The global permanent magnet market, driven by rising demand in electric vehicles, renewable energy systems, and high-performance electronics, is poised for significant expansion. According to Mordor Intelligence, the market was valued at USD 19.78 billion in 2023 and is projected to reach USD 32.54 billion by 2029, growing at a CAGR of approximately 8.7% during the forecast period. A key segment within this growth is high-performance rare-earth magnets, including neodymium-iron-boron (NdFeB) types—commonly referred to as apex magnets due to their superior magnetic strength and thermal stability. With increasing industrial automation and clean energy adoption, the need for reliable apex magnet manufacturers has never been more critical. Based on production capacity, innovation, global reach, and market share, the following five companies stand out as leaders in the apex magnet manufacturing space.

Top 5 Apex Magnets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Apex Magnetic Industries

Domain Est. 1996

Website: indiamart.com

Key Highlights: Rating 4.1 (7) Apex Magnetic Industries provides you the best range of Magnetic Separator, Magnetic Destoner, Industrial Magnets, Magnetic Roll Separator, Drawer Magnet, ……

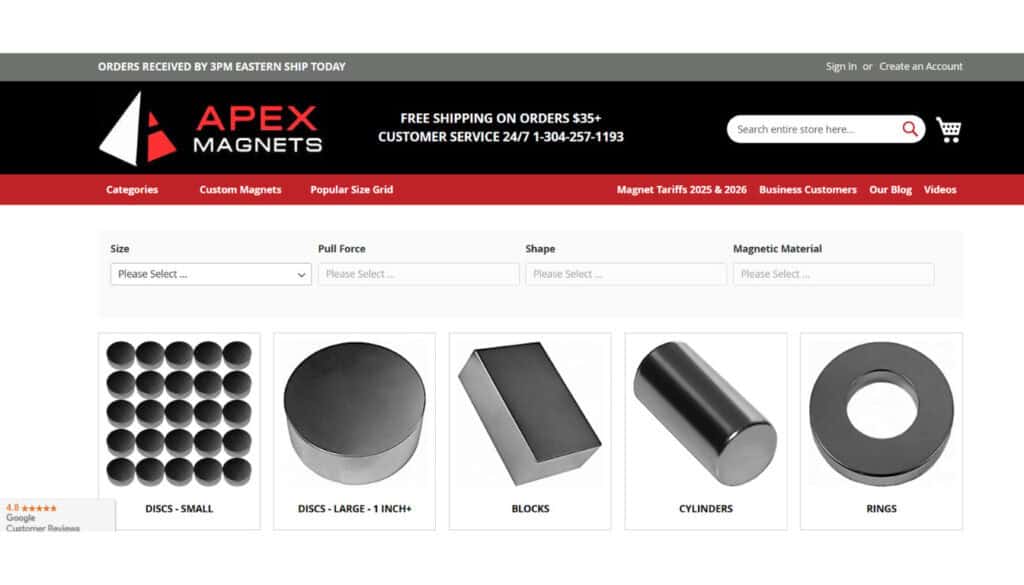

#2 Apex Magnets

Domain Est. 2010 | Founded: 2003

Website: industrialmarinepower.com

Key Highlights: Founded in 2003, Emovendo LLC specializes in a wide range of magnets and magnetic products such as magnetic hooks….

#3 About Leading Magnet Manufacturer

Website: apexmagneticindustries.com

Key Highlights: Apex Magnetic Industries is a leading magnetic equipment manufacturer in India, offering innovative separation solutions with global quality standards….

#4 Apex Magnets

Domain Est. 2001

Website: magnetassemblies.com

Key Highlights: Apex Magnets is a leading provider of high-quality magnet assemblies, offering a wide range of magnetic solutions to meet the diverse needs of industries ….

#5 Apex Magnets

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: At Apex Magnets, we are a leading provider of high-quality magnets and magnetic products for a wide range of applications. With over a decade of experience ……

Expert Sourcing Insights for Apex Magnets

H2: 2026 Market Trends Forecast for Apex Magnets

As we approach 2026, Apex Magnets—specializing in the production and distribution of high-performance permanent magnets, particularly neodymium, samarium-cobalt, and ferrite magnets—is positioned to benefit from several transformative global market trends. The evolving landscape of clean energy, electric mobility, advanced manufacturing, and digitalization is expected to significantly influence demand dynamics, supply chain strategies, and innovation pathways for magnet producers like Apex Magnets.

-

Growth in Electric Vehicles (EVs) and Transportation Electrification

The global EV market is projected to grow at a CAGR of over 20% through 2026, driven by government emissions regulations, falling battery costs, and expanding charging infrastructure. Apex Magnets is well-placed to capitalize on this trend, as high-grade neodymium-iron-boron (NdFeB) magnets are essential components in EV traction motors. With automakers increasingly adopting permanent magnet synchronous motors (PMSMs) for their efficiency and power density, demand for premium rare-earth magnets is expected to surge. Apex Magnets can strengthen its market position by expanding capacity, enhancing magnet coatings for durability, and developing cost-effective, low-dysprosium formulations to address raw material volatility. -

Expansion of Renewable Energy Infrastructure

Wind energy, particularly offshore wind, continues to rely heavily on direct-drive permanent magnet generators, which require large volumes of high-performance magnets. As countries accelerate their net-zero commitments, the global wind power capacity is expected to grow significantly by 2026. Apex Magnets can leverage this trend by partnering with turbine manufacturers and investing in scalable, sustainable production methods. Strategic focus on corrosion-resistant and high-temperature-grade magnets will be crucial to meet the demanding operational conditions of wind turbines. -

Supply Chain Resilience and Rare Earth Diversification

Geopolitical tensions and supply concentration in rare earth elements (REEs)—particularly in China—are prompting efforts to diversify supply chains. By 2026, North American and European initiatives to onshore magnet and REE processing are expected to gain momentum. Apex Magnets can position itself as a leader in regional manufacturing by integrating recycling technologies (e.g., urban mining of end-of-life magnets), investing in sustainable sourcing partnerships, and collaborating with research institutions on alternative magnet chemistries. This aligns with growing customer demand for ESG-compliant supply chains. -

Advancements in Automation, Robotics, and Consumer Electronics

The ongoing proliferation of robotics, drones, medical devices, and high-efficiency consumer electronics continues to drive demand for miniaturized, high-strength magnets. Apex Magnets’ expertise in custom magnet solutions—such as precision-cut, bonded, or multi-pole magnetized components—positions it favorably in high-margin niche markets. By 2026, increased adoption of Industry 4.0 technologies will require magnets with tighter tolerances and enhanced reliability, creating opportunities for product differentiation through advanced quality control and digital design tools. -

Sustainability and Circular Economy Pressures

Environmental regulations and stakeholder expectations will intensify around responsible sourcing and end-of-life management. By 2026, magnet producers will likely face stricter reporting requirements for carbon footprint and REE recovery rates. Apex Magnets can lead in sustainability by developing closed-loop recycling programs, obtaining third-party environmental certifications, and transparently communicating lifecycle impacts to customers in regulated industries such as automotive and aerospace.

Conclusion

By 2026, Apex Magnets is poised to benefit from strong tailwinds across key industrial sectors. To maintain a competitive edge, the company should prioritize innovation in magnet performance and sustainability, strengthen regional supply chains, and expand its value-added services such as rapid prototyping and technical support. Strategic investments today will determine its long-term positioning in a rapidly evolving, high-growth market landscape.

Common Pitfalls When Sourcing Apex Magnets: Quality and Intellectual Property Risks

Sourcing apex magnets—high-performance rare-earth magnets used in critical applications such as aerospace, medical devices, and advanced electronics—can present significant challenges. Two of the most critical areas of concern are quality inconsistencies and intellectual property (IP) vulnerabilities. Failing to address these pitfalls can lead to product failures, legal disputes, and reputational damage.

Quality Control Issues

One of the most frequent problems when sourcing apex magnets is inconsistent quality. Many suppliers, particularly those in low-cost regions, may not adhere to stringent manufacturing standards, resulting in variability in magnetic performance, dimensional accuracy, and durability.

- Inconsistent Material Composition: Low-grade or improperly processed neodymium, samarium-cobalt, or other rare-earth materials can lead to weaker magnetic fields and poor thermal stability.

- Coating Defects: Apex magnets are often coated (e.g., Ni-Cu-Ni, epoxy, or gold) to prevent corrosion. Inadequate or uneven coating increases the risk of oxidation and premature failure.

- Lack of Certification: Reputable suppliers provide certifications such as ISO 9001, RoHS, or REACH compliance. Absence of these documents is a red flag.

- Poor Tolerance Control: High-precision applications demand tight tolerances. Sourcing from manufacturers without advanced machining capabilities can result in magnets that do not fit or perform as required.

Without rigorous supplier vetting and third-party testing, companies risk integrating substandard components into their products, leading to field failures and warranty claims.

Intellectual Property Exposure

Sourcing apex magnets, especially custom-designed ones, poses significant IP risks. These magnets often incorporate proprietary geometries, magnetization patterns, or composite materials protected by patents or trade secrets.

- Reverse Engineering by Suppliers: Some overseas manufacturers may reverse engineer custom magnet designs and sell them to competitors or produce counterfeit versions.

- Weak Contractual Protections: Non-disclosure agreements (NDAs) or manufacturing contracts that lack clear IP ownership clauses can leave buyers vulnerable. In some jurisdictions, local laws may not uphold foreign IP rights.

- Unsecured Design Transfers: Sending detailed CAD files or specifications without encryption or usage restrictions increases the risk of design theft.

- Supply Chain Transparency Gaps: When using intermediaries or brokers, it can be difficult to trace where the actual production occurs, increasing exposure to unauthorized duplication.

To mitigate these risks, companies should work with trusted partners, conduct due diligence on manufacturing locations, use robust legal agreements, and consider patent protection in key markets.

Conclusion

Sourcing apex magnets requires more than cost comparison—it demands a strategic approach to ensure both high quality and IP security. By recognizing these common pitfalls and implementing proactive measures, businesses can protect their innovations and maintain product reliability in competitive markets.

Logistics & Compliance Guide for Apex Magnets

This guide outlines the essential logistics and compliance procedures for handling, shipping, and managing regulatory requirements related to Apex Magnets’ products. Adherence to these guidelines ensures safe operations, regulatory compliance, and customer satisfaction.

Order Fulfillment Process

All customer orders are processed within 1–2 business days of receipt. Orders received before 2:00 PM EST are typically shipped the same day. Order processing includes verification of product specifications, packaging selection based on magnet strength and quantity, and label generation. Each order is double-checked for accuracy before dispatch.

Packaging Standards

Magnets, especially strong neodymium types, must be packaged to prevent demagnetization, physical damage, and interference with nearby objects. Use of non-magnetic materials such as corrugated cardboard, plastic spacers, and foam inserts is required. Individual magnets are separated to avoid clumping. Multi-magnet shipments are arranged to minimize magnetic attraction. All packages must display appropriate internal shielding and handling instructions.

Domestic Shipping Procedures

Apex Magnets utilizes UPS, FedEx, and USPS for domestic shipments within the United States. Standard, expedited, and overnight options are available. Packages are labeled with accurate weights and dimensions to ensure proper rate calculation. Magnetic field shielding is required for shipments exceeding 0.00525 gauss at 15 feet (as per IATA/FAA guidelines, even for domestic transport). All shipments include tracking and delivery confirmation.

International Shipping & Export Compliance

International shipments must comply with export regulations enforced by the U.S. Department of Commerce (Bureau of Industry and Security – BIS). Most Apex Magnets products fall under ECCN 8A992 (No License Required – NLR) under the Export Administration Regulations (EAR). However, verify classification for high-grade or specially formulated magnets. Required documentation includes:

- Commercial Invoice (with HS Code 8505.11 or 8505.19)

- Packing List

- Shipper’s Letter of Instruction (SLI)

- Export Declaration (if shipment value exceeds $2,500 per destination)

Use of Incoterms (e.g., FOB, DDP) must be clearly stated on all export documents.

Magnetic Field Safety & Hazard Communication

Strong magnets (especially N52 grade and above) pose safety risks including pinching, interference with medical devices (pacemakers, ICDs), and data corruption. All product packaging and online listings must include safety warnings:

WARNING: This product contains strong magnets. Keep away from pacemakers, electronic devices, and credit cards. Risk of injury if handled improperly.

Safety data sheets (SDS) are available upon request and include handling, storage, and disposal information.

Regulatory Compliance

- ITAR/EAR: Apex Magnets confirms that its commercial magnet products are not ITAR-controlled and are generally classified under EAR99 or ECCN 8A992.

- REACH & RoHS: All products comply with EU directives REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). Material declarations are available upon request.

- DOT & IATA Regulations: Air shipments (domestic and international) comply with IATA Dangerous Goods Regulations. While most permanent magnets are not classified as dangerous goods, packages must be tested for magnetic field strength. If the field exceeds regulatory limits at 7 feet (2.1 meters), the shipment must be labeled as “Magnetized Material” (Class 9) and accompanied by a Shipper’s Declaration for Dangerous Goods.

Import Considerations

Customers are responsible for import duties, taxes, and customs clearance. Apex Magnets provides accurate product descriptions and values. Some countries (e.g., Australia, Canada) may require additional documentation or have restrictions on high-powered magnets. Proactively inform international customers of potential delays or fees.

Returns & Reverse Logistics

Returns require a Return Merchandise Authorization (RMA) number issued by customer service. Returned magnets must be repackaged using original or equivalent shielding to prevent damage during transit. Restocking fees may apply for non-defective returns. All returned items are inspected upon receipt.

Recordkeeping & Audits

Maintain records of all export transactions, compliance documentation, and customer communications for a minimum of five years. Regular internal audits ensure adherence to export control, packaging, and safety protocols.

Contact Information

For compliance or logistics inquiries, contact:

Apex Magnets Compliance Team

Email: [email protected]

Phone: (800) 555-1234 ext. 205

This guide is subject to updates based on regulatory changes. All staff involved in logistics and sales must review this document annually and receive appropriate training.

Conclusion on Sourcing Apex Magnets

In conclusion, sourcing Apex Magnets requires a strategic approach that balances quality, reliability, cost-efficiency, and supply chain resilience. Apex Magnets, known for their high-performance rare-earth magnets such as neodymium and samarium-cobalt, are critical components in various high-tech industries including renewable energy, electric vehicles, medical devices, and aerospace. When selecting a supplier, it is essential to verify manufacturing standards, material certifications (such as RoHS and REACH compliance), and consistent quality control processes to ensure magnet performance under demanding conditions.

Establishing partnerships with authorized distributors or direct engagement with Apex Magnets’ official channels can help mitigate risks related to counterfeit products and supply disruptions. Additionally, considering logistical factors, lead times, customization capabilities, and technical support enhances long-term sourcing effectiveness. As demand for high-efficiency magnetic solutions continues to grow, a well-vetted sourcing strategy for Apex Magnets will contribute significantly to product reliability, innovation, and competitive advantage.