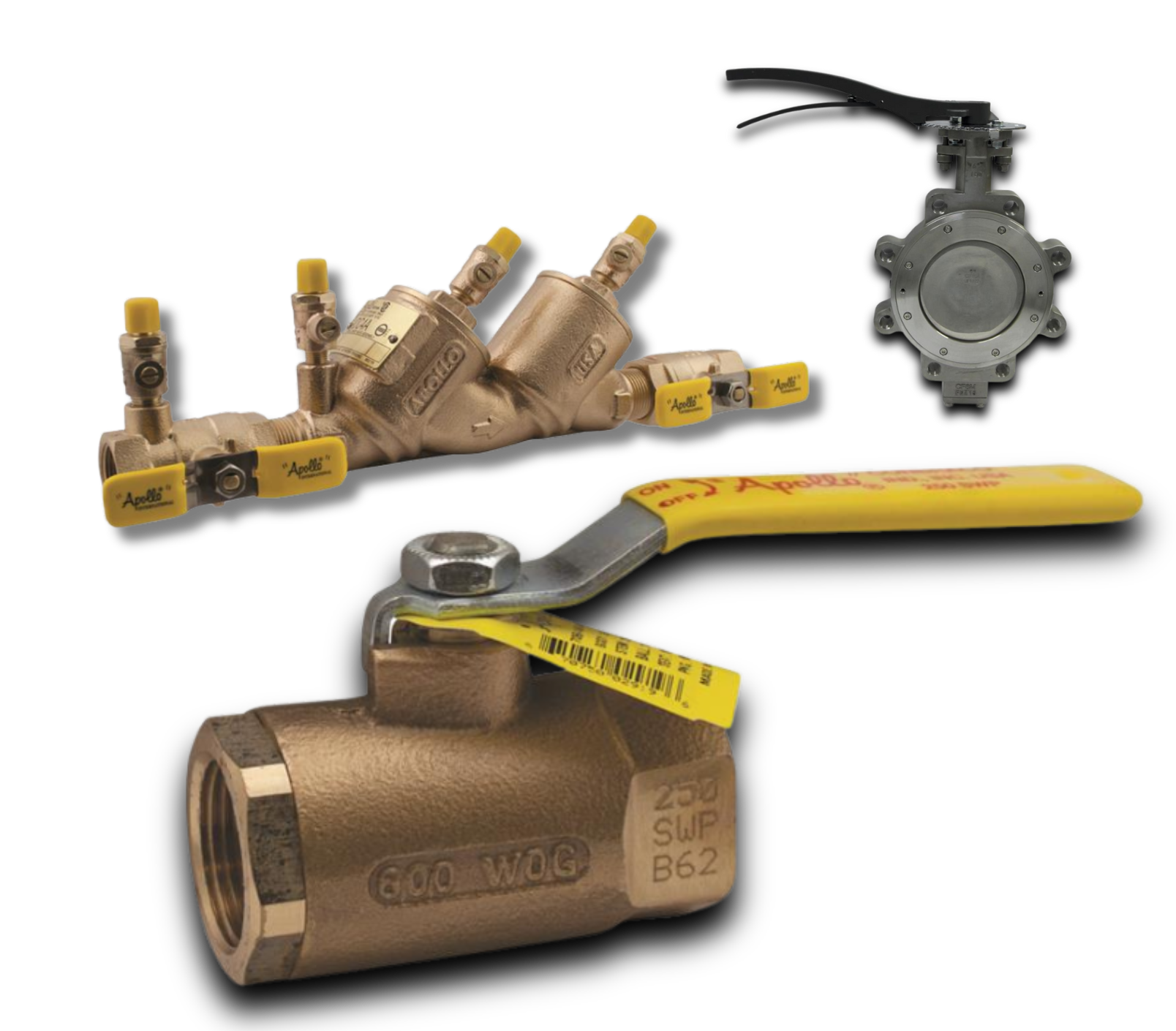

Key Highlights: The Apollo Valves brand delivers a comprehensive range of products, including ball valves, butterfly valves, backflow prevention devices, water pressure ……

#2 Apollo Valves

Domain Est. 1999

Website: macombgroup.com

Key Highlights: Conbraco Industries’ “APOLLO®” Valves is internationally renowned for setting the bar for quality and dependability in the valve technology market….

#3 acquisition Conbraco Industries in America

Domain Est. 2000

Website: aalberts.com

Key Highlights: Conbraco Industries, “APOLLO®“ Valves, is a key player in the North American market for ball valves, safety, relief and check valves, strainers and a new ……

#4 Apollo Ball Valves

Domain Est. 2001

Website: superiorvalves.com

Key Highlights: You can count on Conbraco for top quality Apollo® bronze and steel ball valves in all sizes and shapes, and with all the connections and options you need….

#5 Apollo Online

Domain Est. 2004

Website: online.apollovalves.com

Key Highlights: We are committed to providing 100% accurate, up-to-date information; however, we can not ensure all business processes have completed and posted to this ……

#6 Apollo Valves Distributor

Domain Est. 2005

Website: flosource.com

Key Highlights: As an Authorized Apollo distributor FloSource stocks flanged valves thru 8 Inch. 3 piece valves in carbon & stainless steel thru 2 inch and bronze valves thru ……

#7 Introducing Apollo Valves

Domain Est. 2009

Website: valveman.com

Key Highlights: Apollo Valves offers a comprehensive range of products, from trusted ball valves to failsafe backflow prevention devices, and everything in between….

#8 TMG Ball Valves

Domain Est. 2011

Website: apolloflow.com

Key Highlights: A full-port stainless steel ball valve that combines reliable operation with an all stainless steel body and trim….

#9 Apollo Valves

Domain Est. 2021

Website: aalberts-ips.us

Key Highlights: Aalberts integrated piping systems engineers the most advanced integrated piping systems for the distribution and control of liquids and ……

Expert Sourcing Insights for Apollo Ball Valve

H2: Market Trends Shaping the Apollo Ball Valve Industry in 2026

As we approach 2026, the global market for ball valves—particularly premium brands like Apollo—faces a dynamic landscape influenced by technological innovation, regulatory changes, and shifting industrial demands. Apollo Ball Valve, recognized for its high-performance valves in critical applications across oil & gas, chemical processing, power generation, and water treatment, is poised to benefit from several key trends.

-

Increased Demand in Energy Transition Infrastructure

The global push toward energy transition is accelerating investments in liquefied natural gas (LNG), hydrogen production, and carbon capture, utilization, and storage (CCUS). Apollo Ball Valves, known for their durability and reliability in high-pressure and high-temperature environments, are becoming essential components in these emerging sectors. By 2026, demand is expected to rise significantly, particularly for cryogenic and hydrogen-compatible valves, where Apollo’s engineering expertise provides a competitive advantage. -

Adoption of Smart Valve Technologies

The industrial Internet of Things (IIoT) is driving demand for smart valves equipped with sensors and digital monitoring capabilities. Apollo is anticipated to expand its offering of smart ball valves integrated with predictive maintenance algorithms and remote diagnostics. This shift aligns with broader market preferences for operational efficiency and reduced downtime, especially in automated and unmanned facilities. -

Stricter Environmental and Safety Regulations

Environmental regulations, particularly those targeting fugitive emissions (e.g., EPA Methane Rules, EU F-Gas Regulation), are tightening globally. Apollo’s compliance with API 624 and ISO 15848 standards positions its products favorably in regulated markets. By 2026, valves with low-emission certifications will dominate procurement decisions, reinforcing Apollo’s value proposition in environmentally sensitive applications. -

Growth in Industrial Automation and Modular Construction

Modular and skid-based construction in oil & gas, petrochemical, and water treatment plants is increasing demand for pre-assembled, tested valve packages. Apollo’s ability to supply engineered valve solutions tailored to modular systems enhances its appeal. Furthermore, integration with digital twins and automated control systems will make Apollo valves a preferred choice in automated process environments. -

Supply Chain Localization and Resilience

Geopolitical uncertainties and past supply chain disruptions have prompted industries to prioritize regional sourcing. By 2026, Apollo is expected to strengthen its regional manufacturing and distribution networks—particularly in North America, the Middle East, and Southeast Asia—to reduce lead times and meet localization requirements in key projects. -

Sustainability and Circular Economy Pressures

End-users are increasingly demanding sustainable products with extended lifecycles and recyclable materials. Apollo’s focus on robust construction and repairable valve designs supports sustainability goals. In 2026, lifecycle cost analysis will outweigh initial purchase price in procurement decisions, benefiting premium brands like Apollo.

Conclusion:

By 2026, the Apollo Ball Valve market will be shaped by the convergence of energy transformation, digitalization, regulatory compliance, and supply chain resilience. Apollo’s reputation for quality, innovation, and technical support positions it well to capitalize on these trends, particularly in high-specification and mission-critical applications across evolving industrial sectors.

Common Pitfalls When Sourcing Apollo Ball Valves (Quality and IP)

Sourcing Apollo ball valves—particularly those manufactured by reputable companies like Apollo Valves (a brand under Flowserve) or generic suppliers using the “Apollo” name—can be fraught with challenges, especially concerning product quality and intellectual property (IP) integrity. Being aware of these common pitfalls helps ensure reliable performance and avoids legal or operational risks.

Inconsistent Quality from Unauthorized Suppliers

One of the most prevalent issues is purchasing ball valves that appear to be Apollo-branded but are sourced from unauthorized or third-party manufacturers. These suppliers may mimic the original design and packaging, but the materials, tolerances, and manufacturing processes often fall short of Apollo’s established standards. This can lead to premature failure, leaks, or non-compliance with industry specifications such as ASME, API, or ANSI.

Counterfeit or Replica Valves

Counterfeiting is a significant concern in the valve industry. Illegitimate suppliers may produce and sell replicas of genuine Apollo ball valves, using similar logos, model numbers, and documentation. These counterfeit products lack proper quality control and testing, posing safety and reliability risks in critical applications such as oil and gas, water treatment, or chemical processing.

Misrepresentation of IP and Certification

Some suppliers falsely claim that their valves meet specific certifications (e.g., API 6D, ISO 9001) or are manufactured under licensed intellectual property. In reality, they may not possess the rights to produce Apollo-designed valves or have undergone the required certification processes. This misrepresentation undermines compliance and may expose buyers to liability in regulated environments.

Lack of Traceability and Documentation

Genuine Apollo valves come with full traceability, including material test reports (MTRs), serial numbers, and certification documentation. Sourcing through unofficial channels often means missing or falsified paperwork, making it difficult to verify authenticity, ensure compliance, or support warranty claims.

Supply Chain Vulnerabilities

Using brokers or distributors without direct authorization from the original manufacturer increases the risk of receiving substandard or non-genuine products. These intermediaries may not have stringent quality assurance protocols, allowing counterfeit or low-quality valves to enter the supply chain undetected.

Inadequate After-Sales Support and Warranty

Purchasing from unauthorized sources often voids the manufacturer’s warranty. If a valve fails, the buyer may find it impossible to obtain technical support, replacement parts, or compensation—especially when the source lacks accountability or disappears after the sale.

Price-Driven Procurement Risks

Opting for the lowest-cost option without vetting the supplier can lead to significant long-term costs due to downtime, maintenance, or safety incidents. Apollo’s reputation is built on durability and performance; compromising on source authenticity undermines that value proposition.

Conclusion

To mitigate these pitfalls, always source Apollo ball valves through authorized distributors or directly from the manufacturer. Verify certifications, demand full documentation, and conduct supplier audits when possible. Protecting against IP infringement and ensuring quality isn’t just about cost—it’s about safety, reliability, and regulatory compliance.

Logistics & Compliance Guide for Apollo Ball Valve

Product Overview

Apollo Ball Valves are engineered for reliable flow control across industrial, commercial, and residential applications. These valves are manufactured to meet international standards and are designed for durability, leak-tight performance, and ease of installation. This guide outlines essential logistics and compliance requirements to ensure proper handling, transportation, and regulatory adherence.

Regulatory Compliance

Apollo Ball Valves comply with multiple international standards and certifications, including but not limited to:

– ASME B16.34: Design and pressure ratings

– API 6D: Specification for pipeline valves

– ISO 5208: Valve leakage classification

– NACE MR0175/ISO 15156: Materials for sour service environments

– PED 2014/68/EU: Pressure Equipment Directive (CE marked where applicable)

– CRN (Canadian Registration Number): Registered for use in Canadian provinces as required

Ensure all valves are supplied with proper documentation, including Material Test Reports (MTRs), Certificates of Conformance (CoC), and applicable third-party inspection reports (e.g., API 598 testing).

Packaging & Handling

- Valves are shipped in protective packaging to prevent damage during transit.

- Flanged ends are covered with plastic caps or metal blinds; threaded ends use plastic plugs.

- Larger valves may be mounted on wooden skids and secured with straps.

- Avoid dragging or dropping valves; use appropriate lifting equipment for units over 25 kg.

- Store in a dry, covered area away from direct sunlight and corrosive agents.

Transportation Requirements

- Use vehicles with sufficient load capacity and secure tie-down points.

- Stack valves only as recommended by Apollo; never exceed load limits.

- Protect valves from moisture, extreme temperatures, and contamination during transit.

- For international shipments, comply with IMDG Code (if applicable) and ensure proper labeling for hazardous materials (e.g., grease or protective coatings, if any).

Import & Export Compliance

- Confirm export classification under relevant national systems (e.g., ECCN in the U.S. Commerce Control List). Apollo Ball Valves typically fall under EAR99 (no license required for most destinations).

- Prepare commercial invoice, packing list, and bill of lading/air waybill for customs clearance.

- For shipments to regulated markets (e.g., EU, Canada, Australia), verify CE, CRN, or WaterMark certification requirements based on valve application.

- Maintain records of export transactions in compliance with local laws (e.g., U.S. Export Administration Regulations).

Installation & Usage Compliance

- Install valves in accordance with manufacturer instructions and local plumbing or pipeline codes.

- Perform pre-commissioning inspections and pressure testing per project specifications.

- Use only compatible media and within specified temperature and pressure limits.

- For use in potable water systems, confirm valve materials meet NSF/ANSI 61 and NSF/ANSI 372 standards.

Documentation & Traceability

- Each valve is assigned a unique serial number for traceability.

- Maintain records of purchase orders, shipping documents, inspection reports, and installation logs.

- Provide end users with operation and maintenance manuals and compliance certificates.

Environmental & Safety Considerations

- Dispose of packaging materials in accordance with local recycling regulations.

- Used valves may contain residual process fluids; follow appropriate cleaning and disposal procedures per environmental regulations (e.g., EPA, REACH).

- Personnel should wear standard PPE (gloves, safety glasses) when handling valves.

Support & Contact

For compliance verification, documentation requests, or technical support, contact Apollo customer service at:

– Phone: [Insert Regional Contact Number]

– Email: [Insert Support Email]

– Website: [Insert Official Website URL]

Always refer to the latest product datasheets and compliance statements available on the Apollo website for up-to-date information.

Conclusion for Sourcing Apollo Ball Valves

After a thorough evaluation of suppliers, product specifications, pricing, lead times, and quality assurance processes, sourcing Apollo ball valves presents a reliable and cost-effective solution for our fluid control needs. Apollo’s reputation for durability, compliance with industry standards (such as ASME, API, and ISO), and broad range of materials and configurations aligns well with our operational requirements across diverse applications.

The availability of both stainless steel and brass ball valves in multiple end connections (threaded, sweat, and socket weld) ensures compatibility with existing systems. Additionally, consistent product quality, strong technical support, and competitive pricing from authorized distributors further strengthen the case for selecting Apollo as a preferred supplier.

In conclusion, sourcing Apollo ball valves supports long-term reliability, reduces maintenance costs, and enhances system performance. We recommend proceeding with procurement through certified Apollo distributors to ensure authenticity, warranty coverage, and timely delivery.