The global anti-static plastics market is experiencing robust growth, fueled by increasing demand across industries such as electronics, healthcare, automotive, and packaging, where electrostatic discharge (ESD) protection is critical. According to a report by Mordor Intelligence, the anti-static plastics market was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2029. This expansion is driven by stringent regulatory standards in electronics manufacturing and the rising adoption of anti-static materials in cleanroom environments and medical devices. Additionally, Grand View Research highlights the growing integration of anti-static polymers in automotive components to prevent dust accumulation and enhance safety. As demand surges, manufacturers are investing in innovative, carbon- or polymer-based additives to improve conductivity without compromising mechanical properties. In this evolving landscape, identifying reliable and technologically advanced anti-static plastic producers is essential for businesses aiming to ensure product integrity and compliance. The following list highlights the top 10 manufacturers leading the charge in quality, scalability, and R&D-driven solutions worldwide.

Top 10 Anti Static Plastic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Specialist Manufacturer of Static Control Technology

Domain Est. 2010

Website: fraser-antistatic.com

Key Highlights: Fraser Anti-Static are world leading specialist manufacturers of equipment and solutions used to control static electricity throughout industry worldwide….

#2 Static Control Products

Domain Est. 1996

Website: aclstaticide.com

Key Highlights: ACL Staticide provides static control, dissipative floor paint, ESD polishes and wearables, PCB cleaning chemicals and packaging and static instruments….

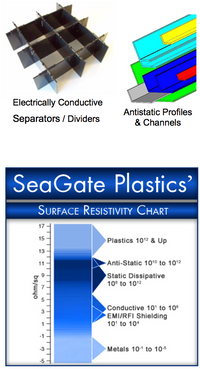

#3 Static Dissipative & Conductive Plastic Components

Domain Est. 1999

Website: seagateplastics.com

Key Highlights: With over 34 years experience, SeaGate Plastics is a trusted manufacturer of quality standard and custom profiles and tubing….

#4 ESD Plastics

Domain Est. 2020

Website: inchr-esd.com

Key Highlights: Professional manufacturer supplying various antistatic additives, antistatic masterbatch, conductive compounds,ESD Plastics,Injection molded peek,PEEK ……

#5 TOYOLAC™ ABS resin Durable Anti

Website: plastics.toray

Key Highlights: TOYOLACPAREL™ is a durable anti-static ABS resin developed by Toray using proprietary polymer technology. In addition to the excellent mechanical properties ……

#6 RTP Company

Domain Est. 1996

Website: rtpcompany.com

Key Highlights: RTP Company’s engineered thermoplastic compounds provide you with solutions, customization, and services for all your thermoplastic needs….

#7 Antistatic Plastics

Domain Est. 1997

Website: primexplastics.com

Key Highlights: Primex offers a wide range of antistatic plastics. Explore our products and services including color compounding, sheet extrusion, and fabrication….

#8 Desco

Domain Est. 1998

Website: desco.descoindustries.com

Key Highlights: ESD Pocket Protector · Tape · Wescorp ESD Cellulose Tape with Paper Cores · Wescorp ESD Cellulose Tape with Plastic Cores · Wescorp ESD Conductive Grid Tape ……

#9 Anti

Domain Est. 1998

Website: caltexplastics.com

Key Highlights: Protect electronic parts with our CPAS 100 electrostatic discharge packaging bags. We offer a large selection of static barriers. Contact us today….

#10 Antistat Inc

Domain Est. 2004

Website: antistat.com

Key Highlights: Antistat is a global supplier of ESD & cleanroom products. Anti-static bags, matting,, wipes, garments, & contamination control supplies….

Expert Sourcing Insights for Anti Static Plastic

H2: 2026 Market Trends for Anti-Static Plastics

The global anti-static plastics market is poised for significant growth and transformation by 2026, driven by increasing demand across electronics, healthcare, packaging, and automotive industries. As manufacturers prioritize electrostatic discharge (ESD) protection and product reliability, anti-static plastics are becoming essential materials in sensitive applications. Below are key market trends expected to shape the anti-static plastics landscape in 2026:

-

Rising Demand in Electronics and Semiconductor Manufacturing

The proliferation of miniaturized electronics and advanced semiconductor devices is amplifying the need for ESD-safe materials. By 2026, anti-static plastics are projected to be integral in manufacturing cleanrooms, component trays, conveyor systems, and protective housings. The expansion of 5G infrastructure, IoT devices, and AI-driven hardware will further drive adoption. -

Growth in Medical and Healthcare Applications

Anti-static plastics are increasingly used in medical devices, diagnostic equipment, and pharmaceutical packaging to prevent static interference and contamination. With heightened regulatory emphasis on safety and sterility, especially post-pandemic, demand is expected to rise in disposable medical tools and ESD-safe hospital environments. -

Sustainable and Biodegradable Anti-Static Solutions

Environmental regulations and corporate sustainability goals are pushing innovation toward eco-friendly anti-static plastics. By 2026, manufacturers are anticipated to introduce more biodegradable and recyclable anti-static polymers, particularly using additives derived from renewable sources or conductive nanomaterials with lower environmental impact. -

Advancements in Conductive Additives and Nanotechnology

The integration of carbon nanotubes, graphene, and intrinsically conductive polymers (ICPs) is enhancing the performance of anti-static plastics. These materials offer superior ESD protection with lower loading percentages, preserving mechanical properties and transparency. R&D investments in nanocomposite technologies are expected to accelerate commercialization by 2026. -

Expansion in Electric Vehicle (EV) and Automotive Sectors

The surge in EV production is creating new opportunities for anti-static plastics in battery enclosures, sensor housings, and electronic control units. With stringent safety standards, automakers are increasingly adopting ESD-protected interior components to safeguard sensitive electronics from static damage. -

Regional Market Growth in Asia-Pacific

Asia-Pacific, led by China, Japan, and South Korea, is expected to dominate the anti-static plastics market by 2026 due to robust electronics manufacturing and rapid industrialization. Government initiatives to boost high-tech industries and domestic semiconductor production will further stimulate regional demand. -

Consolidation and Strategic Partnerships Among Key Players

Major chemical and plastics companies are likely to engage in mergers, acquisitions, and joint ventures to expand their anti-static portfolios and geographic reach. Collaboration with end-user industries will drive customized solutions and faster time-to-market for specialized applications. -

Regulatory and Compliance Drivers

Increasing compliance requirements—such as IEC 61340 and ANSI/ESD S20.20 standards—are compelling industries to adopt certified anti-static materials. This regulatory push will support market growth as companies seek to meet international ESD safety benchmarks.

In summary, by 2026, the anti-static plastics market will be shaped by technological innovation, sustainability imperatives, and expanding applications in high-growth industries. Companies that invest in advanced materials, eco-conscious production, and strategic market positioning are expected to lead this evolving sector.

Common Pitfalls in Sourcing Anti-Static Plastic (Quality, IP)

Sourcing anti-static plastic involves more than just selecting a material with the right surface resistivity. Overlooking key quality and intellectual property (IP) considerations can lead to product failures, compliance issues, or legal risks. Below are common pitfalls to avoid:

Inadequate Verification of Anti-Static Performance

Many suppliers claim their plastics are “anti-static,” but performance can vary widely. Without proper testing, you may receive materials that don’t meet required specifications (e.g., surface resistivity between 10^9 and 10^12 ohms/sq). Always request independent test reports (e.g., ASTM D257) and verify consistency across batches.

Lack of Long-Term Stability Testing

Some anti-static additives degrade over time or under environmental stress (e.g., humidity, UV exposure, heat). Sourcing without evaluating long-term performance can result in materials that lose their static-dissipative properties during use—especially problematic in electronics or cleanroom environments.

Ignoring Regulatory and Compliance Requirements

Anti-static plastics used in sensitive industries (e.g., medical, aerospace, electronics) must comply with standards like ISO 10993, RoHS, REACH, or UL 94 for flammability. Overlooking these can delay product certification or lead to market entry failure.

Poor Documentation of Material Composition

Failure to obtain full material disclosure (e.g., via IMDS or SDS) can create supply chain transparency issues and hinder compliance audits. This is particularly critical in automotive and electronics sectors where substance restrictions are enforced.

Overlooking Intellectual Property Rights

Using proprietary anti-static formulations without proper licensing can expose your company to IP infringement claims. Ensure your supplier has the right to supply the material and that your use complies with any restrictions—especially when reverse engineering or replicating existing components.

Relying on Unverified Supplier Claims

Some suppliers may misrepresent material properties or sourcing origins. Conduct due diligence: audit suppliers, request certifications (e.g., ISO 9001), and perform incoming quality checks to validate specifications.

Insufficient Batch-to-Batch Consistency

Anti-static performance can vary due to inconsistent additive dispersion or manufacturing processes. Without strict quality control, this leads to unreliable product behavior. Demand batch traceability and statistical process control (SPC) data from suppliers.

Assuming All Anti-Static Plastics Are Interchangeable

Different anti-static technologies (e.g., carbon-loaded, surface-treated, inherently dissipative polymers) have distinct mechanical, aesthetic, and processing characteristics. Choosing the wrong type can affect product functionality or manufacturability.

By addressing these pitfalls early, you can ensure reliable performance, regulatory compliance, and freedom to operate when sourcing anti-static plastic materials.

Logistics & Compliance Guide for Anti-Static Plastic

Understanding Anti-Static Plastic

Anti-static plastic is a specialized polymer material engineered to dissipate static electricity, preventing electrostatic discharge (ESD) that can damage sensitive electronic components, ignite flammable substances, or attract contaminants. These plastics are commonly used in electronics manufacturing, cleanrooms, packaging for sensitive devices, and industrial applications where static control is critical.

Regulatory Compliance Requirements

Anti-static plastics must comply with a range of international and industry-specific standards. Key regulations include:

– IEC 61340-5-1: International standard for protection of electronic devices from electrostatic phenomena.

– ANSI/ESD S20.20: U.S. standard for developing ESD control programs.

– RoHS (EU Directive 2011/65/EU): Restricts hazardous substances in electrical and electronic equipment.

– REACH (EC 1907/2006): Regulates chemical substances and their safe use in the EU.

– OSHA and NFPA Standards: Govern workplace safety and fire prevention in the U.S., especially for flammable environments.

Ensure all anti-static plastic products have documentation verifying compliance with these standards, including test reports and material safety data sheets (MSDS/SDS).

Packaging and Handling Procedures

Proper packaging and handling are essential to maintain the anti-static properties of plastic materials during transit:

– Use shielded or static-dissipative packaging (e.g., pink poly bags, metallized shielding bags) to protect against external ESD.

– Clearly label packages with ESD-sensitive symbols and handling instructions.

– Avoid using standard plastic wraps or containers that generate static.

– Store and transport materials in a controlled environment with humidity between 40%–60% RH to optimize static dissipation.

Storage Conditions

To preserve performance and compliance:

– Store anti-static plastics in a clean, dry environment away from direct sunlight and extreme temperatures.

– Maintain a stable temperature range (typically 15°C to 30°C).

– Keep materials off the floor and away from sources of static electricity, such as conveyor belts or high-traffic areas.

– Use conductive shelving or bins when possible to prevent charge buildup.

Transportation Guidelines

When shipping anti-static plastics:

– Use vehicles or containers with ESD-safe interiors if transporting large quantities.

– Avoid mixing anti-static materials with non-compliant plastics or high-static-generating goods.

– Secure loads to prevent friction or movement that may generate static.

– For air freight, comply with IATA regulations if transporting flammable or sensitive materials in conjunction with anti-static packaging.

Documentation and Traceability

Maintain complete traceability and compliance documentation:

– Keep records of supplier certifications, lot numbers, and test results (e.g., surface resistivity, decay time).

– Provide compliance documentation to end customers upon request.

– Implement a quality control system for incoming and outgoing materials to verify anti-static performance.

Worker Safety and Training

Personnel handling anti-static plastics should:

– Wear ESD-safe apparel (e.g., wrist straps, heel grounders, anti-static smocks).

– Be trained in ESD control procedures and proper handling techniques.

– Understand hazard communication, especially if plastics contain additives or flame retardants.

Disposal and Environmental Considerations

Dispose of anti-static plastics in accordance with local regulations:

– Recycle whenever possible, using facilities equipped to handle specialty plastics.

– Do not incinerate unless permitted and controlled, as some anti-static additives may release hazardous fumes.

– Follow WEEE directives for end-of-life electronics packaging in the EU.

Audit and Continuous Compliance

Regularly audit logistics and compliance procedures:

– Conduct internal audits to verify adherence to ESD and environmental standards.

– Review supplier certifications annually.

– Update processes in response to changes in regulations or customer requirements.

By following this guide, organizations can ensure the safe, compliant, and effective handling of anti-static plastics throughout the supply chain.

In conclusion, sourcing anti-static plastic requires a careful evaluation of material properties, application requirements, industry standards, and supplier reliability. Selecting the right type of anti-static plastic—whether dissipative, conductive, or static-dissipative—is crucial to ensuring performance, safety, and compliance in sensitive environments such as electronics manufacturing, cleanrooms, and medical device packaging. Key considerations include surface resistivity, durability, environmental conditions, and compatibility with existing production processes. Additionally, establishing partnerships with reputable suppliers who provide traceability, certifications, and consistent quality control helps mitigate risk and supports long-term operational efficiency. By prioritizing these factors, organizations can effectively source anti-static plastics that meet technical needs while enhancing product reliability and reducing the risk of electrostatic damage.